Professional Documents

Culture Documents

Astm c109 c109m 13pdf

Astm c109 c109m 13pdf

Uploaded by

aminiskandar0 ratings0% found this document useful (0 votes)

31 views10 pagesOriginal Title

Tuxdoc.com Astm c109 c109m 13pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views10 pagesAstm c109 c109m 13pdf

Astm c109 c109m 13pdf

Uploaded by

aminiskandarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

:109/C109M - 13°"

Aly Designation:

‘ureananonat

Standard Test Method for

Compressive Strength of Hydraulic Cement Mortars (Using

2i

“This sda soc wader the fe desgmon C1ONCIOPME the number nerdy llr ese

cas evs, the year of ls ren anes

‘oe ial lp

. or [50-mm] Cube Specimens)!

onde the ear

cases adios ea ft pp

Ament eplion 2) nds ane cage ice the nevis oF eappeva.

"The udu bas he epee ences ofthe US. Drparmant ef Deere

FTNGTESReieense oan wow anal wo palin wae” Ua im oly 201

1, Scope*

LI This test method covers determination of the compres-

sive strength of hydraulic cement montars, 2-in, or

150-mm} cube specimens,

[Noms Tis Method C340 provides am altermitive proces fr this

determination (not io be used for aceapance tes,

2 ‘This test method covers the application of the test using

either inch-pound or SI units. The values stated in either SL

tunits oF inch-pound unils are to be regarded separately as

standarc. Within the text, the SE units are shown in brackets.

‘The values scated in each system may not be exact equivalents:

therefore, cach system shall be used independently of the other

‘Combining values from the (0 systems may result in noncon-

formance with the standard,

1.3. Values in SI units sinall be obtained by measurement in

‘SI units or by appropriate conversion, using the Rules tor

Conversion and Rounding given in IEEE/ASTM SI-10, of

measurements made ia other units

14 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro=

priexe safety and healt practices and determine the applica-

bility of regulatory limitations prior 10 use, (Warning—Fresh

faydraulic cemersitious mixoures are caustic and may canse

chemical buras 10 skin and tissue upon prolonged exposure.*)

2. Referenced Documents

2.1 ASTM Stunderds:*

(C91 Specification for Masonry Cement

06 fe set esonsinity of Subomminee C01 27 6a Senet

‘Chen eon aparved Oc, 1, 2018 Pld November 2013. Crignlly

pyres i 3 Lint provi elitr appt ip 2017 38 CHOBCIOBM 12

1 So the ton on Sf) Manuel of Comert Tenn, Antu Dp of ASTAF

Shand, Ye O40

"er rftcaed ASTM snd, vst de ABTM rc, rare oF

certs ASTM Coscrer Servis at vice srg. For Areal Bok of ASTHE

Shundards vom lueraton, eer to he sands Docomien Sumy paps on

the ASTM went

C114 Test Methods for Chemical Analysis of Hydraulic

Cement

(C150 Specification for Portland Cement

(€230VC230M Specification for Flow Table for Use in Tests

oof Hydraulic Cement

(©3085 Practice for Mechanical Mixing of Hydraulie Cement

Pastes and Mortars of Plastic Consistency

C3410 Test Method for Compressive Strength of Hydraulic

‘Cement Mortars (Using Portions of Prisms Broken in

Flenure)

C31 Specification for Mixing Rooms, Moist Cabinets

Moist Rooms, and Water Storage Tanks Used in the

‘Testing of Hydraulic Cements ari) Concretes

€599 Specification for Blended Hydraulic Cements

C518 Specification for Coal Fly Ash and Raw or Caleined

‘Natural Pozzolan for Use in Concrete

(C520 Practice for Preparing Precision and Bias Statements

for Test Methods for Construction Materials

(C778 Specification for Standard Sand

(€989 Specification for Slag Cement for Use ia Concrete and

Mortars

©1005 Specification for Reference Masses and Devices tor

Determiaing Mass and Volume for Use in the Physical

“Testing of Hydraulie Cements

C157 Performance Specification for Hydraulic Cement

€1328 Specification for Plastic (Stucco) Ceme

C1329 Specification for Morar Cement

C1437 Test Method for Flow of Hydraulic Cement Mortar

E4 Practices for Force Verification of Testing Machines,

System of Units (SD: The Modern Metric System

3. Summary of Test Method

3.1 The mortar used consists of | part cement and 2.75 parts,

fof sand proportioned by mass. Poriand oe airentraining

portland cements are mixed at specified waterlcement ratios.

‘Water content for other cements is that sufficient 19 obtain

flaw of 110 = 5 in 25 drops of the flow table, Two-inch or

[50-mni] test cubes are compacted by tamping in two layers,

A Sumraary of Changes section appear a the end of this andar

Copy AST intra 00 BH Cv FB G7 Wen Crore PA AEE Utes Ses

Alp ctosicio9m - 13°

The cubes ane cured one day ia the ul

immersed in lime water until tested

ds and Stipped

4, Significance and Use

4.1 This test method provides a means of determining the

compressive strength of hydraulic cement and other mortars

and results may be used to determine compliance with speci

fications. Further this test method is referenced by numerous

other specificotions and test methods. Caution must be exer-

cised in using the results of this test method to predict the

uength of coneretes,

5. Apparatus

5.1 Weights and Weighing Devices, sball conform to the

requirements 0° Specification C1005, The weighing device

shall be evaluated for precision and accuracy at a total Jead af

2000

5.2 Glass Graduates, of suitable capacities (preferably larse

enough to measure the mixing water in a single operation) to

deliver the indicated volume at 20 °C. The permissible varia-

tion shall be +2 mL. These graduates shall be subdivided to at

least $ mL, except that the graduation lines may be omnited for

the lowest 10 mL. for a 250-mL graduate and for the low

mL of a $00-ml. graduate. The main graduation lines shall be

circles and shall be numbered. The least graduations shall

ceviend at least one seventh of the way around, and intermediate

sgraduations shall extend at least one fifth of the way around.

3.23 Specimen Molds, for the 2-in. of [50-mm] cube spect-

‘mens shall be ight fiting. ‘The molds shall have not more than.

three cube compartments and shall be separable into not mere

than (wo parts. The parts of the molds when assembled shall be

positively held together. The molds shall be made of hard metal

‘not attacked by the cement mortar. For new molds the

Rockwell hardness number of Uke metal shall be not less U

55 HRB. The sides of the molds shall be sufficiently rigid to

prevent spreading or warping, The interior faces of the molds

shall be plane surfaces and shall eonforn to the tolerances of

Table |.

5.3.1 Cube molds shall be checked for conformance to the

design and dimensional requirements of this test method at

least every 246 years,

54 Mixer Row! and Paddle, an electrically driven mechani

cal mixer of the type equipped with paddle and mixing bowl,

as specified in Practice C305.

5.5 Flow Table rd Fleav Mold, conforming to the equine

‘ments of Specification C230/C230M.

56 Temper 1 venabsorpiive, nonalvasive, nonbeiile mute

rial suci as a rubber compound having a Shore A curometer

hhardiness of 80 + 10 or seasoned oak wood rendered nonab-

sorptive by ininersion for 15 min in paraffin at approximately

292 °F or [200 °C}, shall have a cross seetion of about ¥2 by |

in. or [13 by 25 mim] and a convenient length of about 5 t0 6

in. oF [120 to 150 min}. The tamping face shall be fat an at

right angles to the length of the tamper

5.6.1 Tampers shall be checked for conformance 10 the

design and dimensional requirements of thie rest method at

least every 2% years

5.7 Trowel, having a steel blade 4 (0 6 in. [100 to 150 mm}

in length, with straight edges.

Moist Cabinet or Room, conforming to the require-

‘ments of Specification C:

5.9 Testing Machine, either the hytraulic or the serew type,

‘with sallicient opening between the upper bearing surface and

the lower bearing surface of the machine to permit the use of

verifying apparatus, The load applicd to the test specimen shall

bbe indicated with an accuracy of 1.0%, IFtne load applied by

the compression machine is registered on a dial, the dial shal

tee provided with a graduated scale that can be read to at least

the nearest 0.1 % of the full seale lozd (Note 2). The dial shell

be readable within 1 % of the indicated load at any given load

level within the loading range. In no case shall the loading

range of a dial be considered to include loads below the value

‘tat is 100 times the smallest change of load that ean be read

‘on the scale, The scale sball be provided with a graduation fine

equal to zer0 and so nuuntbered, The dial pointer shall be of

sufficient length to reach the graduation marks; the widkh of the

tend of the pointer shall not exceed the clear distance between

the smallest graduations, Each dial shall be equipped with a

‘ero aljustmicat that is easily accessible fom the cutside of the

ial case, and with a suitable doviee that ot all times until reset,

‘will indicate to within | accuracy the maximam leael applied

to the specimen,

5.9.1 Ifthe testing machine load is indicated in digital for,

the numerical display must be large enough to be easily read.

‘The numeri 1 or bos than 0.10 4

of the full scale load of a given loading range. Inno ease shall

the verified loading range include loads less than the minimum

rnuwetieal inerement rmaliplied by 100. The accuracy of the

indicated load must be within 1,0 % for any value displayed

‘within the verified loading range. Provision mast be made for

adjusting w indicate te ze at zero load. There shall be

provided a maximum load indicator that at all times until reset

TABLE 1 Pormissible Variations of Specimen Molds.

Bin Sone Nala Ta] Subs ue

Parmeter Tate ew ue

Phere TGR og Tots aT TED maT

Dare hence opps sos pin v9mn8 Peon (som =0137m) (50 men +050 mn)

Helge each ecrparmant 2in- corn, 2in + 0otin [80 rm « 025 m0 Ist new = 025 rm

2-019 to-0%3 re] 038 mm

Angie paneer agjacort aces 0-05 ‘sps0s" ease

*easure pts sgn removea rom ve riracter: MeRSures separa or ach Compariventberwee al elnino’ es and Ne AgACE aCe ATG BETWEEN

ver aces sep ae one panos of he ma,

4p ctosictoam - 13"*

sail] indicate within 1 6 system accuracy the maximum load

applied to the specimen,

.2 Compression machines shall be verified in accordance

swith Practices Fe at least anally «0 determine if indicated

loads, with and without the maximum load indicator (when so

equipped), are accurate to +1.0 %.

[None 2—Aceloe a can be reat is eonskered Asn. o°[03 ws] akon

the ane described by the end ofthe pote lsc, one hl of the scale

Jmerval is about as close as can reasonably be reod hen the spacing on

the Hud indicating mechanism is bewee V9 in or {1 ann] ane Yi

11.0 mi} When the spacing s between a. or [LG rt and i

182 hv), cme tint the ale inersal cae he read with reasonable

‘cerain'y, When the spacing fs Ue imo [3.2 mm} or mare, ane tout oF

the scale iaterval car bo oad with fexonable cenit.

5.9.3 The upper bearing assembly shall be a spherically

seatec, hardened metal block firmly attached at the center of

the upper heed of the machine. ‘The center of the sphere shall

coincide with the surface of the bearing face within u tolerance

‘of =5 % of the radius ofthe sphere. Unless otherwise specified

by the manufactuter. the spherical portion af the hearing block

and the seat that holds this portion shall be cleaned and

lubricated with 2 petroleum type oi sueh as motor oil at least

every six months. The block shall be closely held in its

spherieal seat, but shall be free to ti in any direction, A

hhardened metal bearing block shall be used heneath the

specimen to minimize wear of the lower platen ofthe machine.

To facilitate socurate centering of the test specimen in the

compression machine, one of the 1wo surfaces of the hearing

blocks shall have a diameter or diagonal of between 2.83 in.

[70.7 mm] (See Note 3) and 29 in. [73.7 mam}, When the upper

block bearing surface meets this requirement, the lower block

bearing surface shall be grater than 2.83 in, [70.7 mm. Whea

the lower block bearing surface meets this requirement, the

diameter or diagonal of upper block bearing surface shall be

botween 2.83 and 31 in, [70.7 and 79.4 mm]. When the lower

block is the only block with 2 ciameter or diagonal between

2.83 and 2.9 in. [70.7 and 73.7 mi), the lower block shall be

used to center the test specimen. In that ease, the lower block

shall be centered with respect ta the upper bearing block and

held in position by suitable means. The beating block surfaces

intended for contact with the specimen shall have a Rockwell

harness number not less than 60 HRC. These surfaces shall not

depart from plane surfaces by more thaa 0.0005 in, (0.013 mn}

when the blocks are new and shall be maintained within a

sible variation of 0.001 in, or [0.025 mm)

5.9.3.1 Compression machine bearing blocks shall be

checked for planeness in accordance with this test method at

least annually using a straightedge and feeler stock an shall be

refinished if found to be out of tolerance.

‘None $the dgera of» i,[30 mam] cube 2.83 in. (707 mi

6, Materials

6.1 Grodded Standard San:

6.1.1 The sand (Note 4) used for making test specimens

shall be natural silica sand conforming (o the requirements tor

graded standard sand in Specification C778,

Non 4 Segwegatiot of Graded Sand —The graed snd a

should be Kaceled in sich a manner as WO prevent segrcetion, see

‘atations inthe gang of he sand cause vations in the consistency of

the most In erptying ius or sachs cae should be exer preven

the formation of mounts of saat or cutee ir ths snd, down the shops

the coarser pats Wil ol. Hins shot be o scent 76 to

These preciuticns, Devices for daasing dhe sind fram bine by

Brity should not be wed,

7. Temperature and Humidity

7. Temperanere—The temperature of the air in the vicinty

cof the mixing slab, the dry materials, molds, base plates, and

raixing bow, shall be maintained petween 73.3 ~ 3.3 °F or

125.0 © 3.0 °C). The temperature of the mixing water, moist

closet or moist room, and water in the storage tank sball be set

A733 = 4.3 "For [23 * 2°C).

7.2. Humidity —The relative humidity of the laboratory shell

tbe not less than 50 %, The moist eloset or moist room shell

conform to the requirements of Specification C311

8 Test Specimens

8.1 Make 0x0 or three specimens from a batch of mortar for

each period of test or test age.

9. Preparation of Specimen Molds

©.1 Apply thin coating of release agent to tae interior faces

fof the mold and: non-absorptive hase plates. Apply oils and

‘greases using an impregnated cloth or ether suitable means.

Wipe the mold faces and the bese plate with 2 cloth as

necessary to remove any excess release agent and to achieve a

thin, even coating on the interior surfaces. When using un

‘aerosol lubricant, spray the release agent directly onto the mold

Faces and base plate from a distance of 6 to 8 in. oF [150 to 200

zim) to achieve complete eoveruge. After spraying, wipe the

surface with a eloth as necessary to remove any excess aerosol

lubricant. The residue coating should be just sufficient to allow

‘distinc: finger print to remain following light finger pressure

(ow 5),

9.2 Seal the surfaces where the halves of the mold join by,

‘applying a coating of lignt cup grease such as petrolutum, The

amount should be suificient 1o extrude slightly when the two

halves are tightened together, Remove any exeess grease with

acioth,

93 Seal mold to their base plates with a watercsht sealant,

Use microcrystalline was oF # mixture of three parts paratfin

|wat t five parts masin by mass. Paraffin wax is permitted as

sealant with molds that clamp to the base plate. Liquefy the

‘wa by heating ito a temperature of between 280 and 268 °F

or {110 and 120 °C], Effect a watertight seal by applying the

Iiquefied sealant atthe outside coatact lies between the mold

and its base plate (Nove 6).

9.4 Optionally, « watertight sealant of petroleum jelly is

permitted for clamped molds. Apply a small amount of

petioleum jelly to the entre sure ofthe face of the mold that

will be contting the base plate. Clamp the mold te the base

plate and wipe any excess sealant from the interior ofthe mold

and hase

Non Unser tse rion oengect, mt shot

ehecked fora scent eating of cat nme poet se. Ian

cueack peiod of in as elapsed ine ucanem. eresunea sy be

4p ctosictoam - 13°"

Nore 6—Mivenighy Modts—The riisate of yarafin was atx rosin

specified for sang the jos tetween mnakly sd hex ples may Te

{urd dificult 9 remove when molds are being cleaned. Use of sagt

prain vax is permissible if watertight jot is secure, bu de 4 the

of acalfin was shoal! be sod only whe the oli nok

lnyed

aie by sighly

‘molds with parain wid, an yproved se) can he

‘worming the mov an base plate pri to applying the ea. Ms

treats should be allowed to rtm to room lemperacure Delors use.

10, Procedure

10.1 Composition af Mortars:

10.1.1 The proportions of materials for the standard) mortar

shall be one part of cement 10 2.75 parts of graded standard

sand by weight. Use a water-cement ratio of 0485 for all

portland cements and 0.860) for all sir-entraining portland

cements. ‘The amount of mixing water for other than portland

and air-entraining portland cements shall be such as to produce

a flow of 110 Sas determined in accordance with 10,3 and

shall be expressed as weight percent of cement,

10.1.2. The quantities of materials to be mixed at one time in

the bateh of mortar foe making six, nine, anu twelve test

specimens shall be ay fellows:

Numb ot Spires 6 9

Ganen.s oo 7301000

Sands was ais aI

Water,

Potare (04) ne es

-Avvontaina porte (00) zo MO we

Geet ow of HO 3)

10.2 Preparation of Mortar

10.2.1 Mechanically mix in accordance with the procedure

sven in Practice C305,

10.3 Deternuination of Flow:

10.3.1. Determine flow in accordance with procedure given

in Test Method C1437.

10,32 For portland and air-entraining portland cements,

merely record the flow.

10.3.3 In the case of cements other than portland or alt=

eniraining portland cements, make trial mortars with varying

percentages of water until the specified flow is abtained. Make

‘each tial with fresh morta,

10.34 Immediately following completion of the flow test,

eum the moriar from the low table 16 the mixing bow!

Quickly serape the bow! sides and wansfer into the bateh the

‘mortar that may have collected on the side of the bowl and then

remix the entire hatch 15 sat medium speed. Upon completion

of mixing, the mixing paddle shall be shaken to remove excess

‘mortar into the mixing bow,

10.3.5 When a duplicate batch is to he made immediately

fr adkitional specimens, the flow test may be omitted and the

‘mortar allowed to stand in the mixing bow! 90 s without

covering. During the last 15s of this interval, quickly scrape

the bowl sides and transfer into the batch the mortar that may

have collected on the side of the bowl, Then remix for 15 sat

‘medium speed.

104 Molding Test Specimens:

104.1 Complete the consolidation of the morar in the

molds either by hand tampinz or by a qualified alternative

‘method. Alternative methods inelude but are not limited to the

use of a vibrating table or mechanical devices.

10.42 Hand Tumping—Start molding the specimens within

a total clapsed time of not more than 2 min and 20 s after

completion of the original mixing of the most batch. Place a

layer of mortar about 1 in, oF (25 min} approximately one halt

cf the depth of the mold) in all of the cube compurtments

Tamp the mortar in each eube compartment 32 times in about

10 in rounds, each round 4 be at right angles tthe ath

‘and consisting of eight adjoining strokes over the surface of the

specimen, as ilustrated in Fig. |. The tamping pressure shall be

just sufiient wo ensure uniform ‘ling of the molds, The +

rounds of tamping (32 strokes) of the mortar shall be com

pleted in one cube before going 1 the nest. When the tamping

Of the fist layer in all of the cube compartments is completed,

fill the compartments withthe remaining mortar and then tamp

as specified for the firs: layer. During tamping of the second

layer, bring in the mortar forced aut onto the tops of the molds

after each round of iamping by means ofthe gloved fingers nd

the tamper upon completion of each round and before starting

the next round of tamping. On completion of the tamping, the

tops of all cubes should extend slightly above the tops of the

‘molds. Bring in the morar that has been forced out onte the

tops of the molds with « trowel anc! smooth off the cubes by

drawing the fla side of the trowel (with the lewling edge

slightly raised) once acrons the top of each cube at right angles

to the length of the mold. Then, forthe purpose of leveling the

‘mortar and making the moctr that prosrudes above the top of

the mold of more uniform thickness, draw the flat side of the

trowel (with the leading edge slightly raised) lightly once along

the length of the mokl. Cut off the mortar 10 @ plane surface

flush with the top of the mold by deawing the stright edge of

the trowel (held nearly perpendicular 10 the mole) with a

saving motion over the length of the mold

104.3 Alternative Methods—Any consolidation method

‘may be used that meets the qualifietion requirements of this

section. The consolidation method consists of a. specifi

procecie, equipment and consolidation device, as selected and

used in a consistent manner by a specific laboratory. The

mortar batch size of the meibed may be modified to accom

rmoxlale the apparatus, provided the proportions maintain the

same ratios a8 given in 10.1.2

104.3.1. Separate qualifications are required forthe follow-

ing classifications

Class A, Nom-air entrained cements—for use in conere

such as sold under Specifications C150, C595, and C1157.

Class B, Air-enivamed cemeris—for use in concrete, such

as sold under Specifications C150, €595, and C1157.

Class C, Masonry, Mortar and Stucco Cements—such as

sold under Specifications CO1, C1328, and C1328.

Rounds 1 and 3 Rounds 2 and 4

FIG. 1 Order of Tamping in Molding of Test Specimens

fl ct0ac109M ~ 13°*

10.432 An alternative method muy only he used to test the

cement types es given in 10.4.3.1 above, for which it has been

qualified.

104.3.3 Tt can also be used for Suength Activity Tacex

determinations for fly ash and slag, such as sold under

Specitications C618 and C9X9, provided the allemative method

hhas qualified for botlt Class A and Class © cements

104A Quaifieation Procedure—Contuet CCRL to purchase

‘cement samples that have been used in the Protieiency Sample

Program (PSP), Four samples G Ke each) of the class to be

qualified will be required to complete a single qualifieation

(See Now 7)

1044.1 In one day, prepare replicate G-cube or I-cube

batches using one of the cements and east a minimum of 36

cubes, Complete one round of tests on each cement on different

days, Store and test all specimens as prescribed in the se

below, ‘Test all cubes at the age of 7-days.

10.442 Tabulate the compressive strengity dara and com-

plete the mathematical analyses as instrucied in Annex Al.

104.5. Requalipication of the Alemete Compaction Method:

10.4.5.1 Requalification of the method shall be required if

any of the following occur:

(1) Bvideace that the method may not be prow

accordance with the requirements of Table 2.

(2) Results that difter trom the reported final average of a

CCRI-PSP sample with a rating of 3 oF less

we dua in

(2) Results tht difer from the accepied value of 2 known

reference sample with established strength values by more than

twice the mult-laboratory Is % values of Table 2,

Before staring the wequalificition procedure, evaluate all

aspects of cube fabrication and testing process 10 determine if

the offending result is due to some systematic error or just an

‘oceasional raredom event

10.4.5.2 If the compaction equipment is replaced, signif

canily modified, repaiced, or has been recalibrated, requalify

the equipment in accordance with 10-44,

[Nort 7—It's recommenced alge homogenous sample of cement

bbe prepare at tho time of qualification for use a a scoondary standard and

for meio evahsuion. Frogaent testing of this sample wil give eatly

ming of ary changes in ihe performemce of Ba paras

10.5 Storage of Test Specimens—immediatcly upon

completion af molding, place the test specimens in the moist

closet or moist rom. Keep all test specimens, immediately

after molding. in the molds on the base plates in the moist

Closet or moist room ftom 20 16 72 h with their upper surfaces

exposed to the moist sir but protecied from dripping water. If

the specimens are removed from the molds before 24h, keep

them on the shelves ofthe moist closet or moist room: until they

are 24h old, and then immerse the specimens, except those for

the 24-h test, in saturated lime water in storage tanks con-

structed of noncorroding materials. Keep the storage water

clean by changing as required

‘TABLE 2 Procision

Goetert,

eet oe, a

oye arto,

tee

‘Ponind Cements

‘Saat wan Ea

‘Si laberary 1 1 ar

7 38 ne

2 38 8

Nutine aboriores 1 13 24

3 6B Bo

r 68 133

a 88 Be

‘verge . 56 $95

‘ended Cements

Sa Haw a

Sig aber, 3 40 13

z 28 wr

& a4 oe

orgs 38 07

utp uborsones 3 8 ay

z 7s ns

3 tA Do

erage 76 6

Tear Can

CSET a a

‘Shi laberaery z 19 ms

a 75 m2

usage 7 ne

Nunpa wrorsonae z ne we

avenge ne. 37

* These nob ercEE aspect (5H) avd a5) ras as OBST n PraBHGE CATO,

Alp ctosic109m - 13°

10.6 Desermainaiion of Compressive Strengih

10.6.1 Tosi the specimens immediately ufter their remo

from the moist closet in the case of 24-h specimens. and from

storage water in the case of all other epecimens. All test

specimens for a given test age shall be broken within the

permissible tolerance prescribed as follows:

Test ve Peis Taersnce

zh an

3s ar

7 des ab

doe 2h

If more than one specimen at a time is removed from the

‘moist closet for the 24-h tests, keep these specimens covered

swith a damp cloth until time of testing. If more than one

specimen at a time is removed from the storage water for

testing, keep these specimens in water at a temperature of 73.5,

© 35 "Far [23 ~ 2 °C] and of sufficient depch to completely

immerse cach specimen until time of testing,

10.6.2 Wipe cach specimen to a surface-dry condition, and

remove any loose sand grains or incrustations from the faces

that will be in contact with the bearing: locks of the testing

machine. Check taese faces by applying a straightedge (Note

8), If there is appreciable curvature, grind the face or faces t0

plane surfaces or discard the specimen. A periodic check af the

cross-sectional area of the specimens should be made.

Nore Seinen Faces—Results much lower than the tue ste

‘wll he obtained by loading faces ofthe cube speckmer that re et ly

line surfaces. Therefore i 6 eatbil that specimen noice be Rept

orupulusly lee, ss othaie, hee ingulurties i The sarlaces wall

cecur Instruments for cleaning mois should abvoys be soc than the

fmctal in the mokls 9 prevent wear. In case grinding specie laces is

fecessy, Lea be accomplished Hest by tubbing de Spence aseet

fF tne emery mer ve clot piel 14 plane site, using only

moderate presse, Such grading is lectows Jor mare than few

thousandihs of or inch thunddths ofa milimete) were mors haa this

is foun access, i is recommended that the specimen be diseatd

10.6.3 Apply the load to specimen Faces that were in contact

with the true plane surfaces 0° the mold. Carefully place the

specimen in the testing machine below the center of the upper

bearing block, Prioe to the testing of each cube. it shall be

ascertained thatthe spherically seated block is free w tlt, Use

no cushioning or bedding materials. Bring the spherically

sewed block inte uniform contact with the surface oF the

specimen. Apply the load rate at a relative rate of movement

between the upper and lower platens corresponding 10 a

loading on ihe specimen with the range of 200 10 400 Tbsis [900

to 1800 N/s], Obtain this designated rate of movement of the

platen during the ‘irst half of the anticipated maximum load

ani make no adjustment in the rate of movement of the pls

in the later half of the loading especially while the cube is

ylelding before failure

Noone 911s avisble w apply only very Hight coating ef «goo

‘quality, Hehe mineral oi to the spherical seat of the pre piten

LL, Calculation

I1.1 Revosd the total maximum load indicated by the testing,

‘machine, and calculate the compressive strength as follows;

B= PIA a

where

fn = compressive strength in psi or [MPa],

P= ‘otal maximum load in [bf or [N].and

area of loaded surfeee in? or (mm?

Either 2-in, or [50-mm] cube specimens may be used for the

determination of compressive sirength, whether inck-pound or

SL units ave used. However, consistent units for load and atea

‘must be used to calculate strength in the units selected. Ifthe

cross-sectional area ofa specimen varies move than 1.5 % from

the nominal, use the actual area for the calculation of the

compressive strength. The compressive strengih of all accept

able test specimens (see Section 12) made from the same

sample and tested at the same period shall be averaged and

reported to the nearest 11) psi [0.1 MPa}

A

12. Report

12.1 Report the flow to the nearest 1 4 and the water used

to the nearest 0.1 %, Average compressive streagth of all

specimens fiom the sane ssmple shall be repovied 1

pearest 10 pst [0.1 MPa].

13, Faulty Specimens and Retests

13.1 In determining the compressive sirength, do not con

sider specimens that are manifestly faulty

13.2 The maximum permissible range herween specimens

from the same mortar batch, atthe same test age is 8.7 4% of the

average when three cubos represent « test age and 7.6 % when

‘two cubes represent a test age (Note 10).

[Non 10—Mhe probability of excesting these ranges fs fin 100 when

the withi.bateh coeficient of variation 21 %. The 2 % ian average

{fo iaboraiones paticipating in the portland cement and maoary cement

teironce sample prngrome of tbe Cement and Concrete Reference

Laberaters,

13.3 Ifthe range of thtce specimens exceeds the maximum

in 13.2, discard the result which differs most from the average

and check the range of the remaining two specimens. Make a

retest of the sample if less than two specimens remain afte

isgarding faulty specimens or disgarding tests that fail 10

comply with the maximum permissible range of wo speci-

[Non !1—Relible sureagth reals depend upcn eueful observance of

all f the specitiedrequiremms and procedtes. rea results aa given

test pric inicate dat some ofthe requlremerns and procedures hae aa

‘beet carefully observed for exsimple, those covering the testing of the

specimen ar prewribal in 1062 snd 163 lpoper centering of

Spocimens eating in obliga fracareso eral movertom af ne ofthe

fhoads of the testing machine during loading will cause lower srength

sells

14, Precision and Bias

14.1 Precision'—The precision statements. for this test

‘method are Listed in Table 2 and are based on results from the

‘Cement and Concrete Reference Laboratory Reference Sample

Programm (sec Note 12), They are developed from data where a

tost result is the average of compressive strength tests of three

* Supoting et tae to he a AST eer tna Healganesa 19

oats regueing Resa Rept RRGCOI-D

Gp ctosictoam - 13"

cubes moked fromm a single haich of monar

same age (soe No 13),

Nie 12—Osiy the preson ils for conan wstercement mio

ortund coments were revised in ths venion of Test Nlahod C1037

Gibost The recnen vas for ledod onert a masony cents

tne enchant from the prev vein

Nor I-A sgn cng i room wou 2 he

sons mu he sre tance her ian tee

1142 ‘These precision statements are applicable to mortars

rade with certenss mixed and tested atthe uges as noted (2

Note 14),

ud tested at thee

icipated

Now: 4 The aopropsan nls are They somewhat larger for tests a

younger ages rn slightly staler for texts at oler ape

14.3 Bias—The procedure in this est method hus no bi

because the value of compressive strength is defined in terms

cof the test method,

15, Keywords

15.1 compressive strengths hydraulic cement mortar: by

émaulic cement strength; mottar strength; strength

ANNEX

(Mandatory Tatormation)

AL. ANALY

Al. Calewlasion of Averoge Wihin-Boich Standard Devia-

tion and Elimtinacion of Ouatiers—Tabulate the results

for each cement sample (or round) in separate spreadsheots. In

the spreadsheet, [st results of cach bach in columns and

complete the calculations as shown in Table AIL.

AI-1.1 Eliminate any outliers from the tost data and rep:

the calculations until none of the values lie outside the normal

range.

AJ.L.2 Tubulute the cube strengths with all the outliers

‘eliminated and complete the calculations ¢s shown in Table

Al2.

AL.2. Summary of Resutts—Compile the results of the four

rounds and complete the calculations as shown in Table Al 3.

The number of outliers shall not exeeed 5% of the Coral

number of tests when rounded to the nearest whole number (for

example, 4 rounds x 4 batches x 9 cubes = 144 tests x

(5%/100) = 7.2 oF 7),

ALS Precision Qualification —Caleulate the relative within

batch error (RWBE Ye) 4s shown in Table Al.3, This value

‘must be less than 2.1 4 te.comply with the limit establishes

Note 10 of this specification,

Ala Bias Qualification —The test results compiled in Table

AL3 are evaluated against three limits to demonstrate an

faccepiable qualification. The limits have been established

ttistieally trom analyses of historical CCRL data and are

given in Table ALA.

ALS Rationale for the Limits Given in AL.4:

AISA The muli-laboratory pre

fof 7 batehes is given by:

on (15) for the average

SES OF TEST RESULTS FOR QUALIFICATION OF ALTERNATE COMPACTION METHODS

Al

failures

ng. allowed whi

Sn ye AS used in Test Methods CLL4,

4 rounds ane performed) is 12

ALS3 The multi-laborstory precision (1s%) for the mean

of 4 rounds is D5 S44.

ALSA The limit for deviation of the mean of 4 rounds

(95 % confidence) is 1.96 times this, oF 0.98 §%y4,

ALSS The valucs for sfisq. and sco for Cement Classes

A and € (non air-eatrained cements for eoncrete and cements

fxr mortar respectively) are the 7-day values in the curre:

reccision statement of Test Method C100/C109M. There ap-

‘pears to be no data for Cement Class B (ait-entrained cements

for concrete). Working on the assumpdion that the value ofthis

‘quantity is related to the air content, the values adopted for

Class B are the mean of the A- and C.values.

|AL.S6 For the applicable conditions, the equations above

sive the following:

Table Ata

Corer Cone s 8 ¢ 8

Dates ver Aaund io) «= 88 ‘

7

4

2 5m 79 88s

o4 01 0 os

S574 98 58 76 06

dovigten'la «8B 8 M2 Gy ans

single rane >

Umterdovaioncl «84.7306 7E

traan et our inde

Aly ctosicio9m - 13°

‘TABLE Al Example Using 9 Cube Balch

Fond_2

CCL Sumeie #140

cmt due - joo

‘TABLE A1.2 Test Date After the Elimination of Outliers

(Example Using 9 Cube Batch)

Rowe -2

CCALSenpiow 140 vuusty Avenge

‘rena, X= 98.989

CcastDete —o0io000 Raw Gube Date

7 ay Stange, WPs

c

n z 7 z Fi Brg a

aah Ne : 5 : i x 3 ? 5 E

Cant sto negate wach : : e ‘

Sms «ee ea Sy loses

ces at as SS. 0 Ms Bee

fet Rt Me kB Se me ssa

Ses oes oo: et ee

cme Mate Sis BEE

cers eS See gem mi

cms Set mas oe) Me swe

Ges Res eee SB OSS

See sha

segs wea

2 cr a sane, mae ae

Es : ° : : = cr a

me 2 : : :

nso sso sate ate as

rm estes

he ne

arc Boats

Bhan x Se

ai S73 cts

ni ete Oa

Tie oer see sae as me tet

te ao ohn Seay

oles Nee ime__Ges new

ae = saengec vet a esi ern yb re,

— z 2 fa cbeepeanegh gooNTL UBS

x = lot aap stengh (ony, oon

a 2 Reh etecs wet basa bath Soke

& 2 ieawlotagstoen yo

(EooKr

V Ke = ort st al tt prt

(eso, > Samora eeuaton

turtr tit Ss, x Ea meoe aetna mi

2 ae ieemetate casenen %,, = Tran anda dovton of he ra

‘es ror spe et. iy

(fon rtp ft vacua po an (Ein. 0305)

Soar snc ouaton cae jan

(Sw 188

~ooe . = (6) a ant

N, ‘FE, relative ror fo he toured, % = 100\E%,,)

wo ‘asian nonmal doviaion vee Exc uneton

r(2-0.257,0 80) oF aquvaer of use tats

tables to frit the Inverse feared ermal deeruton for

‘agra ue of 1-0250) 8 nomad Ustrtin wih

oo 30,

Normal anges

aan = 2, UND)

Saneeen = 0

‘tier = any et vai lng ute colette rexel tage

lp ctosici09m - 13°'

TABLE At. Summery of Results

a8 ¢ bo © fF @ WO

ORL Oey XO, RE, Ny SDINHIS0?

* Me MPa"

Rowe? 130 Boar Odea 300? GRD

Rowe? M9 2 Shoe Mass ty tas BoB

owed ist 3 Sea Sate 45) MOT 7a

Fomes 142 4 G22 Sol 299 368 Ost 810

Nox ress 636

tear. RE 2 Str

Giiwee, ee 88

PMIBE % Bot

ea RWaE, 3424

Proogen Teeth

vere:

x indsty vege stent, MPa

ca = rand ean vlueo Fa val tess rod,

Re > aime ror = 100% — Ku

8, sean state deviation ofa unt

Sw, 15%)

a

(11907 ered ctesitor,

x = and reo velie af vale et (4 ound),

m {oi wae of val tain xi,

cinae Sand ean wire eror MP

mee = oi tin bath rer = HOKGWBE on

Maz WBE — > ruin clones RABE = 2.10 (See Na 1)

* 5x0 hate 8

‘TABLE A1.4 Bias Guatiieation Requirements

Gib ions 3 be Bes

itn 6 Banos (Mes Scns

ea une fern

Canaan A BG a 8 ©

‘eee e431)

Nenalowebe ree 689 NZ eT Od HS

rot ony tore

waters

Nonatowable wine 6473 «92S 7B

‘rot moan of rounds

Ste ereteienes

5 alr, GRES

inmam alowsbie 5

acs

lp ctosici09m - 13°

TABLE AIS Blas Tests

(Example Using 8-Cube Batches, Class A Cement)

THRE, te mmo rive err valet 688

MARE:*s. ax alowatle MAEs for Table 8

Ba

ras

GRE, he average AE? % of he four a1

‘onde

Masimen intel MORES tom Table ANA 55

Press

Bias contest CL 80.98

Neiumallome corfance tnt, WACL% 5

(rom Tete At)

Pes

“Tho atowo wavs infoxeth deta fale

show eorplance

soe

Mite, Se =the mieten aan are % tana ary amy

valuss eater F, Tle A 3

MARE: % = the madman alewable wate ener, % ef any Pound

(aoe at.

one & the gana singe a8 HE Seve at he out ana,

Maney % Imei slowed GE, % vale (wenge of eclaneF

“able 19) ana

as baseenixerea iris the contdanes with wtich ean be

Stes tral te moro te mann ch 4 un sno 7,

CGausta mis ty us 9" Exaaotnsten ateskerange et

Ireusty meane> range of valime bianec™.1 10. OF

ula er use Satstcl ates vc fe condone

‘ore le, p-value Hust on he Set of ound aos

Nore 1—The_ qualification

‘cxceds the MARE, lini

Timit aid the CL, enceeus 98 %

shoal ils for bies if (2) the: MREx

2) the GRE, % exceeds the MORE

SUMMARY OF CHANGES

Committee COI has identified the location of selected changes to this siandard since the last issue

(C1O9/C109M — 12) that may impact the use of this standard, (Approved Oct. 1, 2013)

(1) Revised 10.1.2 to inelude requirements for twelve test

specimens,

AST btematra aes ce pesitonropccing te val of ny patent rhs asserted a ommccton wih eny Her mented

‘nfo taraard. User he standard oe xpos aaksod at catorinstov lhe ally of any such pata gh, rs ek

St iingemet of sun Heh, ar ertiey tar own eepene).

Te stared slnet oven a any tens by a rspersbie cea corms 27a mst be waned avery ve years and

“Enatrawen eos rsanprnio or nen Your ecrmante fs tad oihertor mean o hie sana ofr sna tne

and cai bo aeavecoed to 2ST rlematcra casuarers Yay oes wi cous eel ermceraten aa Moot oe

‘esponsoi feemea canes, whch you ay abe you fe! al jer corer have 90 eed fa PERNA g YOU SE

[ie ir vows a oe ASTI Gnrion 0 Senden. te actress Se BOW

The saris i crated by ASTI iter ationa, 10 Ba Harbor Sve, FO ne C700, Nest Consbolacsen, Pa rZE2868,

Lnted Stree nines rogers (angle er tiple exes ef ths serdard may be eisined by cartcing AST et fe ate

aderess o7 wt 610-990-9985 how), 610-082-9555 (en) or serves asth.ng (ena) er Uaough the ASTM website

‘wrawasim og). Pomssion sgh fo cetocopy be slardrd fra) also be socued Hom te Copyrg Clearance Corer, 222

Assewccd De, Danvere MA CIOR, Te 197, GA 2500 psn epyignecon!

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Tutorial BNI DirectDocument4 pagesTutorial BNI DirectaminiskandarNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Trial Mix PT Pratama WidyaDocument8 pagesTrial Mix PT Pratama WidyaaminiskandarNo ratings yet

- PANDUAN SINGKAT BNIDirect - PDF Download GratisDocument19 pagesPANDUAN SINGKAT BNIDirect - PDF Download GratisaminiskandarNo ratings yet

- If You Want To Check Balance, Click Account Information-Balance Inquiry-Fill The Account Number-Click ShowDocument4 pagesIf You Want To Check Balance, Click Account Information-Balance Inquiry-Fill The Account Number-Click ShowaminiskandarNo ratings yet

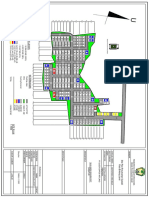

- Gambar Kerja RBLDocument13 pagesGambar Kerja RBLaminiskandarNo ratings yet

- Pelatihan Dua Hari Public Relations Managemen PDFDocument3 pagesPelatihan Dua Hari Public Relations Managemen PDFaminiskandarNo ratings yet

- ASTM C494 Admixtures Types A, F or G & Self Compacting Concrete (SCC) AdmixturesDocument3 pagesASTM C494 Admixtures Types A, F or G & Self Compacting Concrete (SCC) AdmixturesaminiskandarNo ratings yet

- Detail TaludDocument1 pageDetail TaludaminiskandarNo ratings yet

- RAB RAtu Bintang LandDocument364 pagesRAB RAtu Bintang LandaminiskandarNo ratings yet

- PP Penangkal PetirDocument22 pagesPP Penangkal PetiraminiskandarNo ratings yet

- CV DiarySatria 1016Document2 pagesCV DiarySatria 1016aminiskandarNo ratings yet