Professional Documents

Culture Documents

Carbocoat 150 Universal Primer: Selection & Specification Data

Uploaded by

LjubomirSinđelićOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbocoat 150 Universal Primer: Selection & Specification Data

Uploaded by

LjubomirSinđelićCopyright:

Available Formats

®

Carbocoat 150 Universal Primer

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

Generic Type Single Component Phenolic Modified Alkyd

Heavy-duty primer formulated to provide long term protection of structural steel. It provides

Description

excellent adhesion and can be welded through to yield sound welds.

• Good for extended exposure demands

• Ability to be welded through

Features • Heavy-metal free

• VOC compliant for most areas

• Accepts wide range of topcoats

Standard: Red (0500); Gray (0700)

Color

Other unmatched colors are Special Order

Finish Flat

2 - 3 mils (51 - 76 microns) per coat

Dry Film Thickness

Don't exceed 3.0 mils (75 microns) in a single coat. Welding is best achieved when thicknesses do

not exceed 1 mil (25 microns).

Solids Content By Volume 52% +/- 2%

834 ft²/gal at 1.0 mils (20.5 m²/l at 25 microns)

Theoretical Coverage 417 ft²/gal at 2.0 mils (10.2 m²/l at 50 microns)

Rate 278 ft²/gal at 3.0 mils (6.8 m²/l at 75 microns)

Allow for loss in mixing and application.

As Supplied : 3.4 lbs./gal (407 g/l)

Thinner 10 : 6 oz/gal 3.7 lbs./gal (443 g/l)

VOC Values

These are nominal values and may vary slightly with color.

Continuous: 200°F (93°C)

Non-Continuous: 250°F (121°C)

Dry Temp. Resistance

Discoloration and loss of gloss is observed above 200 F (93 C).

May also be topcoated with catalyzed epoxies and urethanes.

Topcoats

Call for specific recommendations.

S U B S T R AT E S & S U R F A C E P R E PA R AT I O N

Surfaces must be clean and dry. Employ adequate methods to remove dirt, dust, oil and all other

General

contaminants that could interfere with adhesion of the coating.

SSPC-SP6 with a 1.0-2.0 mil (25-50 micron) surface profile for maximum protection. SSPC-SP2 or

Steel

SP3 as minimum requirement.

MIXING & THINNING

Mixing Power mix until uniform in consistency.

July 2018 0808 Page 1 of 3

®

Carbocoat 150 Universal Primer

PRODUCT DATA SHEET

MIXING & THINNING

Normally not required but may thin as follows: Spray, brush or roller may be thinned up to 6 oz/gal

(5%) with Thinner #10. Use of thinners other than those supplied or recommended by Carboline

Thinning

may adversely affect product performance and void product warranty, whether expressed or

implied.

A P P L I C AT I O N E Q U I P M E N T G U I D E L I N E S

Listed below are general equipment guidelines for the application of this product. Job site conditions may require modifications

to these guidelines to achieve the desired results.

Spray Application The following spray equipment has been found suitable and is available from manufacturers.

(General)

Pressure pot equipped with dual regulators, 3/8” I.D. minimum material hose, 0.052” fluid tip and

Conventional Spray

appropriate air cap.

Pump Ratio: 30:1 (minimum)*

GPM Output: 3.0 (minimum)

Material Hose: 3/8” I.D. (minimum)

Airless Spray

Tip Size: 0.013” - 0.017”

Output PSI: 2000-2300

Filter Size: 60 mesh

Brush & Roller Multiple coats may be required to achieve desired appearance, hiding and recommended dry film

(General) thickness. Avoid excessive re-brushing or re-rolling.

Brush Use a natural bristle brush.

Roller Use a short-nap synthetic roller cover with phenolic core.

A P P L I C AT I O N C O N D I T I O N S

Condition Material Surface Ambient Humidity

Minimum 35°F (2°C) 35°F (2°C) 35°F (2°C) 0%

Maximum 120°F (49°C) 120°F (49°C) 120°F (49°C) 90%

This product simply requires the substrate temperature to be above the dew point. Condensation due to substrate temperatures

below the dew point can cause flash rusting on prepared steel and interfere with proper adhesion to the substrate. Special

application techniques may be required above or below normal applicaton conditions.

CURING SCHEDULE

Dry to Topcoat w/ Dry to Topcoat w/

Surface Temp. Dry to Touch Tack Free

itself or other alkyds epoxies or urethanes

35°F (2°C) 60 Minutes 4 Hours 12 Hours 16 Hours

55°F (13°C) 35 Minutes 90 Minutes 5 Hours 12 Hours

75°F (24°C) 10 Minutes 45 Minutes 2 Hours 8 Hours

These times are based on a 2.0 mil (50 microns) dry film thickness. Higher film thickness, insufficient ventilation, high humidity or

cooler temperatures will require longer cure times and could result in solvent entrapment or premature failure.

July 2018 0808 Page 2 of 3

®

Carbocoat 150 Universal Primer

PRODUCT DATA SHEET

CLEANUP & SAFETY

Use Thinner #2 or Acetone. In case of spillage, absorb and dispose of in accordance with local

Cleanup

applicable regulations.

Read and follow all caution statements on this product data sheet and on the SDS for this product.

Safety

Employ normal workmanlike safety precautions.

When used in enclosed areas, thorough air circulation must be used during and after application

Ventilation

until the coating is cured.

Caution This product contains flammable solvents. Keep away from sparks and open flames.

PA C K A G I N G , H A N D L I N G & S T O R A G E

24 months at 75°F (24°C)

Shelf Life

*Shelf Life: (actual stated shelf life) when kept at recommended storage conditions and in original

unopened containers.

Storage Temperature & 35° - 100°F (2°- 43°C)

Humidity 0-100% Relative Humidity

Storage Store Indoors.

Shipping Weight 5 Gallon - 66 lbs. (30 kg)

(Approximate) 55 Gallon - 730 lbs. (331 kg)

Flash Point (Setaflash) 76°F (24°C)

WA R R A N T Y

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject

to change without prior notice. User must contact Carboline Company to verify correctness before specifying or ordering. No

guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no

responsibility for coverage, performance, injuries or damages resulting from use. Carbolines sole obligation, if any, is to replace

or refund the purchase price of the Carboline product(s) proven to be defective, at Carbolines option. Carboline shall not be liable

for any loss or damage. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE, EXPRESS OR

IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. All of the trademarks referenced above are the property of Carboline International Corporation unless

otherwise indicated.

July 2018 0808 Page 3 of 3

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Mechanical AptitudeDocument25 pagesMechanical AptitudedestawNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Soil Waste Design Installation Manual PDFDocument21 pagesSoil Waste Design Installation Manual PDFvinit joryNo ratings yet

- Aectp-500 Ede v1 e PDFDocument1,125 pagesAectp-500 Ede v1 e PDFLjubomirSinđelićNo ratings yet

- Scada Ems PDFDocument35 pagesScada Ems PDFGaliousNo ratings yet

- Od-2044 Ed.2.4Document55 pagesOd-2044 Ed.2.4Mathilde Béal100% (3)

- Defence Standard 80-124Document14 pagesDefence Standard 80-124LjubomirSinđelić100% (1)

- Nato Standard: Performance Requirements and Test Method For Paint Systems Resistant To Chemical Warfare AgentsDocument21 pagesNato Standard: Performance Requirements and Test Method For Paint Systems Resistant To Chemical Warfare AgentsLjubomirSinđelićNo ratings yet

- Performance Requirements For Exterior Topsides Coatings: Allied Engineering PublicationDocument46 pagesPerformance Requirements For Exterior Topsides Coatings: Allied Engineering PublicationLjubomirSinđelić100% (1)

- enDocument30 pagesenRegistr Registr100% (3)

- Nato Standard ADMP-01 Guidance For Developing Dependability RequirementsDocument36 pagesNato Standard ADMP-01 Guidance For Developing Dependability RequirementsLjubomirSinđelićNo ratings yet

- Accenture Raising Legal and Ethical Concerns and Prohibiting RetaliationDocument5 pagesAccenture Raising Legal and Ethical Concerns and Prohibiting RetaliationAindrila BeraNo ratings yet

- BSI Standards Publication: BS EN ISO 15609 1:2019Document34 pagesBSI Standards Publication: BS EN ISO 15609 1:2019Ирина Михайлова57% (7)

- Aectp-300 Edd v1 eDocument462 pagesAectp-300 Edd v1 eLjubomirSinđelićNo ratings yet

- L Is Interface ManualDocument85 pagesL Is Interface ManualToderici AdrianNo ratings yet

- 4666 Eed 01Document57 pages4666 Eed 01LjubomirSinđelićNo ratings yet

- Chrome-Free Paint Systems For General Aviation AircraftDocument2 pagesChrome-Free Paint Systems For General Aviation AircraftLjubomirSinđelićNo ratings yet

- Aep 64e (A)Document25 pagesAep 64e (A)LjubomirSinđelićNo ratings yet

- Sigmaguard™ 730: Product Data SheetDocument5 pagesSigmaguard™ 730: Product Data SheetLjubomirSinđelićNo ratings yet

- Performance Requirements For Underwater Hull Paint Systems: Allied Engineering PublicationDocument44 pagesPerformance Requirements For Underwater Hull Paint Systems: Allied Engineering PublicationLjubomirSinđelićNo ratings yet

- Aep 59Document46 pagesAep 59LjubomirSinđelićNo ratings yet

- 2-Protecfull SFP 108 - PE - Eng - v3 PDFDocument2 pages2-Protecfull SFP 108 - PE - Eng - v3 PDFLjubomirSinđelićNo ratings yet

- Eclipse: Technical Data SheetDocument7 pagesEclipse: Technical Data SheetLjubomirSinđelićNo ratings yet

- Ministry of Defence Defence Standard 80-34Document12 pagesMinistry of Defence Defence Standard 80-34LjubomirSinđelić100% (1)

- Alumigrip 4400 Base Coat Application Process InstructionDocument4 pagesAlumigrip 4400 Base Coat Application Process InstructionLjubomirSinđelićNo ratings yet

- Ministry of Defence Defence Standard 80-217Document12 pagesMinistry of Defence Defence Standard 80-217LjubomirSinđelićNo ratings yet

- Konica Minolta 240f Quickguide en 2-1-0Document140 pagesKonica Minolta 240f Quickguide en 2-1-0suso73No ratings yet

- Installation & Maintenance Manual: Condensing Units CU 1-1.5 CUH 1-1.5 CUS 2-12 CUHS 2-12 CFCUS 5-10Document29 pagesInstallation & Maintenance Manual: Condensing Units CU 1-1.5 CUH 1-1.5 CUS 2-12 CUHS 2-12 CFCUS 5-10mirali74No ratings yet

- A Guide To The Lighting of Surface & Underground Railway SystemsDocument20 pagesA Guide To The Lighting of Surface & Underground Railway SystemsEvon ChayNo ratings yet

- Harsha Vardhan PDocument3 pagesHarsha Vardhan Papi-3850325No ratings yet

- Previous Pageblock Return To Previous Menu Next Pageblock: Pratt & WhitneyDocument13 pagesPrevious Pageblock Return To Previous Menu Next Pageblock: Pratt & WhitneyKarina FloresNo ratings yet

- ServerIron 11000 SLBguideDocument488 pagesServerIron 11000 SLBguideahmadhuNo ratings yet

- MTL TP48 ManualDocument2 pagesMTL TP48 ManualGabrielA.MaffioldA.No ratings yet

- Verilog: Codificadores Y DecodificadoresDocument12 pagesVerilog: Codificadores Y DecodificadoresHamza AmariNo ratings yet

- Elmotorer Standarder 803970Document9 pagesElmotorer Standarder 803970sumitsharma2010No ratings yet

- 04 IntegrationDocument22 pages04 IntegrationengrfarhanAAA0% (1)

- ISO7010 Safetysigns Guidebook Europe EnglishDocument32 pagesISO7010 Safetysigns Guidebook Europe EnglishAndrés Sismai Montesinos HernándezNo ratings yet

- Quizzes PDFDocument110 pagesQuizzes PDFAlex Serrano MartinezNo ratings yet

- Capacity DevDocument23 pagesCapacity DevankurmanuNo ratings yet

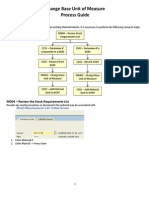

- MM - Change Base Unit of MeasureDocument9 pagesMM - Change Base Unit of MeasureDiwakar_ch_2002No ratings yet

- Internet and Its Applications-UNIT IV-V (Thiruvallur University)Document44 pagesInternet and Its Applications-UNIT IV-V (Thiruvallur University)Ayyasamy Sriram100% (1)

- FRENIC-Multi Instruction ManualDocument224 pagesFRENIC-Multi Instruction Manualpaolovisentin80No ratings yet

- Signet 2751 PH-OrP Smart Sensor ElectronicsDocument6 pagesSignet 2751 PH-OrP Smart Sensor ElectronicsRanaIfteeNo ratings yet

- Manipulating Binary Data Using The Korn ShellDocument5 pagesManipulating Binary Data Using The Korn ShellFinnbarr P. MurphyNo ratings yet

- Legrand Distribution SystemDocument52 pagesLegrand Distribution SystemdekosokolNo ratings yet

- Jesd8 15aDocument22 pagesJesd8 15aSridhar PonnurangamNo ratings yet

- TSP071 BNV Cctalk Protocol Manual V2 (1) .4Document47 pagesTSP071 BNV Cctalk Protocol Manual V2 (1) .4nost winNo ratings yet

- Network Applications Client-Server: (Typically)Document24 pagesNetwork Applications Client-Server: (Typically)Rajesh MandalNo ratings yet