Professional Documents

Culture Documents

GD-A8 Instruction Manual

GD-A8 Instruction Manual

Uploaded by

Макс0 ratings0% found this document useful (0 votes)

9 views16 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views16 pagesGD-A8 Instruction Manual

GD-A8 Instruction Manual

Uploaded by

МаксCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

INSTRURENTS

Gas Detection For Life

RKI INSTRUMENTS, INC.

INSTRUCTION MANUAL

For

Model GD-A8

Riken Diffusion Sampling Type detector Head

(Catalytic Combustion Method)

‘The accompanying instrument is sold and serviced in USA by RKI Instruments Inc, Please contact RKI

Instruments for any follow up service needs, including questions, warranty issues, repairs, and spare

parts and sensors. Thank you for selecting this fine instrument for your use. With proper care and

maintenance, it will provide you with many years of reliable service.

AKI Insiruments, tne, + 39248 Cantral Avenue Union Cly CA 94587 + Phone (S10) 481-5858 - (800) 754-5185 + Fax (510) 441-8650

‘World Leadar In Gas Osieclion & Sensor Technology

‘worenstruments.com

Please read this instruction manual carefully when operate RIKEN DIFFUSION

SAMPLING TYPE DETECTOR HEAD HODEL GD-AB correctly,

‘SPECIFICATIONS

This gas detector head is installed in combination of 1 versus 1 with an

indicator/elara unit usually.

Generally, this gas detector head is installed, in-the hazardous area and

the indicator/alarn unit is installed in the non-hazardous area, d-core

cable is used for the wiring connection between the detector head and the

indicator/alare unit,

This detector head GD-AB is based on the detection principle of catalytic

coubustion, And the values of LEL (Lower Explosive Limit) concentration

are alsost the sane except for sone cases.

Ce. @ = const..,

(Burgers: heeler's Law)

Ce’: Concentration.at the lover explosive Limit (LBL)

@ : Calorific value of conbustion par mol (keal/nol)

48 a detection principle of combustible gas detector which is used for pre

vention of explosion, ‘a method to measure

is the most suitable and ideal.

Combustible gas is introduced to the sensor preheated to an appropriate

teaperature so that its catalytic combustion is caused, and the changes in

electric resistance of platinum filament due to the then generated heat of

combustion are detected on the wheatstone bridge. This electric output is

i calorific value of combustion

Girectly in proportion to the concentration of cunbustible gas in air.

“en

Detecting sensor

+ Compensating sensor

Fixed resistor

(RL, R2 sodul ized)

Tea Neter

Val Zero adj. potentione ter

R2 —: Voltage adj. pctentioneter

oa

Vode! Model GO-A8 : GD of GD-AB is onitted in combination

of the indicator/alarn unit and also,

this detector head may be expressed as

just AB,

Heasuring gas General coabustible ges (standard) or Methane in the

air

Detection principle

Catalytic conbustion method

Explosion proof

Conforms to flame proof 3a4, JTS C-0903

Approved by the Ministry of Labour in Japan,

Approved No.

+ 43642 as mode] GD-A8-16 for general combus-

tible except for Acethylene and Carbon

disulfide measurement,

+ 43644 as model 60-88-18 for Acathylene

neasurénent,

Operating texperature

and hunidity

- 10% to + 40, Less than 95 % RH.

Connecting cable

‘The thickness (sm2) of cable is selected by the

distance: between the indicator/alarm unit and

Getector head and also, by the kind of conbustible

gas sensor.

Disensions and weight

Refér to the external drawing of fig. 1,

Approx. 0.9 kes

Quality of material

Detector head : Aluninun die casting

Sensor flane arrestor : Stainless

Surface treatwent

Painting (Hunsel N5) after the alumilite treatment

Others

tihen the detector head is used at outdoors,

the drip/weather proof cover is necessary.

(Refer to fig. 4, 5. ) Z

moxas eToys Ward

QV-Gb THON NOE ONTAVUG TRICE LITE

(pier)

yuyu, punTD)

(SP 78970)

‘yeuyuse3 puarp

soa

10g uodexai

SRT om

oa |S

yt

7h

woR2eI020 og coupes | 3oa TTD

corsage cod

i wat

[ xoq raupazey

30 oprsut

‘T1B-026

2. HOW TO INSTALL THE DETECTOR HEAD éND HOW TO MAKE EXPLOSLON-PROOF CABLE

CONNECTION WORK

21, Caution in the cable connection work

* Take care of the following itens (1)~(B) when make this work.

(W) Make the cable connection working for explosion proof construction

then detector head is installed in a hazardous area,

(2 When the detector head is installed, consider easy saintenance for

gas calibration and sensor replacexent etc at the place suited for

the detection of gas leakage or gas stagnation.

(8) thea the detector head is installed at the outdoors or at auch

existent place of dust and mist, install the drip/veather proof cover

on the detector head certainly. (Drip/weather proof cover is option.)

(W Take care of the’ crack or flaw on the contact point of explosion proof

construction in working and make tighten each screws fully,

® This detector head may be influenced by sose unexpected outside large

noise. Then, make wiring connection apart fron large generated source

of noise or electrical wire line of high voltage.

() Install the detector head at. the place where a vibration is not caused,

(D The cable connection (4 wire) nethod to the terminal -plate of detector

head is described into the approval drawing or complete drawing. Make

the cable connection in accordance with the drawing of cable connection

between the indicstor/alarm unit and the detector head.

(®) Don't use the paints including the silicone around the drip/weather

proof cover or the detector head. If silicone vapour should exist

around the detector head, the sensor may be danaged.

2-2. How to fix the detector head

Install certainly the detector head and carry out the cable connection

working for explosion-proof ¢onstruction in accordance with the follow

ing procedure from iten No. 1 to iten Wo. 9

(1) Garry out the installation of the mounting bracket and fix the detector

head,

There are following three installation methods for the detector head.

Select one installation frou following three method (© to ©).

After the installation of the mounting bracket or the drip/keather proof

cover base, fix the detector head tenporarily so that the terminal box

should be in oblique direction to the left or right side of front side.

irection for easy wire connection.)

- Rubber cover

Protector pipe for cable

(when required, procure

it in customer's side.)

mozoo eTwuay 4/ead

aa =|

SuryqUOH I

it

Serr say

2

2 gf-@

E I eae) a

a 4 (@PTeaTO) I

; ‘ouput0 pump Kens

eS Tay seem

i iE m suyaunoN

i 3 (4+

3 Cy

3 Froq wotexay, yaed N EE

et woy003;02d ped oq Taupmrey

3 oq, Twuyuses

z oaueg ) MS soy 30409

°

© for the use of drip/weather proof cover (Option)

Drip/veather

proof cover

3-86

fusing none FESS

\ 1

Plastic

Drip/veather

ms+026,

knob

reo! cover

7

I

so.

Installation dimensions

for drip/veather proof cover

Fig. 4

© for installation of pole stand by using the drip/neather proof cover.

(Option)

Mounting

bracket,

Fig. 5

U-bolt, sounting bracket nut

‘and spring washer are options.

mie-026,

8

() Put the cable into the terminal box of the detector bead after passing

through the rubber cover, packing gland, washer and packing.

Install the terminal lug for 4 nm screws to the end of cable (4 core).

Geter to fig. 2

+ Note + The washer and pressure-proof packing consists of following

three kinds and is included as one of accessories in the table.

Select and install an suiteble parts depending upon the outer

dianeter of cable,

‘Guier diemeter | nner diameter | Inner diameter

of cable of packing (ax)| of washer (sa)

() Connect the terminal lug of cable to the terminal plate of detector head

without misconnection for connection procedure of 4 core cable.

(In this case, it is easy to ork if sake tighten the packing gland to

the detector head temporarily.)

The numbers of 3,°4, 5, 6 are narked on the terminal plate of detector

head as following fig. 6. Then, také care so that any cable can not be

Pinched when the cover for terminal box is installed.

4am screw

@ Install the cover for

terminal box and make

tighten 4 pcs of bolt

on it certainly.

Hexagon wrench

(5) Hake loosen the mounting bracket and turn the detector head to direction

of left side. Fix the detector head after turni

side,

he sensor for front

Mounting bracket

(6) After screwing the cable packing gland into the detector head, fix the

packing gland with fixing screw of flange. (Refer to fig. 9)

() Fix the cable after tighting the screw of cable clamp for the packing

gland.

{B) Rise up the rubber cover and put it into the cable gland and flange.

In this case, set it so that the packing gland is net with polygon of

the detector head.

10

© Carry out the installation of the drip/weather proof cover in accordance

with the following procedure,

@ for the use of the box type drip/veather proof cover

= Installation to the wall ete

then the detector head is installed to the wall etc by using the

dcip/veather proof cover, fix the drip/weather proof cover base

to the wall etc and fix the detector head to the mounting bracket

temporarily. (Refer to fig. 4)

Carry out the cable working in accordance with fixing nethod of

the detector head in the ites 2-2 on this instruction manual

« Installation of the drip/weather proof cover to the pole stand

hon the detector head is installed to the pole stand and the pine

by using the drip/weather proof cover, install the drip/veather

proof cover base to the exclusive metal (option) for pole stand.

And then, fix the detector head to the mounting bracket for pole

stand temporarily. efer te fig. 5)

Carry out the cable working in accordance with the fixing nethod

of the detector head in the iten 2-2.

How to renove the drip/veather proof cover

Lift the concave part (MI) of the drip/weather proof cover to

same height of convex part (#4) of the drip/weather proof cover

and when shift to the downward, it is fixed tenporarily.

And fix it by finger pressing the plastic knob on upper part of

the drip/weather proof cover.

Plastic knob

Convex part

Ch) Concave part

Box type drip/weather

Mounting proof cover

bracker =

rusuee

For use of the round type drip/weather proof cover

lihen use the round type drip/weather proof cover for general use or

ship use, install the detector head horizontally and cover the round

type drip/weather proof cover on it as following fig. 11.

Up aide

Round type érip/veather

aBroof_cover

a |

I

k d

7 ls

an

Ol ca

ly i Se =

- al

a

' Mounting bracket

Horizontal plane

Fig. UL

3. HAINTENANCE AND CHECK

Se, Gas sensitivity (calibration) adjusteent method

= Carry out the gas sensitivity adjustment ‘with the calibration gas in

accordance with following nethod every 3 to 6 months.

() Prepare the known gas concentration of calibration (around 1/2 of LEL =

50 % LEL) to the gas sampling bag

( Connect the ges check adaptor to the tube end of the gas sampling bag.

(8) After covering the gas check adaptor to the detector head, introduce

the calibration gas into the detector head by squeezing slightly the

gas sampling bag.

check adaptor

Gas sampling bag

Fig. 12

(W) then the calibration gas starts being introduced into the detector head,

the indication of the indicater/alara unit goes up and gets stable after

sone decade seconds.

Hhen the reading does not coincide with the reading of calibration ges,

adjust the reading of the indicator/alara unit to the reading of cali-

bration gas by use of “cal screw (GAL)”.

then it can be adjusted to the reading of calibration gas, the gas sen-

sitivity adjustuent procedure is finished.

© As result of check for the gas sensitivity adjustment at item (4), when

the sensitivity can not be obtained by turning cal screw at maximum, the

sensor life is terminated, And then replace the sensor with new one

after sake the power switch “OFF”. See iten 3-2 for the replacement of

gas sensor. E

Note) then the sensor is replaced with new one, confirm the sensor

type stuck on the detector head.

(6) When the sensor is replaced with new one, confirm the voltage (bridge

voltage) and electrical current for new sensor.

Carry out the sensitivity calibration in accordance with item (I) - (4).

(a) Calibration ges (standard gas), (b) gas sampling bag and (c) gas check

adaptor are option and supplied by us or our nearest agent if required,

3-2, How to replace the sensor with new one

+ Carry out the replacement of sensor in the following procedure

(@) Turn the power switch of indicator/alara unit to “OFF*.

(the power is not supplied to the detector head.)

(2) Hake loosen 2 pes of hexagon bolt of sensor guard and then renove the

sensor guard. (Hexagon bolt of this seasor guard is not dropped from

sensor guard even if it were loosened.)

(3) Pinch the upper part (sintered netal) of defective sensor by finger and

pull out to front side, .AE this tine, the O-ring can be also renoved,

(When the O-ring is not crookad or danaged, it can be recycled.)

(A) Prepare the new sensor and confirn that one of five pins on the bottom

of sensor is longer than other four pins. Insert slightly (shortly)

this long pin to the socket of hole of detector head as fig. 12.

lihen the long pin is fitted with the socket of hole of detector head by

turning the sensor to left or right side slightly, the pin can be

inserted into the concave ( [WI ) part of socket hole. The sensor can be

further inserted deeply by pushing this sensor,

@ Insert the O-ring renoved on iten (3) or new O-ring to the ditch

correctly between the sensor and detector hole,

(6) Cover the sensor guard on the sensor and sake tighten 2 pcs of hexagon

bolt. E

(D After the finishment of replacenent of sensor, make the power switch

of indicator/alarm unit "ON" and make the check of sensor vol tage

(sensor bridge voliage) or electrical current in the indicator/alarn

unit, (Refer to the instruction manual for the indicator/alara unit.)

(@ In approx. 10 sinutes after pover switch “ON”, make the adjusinent of

gas sensitivity in accordance with iten 3-1.

Long pin

Detector hole

z The figure of gas sensor

geen fret bottom side.

Goble inlet eee

Fig. 13

RIKEN KEIKI STANDARD WARRANTY

GAS DETECTION INSTRUMENTS

RIKEN KEIKI CO, LTD. warrants ges alarm equipment manufactured and sold by us to be free

from defects in materials and workmanship for a period of one year from date of shipment

from RIKEN KEIKICO., LTD. Any parts found defective within Lhat period will be repaired or

replaced, at our option, free of charge, F.O.B. Factory, This warranty does not apply to

‘those items which by their nature are subject’ to deterioration or consumption in normal

service, and which.must be cleaned, repaired or replaced on a roytine basis. Such items

may include :

a) Lamp bulbs and fuses

b) Puimp diaphragms and valves

e) Absorbent cartridges

) Filter elements

e) Batteries

sal_damage, operation,

Werranty is voided by abuse including rough handling, mechar

alteration or repair procedures nat in accordance with instruction manual, This warranty

indicates the full extent of our liability, and we sre not responsible for removal or replacement,

costs, local repair costs, transportation costs, or contingent expenses incurred without our

prior approvel.

THIS WARRNTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER WARRANTIES AND

REPRESENTATIONS, EXPRESSED OR IMPLIED, AND ALL OTHER OBLIGATIONS OR

LIABILITIES ON THE PART OF RIKEN KEIKI GO., LTD, INCLUDING BUT NOT LIMITED TO,

THE WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

IN NO EVENT SHALL RIKEN KEIKI GO. LTD. BE LIABLE FOR INDIRECT, INCIDENTAL OR

CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND CONNECTED WITH THE USE OF ITS

PRODUCTS OR FAILURE OF ITS PRODUCT TO FUNCTION OR OPERATE PROPERLY.

‘This warranty covers instruments and parts sold (to users) only by authorized distributors,

dealers and representatives as appointed by RIKEN KEIKI CO., LTD,

We do not assume the indemnification for any accident or damage caused by the operation of

this gas monitor and our warrenty is limited to the replacement of parts or our complete

goods.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- NFPA CaseStudyConstellationBrandsDocument2 pagesNFPA CaseStudyConstellationBrandsNyhcnawNo ratings yet

- KAFO - CV-7A - SV-1000 BrochureDocument13 pagesKAFO - CV-7A - SV-1000 BrochureNyhcnawNo ratings yet

- The Evaluation and Control of Hazard DT Self HeatingDocument9 pagesThe Evaluation and Control of Hazard DT Self HeatingNyhcnawNo ratings yet

- Wood IgnitionDocument98 pagesWood IgnitionNyhcnawNo ratings yet

- Oxidation Pattern in MV Fire and Arc Breakdown in AirDocument68 pagesOxidation Pattern in MV Fire and Arc Breakdown in AirNyhcnawNo ratings yet

- 2014 10 18 Fires Involving Electrical IntakesDocument61 pages2014 10 18 Fires Involving Electrical IntakesNyhcnawNo ratings yet

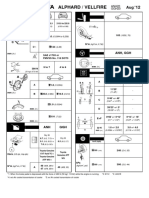

- Toyota Body Electrical SystemDocument95 pagesToyota Body Electrical SystemNyhcnawNo ratings yet

- Spec GD-A8 Gas DetectorDocument4 pagesSpec GD-A8 Gas DetectorNyhcnawNo ratings yet

- ALPHARD/VELLFIRE Service SheetDocument2 pagesALPHARD/VELLFIRE Service SheetNyhcnaw100% (1)