Professional Documents

Culture Documents

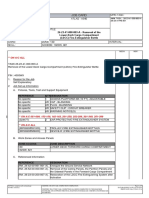

Scan20200923 07563765

Scan20200923 07563765

Uploaded by

hoby christian0 ratings0% found this document useful (0 votes)

37 views1 pageOriginal Title

SCAN20200923_07563765

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

37 views1 pageScan20200923 07563765

Scan20200923 07563765

Uploaded by

hoby christianCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

62 | MAINTENANCE & ENGINEERING

between each M&CE system, the ETL

‘middleware, and the ETL

“In creating the ETL interfaces, a

certain amount of ‘bespoking" is required

to match each specific customer request

regarding the information they wish to

transfer between our OASES M&E

system and the chosen ETL device,”

explains Julian Beames, OASES product

owner. “Therefore, we use a base

incerface specification which we ean alter

to meet the actual requirements of the

individual airline, We define the data

flows jointly with the ETL provider and

then create an interface. This is then

followed by a period of testing within a

separate test system until we prove that

the data flows are correct. Once this stage

is complete then i is generally a case of

the airline gaining approval for the ETL

to be used ina live environment, at which

point the interface can be activated.”

In most cases, middleware is required

to allow an ETL to interface with an

M&E system. This middleware can form

a backend application in its own right,

allowing ETL software designers to give

cach airline a configurable ETL solution

which suits their operation, while also

acting as a firewall between the devices

and the M&E system,

“eCentral8 isthe middleware for the

Conduce ETL eTechLog8,” explains Paul

Boyd, managing director at the Conduce

Group. “Ie contains the business logic ot

rules for sending and receiving data

between the ETL and the airline M&E

systems. For airlines dealing with

multiple M&CE systems this will include

the different business logic for each

CAMO or Part 145 maintenance repaie

‘organisation (MRO) involved. It allows

the eTechlog8 co be completely agnostic

to the airline systems in use with any

“The ULTRAMAIN ELB Ground

System repository is where the ELB data

js ultimately stored and from where the

information exchange takes place,” adds

Stone. “So even though Uleeamain has its

‘own MCE system, it was decided that

customers would nor have to use both,

sides of our products. The ELB interface

schema is designed to conform to

industry Spee 2000 Chapter 17 standards

of information exchange between the

ELB systems and the M&CE IT system in

use. Therefore, any company compatible

with Spec 2000 Chapter 17 standas

will be able interface with our ELB.

The transfer of information between

the M&CE system and the ETL, and the

ETL middleware depending on product

choice, normally use 3G, 4G, WiFi, or

Satcom internet connections.

=

ETL back-up

Iris a regulatory requirement to leave

a copy of the last TLP behind before

further flight. With paper logs, individual

sheets ofthe log are physically removed

from the log to remain on ba

To mirror this function in an

electronic environment, when there is a

loss of connectivity or damage to the

device, ETL information must be

transferred to the line station using

“Bluetooth is an option in use by

‘Trax to transfer ETL information to the

line station engineer’s mobile devices to

provide a back-up if all other connectivity

means is lost,” explains Reed. “This

allows the ETL to receive the confirmed

file transfer notification it needs for it to

be able to release the aircraft to service.

The line maintenance mobile device that

contains the stored log information then

feeds the data back to the M&E system

once ie returns 10 an area of

connectivity.”

“When using ULTRAMAIN ELBs, if

a device is lost or damaged there are

Eris have become mare than ust electronic

representations ofpaperlog defects providing

‘access to historical infomation and

‘communicating new defects outomaticely to

the MAE system,

usually other iPads on the aircraft that

are storing the log book data,” adds

Stone. “One of the iPads is always

designated the master, and is always in

control while the other iPads are kept in

sync. If there isa situation of zero

connectivity, then the ELB can download

to a logbook data recorder (LDR) storage

device tha is taken to a ground station

personal computer (PC) to syne back the

information automatically to the ground

server. The aim is that in all such

uations the operation can stay

less. Somerimes, however, whether

(or not an operator ean stay paperless

during loss of connectivity is determined

by

local regulator”

ick-up of the data stored on the

ETIsis also requited for compliance. For

TechLog8, the airerafr’s rechlog

information will be stored in multiple

back-up locations. This includes on the

device's solid state drive (SSD) hard drive,

‘on the encrypted micro SD ard in the

device in eCentral8 (which is hosted on

‘MS Azure and backed up to Amazon

Web Services every 15 minutes), plus any

additional archiving and M&E systems.

‘When M&E systems go offline

temporarily, ETL middleware can also

store ETL inbound information so that

‘operational services are not affected,

eCentral8 acts as the main data

repository forthe eTechLog8 dats,”

explains Boyd. “This means that when

MBE systems close down (for internal

scheduled maintenance or to change a

registration for example), eTechLogS

does not cease to function. Data is simply

{queued in eCentral8 ready to be ingested

into the MEE system, in order, when ;

integration is turned back on.”

—

ETL data entry

A major advantage when practising

electronic maintenance is the ability to

include safeguards These are bul into

the system sofevare, and can prevent data

information having tobe late re-entered

FH, EC, fel uplift, ol usage, and ATA

reference numbering for defer ents are

all examples of data that must be entered f

into techlogs during aircraft turnarounds

“cTechlog® has been designed to

exponentially increase data quality,”

explains Boyd. “This is achieved by

ving a clear workflow onthe

eTechLogS device, with fields becoming

completed, and by having a variey of

8 h/hay 208 an

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Echannel Tech Pub DownloadDocument12 pagesEchannel Tech Pub Downloadhoby christianNo ratings yet

- ZL 141Document1 pageZL 141hoby christianNo ratings yet

- Compresseur 100L 5.5CV Triphasé GGA - Sanifer - CopieDocument3 pagesCompresseur 100L 5.5CV Triphasé GGA - Sanifer - Copiehoby christianNo ratings yet

- Del Is LendsDocument56 pagesDel Is Lendshoby christianNo ratings yet

- Hocking Locator 2 Price 1Document1 pageHocking Locator 2 Price 1hoby christianNo ratings yet

- COMPRESSEUR 7.5 KW, 300 L EKO POWER PRODUCT 2010301005 - Batimax - CopieDocument2 pagesCOMPRESSEUR 7.5 KW, 300 L EKO POWER PRODUCT 2010301005 - Batimax - Copiehoby christianNo ratings yet

- Sonatest Wave Price 1Document1 pageSonatest Wave Price 1hoby christianNo ratings yet

- Thories Du ManagementDocument4 pagesThories Du Managementhoby christianNo ratings yet

- IC Sales Management Dashboard Template Free FR2Document105 pagesIC Sales Management Dashboard Template Free FR2hoby christianNo ratings yet

- IC Project Management Dashboard Template Free FR2Document18 pagesIC Project Management Dashboard Template Free FR2hoby christianNo ratings yet

- Tendance de Dépenses de Budget1Document14 pagesTendance de Dépenses de Budget1hoby christianNo ratings yet

- Copie de Content Calendar and Plan TemplateDocument2 pagesCopie de Content Calendar and Plan Templatehoby christianNo ratings yet

- JIC 32-42-55 CHK 10000: CHECK OF BRAKE Assy For Damages, Leak and WearDocument3 pagesJIC 32-42-55 CHK 10000: CHECK OF BRAKE Assy For Damages, Leak and Wearhoby christianNo ratings yet

- Job Card: 21-23-98-920-851-A - Replacement of The Filter Elements of The Smoke Extraction SystemDocument6 pagesJob Card: 21-23-98-920-851-A - Replacement of The Filter Elements of The Smoke Extraction Systemhoby christianNo ratings yet

- Job Card: Mpd-Task: ATLAS - A340Document9 pagesJob Card: Mpd-Task: ATLAS - A340hoby christianNo ratings yet

- Job Card: MPD-TASK: 324200-01 ATLAS - A340Document6 pagesJob Card: MPD-TASK: 324200-01 ATLAS - A340hoby christianNo ratings yet