Professional Documents

Culture Documents

DA26 6cd Deck

Uploaded by

xx0 ratings0% found this document useful (0 votes)

9 views10 pagesFujitsu ten 6cd changer mechanism

Original Title

DA26_6cd_deck

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFujitsu ten 6cd changer mechanism

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views10 pagesDA26 6cd Deck

Uploaded by

xxFujitsu ten 6cd changer mechanism

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

46

6-Disc In-dashboard CD Changer Deck

© Ryuichi Fujie © Takeshi Tanaka © Hiroaki Umezawa

In recent years, sales of cise media equipment for cars have been growing sharply. In this sector, sales

of CD players have also been brisk, particularly those with the changer feature which ean stor

and play CDs, As popular as CDs have been, they have had their disadvantages: They are too big too ft

in any place other than the trunk, and changing CDs has been troublesome forthe user.

ire for more compact units that can be

Accordingly, users of car CD players have voiced their de

‘mounted in the center console ofa ca.

Fujiteu Ten has worked to futfil the needs of our customers by developing the DA-26, 8 isk changer

‘that fits in the console.

This paper outlines the DA-26 CD changor and describes its features.

FUJITSU TEN TECH. J, NO. 11 (1998)

1. Introduction

Recently, the car audio equipment market has

experienced rapid growth in sales of compact disk (CD)

players. Salesinthissectorhavebeen particularly noticeable

for changer-equipped versions that can hold more than one

CD. However, changer-equipped CD players tend to be

bulky, making it necessary to installed them in the trunk of

the car or under the seat. As a result, changing CDs has

been troublesome. Users want an changer-equipped CD

player that can be installed in the audio space in the center

‘console, as is the case with conventional CD players.

‘Toaccommodate thisneed, Fujitsu TENhas developed

an changer-equipped CD player that holds up to six CDs

and that be installed in the center console, a first for the car

audio industry. This paper is anexplanation and an outline

of the features of the CD changer deck DA-26 used with

this CD player.

2. Purpose of development

"The CD changer deck DA-26 was developed as the

‘component of aCD player that can be installed in the audio

space in the center console. When we embarked on our

product development planning activities, we established

three goals: (1) the CD changer deck size must be within

1 DIN; (2) the disk change operation must be easier than

that for conventional models (“slot-in” method (a front

Joading manual insertion method) isused); and (3) the deck

‘must have a capacity of six CDs, as is the case with

conventional models (See Figure 1).

To succeed in developing a changer-equipped CD

player having a size within | DIN, we succeeded in

reducing te sizes of components significantly ascompared

with conventional CD changers. At the same time, we had

to give consideration to the space for the deck control PC

board, the space forthe front operation section (including,

buttons and PC boards), and space for vibration tolerance

(vibration amplitude). Asindicatedin Table 1, we succeeded

in developing a CD changer deck much smaller than

conventional models.

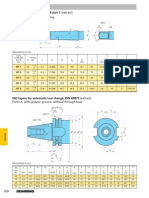

‘Table 1 Development specification

Conventional Developed

model DA23 model DA26

(Oniside dimensions | 150% 287% 58 | 150.165 42,

ov xDxH) compatible witht DIN

[CDeapaciy 6 6

[CD ivading method | Magazine loading [Sorin

FUJITSU TEN TECH. J, NO. 11 (1998),

_REFujie tals 6-Dise n-dashboard CD Changer Deck

‘There are two methods for loading CDs: magazine

loadingandslotin. Weadopted theslotinmethod because

operation using this method is easier.

Figure 1, In-dashboard CD changer assembly

(oithout the top cover)

3. Overview

‘The DA-26 consists of five units as follows (See

Figure 2)

(1) Chassis unit

(2) Stacker unit

3) Shuttle unit

(4) Pickup unit

(5) Control PC board

‘The chassis unitis the base ofthe deck. Allother units

are assembled on the chassis unit. Motors for driving the

shuttle and stacker units are also mounted on the chassis

‘The stacker unitholds CDs. Itmoves vertically before

@ CD is loaded, unloaded, played, or exchanged with

another CD.

The shuttle unit contains a disk loading/unloading

‘mechanism and apickup unit or CD playback. Before CD

playback, the pickup unit is fed into the stacker unit. ‘The

‘motor for this operation is mounted on the shuttle unit.

‘Thepickupunit worksforCD playback. Its components,

include an optical pickup, a disk clamp, and others.

‘The control PC board contains all of the circuitry

required for deck control, including a microcomputer for

controlling deck operation and a signal processor for

reading CDs.

av

Fuji al: 6-DiseIn-dashboard CD Changer Deck

CD loading/unlonding mechs

Shuttle nit

CD slot Chassis unit

Figure, Insertion ofa CD (suction)

(3) When the rollers separate from the CD, a push lever

pushes the CD into the stacker. When complete

insertion of the CD is detected by a sensor, the rollers

stop rotating (See Figure 5),

Pickup unit

igure 2 Structure ofthe DAs

4. Operation

‘The DA-26 is designed so that the stacker splits to

allow the pickup unit to be inserted between the split parts

of the stacker when a CD is to be played. This design has

‘made it possible to achieve the targeted small size.

‘The rest of this chapter explains the newly developed

‘operation method used in the DA-26.

4.1 CD insertion

The steps for inserting a CD into the stacker are as

follows:

(1) The stacker moves until the height of the CD slot

‘matches the height of the desired stacker (See Figure

>.

[igure 3. Insertion ofa CD (stacker unt move)

(2) When the CD is detected by a sensor, itis adsorbed by

rotating rollers (See Figure 4).

Figure 8, Insertion ofa CD (completion of insertion)

42 CD ejection

‘The steps for ejecting a CD are as follows:

(1) The stacker unit moves until the height of the CD stot

‘matches the height ofthe desired stackerb (See Figure

o.

Figure 6, Ejection ofa CD (stacker unit move)

2) A push lever pushes the CD until the CD can be fed

with rollers. The rllersthen begin torotate to feed the

CD out of the stacker (See Figure 7).

Figure 7. Ejection ofa CD (CD feed)

FUJITSU TEN TECH. J, NO. 11 (1988),

(3) When complete ejection of the CD is detected by a

sensor, the rollers stop rotating,

4.3 CD playback

The steps for playing a CD are as follows:

(1) The shuttle unit moves tothe height ofthe desired CD.

(See Figure 8),

Fuse eta: 6-DiseI-dashboard CD Changer Deck

(5) The pickup unit (together with the CD contained init)

is pulled forward (See Figure 12).

Figure 8. Preparation for playback (shuttle unit move)

(2) The stacker splits (See Figure 9).

Figure 12. Preparation for playback (CD palling)

(6) The stacker moves up and the CD begins to tum for

playback (See Figure 13).

Figure 9. Preparation for playback (stacker unit spi)

(3) The pickup unit is inserted between the split parts of

the stacker unit (See Figure 10).

C=

===

Figure 10. Preparation for playback (pickup unit insertion)

(4) Thestackerunitdescends andthe CD isclamped tothe

‘umtable (See Figure 11).

igure 11, Preparation for playback (CD clamping)

FUJITSU TEN TECH. J, NO. 11 (1996)

Figure 13. Playback (stacker ascent for playback)

5. Structur

‘These units are structured and combined to perform

the operations explained in the preceding chapter. The

individual units are explained in detail below (See Figure

14,15),

Figure 14. Exterior ofthe deck assembly

Fuji eal: 6 Die In- dashboard CD Changer Deck

Figure 1S, Exterior ofthe dcek assembly without thet

chassis

SL Chassis unit

‘The chassis unit has left and right stepped levers on

‘which the shuttle unit is mounted (See Figure 16). The

shuttle unit ascends or descends when these levers are

‘moved forward or backward. A stepper motor is used to

drive the stepped levers. The motor isalsoused tomove the

lever for opening or closing the front door.

5.2 Stacker unit

‘The stacker unit holds CDs (See Figure 17). Itis fitted

with a selector lever which determines the position at

which the stacker unit splits. A special coating is applied

to the surface of the stackers to protect the CDs contained

in the stackers (See Figure 18).

Figure 17, Stacker unit

‘Ascending descending 7

{ Totematly ueaded screw)

‘Selector lever

Figure 16, Chassis unit

For disk jection, the stepper motor drives push lever

which moves the CD from the stacker to the insertion’

ejection mechanism in the shuttle unit

‘The ascending/descending motor moves the stacker

unit vertically via gearing attached to the top chassis. The

vertical level of the stacker unit is sensed by a sliding-

contact resistor (potentiometer).

Figure 18, Selector lever

For inserting aCD into, orejecting it from a stacker, it

is necessary to adjust the height of the stacker (having the

targeted number of CDs) to that of the CD slot. Inthisease,

the stackerunit moves vertically withoutbeingsplit. Driving,

the ascending/descending motor while the selector lever is

engaged with the hook of the first stacker causes the

ascending/descending screw to turn, thereby moving the

stacker unit vertically (See Figure 19).

FUJITSU TEN TECH. J, NO. 11 (1998)

Figure 19. CD inserionejection

Before the pickup unit canbe inserted into the stacker

unitto play aCD, the stackerunit must be split. In this case,

the selector leveris moved until itis engaged withthe hook

of the stacker with the appropriate number, then the

ascending/descending screw istumed See Figure 20). The

selector levers linked with the stepped lever which moves.

the shuttle unit vertically. Therefore, when the shuttle unit

is moved vertically to the desired level, the selector lever

‘moves tothe desired stacker hook in synchronization,

Figure 20, Playback (ofthe fourth CD)

Information about the height of a stacker can be

‘obtained with a sliding-contact resistor (potentiometer)

(See Figure 22). A voltage of 5 V is applied between the

terminals of the sliding-contact resistor and the output of

the potentiometer is fed to the A/D port on the control

microcomputer (See Figure 21).

‘The sliding-contact resistor used in the DA-26 can

detect 25 mm of travel (a full stroke). Since the A/D

resolution of the microcomputer is 8 bits, the control

accuracy is 0.098 (= 25/28) mm/bit. This means that height

control can be achieved with an accuracy of about.1 mn.

FUSITSUTEN TECH. J, NO. 11 (1998),

Rue et al 6-Dise In-dashboard CD Changer Deck

OVwsv

Shding-comtact resistor

Figure 21. Equivalent eieuit

Figure 22. Sliding-contact resistor

5.3 Shuttle unit

‘The shuttle unit consists of a mechanism for inserting

aCD into, orejecting itfroma stacker andamechanism for

inserting the pickup unit into, or removing it from the

stacker unit at playback (See Figure 23). For CD insertion’

ejection, rollers provided atthe front ofthe shuttle unit are

drivenby the insesting/ejecting motor. The pickupunit can

also be moved forward and backward by running the

inserting/ejecting motor after a planetary gear is switched,

Pickup nit

igure 23, Shuttle unit

5

Ful ota:6 Disc In-dashhoard CD Changer Deck

Sa

up unit

‘The pickup unit consists ofa pickup for CD playback,

spindle motor (for CD rotation control), and a feed motor

‘which moves the pickup tothe playback position onthe CD

at track search (See Figure 24).

Spindle motor

Feed motor

Figure24, Pickup unit

5.8 Control PC board

‘The control PC board containing circuit for deck

control had to be installed on the side of the deck and had

tobe very small to achieve the purpose ofa I DIN size (See

Fifuew 25). This means that it was necessary to design the

control PC board, including the relief holes for the eight

screws (M5) used to install the deck on the vehicle, tobe of

less than one-third of the area of the control PC board in

conventional models.

‘The desired size was achieved by using a multilayer

(four-layer) PC board and selecting small components

‘Table 2 compares the developed control PC board with a

conventional control PC board.

Telit hoes for screws wed io

instal te deck onthe vehicle

Figure 25. Control PC board

6. Vibration-proof design

Since all car-mounted CD players are always exposed

tothe effects of vehicle vibration, a vibration-proof design

is essential for reliable playback. In general, the entire deck

is isolated from the mounts on the vehicle (floating deck)

by using springs and dampers so as to reduce vibration

transmitted to the pickup. For the DA-26, we developed a

small, high-performance damper and installed shock

protection buffer. Asaresult, the vibration resistance of the

deck are superior (See Figure 26).

Deck

=

‘Table 2 Control PC board compared with a previous model

Conventional model | Developed model

Daas DA26

Number ofPC [3 (main, preamplie, || (integrated PC toand)

oards iter PC boar)

Size (WD) | 100% 115 (ruin, 150% 47

| 10575 (preampiinen,

115 40 fier)

Toa rea 21350 mm? 7030 mm?

[Number of ayers 2 4

82

|

Figure 26. Vibeaton-proof structure

Fico

‘bration amplitade

FUJITSU TEN TECH. J, NO. 11 (1888)

6.1 Shock protection buffer

‘The developed high-performance damper assures

superior vibration resistance that is sufficient for normal

use conditions. However, whenever a vehicle runs on an

unpaved road at high speeds, travels over large bumps

(uch as reflective lane markers) while running at high

speeds, or encounters similar unusual conditions, the CD

player may skip.

To prevent skipping even under such unusual

conditions, the DA-26 is our first CD player to use shock

protection buffer incorporating an electrical means of

improving vibration resistance.

While sound data fromtheCDisbeing played,

stored inthe shock protection buffer. When shock occurs

and data being read from the pickup is interrupted, data

from the buffer continues to be supplied to the sound

system, Normal reading is restored before the contents of

the buffer are used up. In this way, continuous, skip-free

playback is assured (See Figure 27 - 29)

The storage capacity in terms of time is determined by

the capacity of the RAM contained in the circuit. Since the

DA-26 uses 4 megabytes of DRAM, 2.5 seconds of sound

data can be stored inthe shock protection buffer (See Table

Co) ss

Double speed

reading. Peet cD

—

Sound datais output |

DAC while being stored in|

J the butfer.

Sound

Figure 27. Shock protection buffer (ordinary playback)

FUJITSU TEN TECH. J, NO. 11 (1998),

REFujie eo 6-Dis In-daskboard CD Changer Deck

Reading

interruption

4 When shock occu,

Sound anattempt is made to

restore normal pickup

reading while sound

| tn is being output

| from the buffer.

bares el

Figure 28. Shock protectin buffer (how it works

hen a shock occurs)

——

| since normal sound

[data reading has been

restored, sound data is

output while being

stored in the butfer.

whe

Figure 29, Shock protection buffer (how it works when normal

reading is restored)

53

Fuji al: 6 Disc In-dashboard CD Changer Deck

‘Table 3 Etec of shock protection buffer

‘Number of sound skips

‘Witt butter | Withbutfer

Unpaved oad 3 0

Unsdulte road 2 0

Passing over refective 1 °

ane markers

Vehicle speed: 40 kmvh

7. Conclusion

‘The CD changer deck DA-26 developed this time has

been explained above.

Using a lot of new technology and mechanisms in

addition to technology accumulated in the past, we were

able to achieve the target size equivalent to 1 DIN.

We plan to develop this product further so that it can

‘support new media and satisfy diversifying user needs.

54

FUJITSU TEN TECH. J, NO. 11 (1998)

Ryuichi Fujie

Employed by Fujitsu TEN since

1879; engaged in press mold

design, manufacture engineering,

se cassette deck mechanism design,

‘and CD changer deck mechanism

design; currently CH Project

Manager, Deck Mechanism

Engineering Department, A.V.

Products Group,

Takeshi Tanaka

Employed by Fultsu TEN since

1988; engaged in CD dock circuit

dosign; currently CH Project, Deck

Mechanism Engineering

Department, A.C. Produete Group.

FUJITSU TEN TECH. J, NO. 11 (1988)

Fiji ota: 6-Dise In-dashboard CD Changer Deck

Employed by Fujitsu TEN since

e 4988; engaged in CD deck circuit

design and CD changor deck control

software design; currently DF

= Project, Deck Mechanism

j Engineering Department, A.C.

d:hm Products Group

You might also like

- Eliminating Common SCPI ErrorsDocument4 pagesEliminating Common SCPI ErrorsxxNo ratings yet

- Sat Filter Left 110HzDocument2 pagesSat Filter Left 110HzxxNo ratings yet

- WT631 SCHDocument1 pageWT631 SCHxxNo ratings yet

- Microchip All 8bit MCUsDocument92 pagesMicrochip All 8bit MCUsxxNo ratings yet

- Analog BlockDocument4 pagesAnalog BlockxxNo ratings yet

- Axial 100 Manual Check ProcedureDocument9 pagesAxial 100 Manual Check ProcedurexxNo ratings yet

- Service Manual: MODEL FG-8110 Sweep/Function GeneratorDocument31 pagesService Manual: MODEL FG-8110 Sweep/Function GeneratorxxNo ratings yet

- Mini USB 5.0 board schematic overviewDocument1 pageMini USB 5.0 board schematic overviewxxNo ratings yet

- WT631 SCHDocument1 pageWT631 SCHxxNo ratings yet

- Milling Machine SX3 SpindleDocument1 pageMilling Machine SX3 SpindlexxNo ratings yet

- Still 7062 FaultcodesDocument1 pageStill 7062 FaultcodesxxNo ratings yet

- Still r70 PDFDocument86 pagesStill r70 PDFMyhaiKatalina100% (4)

- Harting Current SensorsDocument36 pagesHarting Current SensorsxxNo ratings yet

- MXG 9810 UMDocument20 pagesMXG 9810 UMxxNo ratings yet

- 2.0l Diesel Engine, DSRA, DSRB: Current Flow DiagramDocument28 pages2.0l Diesel Engine, DSRA, DSRB: Current Flow DiagramxxNo ratings yet

- Rpi-574 Rohm Phot InterrupterDocument4 pagesRpi-574 Rohm Phot InterrupterxxNo ratings yet

- LG Funtion GenDocument1 pageLG Funtion GenxxNo ratings yet

- Bobisoft Winding Design Software PDFDocument17 pagesBobisoft Winding Design Software PDFxxNo ratings yet

- Motor K80!4!0.55kw-Test ReportDocument1 pageMotor K80!4!0.55kw-Test ReportxxNo ratings yet

- Selection of Copper vs. Aluminum Rotors For Induction MotorsDocument11 pagesSelection of Copper vs. Aluminum Rotors For Induction MotorskachanansNo ratings yet

- Spindle, 7x10, 12 Mini LatheDocument1 pageSpindle, 7x10, 12 Mini LatheramaaramaaNo ratings yet

- Algorithmic Method of Design and Analysis of Fractional Slot Windinf of AC Machine CO-UV-0000313 - 01 PDFDocument8 pagesAlgorithmic Method of Design and Analysis of Fractional Slot Windinf of AC Machine CO-UV-0000313 - 01 PDFxxNo ratings yet

- Spindle SC2 SC3Document1 pageSpindle SC2 SC3xxNo ratings yet

- BOC TIG185 Service Manual D5Document19 pagesBOC TIG185 Service Manual D5xx0% (1)

- Rewinding Induction MotorsDocument3 pagesRewinding Induction MotorsxxNo ratings yet

- Bobisoft Winding Design Software PDFDocument17 pagesBobisoft Winding Design Software PDFxxNo ratings yet

- Din 228 - Din 69871Document1 pageDin 228 - Din 69871jromero_rpgNo ratings yet

- Motor Sizing Calculations PDFDocument9 pagesMotor Sizing Calculations PDFGaleano CesarNo ratings yet

- Rewinding Induction Motors PDFDocument85 pagesRewinding Induction Motors PDFxxNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)