Professional Documents

Culture Documents

Method Statement: Location: JV GAS in Amenas. Costumer: KBR

Uploaded by

hicham boutoucheOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement: Location: JV GAS in Amenas. Costumer: KBR

Uploaded by

hicham boutoucheCopyright:

Available Formats

Method Statement

Location: JV GAS In Amenas.

Costumer : KBR.

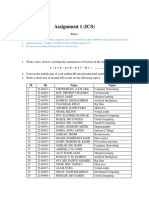

Editor Date Version Page

S.MEZIANI 19/08/2020 01

1

S.MEZIANI 19/11/2020 02

S.MEZIANI 30/11/2020 03

H.BOUTOUCHE 18/03/2021 04

Contents

1 Personnel involved : .............................................................................................................................. 3

2 Tools and material required :................................................................................................................ 3

3 Equipment : ........................................................................................................................................... 3

4 Safety information: ............................................................................................................................... 3

5 Arrange The new drawer: ..................................................................................................................... 4

5.1 Operation sequences: ................................................................................................................... 4

5.2 Works duration: ............................................................................................................................ 5

5.3 Testing: .......................................................................................................................................... 5

5.4 Installation ending: ....................................................................................................................... 5

Editor Date Version Page

S.MEZIANI 19/08/2020 01

2

S.MEZIANI 19/11/2020 02

S.MEZIANI 30/11/2020 03

H.BOUTOUCHE 18/03/2021 04

This report outlines the necessary interventions needed to install 250A MCCB in the vacant module

located on 11-NN-719.

1 Personnel involved:

- Commissioning Engineer.

- Commissioning Technician.

2 Tools and material required:

- Toolbox including screwdrivers and all materiel needed.

- Measuring instrument.

3 Equipment:

Personal protective equipment including:

- Safety shoes.

- Safety gloves.

- Protection glasses.

- Coverall.

- Helmet.

4 Safety information:

The commissioning team should be:

- Aware of method of access and egress to the work area.

- Aware of specific identified residual hazards.

- Informed about the necessary consigns regarding emergency situations of the site.

- Informed about the nearest assembly point to the work area.

To proceed correctly a permit to work should be signed (with risk assessment filled).

Tripping and locking the main circuit breaker (11-NX-705 EMAX3N): the key of the lock must be kept

with the commissioning team of GATECH SPA.

The lifting of the drawer must be done with a cart to prevent any injury to the commissioning team.

Any stain done inside the switchgear during drawer installation, the main breaker must be opened and

locked.

During the testing phase, the commissioning team must wear their personal protective equipment, such

as one person for testing and the other to control his colleague, in order to ensure his protection and

avoid his injury.

Editor Date Version Page

S.MEZIANI 19/08/2020 01

3

S.MEZIANI 19/11/2020 02

S.MEZIANI 30/11/2020 03

H.BOUTOUCHE 18/03/2021 04

The commissioning team should be equipped by:

- Electrical insulating mat.

- Electrical insulting gloves.

5 Arrange the new drawer:

5.1 Operation sequences:

1) Good identification of the MCC on which the installation will be done to determine the placement

where the deferential CT will be fixed, the placement of the auxiliary supply of the deferential

relay and the placement the auxiliary terminal block (11-NN-719).

2) Identify the appropriate space on MCC (according to EBT15063 02 120) where the drawer will

be installed (11-NN-719).

3) Prepare a lightning source if the tripping of the main circuit breaker turns off the light.

4) Tripping and locking the main circuit breaker (11-NX-705 EMAX3N).

5) Remove the blank cover from the cubicle

6) Remove the 4 cover mounting angles

7) Ensuring that there is no dust or foreign object in the placement of the drawer.

8) Insert and tighten a division tray to a new position regarding the size of the drawer.

9) Slide and push the drawer into the vacant space defined by the division tray.

10) Ensure the intermediate stabs connectors are full positioned on the vertical riser.

11) Install and tighten the auxiliary terminal block with two screw.

12) Install and tighten the deferential CT.

13) Teste the drawer mechanically (5.3).

14) Connect the deferential relay supply from the combed connection rail on the side of the cubicle.

Check drawing before connecting (according to EBT15063 02 210).

15) Connect the deferential CT with the deferential relay (according to EBT15063 02 222).

16) Adjust circuit breaker settings (short circuits current, thermal protection ...)

17) Clean the work area and proceed at tools and materials tidy up.

18) Power cables can be connected later.

19) Teste the drawer electrically (5.3).

5.2 Works’ duration:

- The power shutdown is programmed for 4 hours. It is the minimum required to execute the

steps described above.

Editor Date Version Page

S.MEZIANI 19/08/2020 01

4

S.MEZIANI 19/11/2020 02

S.MEZIANI 30/11/2020 03

H.BOUTOUCHE 18/03/2021 04

5.3 Testing:

- Mechanical test (the main circuit breaker is OFF):

1) Turn OFF the circuit breaker of the drawer and pull and push the drawer by pressing the

indexing push button to ensure that the drawer is not blocked.

2) Turn ON the circuit breaker of the drawer and pull the drawer by pressing the indexing push

button to ensure that the drawer is blocked when it’s ON.

- Electrical test (the main circuit breaker is ON):

1) Ensuring that the status of the circuit breaker of the drawer provided by the auxiliary

terminal block is correct (according to EBT15063 02 222).

2) Ensuring that all the inputs of the circuit breaker of the drawer are powered by the vertical

riser of the switchgear by the measurement of drawer’s output when the circuit breaker is

ON.

3) Test the deferential relay by pressing its test button.

4) Test the circuit breaker of the drawer by pressing its test button.

5) Test the continuity between live part and the enclosure when the circuit breaker of the

drawer is ON and the main circuit breaker is OFF.

5.4 Installation ending:

1) Put back into service.

2) Verify everything is in accordance with client’s request and proceed at PTW ending signature.

3) Sign all report documents.

Editor Date Version Page

S.MEZIANI 19/08/2020 01

5

S.MEZIANI 19/11/2020 02

S.MEZIANI 30/11/2020 03

H.BOUTOUCHE 18/03/2021 04

You might also like

- Method Statement for Switchgear InstallationDocument5 pagesMethod Statement for Switchgear Installationhicham boutoucheNo ratings yet

- Manual 800 KvaDocument87 pagesManual 800 Kvavicvarg100% (3)

- Audiolab 8000S Service Manual PDFDocument36 pagesAudiolab 8000S Service Manual PDFMarcelo IpolitoNo ratings yet

- Practical Grounding, Bonding, Shielding and Surge ProtectionFrom EverandPractical Grounding, Bonding, Shielding and Surge ProtectionRating: 4 out of 5 stars4/5 (15)

- Alcatel-Lucent GSM: IO 115 - Change AC Powered MBO To DC Powered MBODocument24 pagesAlcatel-Lucent GSM: IO 115 - Change AC Powered MBO To DC Powered MBOWassim AdraNo ratings yet

- Trilogy of Connectors: Basic Principles and Connector Design ExplanationsFrom EverandTrilogy of Connectors: Basic Principles and Connector Design ExplanationsRating: 5 out of 5 stars5/5 (1)

- In190 Gysmi - Repare 195Document14 pagesIn190 Gysmi - Repare 195vik_mdNo ratings yet

- 5.beam On Window (BOW) Alignment ProcessDocument7 pages5.beam On Window (BOW) Alignment ProcessLê Hồ Nguyên ĐăngNo ratings yet

- Hisense 32E5606EX Chassis MSD6683TDocument52 pagesHisense 32E5606EX Chassis MSD6683Tsundaresan viswanathanNo ratings yet

- MS 01-900-00 Lighting PoleDocument12 pagesMS 01-900-00 Lighting Polemutasim.jadallaNo ratings yet

- MTK5659 (FHD Models) AM Service Manual Ver1.0 2018-5-31Document57 pagesMTK5659 (FHD Models) AM Service Manual Ver1.0 2018-5-31MarcosRomano100% (2)

- MT9602 US Service Manual V1.0 2020-3-27-1Document57 pagesMT9602 US Service Manual V1.0 2020-3-27-1Tena y EstebanNo ratings yet

- Digital Level Transmitter DLT1: Installation and Operating InstructionsDocument21 pagesDigital Level Transmitter DLT1: Installation and Operating InstructionsAlik KhoshtariaNo ratings yet

- LCD Television Service Manual: ChassisDocument50 pagesLCD Television Service Manual: ChassisLeo NarvaezNo ratings yet

- Mt5659auht 43FHD Fs9aDocument58 pagesMt5659auht 43FHD Fs9aAlexander OrueNo ratings yet

- Method Statement For DS Installation Rev0Document15 pagesMethod Statement For DS Installation Rev0Mark DizonNo ratings yet

- ADNOC OFFSHORE ZK-237 MIT Analysis Reveals Minor Internal Tubing IssuesDocument43 pagesADNOC OFFSHORE ZK-237 MIT Analysis Reveals Minor Internal Tubing IssuesSyed Aamir AzizNo ratings yet

- ManualDocument16 pagesManualSean LancasterNo ratings yet

- MTK5660 US ATSC Service Manual Ver1.0 2018-5-28Document49 pagesMTK5660 US ATSC Service Manual Ver1.0 2018-5-28Ross RebelNo ratings yet

- Temporary Lifeline InstallationDocument14 pagesTemporary Lifeline InstallationbareekNo ratings yet

- Hoh Singh VP 70 Manual English 1Document32 pagesHoh Singh VP 70 Manual English 1David Zoracá HNo ratings yet

- Unidad Oftalmologica - Bon - E-20 SeDocument23 pagesUnidad Oftalmologica - Bon - E-20 SeMariö OlveraNo ratings yet

- Jif 20 Van 014 Fat Qad 2419 Fat ShelterDocument10 pagesJif 20 Van 014 Fat Qad 2419 Fat Shelteransalkr_6232335No ratings yet

- Diag SLMCD 1-604454Document33 pagesDiag SLMCD 1-604454alex180777% (13)

- Solo 2 Response Man-1064Document7 pagesSolo 2 Response Man-1064Gelu BordeaNo ratings yet

- CCTV O&M ManualDocument64 pagesCCTV O&M ManualDilan ThilangaNo ratings yet

- BCI000002 MASTER T Service Manual 1.0 PDFDocument59 pagesBCI000002 MASTER T Service Manual 1.0 PDFWOLAENo ratings yet

- TurbinasadrDocument18 pagesTurbinasadrkatty_89No ratings yet

- MA-EN-3005 - En-Rev10 - Installation Manual - Tracker Control BoxDocument21 pagesMA-EN-3005 - En-Rev10 - Installation Manual - Tracker Control BoxWenceslao EscorzaNo ratings yet

- MTEBS04Document26 pagesMTEBS04d_abdosNo ratings yet

- Uc51x Series User Guide EnDocument24 pagesUc51x Series User Guide EntsipornNo ratings yet

- MD1096 A T251 A 2 Service ManualDocument30 pagesMD1096 A T251 A 2 Service ManualJohn TolozaNo ratings yet

- Bosch Tronic 3000T ES2.5-ES4-ES8 Installation Manual PDFDocument28 pagesBosch Tronic 3000T ES2.5-ES4-ES8 Installation Manual PDFАдам ИутяоNo ratings yet

- Krohne Optiflux 2000 Quick StartDocument24 pagesKrohne Optiflux 2000 Quick StartIstván FigeNo ratings yet

- Model No. HLC22R1: Color TVDocument50 pagesModel No. HLC22R1: Color TVJavier CaviedesNo ratings yet

- DE-0425 Installation Manual - H2S StripperDocument16 pagesDE-0425 Installation Manual - H2S StripperAkhil SurendranNo ratings yet

- DKB0002 - Ed0 - ECB - III CMSDocument9 pagesDKB0002 - Ed0 - ECB - III CMSfirstpenmanwriterNo ratings yet

- Rsag7.820. 6135 (MTK5657) Dexp U40b9000h (50,55,58) PDFDocument60 pagesRsag7.820. 6135 (MTK5657) Dexp U40b9000h (50,55,58) PDFchaghouf100% (1)

- Indicador ID1 PLUS User ManualDocument52 pagesIndicador ID1 PLUS User ManualArcangel2111740% (1)

- 2.manual TC 110 KV 70788001 - 05Document17 pages2.manual TC 110 KV 70788001 - 05Pop GabrielNo ratings yet

- CEC ELECTRICAL ENGINEERING SDN BHD HT/HV CABLING WORK METHOD STATEMENTDocument6 pagesCEC ELECTRICAL ENGINEERING SDN BHD HT/HV CABLING WORK METHOD STATEMENTtanaNo ratings yet

- Fire Protetion Alarm Check ValveDocument7 pagesFire Protetion Alarm Check ValveAbdul HakkimNo ratings yet

- 50 20-RP1Document10 pages50 20-RP1h1234bNo ratings yet

- Ball Valve Assembly Procedures GuideDocument10 pagesBall Valve Assembly Procedures GuideMIGUEL ANGEL SOTELO HANCCONo ratings yet

- CPT GEOTECH NOVA Manual GuideDocument44 pagesCPT GEOTECH NOVA Manual GuiderezajakakusumaNo ratings yet

- Ebang Ebit E12 Hash Board Repair GuideDocument29 pagesEbang Ebit E12 Hash Board Repair Guideluis pintoNo ratings yet

- Modulo Controlador Válvula MIQ - CHVDocument38 pagesModulo Controlador Válvula MIQ - CHVigize2No ratings yet

- GoodWe Inverters DS Series User ManualDocument50 pagesGoodWe Inverters DS Series User ManualJose Luis ArellanoNo ratings yet

- Color TV Troubleshooting GuideDocument50 pagesColor TV Troubleshooting GuideWasantha MunasingheNo ratings yet

- Service Manual Highlights for Sony LCD TVDocument34 pagesService Manual Highlights for Sony LCD TVHamza AbbasiNo ratings yet

- PIR Detector Switch: Catalogue Number(s) : 488 03Document3 pagesPIR Detector Switch: Catalogue Number(s) : 488 03Sonal RamjununNo ratings yet

- Guide ReparationDocument38 pagesGuide ReparationLa perrritaaaNo ratings yet

- Eurodent Absolute - Service ManualDocument37 pagesEurodent Absolute - Service ManualFrepa_AL100% (1)

- C4910 13201 MS e 003Document28 pagesC4910 13201 MS e 003Arby GocNo ratings yet

- UTDocument28 pagesUTMohdHuzairiRusli100% (1)

- XN-L E Chap07 InstallationDocument46 pagesXN-L E Chap07 Installationsuraj adhikariNo ratings yet

- Scroll SolenoidDocument11 pagesScroll SolenoidRauf AlirzayevNo ratings yet

- 1sac200043h0005 A Pei Af265... Af370Document4 pages1sac200043h0005 A Pei Af265... Af370hicham boutoucheNo ratings yet

- LL226Document20 pagesLL226gordon_gadney123No ratings yet

- The Load Performance of Multi-Level Alternating Voltage Provided by Upgrade EffectDocument13 pagesThe Load Performance of Multi-Level Alternating Voltage Provided by Upgrade Effecthicham boutoucheNo ratings yet

- H7920/H7921 3G/4G Router: User ManualDocument59 pagesH7920/H7921 3G/4G Router: User Manualhicham boutoucheNo ratings yet

- TeSys DF - LS1 - GK1 - DF22NDocument3 pagesTeSys DF - LS1 - GK1 - DF22Nhicham boutoucheNo ratings yet

- FafaDocument12 pagesFafaAmsalu SeteyNo ratings yet

- Log data under 40 charsDocument4 pagesLog data under 40 charshicham boutoucheNo ratings yet

- Capture D'écran 2022-11-29 213704Document2 pagesCapture D'écran 2022-11-29 213704hicham boutoucheNo ratings yet

- Building Lighting Protection CalculationDocument5 pagesBuilding Lighting Protection CalculationSid BlankNo ratings yet

- Dda200 05-2017Document1 pageDda200 05-2017hicham boutoucheNo ratings yet

- Mech Eng LDPDocument9 pagesMech Eng LDPhicham boutoucheNo ratings yet

- AD2019A1 Weighing Controller: Operation Manual V6.5Document77 pagesAD2019A1 Weighing Controller: Operation Manual V6.5hicham boutoucheNo ratings yet

- 9842 TechdataDocument2 pages9842 Techdatahicham boutoucheNo ratings yet

- Eav83639 02Document4 pagesEav83639 02hicham boutoucheNo ratings yet

- Millingmixing EnglishDocument14 pagesMillingmixing Englishhicham boutoucheNo ratings yet

- 1sac200044h0006 A Pei Af580... Af750Document4 pages1sac200044h0006 A Pei Af580... Af750hicham boutoucheNo ratings yet

- Installation Manual TL Line-2Document4 pagesInstallation Manual TL Line-2hicham boutoucheNo ratings yet

- Assessment Using CFD of The Wind Direction On TheDocument16 pagesAssessment Using CFD of The Wind Direction On Thehicham boutoucheNo ratings yet

- BEAMA Guide To Circuit Breaker Selection For LED LightingDocument12 pagesBEAMA Guide To Circuit Breaker Selection For LED Lightinghicham boutoucheNo ratings yet

- Protection Criteria For UPS SystemDocument2 pagesProtection Criteria For UPS Systemhicham boutoucheNo ratings yet

- Smart Tricks To Improve Power Supply ReliabilityDocument12 pagesSmart Tricks To Improve Power Supply ReliabilityTaner ErtürkNo ratings yet

- 50W LED Driver For Streetlight & FloodlightDocument5 pages50W LED Driver For Streetlight & Floodlighthicham boutoucheNo ratings yet

- Sace Tmax XT: W S51 Only F-PDocument12 pagesSace Tmax XT: W S51 Only F-Phicham boutoucheNo ratings yet

- PowerHour Overcurrent Protection 2019-09-24Document41 pagesPowerHour Overcurrent Protection 2019-09-24Rebekah PowellNo ratings yet

- Dual Power Source Installation and Operating InstructionsDocument4 pagesDual Power Source Installation and Operating Instructionshicham boutoucheNo ratings yet

- Temperature Sensing With PTC Circuit: Analog Engineer's CircuitDocument6 pagesTemperature Sensing With PTC Circuit: Analog Engineer's Circuithicham boutoucheNo ratings yet

- Edesign ReleaseNotesDocument14 pagesEdesign ReleaseNoteshicham boutoucheNo ratings yet

- PDF RTDocument8 pagesPDF RThicham boutoucheNo ratings yet

- Effects of Heat Airflow Inside An Enclosure en Us 170664Document6 pagesEffects of Heat Airflow Inside An Enclosure en Us 170664hicham boutoucheNo ratings yet

- SEX Rotary Paddle Level Switch - NewDocument23 pagesSEX Rotary Paddle Level Switch - Newhicham boutoucheNo ratings yet

- Date Sheet For Final Exams For Main Campus, All Sub-Campuses and All Government Affiliated CollgesDocument29 pagesDate Sheet For Final Exams For Main Campus, All Sub-Campuses and All Government Affiliated Collgessalman 541No ratings yet

- Resume of Jhune Perez RTDocument2 pagesResume of Jhune Perez RTByahe Ni GeloNo ratings yet

- Digital Forensics On Facebook Messenger Application in An Android Smartphone Based On NIST SP 800-101 R1 To Reveal Digital Crime CasesDocument7 pagesDigital Forensics On Facebook Messenger Application in An Android Smartphone Based On NIST SP 800-101 R1 To Reveal Digital Crime CasesTeguh RijanandiNo ratings yet

- A Practical Guide To Artificial Intelligence-Based Image Analysis in RadiologyDocument7 pagesA Practical Guide To Artificial Intelligence-Based Image Analysis in RadiologyGeneNo ratings yet

- Ablan, Arjay I. Other Examples of Quantitative Models For Decision Making SimulationDocument13 pagesAblan, Arjay I. Other Examples of Quantitative Models For Decision Making SimulationVJ CarbonellNo ratings yet

- Airframe and SystemsDocument104 pagesAirframe and SystemsVivek Baskar50% (2)

- Dgi ps-3206 SMDocument229 pagesDgi ps-3206 SMHoffman Elizalde100% (1)

- XNX Universal TransmitterDocument12 pagesXNX Universal TransmitterDiego Costella100% (1)

- Eaton 7.2 KV Motor Control Ampgard Medium Voltage Design Guide Dg020001enDocument46 pagesEaton 7.2 KV Motor Control Ampgard Medium Voltage Design Guide Dg020001enAlvaro Seguel SanhuezaNo ratings yet

- Ac6905a DatasheepDocument10 pagesAc6905a DatasheepMUSIC ELECNo ratings yet

- Catalogo VPFT 4535Document91 pagesCatalogo VPFT 4535PRISCILA FAGUNDESNo ratings yet

- Example of 500 Word EssayDocument8 pagesExample of 500 Word Essaylud0b1jiwom3100% (2)

- User Manual: Digital-Control and Programmable DC Power SupplyDocument10 pagesUser Manual: Digital-Control and Programmable DC Power SupplyElib SekeeveNo ratings yet

- Price Fokus 2015 (Print)Document10 pagesPrice Fokus 2015 (Print)ariotwNo ratings yet

- (CIDECT DG3) - Design Guide For Rectangular Hollow Section (RHS) Joints Under Predominantly Static LoadingDocument156 pages(CIDECT DG3) - Design Guide For Rectangular Hollow Section (RHS) Joints Under Predominantly Static Loading_at_to_75% (4)

- AWM 5000 Series Microbridge Mass Airflow Sensor: Installation Instructions For TheDocument2 pagesAWM 5000 Series Microbridge Mass Airflow Sensor: Installation Instructions For ThewidsonmeloNo ratings yet

- Module Chapter 4 - GE 106Document7 pagesModule Chapter 4 - GE 106Justin Roi ConstantinoNo ratings yet

- Computer Network QuestionsDocument1 pageComputer Network QuestionsDhruv Sharma100% (1)

- How To Change Word Default Font in WPS Office WordDocument5 pagesHow To Change Word Default Font in WPS Office WordAkib ManzoorNo ratings yet

- Queuing TheoryDocument25 pagesQueuing TheoryVishal Kapoor100% (1)

- PLDT REFUND FORMDocument4 pagesPLDT REFUND FORMKitchenHacksNo ratings yet

- Mid-Term Assignment Spring22Document2 pagesMid-Term Assignment Spring22Sameer SayedNo ratings yet

- No. Hotel Address City Star Number of Room Room Allocation PIC Phone EmailDocument27 pagesNo. Hotel Address City Star Number of Room Room Allocation PIC Phone Emailali71usmanNo ratings yet

- 8051 MaterialDocument198 pages8051 Materialsupreetp555No ratings yet

- 5G-NR Protocol Stack Testing TrainingDocument6 pages5G-NR Protocol Stack Testing Trainingmansoor 31 shaikhNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument4 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceJagdeep Singh DeepiNo ratings yet

- The Influence of The Mass Media in The Behavior Students A Literature Study PDFDocument9 pagesThe Influence of The Mass Media in The Behavior Students A Literature Study PDFclarissa OrosaNo ratings yet

- Notes:: Brisbane City Council Standard DrawingDocument1 pageNotes:: Brisbane City Council Standard DrawingShaunitchi El GrecoNo ratings yet

- Multi-Function Instrument Installation Manual: 190-02246-00 November, 2019 Revision 1Document14 pagesMulti-Function Instrument Installation Manual: 190-02246-00 November, 2019 Revision 1joel alvarado100% (1)

- Assignment & LabDocument5 pagesAssignment & LabXyus PoudelNo ratings yet