Professional Documents

Culture Documents

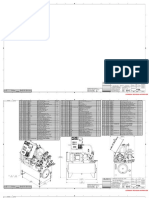

Current Revision Approved: Upper Frame, 68Sbs

Uploaded by

capslive_001Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Current Revision Approved: Upper Frame, 68Sbs

Uploaded by

capslive_001Copyright:

Available Formats

TEMPLATE VERSION: 09/16/08

8 7 6 5 4 3 2 1

1025463 1 OF 3 ITEM QTY. UM SPC PART NO. PART DESCRIPTION FWT/UNIT (lb)

1 1 EA Y RA-272-2503 UPPER FRAME,68SBS 9862

2 6 EA Y 23C60 FTG,LUBE,1/8",STR,11/16"LG 0

TAP PLUG PROVIDED 3 2 GA Y 63N95 GREASE,MOBILGREASE XHP322 MINE 7

WITH CAM FOLLOWER 4 83.4 FT Y 11F11 FELT STRIP 3/4" SQ 1

INTO STUD END HOLE 5 3 EA Y MA-272-2574 PIN, RETAINER 72

6 12 EA Y 62E52 SHCS,3/4"-10x10" Gr8 1

7 24 EA Y 26B48 CHW,3/4" 0

8 3 EA Y KA-272-2503W THRUST PIN BUSHING 14

9 3 EA Y 10B25 RETAINING RING 4.692"ID 0

18 21 10 3 EA Y 20N84 CAP,PIPE 5" 6

28 01 11 1 EA Y 1041897 LOCKNUT,68SBS 4899

12 1 EA Y 1031709 DRIVE RING,68SBS 2031

D 13 8 EA Y TA-272-2573 LINEAR BEARING STRIP 0 D

14 1 EA Y 64A23 EPOXY KIT,FAST CURE,50mL 0

15 12 EA Y 13K38 HHCS,5/8-11X2-1/4" GR5 0

16 30 EA Y 26F83 CHW,5/8" 0

17 12 EA Y 27C98 NUT,HEX 5/8" 0

18 4 EA Y 62E24 CAM FOLLOWER,2-SB 1

19 4 EA Y 27L88 LOCKWASHER,7/8" 0

15 DETAIL A 20 4 EA Y 62E53 NUT,HEX 7/8"-14UNF Gr8 0

21 0.01 EA Y 10H53 ANTI-SEIZE&LUB.COMP. #NS-160 1

16 4 SCALE 1 : 2 22 3 EA Y BD-272-2573 KEEPER 5

23 6 EA Y 13J41 HHCS,5/8-11X3" GR5 0

24 2 EA Y 62Y72 FTG,HYD,ST OR,HOL HEX PLUG,20 0

25 1 EA Y 1031742 SUPPORT BOWL,68SBS 12323

26 3 EA Y 1031777 DRIVE KEY,68 23

27 12 EA Y 12T65 SHCS,3/4"X3-1/4" 1

28 1 EA Y 1031783 DRIVE RING COVER,68SBS 1329

29 1 EA YS 1025462 UPPER FRAME HYDRAULICS,68SBS 755

TORQUE NOTE:

1500 in-lb (125 ft-lb) DRY

750 in-lb (63 ft-lb) LUBRICATED

20

19

12 13 14

C C

21 23

4

16

16 6 21

17 7

5

24

10

A

18 21 22 8

3 11

01

B B

27

7

26 1 3

3 25

9

2

29 4

A A

TITLE SCALE WT(lbs)

UPPER FRAME,68SBS 1:16 31713

DRAWN DATE

SDN 09/17/2007

FOR SIMILAR TO CHECKED DATE

68SBS CONE AE-272-2500B RCB 11/26/2007

ALL INFORMATION CONTAINED ON TELSMITH INC. APPROVED DATE

THIS DRAWING IS CONSIDERED N10910 INDUSTRIAL DRIVE PQ 11/26/2007

DIMENSIONS ARE IN INCHES UNLESS NOTED CONFIDENTIAL AND IS THE SOLE MEQUON, WI. 53092 DRAWING NO.

01 QTY (1) OF 1041897 REPLACES QTY (1) OF 1031688 42055 11/18/2008 RCB SDN TOLERANCES UNLESS NOTED: PROPERTY OF TELSMITH, INC.

1025463

D

00 RELEASED FOR PRODUCTION --- 11/26/2007 SDN PQ ANGULAR: MACH 0.5 BEND 2 ANY REPRODUCTION IN PART

ONE PLACE DECIMAL: .2" OR AS A WHOLE WITHOUT THE

REV DESCRIPTION ECO DATE BY APP

TWO PLACE DECIMAL: .06" WRITTEN PERMISSION OF SPC REV. SHEET NO.

REVISIONS THREE PLACE DECIMAL: .010" TELSMITH, INC. IS PROHIBITED. YS 01 1 OF 3

8 7 6 5 4 3 2 1

CURRENT REVISION APPROVED

TEMPLATE VERSION: 09/16/08

8 7 6 5 4 3 2 1

1025463 2 OF 3 ITEM QTY. UM SPC PART NO. PART DESCRIPTION FWT/UNIT (lb)

1 1 EA Y RA-272-2503 UPPER FRAME,68SBS 9862

2 6 EA Y 23C60 FTG,LUBE,1/8",STR,11/16"LG 0

3 2 GA Y 63N95 GREASE,MOBILGREASE XHP322 MINE 7

4 83.4 FT Y 11F11 FELT STRIP 3/4" SQ 1

5 3 EA Y MA-272-2574 PIN, RETAINER 72

6 12 EA Y 62E52 SHCS,3/4"-10x10" Gr8 1

7 24 EA Y 26B48 CHW,3/4" 0

8 3 EA Y KA-272-2503W THRUST PIN BUSHING 14

9 3 EA Y 10B25 RETAINING RING 4.692"ID 0

10 3 EA Y 20N84 CAP,PIPE 5" 6

01 11 1 EA Y 1041897 LOCKNUT,68SBS 4899

12 1 EA Y 1031709 DRIVE RING,68SBS 2031

D 13 8 EA Y TA-272-2573 LINEAR BEARING STRIP 0 D

14 1 EA Y 64A23 EPOXY KIT,FAST CURE,50mL 0

15 12 EA Y 13K38 HHCS,5/8-11X2-1/4" GR5 0

16 30 EA Y 26F83 CHW,5/8" 0

17 12 EA Y 27C98 NUT,HEX 5/8" 0

18 4 EA Y 62E24 CAM FOLLOWER,2-SB 1

19 4 EA Y 27L88 LOCKWASHER,7/8" 0

20 4 EA Y 62E53 NUT,HEX 7/8"-14UNF Gr8 0

28 21 0.01 EA Y 10H53 ANTI-SEIZE&LUB.COMP. #NS-160 1

22 3 EA Y BD-272-2573 KEEPER 5

15

23 6 EA Y 13J41 HHCS,5/8-11X3" GR5 0

24 2 EA Y 62Y72 FTG,HYD,ST OR,HOL HEX PLUG,20 0

16 25 1 EA Y 1031742 SUPPORT BOWL,68SBS 12323

26 3 EA Y 1031777 DRIVE KEY,68 23

16 27 12 EA Y 12T65 SHCS,3/4"X3-1/4" 1

27 28 1 EA Y 1031783 DRIVE RING COVER,68SBS 1329

17 29 1 EA YS 1025462 UPPER FRAME HYDRAULICS,68SBS 755

7

26

4

4

12

4

C 12 C

24

20 23 21

13

4 16

19

12

18 21

22

11 01

01 11

6 21

11

7

4

5

1 10

B B

8

4

4

25 25

A A

TITLE SCALE WT(lbs)

UPPER FRAME,68SBS 1:4 31713

DRAWN DATE

SDN 09/17/2007

FOR SIMILAR TO CHECKED DATE

68SBS CONE AE-272-2500B RCB 11/26/2007

ALL INFORMATION CONTAINED ON TELSMITH INC. APPROVED DATE

THIS DRAWING IS CONSIDERED N10910 INDUSTRIAL DRIVE PQ 11/26/2007

DIMENSIONS ARE IN INCHES UNLESS NOTED CONFIDENTIAL AND IS THE SOLE MEQUON, WI. 53092 DRAWING NO.

01 QTY (1) OF 1041897 REPLACES QTY (1) OF 1031688 42055 11/18/2008 RCB SDN TOLERANCES UNLESS NOTED: PROPERTY OF TELSMITH, INC.

1025463

D

00 RELEASED FOR PRODUCTION --- 11/26/2007 SDN PQ ANGULAR: MACH 0.5 BEND 2 ANY REPRODUCTION IN PART

ONE PLACE DECIMAL: .2" OR AS A WHOLE WITHOUT THE

REV DESCRIPTION ECO DATE BY APP

TWO PLACE DECIMAL: .06" WRITTEN PERMISSION OF SPC REV. SHEET NO.

REVISIONS THREE PLACE DECIMAL: .010" TELSMITH, INC. IS PROHIBITED. YS 01 2 OF 3

8 7 6 5 4 3 2 1

CURRENT REVISION APPROVED

TEMPLATE VERSION: 09/16/08

8 7 6 5 4 3 2 1

1025463 3 OF 3

01 11

29 Installation Procedure for Turcite-B Linear Bearing Material

1. Surface Finish Preparation

Sand metal surfaces with 40 grit sandpaper. Surface roughness of 125-250 min is required.

2. Cleaning Bonded Surfaces

D D

Thoroughly wipe down metal surface with lacquer thinner. Wipe multiple times if necessary

to thoroughly clean surface. All dirt and oil must be removed to ensure proper bonding. Let surface air dry.

Wipe down etched surface of Turcite material with lacquer thinner and allow to air dry. The etched

surface is identified by it's brown to black color. Let surface air dry.

3. Final Preparation of Surfaces

After the etched side of Turcite material and the metal bonding surface are clean and dry, wipe each

surface with a clean, white, lint free cloth saturated with pure isopropyl alcohol (do not use the diluted

variety). This removes any surface residue. Repeat if white cloth shows any dirt or oil. Allow surfaces

to air dry. Do not use compressed air! Take care not to touch or let surfaces become contaminated

before bonding. Final cleaning should be done just prior to applying adhesive.

4. Bonding the Two Surfaces

Ambient temperature should be at least 60 F.

Using an application gun and a new mixing nozzle, apply a thin, even layer of fast cure Waylock

bonding adhesive to both surfaces. Apply adhesive to the etched side of the Turcite material. To ensure

the proper amount of adhesive is applied to each surface, use a serrated spatula to spread the adhesive

Using clamps or weights, apply a light contact pressure of 3 to 10 psi to hold the bonded surfaces together.

Allow 6 hours to cure before use.

C C

13 14

82.00 LINE UP INSIDE EDGE OF

BEARING STRIP WITH

82.00 ON DRIVE RING

B B

8X 45.0°

A A

TITLE SCALE WT(lbs)

UPPER FRAME,68SBS 1:8 31713

DRAWN DATE

SDN 09/17/2007

FOR SIMILAR TO CHECKED DATE

68SBS CONE AE-272-2500B RCB 11/26/2007

ALL INFORMATION CONTAINED ON TELSMITH INC. APPROVED DATE

THIS DRAWING IS CONSIDERED N10910 INDUSTRIAL DRIVE PQ 11/26/2007

DIMENSIONS ARE IN INCHES UNLESS NOTED CONFIDENTIAL AND IS THE SOLE MEQUON, WI. 53092 DRAWING NO.

01 QTY (1) OF 1041897 REPLACES QTY (1) OF 1031688 42055 11/18/2008 RCB SDN TOLERANCES UNLESS NOTED: PROPERTY OF TELSMITH, INC.

1025463

D

00 RELEASED FOR PRODUCTION --- 11/26/2007 SDN PQ ANGULAR: MACH 0.5 BEND 2 ANY REPRODUCTION IN PART

ONE PLACE DECIMAL: .2" OR AS A WHOLE WITHOUT THE

REV DESCRIPTION ECO DATE BY APP

TWO PLACE DECIMAL: .06" WRITTEN PERMISSION OF SPC REV. SHEET NO.

REVISIONS THREE PLACE DECIMAL: .010" TELSMITH, INC. IS PROHIBITED. YS 01 3 OF 3

8 7 6 5 4 3 2 1

CURRENT REVISION APPROVED

You might also like

- Current Revision Approved: C'Shaft Box Assy, 68H/SbsDocument2 pagesCurrent Revision Approved: C'Shaft Box Assy, 68H/Sbscapslive_001No ratings yet

- Counter shaft box assembly parts listDocument1 pageCounter shaft box assembly parts listCampel SilvaNo ratings yet

- Hydraulic assembly bill of materialsDocument2 pagesHydraulic assembly bill of materialscapslive_001No ratings yet

- Current Revision Approved: Base Unit, 68H/SbsDocument1 pageCurrent Revision Approved: Base Unit, 68H/Sbscapslive_001100% (1)

- Current Revision Approved: Power Rotate System, 68SbsDocument2 pagesCurrent Revision Approved: Power Rotate System, 68Sbscapslive_001No ratings yet

- Current Revision Approved: Upper Frame Hydraulics, 68SbsDocument1 pageCurrent Revision Approved: Upper Frame Hydraulics, 68Sbscapslive_001No ratings yet

- Telsmith Cone Sbs PDFDocument1 pageTelsmith Cone Sbs PDFoncombro100% (2)

- Current Revision Approved: Eccentric Assy, 68H/SbsDocument1 pageCurrent Revision Approved: Eccentric Assy, 68H/Sbscapslive_001No ratings yet

- Hydraulic power unit specificationsDocument9 pagesHydraulic power unit specificationsJavier Pineda GalvisNo ratings yet

- HP4 Spear PartsDocument135 pagesHP4 Spear PartsDmitry Sidlak50% (2)

- Raptor XL900 Cone CrushersDocument8 pagesRaptor XL900 Cone CrushersLmf DanielNo ratings yet

- Trituradora CH550-02 - SPC - R 223.1442-01Document168 pagesTrituradora CH550-02 - SPC - R 223.1442-01AndersonNo ratings yet

- 2.3 - Td7-B152-E-04Document17 pages2.3 - Td7-B152-E-04Julio Suarez Zedano100% (2)

- c116 Pitmany AssyDocument2 pagesc116 Pitmany AssyYeco MachineryNo ratings yet

- 8.12.01.03 - Technical Data CH890Document8 pages8.12.01.03 - Technical Data CH890gytoman100% (1)

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFมนต์ชัย บุญธนลาภNo ratings yet

- Standard Spare Parts List JM 1108HD - CJ411Document1 pageStandard Spare Parts List JM 1108HD - CJ411Mf LuiNo ratings yet

- Excel Components For Cone and Gyratory Crushers PDFDocument2 pagesExcel Components For Cone and Gyratory Crushers PDFDanny Joel Espinoza CastañedaNo ratings yet

- Terex Crushers (DA) CompressedDocument24 pagesTerex Crushers (DA) CompressedAnonymous OVhnLp100% (1)

- Barmac B7150SE S N B7100179Document147 pagesBarmac B7150SE S N B7100179Javier Jimenez PerezNo ratings yet

- Sandvik JM1108 Crusher Parts ManualDocument1 pageSandvik JM1108 Crusher Parts ManualTomas ChienNo ratings yet

- Gyrasphere Parts CatalogDocument68 pagesGyrasphere Parts CatalogSergey Slomchinskiy100% (2)

- PDFDocument108 pagesPDFCristian MosqueraNo ratings yet

- JM1312-06 WPC R222.307.en-02Document12 pagesJM1312-06 WPC R222.307.en-02cachitNo ratings yet

- 2009破碎机备件及耗材重量Document184 pages2009破碎机备件及耗材重量Lina JiaNo ratings yet

- Lokotrack LT300HP S N 77675Document763 pagesLokotrack LT300HP S N 77675Oscar BermeoNo ratings yet

- Feed Opening: ArrangementDocument6 pagesFeed Opening: ArrangementJavier Jimenez PerezNo ratings yet

- Bearings For Cone Crushers: Serving Industries WorldwideDocument4 pagesBearings For Cone Crushers: Serving Industries WorldwideJgonzalez GonzalezNo ratings yet

- Recommended Setting Maximum Setting: Current Revision ApprovedDocument1 pageRecommended Setting Maximum Setting: Current Revision Approvedtecnicomineria14060No ratings yet

- Svedala 1208 PDFDocument8 pagesSvedala 1208 PDFrobertoNo ratings yet

- 57sbs Modular Plant, Station 3 - 1084742.01Document2 pages57sbs Modular Plant, Station 3 - 1084742.01JaredNo ratings yet

- SANDVIK CS660:01: Spare Parts CatalogDocument36 pagesSANDVIK CS660:01: Spare Parts CatalogMf Lui100% (1)

- Crusher Wear Parts Selection Guide: Jaws, Cones & ImpactorsDocument14 pagesCrusher Wear Parts Selection Guide: Jaws, Cones & Impactorsgildemeister gerencia100% (2)

- NP15MAC0043 - RU - SN c СМ артикуламиDocument119 pagesNP15MAC0043 - RU - SN c СМ артикуламиLevrdna100% (1)

- PDF Conciliacion Materiales DLDocument96 pagesPDF Conciliacion Materiales DLCarlos Augusto100% (1)

- TRIO TC Cones DiamondDocument12 pagesTRIO TC Cones Diamondcarrialdi100% (1)

- 7.2 Crusher Erection and Maintenance Data - FlsmidthDocument3 pages7.2 Crusher Erection and Maintenance Data - FlsmidthWILSON JUAN DE DIOS QUISPE YUPANQUINo ratings yet

- Nordberg C110 Parts List and SpecificationsDocument53 pagesNordberg C110 Parts List and SpecificationsLina Jia100% (1)

- Metso Quote For SparesDocument8 pagesMetso Quote For Sparesmanian_arsNo ratings yet

- hp300 PDFDocument2 pageshp300 PDFsam samin100% (1)

- MP™ Cone Crusher Parts ManualDocument3 pagesMP™ Cone Crusher Parts ManualPOWERUPS100% (1)

- ASRi20 SPC R223 1355 en 01 PDFDocument18 pagesASRi20 SPC R223 1355 en 01 PDFThinhNo ratings yet

- SANDVIK CH660:01: Wear Parts CatalogDocument18 pagesSANDVIK CH660:01: Wear Parts CatalogEduardoNo ratings yet

- HP300 GA and Dimensional Drawings MM1472950 - 0Document10 pagesHP300 GA and Dimensional Drawings MM1472950 - 0Thiago PaivaNo ratings yet

- Excel Components For Symons Templates PDFDocument1 pageExcel Components For Symons Templates PDFAnonymous 8t0V9SNo ratings yet

- DATA SHEET MP1000 CrusherDocument6 pagesDATA SHEET MP1000 CrusherRichard Vica CalvoNo ratings yet

- Moledor de Impacto VerticalDocument128 pagesMoledor de Impacto VerticalAdrian Alonso Bustos GonzalezNo ratings yet

- Nordberg C120中文手册12400Document60 pagesNordberg C120中文手册12400Hyton CastingNo ratings yet

- CJ409-01 WPC R222.341.en-02Document14 pagesCJ409-01 WPC R222.341.en-02Marcos Guardia100% (1)

- Sandvik Cone Crusher Components - E PDFDocument6 pagesSandvik Cone Crusher Components - E PDFoncombroNo ratings yet

- 38, 44, 52, 57, 68H and SBS Cone CrushersDocument4 pages38, 44, 52, 57, 68H and SBS Cone Crushersjuanandres_martinez100% (2)

- Parts identification for tension rod and toggle plate assemblyDocument11 pagesParts identification for tension rod and toggle plate assemblyAshik Rahaman100% (2)

- TV95 VSI Parts ManualDocument35 pagesTV95 VSI Parts ManualGuillermo Balarinni100% (3)

- Decal and label parts list for jaw crusherDocument1 pageDecal and label parts list for jaw crusherJavier Pineda GalvisNo ratings yet

- b5-132 Cone Crushers EngDocument9 pagesb5-132 Cone Crushers Engfacilmoreno77100% (1)

- Bulletin 1047Document2 pagesBulletin 1047Cesar Casachagua DavilaNo ratings yet

- Catalogo Giratorio MetsoDocument5 pagesCatalogo Giratorio MetsoPaulaNo ratings yet

- 53970t 8HSFD 225Document3 pages53970t 8HSFD 225Richard Junian GeraldyNo ratings yet

- 1624STK Parts ManualDocument40 pages1624STK Parts ManualGanesh SainavarapuNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Current Revision Approved: Eccentric Assy, 68H/SbsDocument1 pageCurrent Revision Approved: Eccentric Assy, 68H/Sbscapslive_001No ratings yet

- Thyssenkrupp - Catalogos PrimariosDocument12 pagesThyssenkrupp - Catalogos Primarioscapslive_001No ratings yet

- HarneroDocument109 pagesHarnerocapslive_001100% (1)

- Catalogo - Britador Giratório - FLSMIDTHDocument8 pagesCatalogo - Britador Giratório - FLSMIDTHandreiaabrahaoNo ratings yet

- Pulp and Paper Tech - I Introduction and History of Pulping ProcessDocument62 pagesPulp and Paper Tech - I Introduction and History of Pulping ProcessVishnu KollarethNo ratings yet

- Datasheet 709Document8 pagesDatasheet 709manojpeehuNo ratings yet

- A Generalized Common Fixed Point of Multi-Valued Maps in B-Metric SpaceDocument10 pagesA Generalized Common Fixed Point of Multi-Valued Maps in B-Metric SpaceBrenton MorrisonNo ratings yet

- Basson Considerations 2005Document113 pagesBasson Considerations 2005Maxmore KarumamupiyoNo ratings yet

- L3 Shape Earth 2Document5 pagesL3 Shape Earth 2Hahahhaa rubbishNo ratings yet

- Pressure Drop and Flooding in A Packed ColumnDocument7 pagesPressure Drop and Flooding in A Packed ColumnEdu Cordon50% (2)

- Equilibrium LeChateliers PrincipleDocument11 pagesEquilibrium LeChateliers PrinciplesaraNo ratings yet

- MKKL 2063Document10 pagesMKKL 2063Anas Abd RahmanNo ratings yet

- Analysis and Design of PA Fan Foundation CalculationsDocument28 pagesAnalysis and Design of PA Fan Foundation CalculationsLandon MitchellNo ratings yet

- 2 - ARM Parallel IO 123Document42 pages2 - ARM Parallel IO 123Nishit KatiraNo ratings yet

- CD4051BCDocument10 pagesCD4051BCBakhtiar TiarNo ratings yet

- Quarterly Assessment Report in Mathematics Grade 1 First Quarter, SY 2019-2020Document5 pagesQuarterly Assessment Report in Mathematics Grade 1 First Quarter, SY 2019-2020William Felisilda100% (1)

- Math Lesson 26 - Week 1Document42 pagesMath Lesson 26 - Week 1Eubelle MalimbanNo ratings yet

- Calculation of Electrical Energy With SolarDocument4 pagesCalculation of Electrical Energy With Solarmohamed parvez100% (1)

- Question Paper Unit g481 MechanicsDocument16 pagesQuestion Paper Unit g481 Mechanicsanon_415992461No ratings yet

- Homework Solution: Investment Science: Solution Problem 5.2: The RoadDocument7 pagesHomework Solution: Investment Science: Solution Problem 5.2: The RoadAbdu AbdoulayeNo ratings yet

- Footing - Axially Loaded - NSCP by RGCEDocument5 pagesFooting - Axially Loaded - NSCP by RGCEJet ToledoNo ratings yet

- Pipe Cleaning Systems Operating Waterblasting Equipment Safety GuideDocument1 pagePipe Cleaning Systems Operating Waterblasting Equipment Safety GuideЮрийNo ratings yet

- Mapeo ComputoDocument20 pagesMapeo ComputoGuillermo Santiago Robles RangelNo ratings yet

- EPC Control Wiring Applications 836269cDocument110 pagesEPC Control Wiring Applications 836269cdylan_dearing@hotmail.comNo ratings yet

- Grouting of The Annular Gap in Shield TunnellingDocument9 pagesGrouting of The Annular Gap in Shield TunnellingJose David Garcia100% (1)

- Cer Alum Ladder Tray CatalogDocument37 pagesCer Alum Ladder Tray Catalogmashan98No ratings yet

- DDW 2Document5 pagesDDW 2celmailNo ratings yet

- Bodymeasurement 200525182452Document21 pagesBodymeasurement 200525182452Christine RodriguezNo ratings yet

- Calculate Head Loss in PipesDocument10 pagesCalculate Head Loss in PipesJeffrey Fernandez SalazarNo ratings yet

- Lampiran COF POFDocument7 pagesLampiran COF POFfikriNo ratings yet

- Sage Erp X3 V7: Development Part 1 Exercises Level 2Document21 pagesSage Erp X3 V7: Development Part 1 Exercises Level 2Yahya Chiguer100% (1)

- wph13 01 MSC 20200123 PDFDocument11 pageswph13 01 MSC 20200123 PDFfadi baqainNo ratings yet

- Reaction Rate Theories and CatalysisDocument7 pagesReaction Rate Theories and CatalysisJosephine ChenNo ratings yet

- RF Surge Device Installation GuideDocument3 pagesRF Surge Device Installation GuideThắng TrầnNo ratings yet