Professional Documents

Culture Documents

Milano Stainless Steel Centrifugal Pump

Milano Stainless Steel Centrifugal Pump

Uploaded by

Wawan Smocil0 ratings0% found this document useful (0 votes)

33 views8 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views8 pagesMilano Stainless Steel Centrifugal Pump

Milano Stainless Steel Centrifugal Pump

Uploaded by

Wawan SmocilCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

el end suction

mp

MILANO PRL PCL O CLE

Outstanding Features

Superior Hydraulic Design

Easy Dismantling

Stainless Steel Wet parts

PO ae eB CIEL

Designed for

Br Nery as

Water Supply

perry es

Environment Engineering

Petsson

Neri amen entn

po)

ee Cav tg

Crees

Pumped Liquid: -15°C to + 180°C

Operating Pressure: 16 bar max

lose Couple

Sete)

MILANO

Stainless Steel Centrifugal Pump

Prostain ISO Pump and Supreme Motor Pump are

designed in accordance with ISO 2858- DIN 24256

Standard. All wet parts, including volute casing,

shaft, impeller, are made of Stainless Stee! for long,

time endurance, acid-alkali resisting, and rust free

liquid transfer,

piety Ff

Water supply

Wat

supply &

waterworks and substations, sprinkler, drip and.

Alood irrigation,

bution; pressure boosting in

Industry

Water supply and circulation in cooling and

heating systems. Pumping of cooling brine and

cooling agents in equipment and mechanical

ering. Paper and sugar industries, iron and

steel production, condensate transfer and boiler

fall,

Washing and cleaning installations, water-curtain

spray-paint bays, emptying and filling of tanks and

reservoirs, pumping Of seawater and brackish water,

moistening in dedusting plants.

Building servi

es

Circulation’ of liquids, heating and cooling water in

central ‘hésting, ventilation and air-conditioning

systems: Fire fighting service: Water circulation for

Swimming pools, general mechanical ’se

fayifonment Engineering

water treauhent systems,

recooling//systems, and

adinfiltration

¢ plants

ingtallations for soil sanitation

water treatment. {

Vesbels

Circulation of coo!

supply and gene:

system for fish catch, water

| mechanfeal service.

EET

Prostain ISO Pump and Supreme motor pump have

superior hydraulic design and incorporate high

technology manufacturing methods, which enable

significantly higher efficiencies for less power

consumption and minimum maintenance. All these

features guarantee Prostain pump users continuing

yy in all applications

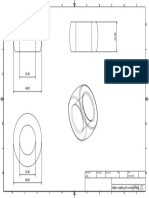

Prostain ISO Pump and Suprem

Pump are single

stage, non self-priming, centrifugal volute pumps,

‘conforming to ISO 2858 Standard.

TUSE LL Oy |

Flow: Max. 150m!

Head: Max. 120m,

Liquid Temperature: -15°C to+180°C

Operating Pressure: max. 16bar,

Designed for non-aggressive, non-explosive thin and

clean liquids without solid particles or fibers,

International St

G

forming to ISO 2858 Standard means

dimensional interchangesbility with other makes of

pumps, manufactured to the same international

standard. Prostain pumps exceed the ISO

performance standard because of hydraulic design

superiority. Due to the pump design, the backplate

and impeller can be easily dismantled from the drive

thout removing the volute casing from the

pipework. As standard of Prostain ISO Pump, a

support foot is fitted to the bearing housing,

MEIN eae 4

tandard Feat

Prostain pumps include taper mounted and keyed

impeller for easy removal from shaft during

servicing and positive locking during operat

heavy duty shaft with large capacity impeller and

bearing for safe operation at high speed. As type

304 stainless steel volute for added safety; reusable

ting body seal; mi

num number of parts for

full range (only two shaft modules) reduces spare

parts stocking; double curvature

eller v

produce highly efficient suctio

perforn

Type 316 stainless steel shaft; ductile iron shaft

clamp; type 304 stainless steel volute with integral

suction and discharge flanges and mounting fe

pressure rated to 1200 KPa (120 meter heady;

SS 304 impeller, backplate, and impeller nut;

cast iron housing with sealed for life grease

packed bearings; lip type shaft seals to protect

ingle mechanical seal

Cee ei

Type 316 stainless st

1 impeller, volute, and

backplate; optional mechanical seal; work

certified

and witnessed tests for guaranteed performance:

flexible and spacer couplings: pulleys: pressed/

welded stainless steel or carbon steel haseplates.

, = L

cae

“a TIRE LE

od

The Prostain standard motor is a totally enclosed,

fan-cooled squirrel-cage motor that dimensionally

complies with IEC and DIN. The motor pump uses

standard off the shelf foot mounted and flange

electric motors which require no modification and

are therefore no more difficulty to purchase than

‘motors used on long coupled units. Foot mounted

on the motor and on the pump body combine to

ally rigid mounting for the

provide excepti

nplete unit

Enclosure Class: IP 54

Insulation Class: class F from 15 kw; Class B

Ambient Temperature: According to IEC

50 HZ Voltages: 3x220-240/380-415V

60 HZ Voltages: 3x200-230/380-460V.

Optional Base Asse

Baseplate Kit

‘A baseplate kit is available to allow on-site basing up

of pump and motor, sizes to suit all models and

motors.

The kit includes baseplate, flexile or spacer coupling,

coupling guard, all fasteners and shims required for

on-site alignment,

Couplings

Flexible and spacer coupling,

A coupl

complete discharge cover including shaft seal and

impelter without removing the motor or pump body

with spacer enables dismantling of the

from the baseplate,

Maximum Operating Temperature

Maximum pumped liquid temperature for th

standard ISO Line pump is 80C using standard

seals. Liquids up to 180C can be handled using

special seals.

Pump Selection Chart

60Hz 2/4 Poles Motor

50Hz 2/4 Poles Motor

RPM (Nominsl Speed)

ar se fs

fee oe

ay

A|

i :

4

lat al

4

sit ee er

ET el | BA

+—n2— -+—w—|

NL

30] 32 |160) 1 | a0| 385/132] 160] so | 100) 70240) 190] 110] 10] 4 | 2ss;suzlniz| 24] so] 100 | 38

s0| 32200) 1 | 80 |385} 160] 180] 0 |100| 70] 240) 190] 110| 10) 4 | 285,M12|st12) 26] so|100| 44

65 | 50/160) 1 | s0 388) 132] 160] 50 |100| 70 |240| 190] 110] 10] | 2ssimiantia| 28] so] 100 | 39

68 [40 [200] 1 [100{ 385] 160| 180] so | 100) 70 265) 212| 110| 10] «| 28s va2}a12| 2s] so| 00 | 46

6 | 40 250] 2 —[100|s00| 180] 22s] os |125] 95 | 320) aso] 110] 12| s |3rolwaa|aia| 32) s0| 100) 6s

a0 | 65 ]160] 1 [100] 385] 160180] so | 100] 70] 265) 212) 110] 10] 4 |2ss|waz|i2| 26) so] ion) 44

80 | 50 [200] 1 [100] 385| 160| 200] 50 | 100] 70 | 265) 212| 110] 10] 4 |2as|waa|iia| 26) so] 100) 48

an [30 [2so) 2 |125| soo] 180] 205] 6s [125] 95/220] 2s0| 110] 12] s | arolwaa}ra| 2] so] 00 | 70

100| 80 |160] 2 |100| 00/160) 200] os | 123] 93 [280 212| uo] 12] 5 | srommzani| 32) ao|1o0 | a2

100/65 |200) 2 100] s00| 180] 225] 65 | 128] 95 |320| 250] 110| 12] 5 | 370\Maalstia] 32| so] 140) 66

1w0| 65 [2s0| 2 | 125) s00|200| 22s] so | 160] 120] 360| 280] 110) 12] 5 | s7oMnooa12] 32| s0|i40 | 78

125100] 200] 2 _[125|s00] 200/240 s0 | 15) 120] 00] 2so 10] 13| 3 | sroagani| s2| soliao| st

‘Specifications subject to change without prior notice

PETE eee Ea

4

Supreme Motor Pump (close coupte)

"160", "200" and "250" series pump with T.E.F.C. Motors

2900/3500 rpm (Nominal speed)

[owes] TaTsy ele [FH] s [x [MN] Py QTR] S| ry]

0332-160 [30/901 140125] 90)274|16]3sa{taa 10 [132|199)240 14 [170 s832

U

0

668x30-160_| 4.0| 112m | 190] 140112298] 160378] 122| 12 [132] 190 240 14|224)640]371] 70 [100

70

9

70

‘80x65-160 || 1325 |216] 140132298] 180) 398] 143] 12 jt60)212) 209, 14 [250] 683]37

100x80-160_| 11 | 160m |254|210| 160355] 200) 485] 180| 15 [160212 280 14 |300]845] 499)

'50x32-200_|.5| 1328 [2t6|140|132)298] 160) 379] 145] 12 [160] 190 244 14 |250| 663):

65x40-200 [7.5] 1328 [2t6| 140132298] 180) 399] 145] 12 [x60] 212) 269, 14 [250] 683]374| 70 |100|

{30x50-200_ | 11 | 160M [2s4|210| 160) 347|200) 447] 180] 15 [160) 2121265, 14 |300]$37] 499] 70 [100]

4100x65-200 | 15 | 160M |254/210) 160] 355] 225] 455]180) 15 |180| 2501320] 14 [300] 84808 95 [125|

425x100-200 | 22 | 180m |279]24i| 180 368] 280] 493]200| 15 [200| 280 360 18/355] 934] 562] 120|160]

f

r

65x40-250 | 11 | 160M [254210] 160 355]225|455|180| 15 [180250 32d 14

80x50-250 |185| 160L. [2s4]2s4) 160] 355]225| 15 |180]250 32d 14] 300] 914) 42] 95 [125

100x68-250 | 30 | 1801 |279}279] 180] 368]250|93]20| 15 [200280 360, 18 |355]972] 609] 120|160

Ae

1450/1750 rpm (Nominal speed)

32-160 [2.2] 1001. [16140 to}252| oo]. 12 [32|190 24014 |19s}584]319 70 [100

6$x50.160 | 30] 1001. |160f 140 rosa] of 3az| al 13 [123 |s00)2ad 14 10s|sedais] 70 [roo

80x65-160_|3.7| 112M |190]140]112]298| 180|398| 122] 12 [160|212/ |224| 660] 371) 70 |100]

100x80-160 [5.5] 1328 [216 140|132]306|200) 406] 145] 12 |160|212) [250] 690] 374) 95 |125\

50x32-200__| 3.7 | 112M |190] 140] 112} 298] 180|378) 122] 12 /160|190 [224] 640] 371] 70 | 100)

65x40-200 | 3.7| 112M [190140 112]298]180|395|122| 12 [too 212/205 14 [224] 000]371] 70 100

80%50-200 | 5.5| 1328 [216 140|132]298]200] 399] 145] 12 |1c0 [212/205 14 [2s0]os3]374 70 |100

100365-200_|7.5 | 132M /216|178|132|306|225| 40914512 [190 250 320 14 [250]729] 412] 95 [125

125e100-200 [11 | 10 [2s axe e355] 15 00280360 18 003040 120]

(65x40-250_|5.5| 1328 [216] 140] 132|306|725) 406) 145] 12 [180 250 320 14 [250]691|374 95 |12s| 7}

80x50-250 | 7.5 | 132M [216178132] 306)225) 43114512 [180 250/320 14 [250751412] 95 [125 ,

100x65-250 | 15 | 1601 [254)254] 160] 355|250] 480) 180] 15 [200 [280] 360 18 [300/914] $42] 120)160|

“Specifications subject to change without prior notice. J

"Other size of motors available upon customer request.

Q

Ss

=)

io

=

o

iS

=

S

=

Co

1S)

o

iS

os

7)

wn

n

x

ss

By

st

¥I

er

Fexwont

(ueus-e1eg) PABPULIS BC¥Z OST

Motor Selection Chart

waneea] Fusnon ipa | _L

eae Super wojsuna yeas | 9

1 es rau! Bont.o. | _$

« ea

61 | syidyoeg 1 Susn0y Baese sents

Se ean

frase omen ov sea

a res Supey amen |

om mnie] womisaca fon won

“are 14

lh.

daddoe

180 2858-DIN 24256 Standard

STAINLESS STEEL CENTRIFUGAL PUMP .

ELC

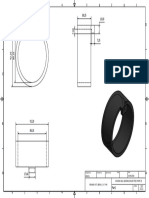

Pump component

‘Bearing Housing (ISO Pump)

Bell Housing (Supreme Motor Pump)

Volute Casing

Impeller

Backplate

Impeller Washer

Impeller Key

‘Casing and Flange Plug

‘Casing O Ring

‘Motor Shaft Clam |

‘Mechanical Se:

EE Te |

DIN 24256

32-160

~ 50-160

65-160

80-160

32-200

40-200 __65x40-200

50-200 80x50-200_

65-200 —10068-200

100-200

40-250

50-250

65-250 100x65-250

D7. URES (ESD

Ln Ta Cnr Oa NB

a

ct

wccsncgiencrmne TdORESTS

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fire Brick Frame 1Document1 pageFire Brick Frame 1Wawan SmocilNo ratings yet

- Rubber Coupling Ash Screw ConveyorDocument1 pageRubber Coupling Ash Screw ConveyorWawan SmocilNo ratings yet

- Housing Ball Bearing Boiler Feed Pump 2BDocument1 pageHousing Ball Bearing Boiler Feed Pump 2BWawan SmocilNo ratings yet

- Perlengkapan Las GTAWDocument1 pagePerlengkapan Las GTAWWawan SmocilNo ratings yet