Professional Documents

Culture Documents

Manual For 2 Stroke Engine Propulsion Type

Uploaded by

SWASTIK MISHRA0 ratings0% found this document useful (0 votes)

225 views187 pagesIt's good

Original Title

MANUAL FOR 2 STROKE ENGINE PROPULSION TYPE

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIt's good

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

225 views187 pagesManual For 2 Stroke Engine Propulsion Type

Uploaded by

SWASTIK MISHRAIt's good

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 187

INSTRUCTIONS

HYUNDAI-MAN B&W DIESEL ENGINES

COMPONENTS NO. 1

(CODE BOOK)

‘This book must in no case be wholly or partially copied and published

fr passed to unauthorized persons without the permission of HYUN-

DAI HEAVY INDUSTRIES CO., LTD. ENGINE & MACHINERY DIVISION.

Instructions for Main Engine

Type SS0MC-C

‘This book forms part ofa sat of Books consisting of three volumes anti:

Vol OPERATION

Vol Il MAINTENANCE

Vol COMPONENTS AND DESCRIPTIONS

‘The purpose of these books i o provide ganeral guidance an operation and maintenance and

to describe the construconal features ofa stardard version ofthe above engine ype. Deviations

may be found ina specie plant. In additon, the books can be used for rtorance purposas, for

instance in correspondance and when ordering spare pats.

tis ossontal thatthe folowing data is stated in spare gars ordors as It's usod by us to ensure

the supply ofthe correc pats forthe individual engires:

‘Name of vess

Engine No bultby

Pata No.

PartNo.

‘Quanity requitad (and description)

Examble: M/S Nybo 7730 BAW - 90201 - 00-059

10 0 (pion ving)

Furthermore, 19 ensure optimum afiency, ralabilly and Mfetme of the engine and its

‘components, only orignal spare pats should be use.

‘The designation ‘0’ used in taxts ane iystrations refers to the information given on the data

sheets inserted in the respective books,

‘As rlable and econemcal operation of the cael engines is conakonal on correct operation and

‘maintonance, tis essential tha! the engine-room personne is fully acquainted wit ta contants

of his book.

‘This book is subject to copyight protection. The bock must not, ether wholly or party, be copied

‘produced, made public ain any other way made avaiable toa third party without

‘the writen consent of ths etfact rom MAN B&W Diesel AS.

Hyundai Heavy Industries Co., Ltd.

Engine & Machinery Division

1, Cheonha-Dong, Dong-Ku, Ulsan, Korea

hittp:// wwww.hhi.co.kr

hitp// as. hyundai-engine.com

Engine After Service Dept. Engine Parts Sales Dept.

‘TEL (82) §2-280-7412~20 TEL : (82) §2-290-7311~20

FAX + (62) 52-230-7581 FAX : (82) 52-280-7582

(82) 52250-9841

E-mail: engineas@hhi.co.kr E-mail : eservice@hhl.co.kr

CONTENTS

‘A. EXPLANATION & CODE BOOK

CYLINDER COVER

PISTON WITH ROD AND STUFFING BOX

CYLINDER LINER AND CYLINDER LUBRICATION

(CROSSHEAD WITH CONNECTING ROD

(CRANKSHAFT, THRUST BEARING AND TURNING GEAR

MECHANICAL CONTROL GEAR

‘STARTING AIR COMPONENTS

EXHAUST VALVE.

FUEL OIL SYSTEM

‘TURBOCHARGER SYSTEM

‘SAFETY EQUIPMENT

ASSEMBLY OF LARGE PARTS

GENERAL TOOLS

B. OVERSEAS NETWORK

A. EXPLANATION & CODE BOOK

INDEX

CYLINDER COVER

PISTON WITH ROD AND STUFFING BOX ..

CYLINDER LINER AND CYLINDER LUBRICATION ..

‘CROSSHEAD WITH CONNECTING ROD

CRANKSHAFT, THRUST BEARING AND TURNING GEAR

MECHANICAL CONTROL GEAR

STARTING AIR COMPONENTS

EXHAUST VALVE

FUEL OIL SYSTEM

TURBOCHARGER SYSTEM ..

SAFETY EQUIPMENT

ASSEMBLY OF LARGE PARTS

INDEX

CYLINDER COVER

PISTON WITH ROD AND STUFFING BOX

(CYLINDER LINER AND

‘CYLINDER LUBRICATION

(CROSSHEAD WITH CONNECTING ROD

(CRANKSHAFT, THRUST BEARING

‘AND TURNING GEAR

MECHANICAL CONTROL GEAR

‘STARTING AIR COMPONENTS:

EXHAUST VALVE

FUEL OIL SYSTEM

‘TURBOCHARGER SYSTEM

‘SAFETY EQUIPMENT

‘ASSEMBLY OF LARGE PARTS

Cylinder Cover

General

‘The oylinder cover is made of steel and has

a central bore for the exhaust vawve, which

Is attached by means of four studs. The

cover furthermore has bores for the fuel

valves, which are mounted with tubular

spacers and nuts. Other bores have boen

provided for starting vaive, staring ar inet,

‘alaly valve and incieator cack.

[A cooling jacket is mauris an the lowor

Patt of the cylinder cover, wheraby a cosh

Ing water space is tormed.

‘Another cooling water space is formed

‘round the exhaust valve seat, when the

exhaust valve is installed. These two

spaces communicate through a large num-

ber of obliqueiradial cooling bores in the

‘The water is supplied from the cooling

Jacket surrounding the cyinder tier and

asses through water tvansitons to tne

fooling jacket surrounding the cylinder

Cover and, further on, through the cooling

bores, to the space around the exhaust

valve seat

From here the water is discharged to the

‘main cooling watar outlet pipe,

‘The cylinder cover is tightened against the

top of the cyiindes liner by means of nuts

and long studs fied In the cylinder trame.

‘The nuts are tightened by means of hycrau-

lic jacks.

Sealing between the cylinder cover and

fylindar liner Is obtained by means of a

sealing rng, made of mild steel.

1901.01.46

3

ah basad Cylinder Cover

fd

When refering eis page, please quote Pate P8001 Eationo163

Plate 90101-0163,

xy

Plate 90101-0163 Cylinder Cover

tom tom Description tem tem Deserstion

cis | Seren

G21 Preece cap

out

tes | St

om | nit

0 | Sts

82 | Cynder cover

‘oe | Oring

1% | Cosa ncet

tos | fee

481 | Dares pipe

16) | St

tor | Sew

INDEX

CYLINDER COVER

PISTON WITH ROD AND STUFFING BOX

CYLINDER LINER AND

‘CYLINDER LUBRICATION

(CROSSHEAD WITH CONNECTING ROD

CRANKSHAFT, THRUST BEARING

AND TURNING GEAR

MECHANICAL CONTROL GEAR

STARTING AIR COMPONENTS

EXHAUST VALVE

FUEL OIL SYSTEM.

‘TURBOCHARGER SYSTEM

‘SAFETY EQUIPMENT

ASSEMBLY OF LARGE PARTS

Piston with Rod and Stuffing Box

Piston and Piston Rod

Plate 90201

The piston consists of two main parts

‘= Piston Crown

‘+ Piston Skirt

‘The piston crawn is tightened to the upper

‘and of the piston rod by means of screws,

‘The screws are locked with locking wite.

The piston skit is tightened to the piston

crown by means of Hanged screws.

The serews are locked with locking wie

The piston crown is provided with chro:

mium-plates grooves for four piston rings.

‘The one unpermost rings have increased

height.

Piston ring No. 1 is a Controle Pressure

Raliet ring (CPR). CPR rings may have

‘been coated on the external surface.

Handle with care, as impact may cause the

coating to crack and peel of.

‘The piston rings Nos. 2, 9 and 4 have

oblique cuts:

= piston ring No. 2

has righthand ext,

and

= piston rings Nos. 2 and 4,

Fave ltt-hand cuts

AN the top, the piston crown has a groove

for the fiting of lting tools.

The pistor cod has a trough-going bore for

the cooling ol pipe, whichis secured to the

Piston rod top by means of flanged screws.

Costing oil is supplied through a telescopic

pipe ‘connection on the crosshead and

assed through a bore in the piston rod foot

and, through the cooling oll pipe in the

piston rod, tothe piston crown.

902,01-65

‘The aif is passed on through a numer of

‘bores inthe thrust part of the piston crown

and tothe space around the cooling all

in the piston rod.

From the bore in the pfton rod foot, the oll

is led through the crosshead to a discharge

spout and to a slotted pipe inside the on

gine frame as well as through @ contro!

device for checking the flow and tempera-

ture.

“The piston rad foot rests on a face cut-out

Jn the crosshead pin and is guided by a

pipe in the erosshead.

{A shim is inserted between the piston roa

fand the crosshead. The thickness of the

‘him is calculate for each angine, in order

to match the actual engine layout

‘The rod is fastened tothe crosshead pin by

means of four screws. The serews ore

locked with locking wie.

Piston Rod Stuffing Box

“The bore for the piston rod in the bottom of

the scavenge air box is fited with 2 giston

fad stufing box, which is designed to pre-

Vent the lubycating oll In the crankcase

trom Ooing drawn up into the Sravenge air

space.

‘The stutting box also prevents scavenge air

{in the scavenge air space) from leaking

Into the crankcase,

The stutfing box ig mounted on a flange

wien is bolted to the bottom of the sca

‘venge air space.

Ths stutling box is removed together with

the piston rod during piston inspection, but

‘can also be cismantied for inspection in the

crankcase while the piston remains mount-

29 inthe engin.

‘The stutfing box Nousing consists of two

parts, whicr are bolted together.

a

‘The housing is provided with seven mac

red ring grooves:

= The uppermost groove is provided with @

four-part serapor ring with obique edges,

‘which sores to prevent sludge from the

‘scavenge box rom being drawn down to

the otner rings,

Furthermore, an eight-part sealing ring is

located below the scraper ring to provent

scavenge alr trom passing downwards

‘along the piston rod

‘Tho scraper ring and the seating ring aro

guided by two cylindrical pins.

= The next two ring grooves are each pro:

vide with a four-part sealing ring and an

‘ight-pan sealing ring below. The rings,

‘fe guided by two cylindrical

= The four lowermost sing grooves are

fitted with three-part scraper rings which

scrape the lubrieating ol! off the piston

rod.

Each of the three parts consists of a

base sing with two machined grooves,

‘each containing a pressed-in lama,

with a scraping edge facing the piston

fod.

From the three lowormost grooves, the

oll is returned to the eankease, through

Doras in the stuting box housing:

Through bores in the housing and a pipe,

the uppermost scraper ring groove commu

loates with a contrat tunnel on the outside

of the engine

‘This tunnel provides @ means of checking

that the seating rings and seraper rings are

functioning correctly

= Biow-by of ar inicates detective sealing

rings, ‘while excessive oll indicates

ofective scraper rings,

“The parts are held in place round the piston

fad by means of helical springs, which aro

located in machined grooves on the outside

of the scraper rings and sealing rings.

sure that the rings will baer against the

piston rod even in worn condition,

3

Piston and Piston Rod

Prey

fe

Wen refering to this page,please quote Plate P9201 Editon 0202

Plate 90201-0202 Piston and

| 7 Item Description a Item Description

011 Scrow

2s | scew

oar | Losing wie

059. | screw

60. | Screw

072 | Piston ing

1084 | Pieton ring

(096. | Pieton rng

118 | Pston cown

143, | Pipe for cooling insert

155. | Piston oa

187 | o-ring

ara | O-ing

80 | Piston skit

182 | Screw

Piston Rod Stuffing Box Plate 90205-0115

‘non rearing to this page lease quote Pate PaQ20s Eationd15|

Plate 90205-0115

Piston Rod Stutfing Box

lem Description Description

in fc sip ine tem Descripti

org | nt

025 | Housing fr stung box

sr | Seraper ing

49 | Scraper sng

(050 | Fange

062 | Gudea

186 | Screw

088 | Sprngpin

121 | Lamesa

145 | Oving

187 | Seraper eng

169 | Seating og

170 | Seaingrng

(2 | Screw

204 | Fitodbot

216 | Housing lor stating Hox, compete

241 | Spring

2s | Spring

INDEX

4

CYLINDER COVER,

PISTON WITH ROD AND STUFFING BOX

CYLINDER LINER AND

CYLINDER LUBRICATION

(CROSSHEAD WITH CONNECTING ROD

(CRANKSHAFT, THRUST BEARING

AND TURNING GEAR

MECHANICAL CONTROL GEAR

‘STARTING AIR COMPONENTS

EXHAUST VALVE

FUEL OIL SYSTEM

‘TURBOCHARGER SYSTEM

SAFETY EQUIPMENT

ASSEMBLY OF LARGE PARTS

908.01-62

Cylinder Liner and Cylinder Lubrication

cylinder Frame

‘The eyliader section of the engine consists

of a cast cylinder frame, which is tightened

together with the tramébox ang the bad-

plate by means of stay bolts, the bottom

‘nd of which le serewed into the bedpate

It the cylinder frame consists of more than

‘one par, these paris ave tightened together

sere vertical joints.

{central bore for aach eylinder, atthe top

(of the eylinder trame, encloses the cylinder

liner.

AA central bore for each cylinder, at the

bottom of the cytinder frame, encloses the

piston rod stuting boxes,

(On the exhaust side of the cylinder frame

there are openings which connect the sca-

venge air spaces around the cylinder liners

with the longitudinal scavenge alr receiver

ofthe engine

Furthermore, there aro inlet pipes for cool

Ing and lubriating oi.

‘The oylinder trame is provided with cleaning

and inspection covers giving access to the

‘avenge air spaces

Studs fr fastening the cylinder covers are

‘mounted in the cylinder frame,

Cylinder Liner

The cylinder liner is tightened against the

top of the cylinder frame by the cylinger

cover, so that it can expand freely down.

wards when healed during the running of

the engine.

‘A rubber ring is located in a machined groo-

ve on the extemal diameter of the cylindor

liner, inorder to guid the liner in the

cylinder teame,

‘The cylinder liner is surreunded by a cool-

ing Jacket

uber eags iosated in machined grooves,

In the cylinder liner ensure cooling water

sealing

‘The part of the cylinder liner which is

located in the scavenge. air space of the

eylinder frame is provided with a number of

scavenge alr pons whict are uncovered by

the piston when this isin ts bottom pos

tion. The scavenge air ports are bored at an

‘bique angle to the axis of the cylinder

liner so as to glve the scavenge air a rotary

‘ovement in the cylinder.

In the free part of the cylinder liner, be-

tween the cooling jacket and the cylinder

frame, there area nimber of bores with

non-return valves for supply of lubricating

ail to the cylinder

(On the working surface of the cylinder the

bores are connected to a lubccating groove

ta ensure an even distritution ofthe oil

Cylinder Lubricators

Plate 90305

“The cylinder frame is tted with two eyllndsr

lubricators. The lubricators incorporate a

rhumber oll pumps, corresponding to the

‘number of lubricating orices in cylinder

Tnars,

Tho lubricators are inter-connected by

‘means of shaits with couplings which aro

fig in the direction of rotation.

‘The lubricators are driven through a gear

transmission from the end of he eamshatt

For fixed pitch propeller plants (FPP), the

lubricaters are speed-dependent, whore the

cylinder oll dosage follows the engine

speed. For contrafable pitch propeller

piants (CPP), the lubricators. are mean

Indicated pressure (MEP)-dependant, wnere

the eylinder oll dosage folows the engine

loa,

‘Tho lubricators are of the load-change

engine ype

* engine number

* point of application

the distance in mm

otween the measuring points.

Furthermore, the length ofthe pin gauges is

Indicated. in' te rlevant section of the

‘maintenance book (Volume I) forthe plant.

Indicator Valve

Plate 90612

Each cylinder ie fited with an indicator

valve, which communicates with the com

bustion chamber af the eylinder through a

bore. The indicator valve is a double-seated

valve with a spring-loaded closing face.

In order to provent overstrossing,closo the

valve with 2 light hang betore starting the

engine, and rotighten tne vave when the

‘engine has reached its normal service tem-

perature

indlcater Drive (option)

Plate 90612

[An incicator cam is fitted for eacn eylinder.

‘An ingleator drive is arranged above this

The indicator drive consists of @ spring

loades spindle which is able to move up

‘and dwn, corresponding to the movement

of the main piston within the engine

tylinder. This motion is transmitted from tne

Indicator cam through a roller at the bottom

of the spindle. At the top, te spindie has

fan. eye to whicn the indicator cord Is

fastened after the Indleator nas been

‘mounted on the indicator valve.

During normal running of the engine, the

spring-loaded spindles ited clear of the

indicator cam, the nande of the spin

being inthe locked pasion.

‘when diagrams are to be taken, the handle

is tumad 60° whereby the spindla enters a

eyway which enables the spindle to be

Jowered onto the incicator cam. The keyway

wl uae te spindle dng ts up-ané

jown movemet.

For use of the indicator, s8@ Vol. |, OPERA

Tron, Chapter 706.

Moment Compensators

2nd order moment

4,5, and G-eyl. engines have a 2nd order

‘extemal moment which might excite vibra-

tion ofthe hull and decknouse,

Based on calculations, these cylinder

‘numbers may be provided with tywoights

built into the main chain drive

Flyweights may also be built into a second

chain deve, which is driven from the fore

fend of the crankshatt, This chain orve Is

‘equipped with a spring-loaded chain tight

fener

Optionally, an electrically cron compen-

sator can be installed gutsige the engine

1st order moment

‘4rcyl. engines may have a rather high 1st

forder external moment, and ean, therefor,

‘be provided witha tst order moment com:

ppensator arranged as adjustable counter-

‘weights on the fore and aft ends of the

crankshaft

Atenatively, the tst order moment com-

pensator can be arranged in tre main chain

rive,

‘This moment compensator consists of a

{new) chain-tightonar wheel with an ‘cor.

porated counterweight and a counterwerght

Fotating withthe crankshatt.

If the chain drives for the above compen:

sators have baen dismanted, the fywaights

must be posiionad correctly in relation to

the crankshatt of the engine

‘$00 the instruction book, Vol. I, MAINTE:

Nance,

Incorrectly fited moment compensators

may excite heavy vibcations

Load Transmitter

A lead transmitter may be mounted on the

fuel regulating shatt to give a remote in-

dlcatior ofthe tust pump index.

W5E

90699-72

Up FA

=

q

Plate s0601-69

Plate 90601-89 Chain Drive and Guide Bars

SP.

tom

No.

016

028

ost

063

065

069

080

109

2

124

136

148

161

173

185

23

315

a7

Part Deseription

Bracket for gudeber

Guidebar

Beam for qudebar

Washer

‘Screw

‘Screw

Bracket

Dise

‘Screw

‘Beam for guidebar

Screw

34" Chain, complete

‘Chain link, complete

‘Outer ln

Inner ink

ne Part Description

Err

HORE Chain Orive - Lubrication Plate 90602-111

‘S50MC-C

202

Plate 90602-111 Chain Drive - Lubrication

hem

No.

Part Description

tem

Pat Description

er

023

035

047

060

o72

095

108

131

43

167

179

180

202

Soray pine

Lab pipe

Spray pipe

Libat pe

Spray ine

Lib.o pipe

Lib. pipe

Spray pipe

Spray pipe

Lb pipe

Lib pe

Lib ip

Steppe, i=1780

dae Chain Tightener Plate 90693-0114

fr

137

When refering fo hispage,pleaso quote Plato P9060 EdtionDTT4

Plate 90603-0114

Chain Tightener

es

Iter Deseription

Nut

Locking pate

Gude nat

Guise rut

Tightsning bot

Ne sotocting

Gover

‘Seren

Locking wie

‘Shaft

Serew

Screw

Flange

Stop screw

shat

Cove

Serew

rack

(Chain whee!

Bushing

Shaft

Distance piooe

Couping

Libreationol pipe

bration ie

Coupling

Distance pipe

‘Serew

Nut

Sh

Orn

G68 pin

xing

Sat

tem

No.

tem Description

OT.

Pe

POROIND Chain Wheel on Camshaft Plate 90610-E04

‘SSOMC-C ¢

om

Plate 90610-E94 Chain Wheel on Camshatt

(

ie

‘ee Par esrpon i Pa besipen

076 | Screw

088 | Bearing, upper pan

111 | Bearing shel

123 | Bearing lower part

347 | Nut

159 |Stua

172 |Scrow

186 | Guide pin

196 | Guide pin

208 | Shim

231 | Bearing, upper pat

243 | Tanstring

£255 |Boaring, lower part

279 | Seow

$

BOTT camshert

fd

‘S50MC-C.

Plate 90611-E115,

Plate 90611-E115 Camshaft

67

= Past Deseoton ion Pan Deseston

O10 | Gana

O15 | Gran wee

07 | Lackeg wee

09 | exaust cam

a9 | Soew

0 | Gar woe

os | Fl cam

ose | Tost ase

068 | Inesor cam compte

oe | Po

117 | Pa por

120 | Sof borg out

sot | cox wnat

To bo mougtod f woodward governor

1s wed

‘cde

ery

HARRAH Indicator Drive Plate 90612-51

‘SsoMe-o C

Plate 90612-51 Indicator Drive

hom

No.

Part Description

hem

No,

Part Description

016

025

oat

083

085

or

039

030

12

124

136

148

173

185

207

220

22

28

256

288

zat

293

308

327

339

352

376

388

423

435

459

460

466

496

508

531

543

587

579

580

Handle

Serew

Roller guido

‘Serow

Liner

Housing

Screw

‘Washer

Packing

‘stud

Selocking nut

Extension

Screw

Kook washer

Spring

Connecting piece

Guard

Screw

Lock washer

Packing

Packing

Flange

Incieator valve

Beating

Dise spring

Valve cone

Valve seat

Spindle guide

Spindle

[Gasket

Valve housing

Handwhee!

Plato sas:

red

FOREN Arrangement of C:

‘S0MC-C

Plate 99813-85 Arrangement of Camshaft

tem

i Part Descriation

re Part Description

023 | Oving

035 | Connecting pipe -ub.0f

(058 | Basaplate

072 | Screw

084 | Guido pin

096 | Bearing cap

118 [Bearing shel

131 |Screw

+ TOBE MOUNTED IF NORCONTROL

DGSSB00E GOVERNOR 1S USED

9013-81906 s1eId

yy

Plate 90615-E105 Electrical Governor

rH Pat Deseo a Pant Deseo

ora | Gua

26 | Saow

{51 | Guise pn

ra | Seow

85. | Washer

107 | Bec govemor actin

19 | Lover

420 | Seow

122 } Washer

ae | Bracken

901 | Name plane

902" | tnaiater

"To be mounted If norconro

[DGSBBOOE governor fe used,

EXT reouiating shatt Plate 90618-1065

rd

ors

929

0321

oss

Plate 90618-E106 Regulating Shaft

: 7S

tem

ne at Osserption i Part Doserpton

019 | Forked lever

20 | Pin

022 | Cretp

(044 | Pu rod complete

068 | Bearing

003. | Regulating shat

102 | Bearing

127 | Distance pipe

109 | Washer

14 | Setccking nut

164. | Washer

176 | Fitad bot

188 | Eye not

ait | sping

225 | Spring in

247 | Clamping arm

259 | Seren

260 | Lock washer

284 | Spring toaded lever complete

208 | scr

‘318 | Guide in

349 | Nut

2355, | Lock washer

267 | Lever

380. | sping pn

oe

Prd : ae

HORII Emergency Console late 90620-68

‘SSOMC-C.

rs

0620-68 Emergency Console

Part Description

tom

No.

Part Description

057

60

070

82

094

108

116

1

153

185

7

169

190

200

212

226

248

261

273

285

307

319

320

332

355

368

381

4403

a5

a7

464

476

5i

559

572

est

655

667

680

602

m4

728

Screw

Mande

Shaft

Settcking nut

Washer

Pate

St0p rng

Bushing

Shalt

Sry lock

Sua

(Groase nipple

Seltiocking nut

Washer

Emergency console

Forked lover

Screw

Angi lover

Sit shoo

Lock washer

Screw

Hand whee!

vst

Spin

Soew

Retalning ring

Tapered pn

Clamping Bock

Sande

Stop ave

i

Bal bearing

ireip

Set focking nut

Valve “Anoad-Astacn*

Yelve ‘emote Emagen”

seen

eating cn

Name plate

Screw

Tus ring

Sten vave

Ba bearing

Circip

738

75

763

75

Bearing

Pressure switch

Seraw

Beliows gland

ve

Pry

oui

'S50MC-C C

‘Arrangement of Layshaft Plate 90621-62

tt

Plate 90621-62 Arrangement of Layshatt

item Tom ry

= Part Description ie Pant Descriptio

015 Lover, complete

027 | Grease nipple

039 | Laver

040 | cone

082 | Pin

076 |Lever

988 | Scrow

111 | Washer

123 | Bushing

147 |Serow

4159 |Washer

160 | Bushing

172 |Lever

184 | Switen

198 {Cone

206 | Snitocking nut

218 |Wasner

243 | Screw

255 [Nut

278 | impact socket

280 | Impact handunest

202 |Pin

202 } Stop ring

314 |Ctamping arm

2338 |Pullrog

251 [Fited bot

363. |Soltoeking nut

387 | Screw

398 | Lock washer

410 | Fited bow

422 | Fited bot

448, | Pull 10d, completa

INDEX

380

CYLINDER COVER

PISTON WITH ROD AND STUFFING BOX

CYLINDER LINER AND

CYLINDER LUBRICATION

(CROSSHEAD WITH CONNECTING ROD

CRANKSHAFT, THRUST BEARING

‘AND TURNING GEAR

MECHANICAL CONTROL GEAR

STARTING AIR COMPONENTS.

EXHAUST VALVE

FUEL OIL SYSTEM

‘TURBOCHARGER SYSTEM

SAFETY EQUIPMENT

ASSEMBLY OF LARGE PARTS

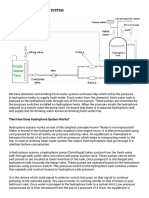

Starting Air System

‘Tho starting air system consists of the

manoeuvring System and the starting air

components.

Tae following items are described:

'= Manoeuvring System

‘© Main Starting Valve

‘= Starting Air Distributor

«= Starting Valve

Manoeuvring System

See also Vol. |. oF=4zi0w, Chapter 703.

The manoeuvring system is of electric!

pneumatic design. tis designed for

+ Control from or

control console,

‘Soe also Chapter 206

ne side

‘= Remote contol from engine

Control-roam andlor bridge.

‘The system consists of thrae sub-systems:

= The regulating system

‘+ The reversing system

* The safety system

Regulating system:

By means of ae regulating system it is

possible to start, stop and contol the

engine.

‘The START and sToP functions are control:

led pneumatically

3-sotting during remote control

During remote contal, the spaud-setting is

controlled by the control handle on the

‘manoeuvring console, which sends a signal

ta the governor system.

907.01-83

‘The engine speed depends on the magni:

tude ofthe signal. The governor system wil

‘Maintain this speed independent of the

engine oad.

ting during

During contrat from tne engine sido contre!

onsale, the governor is disconnected from

the fuel pumps, and the speed control is

effected through the requlating handwheet,

‘See also Vol. , oPeAArion, Chapter 703

‘and Plate 90620.

anual contol:

Reversing system:

‘The reversing system contains two pneu

‘matic valves. (AMEAD and ASTERN). These

valves control the reversing cylinder of the

staring alr distributor and the alr cyindors

for reversing the fuel pump rolers.

Safety system:

‘Tho safety system Is separately supplied

with air and ie controlled ty the engine

‘monitoring ‘system (with separate power

supply). In case of shut-down, the safety

system leads an air signal to the puncture

valve on each fuel pump ereby outing

the dotivery of high-pressure fuel ol, ator

which the engine stops.

‘The safety systom is connected during all

modes of engine contol.

Main Starting Valve

late 90702

‘The main starting valve is interposed in the

starting air main pipe.

‘Tho main starting valve consists of a large

ball valve and, optionally, smaller ball

valve which Is fited as a by-pass for the

large valve. Both valves are operated by

means of pneumatic actuator.

1 the smaller ball valve is installed, an

adjusting screw wil be mounted for seting

tha slow-turning speed,

al

07-02-83

Furthermore, 2 aon-retuen valve is incor

porated which prevents blow-back in the

vont of excessive prossur nth staring

airline.

The main starting valve is equipped with 2

blacking device consisting ofa plate which,

by means of a hanawheel, can be made to

block the actuators.

The ball valves and their actuators are,

together with the non-etum valve and

blocking device, ull together {© form a

nit.

(On receipt of telegraph order ‘Finished with

engine’, move the biecking device to the

BLOCKED position,

‘To avoir alarm, move the telegraph handle

Into Sop positon.

farming t

During ail inspections ofthe engine,

blocking device of the main starting

valve must bin the BLOCKED position.

‘The only exception is when the staring

valves ate tested for tightness, in which

case the blocking device of the main

starting valve must bein the WORKING

ppasition and the shut-off valve for the

Starting ait cfstrbutor must be in the

‘cLoseo position.

Seo Vol. |, ERATION, Chapter 709,

‘Operations after arrival in port:

Starting Air Distributor

Plate 90703

‘The stating air distributor is mounted on

the end of the engine and is even from the

‘end of the camshaft Uiough Gear wheels.

‘The distibutor consists of:

© Distributor ise

1 Reversing die

= Housing

f= Shatt and bushing

Distributor ise:

‘Short and long recesses are milled into the

Contact face of the cistributor disc. They

form two concontic circles.

For an engine which runs clockwise during

‘AHEAD (seen from al), the outer recesses

‘contro starting in AHEAD direction, and the

lana recesses conte! staring in ATEN

rection.

‘Through the short recesses, starting air is

supplied to each staring air valve in turn

Each of the short recesses Is divided into

two parts. Tha par, which during AHEAD or

ASTERN is the fist in the ranning dtecton,

‘gets its supply air from space At and the

Next ges its supply from space A2

Through the tong recesses, the starting

valves that are not supplied with starting air

{are vanted. Through bores, the long céces

‘ses communieate with the central shace

between the shaft and the reversing disc

and from there leads through bores In the

distributer housing, to the atmosphere.

Floversing disc:

The reversing dist Is designed with two

sets of bores opposite the mentioned two

sets of concentric recesses in the distib-

tor disc. By means of an air cylinder con-

‘nected to the arm of the reversing disc, one

of these sets of bores can be cut off wily

the ather set of bores is brought to com

‘municate with the outst holes which lead to

the starting valves.

Furthermore, for engines with remote con

trol, the revarsing arm acts as 2 cam for

{wo 2-way valves, controling the end posl-

tions of the reversing movement.

Housing:

Each outlt hole from the distributor hous

Ing leads to 2 starting valve, and the post

tion of the reversing dise detstmines whet

her air for AHEAD or ASTERN running is

‘supplied to the starting air valves.

Shatt and bushin

‘The shaft rotates in a bushing fited in a

bore placed centrally inthe distributor hous-

ing. The shat is driven by the camsrat

‘through gear wheels. The distributor disc is

‘mounted on the other end of the sha

During running, the distributor disc is kept

free ar the reversing disc by means of oll

pressure:

Closest to the distrnutor disc, the bushing

hhas a larger diameter than atthe other end.

‘Tho oil pressure, which Is applied at the

centre of the bushing, acts on different

shaft diameters and gives @ small displace:

ment ofthe distributor disc.

Function:

When contol alr is admitted to the starting

air dstributer, a control air pressure builds

Up in spaces At and A2, causing distributor

isc B to be pressed against the raversing

disc.

Control air passes through bores in the

distributer alse to the shor recesses, and

further on through bores in the reversing

disc and via bores inthe distrbutor housing

to the starting valve, thus activating the

starting valve.

‘The long recess in the distributor disc com-

municaies with the remaining starting val

ves through the bores in the reversing disc

and the distrouter housing. The pilot alt

‘rom the starting valves is vented through

these bores and through bores in the dist

Dutor dse and the distributor nousing to the

atmosphere.

When the crankshaft stars turning, the

istrbutor disc also tums, thereby moving

the short recess from one bore into @ posi-

tion apposita the next bore. Thereby the

starting valve which is connacted with this

bore is supplied with contol air, and the

starting valve opens. Simuitanecusly, the

long recess in the distributor disc is posi-

Tioned opposite the bore from the starting

valve activated directly before, and the

oa

1907.03.69,

contro! air of that starting valve is vented,

Causing the valve to close.

‘When the start lavel APM of the crankshaft

hhas been reached, and the START signal is

vented, space At is vented through a pneu-

‘matic valve. At the same time the fuel pumo

puncture valves are vented, causing fue of

tobe injected into the cylinders. The control

air supply through space A2 continues a

‘shot time (adjustable) In order to facilitate

the staring

The venting of space At means that the

opening of the staring valves is dolayed

land that fuel ol therefore can be injected

into the cyinger without any risk of blow-

back to stating air pipes.

Starting Valve

Plate 90704

The starting valve (spring loaded) is fitted

fon the cylinder cover. It is controlled by

control ait rom the staring air cistibutor

80708.

Funetion:

When the main stating valve is open,

‘chamber P of the stating valve is pressu-

rised through the staring air pipe.

‘The starting valve is kept closed by #

spring. When chamber U-above the piston

of the starting valve is pressurised with

‘control air trom the starting air distributor,

the staring valve opens, and starting air

ow flows from the starting ar pipe to the

eylinder.

When the starting period is tinished,

‘chamber U is vented tough the vent pipe

‘of the starting air distributer, and the start-

ing valve will close,

Venting ofthe starting air in chamber P and

the starting air pipe takes place slowly

through small holes inthe staring air pipe.

Pry

ed

‘SSOMC-C

MainStarting Valve Plate 90702-45

363

275

287,

Plate 90702-43 Main Statting Valve

tem

No

Part Description

Part Description

015

wr

029

040

052

064

076

088

123

135

a7

159

160

172

196

206

218

231

243

255

267

279

280

314

328

338

351

375

387

409

410

a2

436

406

458

489

Securing pate

‘Screw

Switch

Distance pipe

Plate

Actuator

Screw

Intermediate piece

Scrow

Ball valve

Name plate

‘Name plate

Serew

Nut

Washer

Washer

Scrow

Handwheet

Pin

[Screw

'Sorng

Spindle

Nut

Plug screw

Screw

seem

intermediats piece

Spit pin

Chain

Spit pin

Packing

Housing for non-retun valvo

Non-return valve,

Housing

Upstream seat

Downstream seat

Packing

-owoss

rr

enue

e

2

a

333 3s7 3am z

345 | 370/ 394

i lea foe 2

| LK g

| Las €

130 ne 130

£8

Plate 90703-£82 Starting Air Distributor

Tem

No.

Part Description

Tem

No,

Pant Desedption

oro

22

038

045

058

083

095

105

a7

129

130

154

166

191

201

205

37

24g

262

24

285

288

308

330

345

37

370

382

206

408

416

28

4a

Seraw

Gasket

Screw

Name plate

Brackot

Fitted bot

Seltocking nut

Air oyinder

Spring in

Screw

912-way valve

‘Stue

Nut

Guide pin

Guide pin

JGear whe;

Lock washer

Nut

Bushing

Spring pin

Key

Screw

Bracket

Distributor housing

Shatt

Sealing ing

Rloversing ise

Sealing ring

Distributor dise

Piston sing

Cover

Fite bok

Washer

iN Plat

‘Viner rataring tothis pag, please quote Pate PB0704 Eaton0s8

Plate 90704-0058 Starting Valve

fay tem Description ra {tem Description

016 Screw

028 | Cover

(41 | Packing

053 | ‘Setnceking nut

085 | Picton

07 | Piston

189 | ‘Spring

080 | Distance pipe

100 | Une

112 | Vale rousing

124 | Seaingring

196 | Valve spindle

INDEX

89

CYLINDER COVER,

PISTON WITH ROD AND STUFFING BOX

CYLINDER LINER AND

CYLINDER LUBRICATION

(CROSSHEAD WITH CONNECTING ROD

(CRANKSHAFT, THRUST BEARING

‘AND TURNING GEAR,

MECHANICAL CONTROL GEAR

‘STARTING AIR COMPONENTS

EXHAUST VALVE

FUEL OIL SYSTEM

‘TURBOCHARGER SYSTEM

‘SAFETY EQUIPMENT

ASSEMBLY OF LARGE PARTS

go

tacce ssonies)

a

ry

IAN BW Engine Types 50-98MC Description

i aa 90030-0003

908 Exhaust Valve

Exhaust Valve Each cylinder i equipped with an exhaust vave, which is mounted in @

cent! bore Inthe cyber cover. The valve Pousig Is attaches with fot

Studs and nuts to form 8 25 igh geal against a seat nthe cylinder cov

Valve housing ‘The valve housing has an exchangeable botiom plese

‘The bore for ne valve spindle Is proviced wih an exchangeable spindle

‘guia in

cooing ‘The valve nousing is water cooled. The cooing wales passes to he

Valve housing after i has passed the cylinder cover. Ta water ig die

‘charged ftom the upper par of te valve housing.

(On he ror of the valve housing ther® isa cleaning cover hough which

‘he cooling water space ean be checkea and cleaned

Valve spindle ‘Tne part ofthe spindle stem whic travels wih the sealing arrangement

cl the ar einer is coated with a wear resistant mintureol metal carbide

‘and super aloy, applied by tne HVOF process

(On the lower cylindrica! part of he valve spine 2 vane whet is titeg

lamien cause the valve spindle to volae wile the engine ' running.

Lutinglotation ehgok oe

‘To enable checking tne functioning ofthe exaust valve wile the engine

‘running, a itingiotation ehack tod i mounted on tone tha hydraulic

fe yinder On the exhaust waive

‘Spine rotation is ingested by regular changes inte tp and bottom

postions of the check rod

( Note!

“This check od is only for checking purposes, an must not be perma:

erty activated,

Pistons

[At he top ofthe spindle, two pistons are ited

1A piston

‘The piston saves to close the exraus va, The pion is locked to

the spindle by a mo:

2 Hydraulic piston

The piston serves to open the exhaust vav.

‘The hydraulic piston Nas two piston rings and @ damper arrange:

rant, designed to dampen the closing ol the vave,

non refering to tis tx, please quote Descrpion A90080 Edior GO0S Paget)

aa

Description

‘90030-0003.

Air cylinder

Hydraulic eyinder

Sealing System

nd

Engine Types 50-98MC MAN B&W

Caution! 1

[Alter the exhaust valve nas been overhauled, ls important © check

the damper, 0 avoid knocking

‘See Volume Il, MAINTENANCE, Procedure 908,

‘The ai cylinder is mounted on top ofthe valve housing. Ai fo closing

the exhaust valve is supplied tivough & non-etur vane to the space

below the piston,

A safety valve ‘= mounted in the bottom of the air cylinder. The safety

valve is connected to the drain pipe which leads tothe camshaft housing.

The hydraulic cylinder ig attached wit studs and nuts on heat eylinder

‘on top of tha exhaust valve hovsing

‘The exhaust valve i opened by the valve spindle being forced down by

the piston in the hydraulic eyinéer.

“Throtiewalve:

(On some engine types, a combined thataivalve designed fr deaerat

ing the oi eystom Is filed atthe top ofthe cylinder,

\When he exhaust valve is closed, the pressure inthe hydraule oyinaer

{s tow. A tyust spring opens ihe valve, enabing ol and ai, if any, to

‘escape through the throttle,

‘The oil's led through a duct tothe space around the ac cylinder ane Is

rained of through a bore X, together wih leakage ol ram the piston

When the exhaust valve fs activated, the high ol pressure closes the

valve, an the oi flow sos

‘Seating at (whe

{A sealing air arrangements ited around the spite shaft blow the air

cylinder.

sed

‘The sealing ati supplied from the air cylinder via a sealing air control

‘The sealing air will prvent the exhaust gas and parices from penatat

ing upwards and wearing out the running surfaces and polling the

‘pneumatic system a! the valve gear

‘The ol content inthe alt from the ar cylinder improves the service con:

dion of the sealing rings

“The sealing ar controt unit contain a valva which automatically cuts oft

the ai lw then the engine isn FINISHED WITH ENGINE status, anc

2 filer housing,

Page 2.3)

‘nen rterting to his text. please quote Description A80000 Eaton 0003

as

Bry)

fw Engine Types 50-98MC Description

90030-0003

Sealing ol jwnere used)

{A sealing ol attangement i ited around the spindle shaft tetw the aie

eylinder

“The sealing ois supplies from 2 canto un fited on op ofthe exhaust

valve hydraulic actuator

During the exhaust valve iting period, oll escapes from tne hydraulic ac:

talor tough the resticion chamber tothe contol unt whieh, in tun,

gives a certain amount of ol (dosage ol 10 the exnaust valve sping

‘The sealing ol will prevont the exhaust gas and panies tom penetra:

Ing upwards and wearing out the running surfaces and poling the

[Preumatic system ofthe valve gear

‘The oil improves the service condition ofthe sealing ring,

Hydraulic Valve ‘The exhaust valve is actuated by @ cam on the camshat through a hy

Actuating Gear raul transmission

Myéraule eyingor ‘The hydraulic oyinder is attached to the camshaft housing by studs and

A piston enclosed inthe nyersute cyincer rests on a thst piece inthe

neck af the roll gue and is locked to the rol guide by = Bayonat

rein

“The hydraulic cylinder on the camshaft housing is connected tothe hy:

sraule cylinder on the exhaust valve by a high pressure pp.

(lis supplied trom the iuoicating ol systom through @ non-return valve,

Leakage oil rom the hydrate cyinder on the exhaust valve Is drained

Yhrough @ pipe connection

Puncture Valve (On cylinder reversible engines as wel as on S-cyinder reversible

SMC engines, a puncture valve may be mounted on the exhaust valve

actuator. During starting, hs valve prevents the exraust valve trom

‘pening during the fist part of the actuator pistons upward stroke

“This function provents the starting valve and exhaust vaive rom being

‘open atthe same time, thus ensuring a sal stat

nen refering otis text, pease quote Descrton AB0030 Eston 0003, Page 96)

oe

Pret) ~

etn exhaust Valve - Lower Parts Plate 90801-0190

{FS0H03)

30

Wher refering otis page,please quote Plate P90801 Eationd190

Plate 90801-0190

ae

Ta Item Description ny Item Description

013 Packing

025 | Covers

037 | Screw

‘62 | Packing

ova | Panga

096 | screw

08 | O-ing

121 | Bottom piece

188 | Seaing ing

187 | Valve spindle

170 | Packing

182 | Phug screw

194 | Valve housing

204 | Spindle guide lower

Packing

et | Plug screw

Spring pin

265 | soow

277 | Sealing ting

289 | Sealing rng

300 | Tread insert

Plate 90802-0047

Exhaust Valve - Details

Prey

er

‘nen refering to is page please quate Piste PE06A2 Ein 0047

Plate 90802-0047

Exhaust Valve - Details

v7

tom Tem a

we | Item Description = ‘Mem Descriptio

(019 | Sealing ot unit, complete

032 | Steolpipe

ao

benuetn Exhaust Valve - Upper Parts PI

Hanene aust Valve - Upper late 90803-0031

Wen referring this page,please quote Pate P90803 Elion 0037

Plate 90803-0031,

Exhaust Valve - Upper Parts

tor tombesspon Tee] tam Description

| Lagat

ts | Sone

oe | me

88 | Psi

Ser | Steg

ois | See

To | Bayada

1 | Parone

tm | Seatoro

‘| comno

Bs | Boe

37 | Sconewrg

i | sents

Sie | Sherman

a | ae

ae |

Be | Sinan

3 | Pogscew

| Sacm

St | Arent cooite

3e | Bi

38 | eg wate

28 | Sow

3 | tow

3 | Siew

# | Sonduroonae

& | Band

‘er | Seen

‘on | Be

it | Soanoe

we | a

{St | Slowed cancion

See | peste

Be | ocho

be | Secs

8 | Selon

| See

885 | Ron oe

$i | tenure

oes | Pan

Ste | Peseta

oat | Poon

| on | Gee

85 | conte

not:

“when ordoring, please sate Uae.

ness oF dice

100.

Libediaeeal Exhaust Valve, Upper Parts - Details Plate 90804-0008

MAN Baw

\Whnen refering otis page,please quote Plato P90804 Eaton 0006

Plate 90804-0006 Exhaust Valve, Upper Parts - Details

rer

IE | __ Yen cosenton "am | tem Deetption

at | Poa

oss | Oana

45 | Safety valve

Ih

Pry

Pid Valve Gear Plate 90605-97,

‘S50MC-C

Plate 90805-97 Valve Gear

Tem

No.

Part Description

405%.

Part Description

ors

27

039

40

052

064

088

am

135

159

172

104

196

208

218

2a

243

267

279

280

202

302

314

328

351

a5

207

410

422

434

458

an

505

317

520

Lack washer

Pron

et

Seating ring

Packing

Reding socket

Sue

St

Puncture valve

Pole quis, complete

istise

Role gide

Stator ter

Pug

ctw

Siang

Bie

Bushing lr ater ude

Guide pn

Screw

vate hous

Sealing ‘ag

Spndie

Spina

Plson

Nonvtumn vive

wat

Si yindr

Paton

Dise "8

Seow

Seow

Ks

Roler

Dee

Sexng

we

Pr

MORAINE Valve Gear - Details Plate 90806-58

‘S5OMC-C

oss. 12

Plate 90800-58 Valve Gear - Details

70s

tom

No.

art Description

Part Deseription

‘10

or

one

038

048,

058,

083

095

7

129

12

168

166

176

201

213

225

27

bot

[Connecter

Gasket

'Serow

[Support

[Coupling

Sealing ring

Sealing ring

Pips, L=2160

Coupling

Thrast ange

Sieove in 272

/Scrow

O-ring

High-pressure pipa

Spring sing

Intermediate piece

High-pressure pipe, complate

(6

Pry

FORCE Arrangement of Cooling Water Pipes

‘SSOMC-C,

275

333]

240

Boe

216

be

nr

323

A\

Plate 0810-43

37

240

33

ors

024

Si

o7

Plate 9010-43 Arrangement of Cooling Water Pipes

tem tem

Cy Part Description i Part Description

012 |Vave

024 | Couping

036 | Pipe

9st [Buttery valve

073 | Screw

085 Pipe

037 | Screw

107 | Packing

120 |Ball vaio

182 }orain pipe

168 | Pipe (inside valve housing)

181 |Packng

183 |Screw

i 203 | Serew

227 | Screw

230 | Nur

240 [Packing

252 | Ortce pate

276 | Cooling pipe

288 | Packing

328 | Cooling pipe

347 | Screw

358 | Compensator

372 [Pipe

396 | Packing

406 | Seraw

418 | Screw

431 | Coating pice

+443. ortce pate

455 {Nut

CYLINDER COVER

PISTON WITH ROD AND STUFFING BOX

(CYLINDER LINER AND

‘CYLINDER LUBRICATION

(CROSSHEAD WITH CONNECTING ROD

CRANKSHAFT, THRUST BEARING

‘AND TURNING GEAR

MECHANICAL CONTROL GEAR

‘STARTING AIR COMPONENTS

EXHAUST VALVE,

INDEX

FUEL OIL SYSTEM

‘TURBOCHARGER SYSTEM

‘SAFETY EQUIPMENT

ASSEMBLY OF LARGE PARTS

rey

ow

‘909 Fuel Oil System

Fuel Pump

"nen refering otis ton, please quote Desrcton 490090 Eton 0001

ciel

i 5 Description

Engine Types 35-98MC anise

Each engine cylinder is equipped wih is own uel pump, which i mount-

dln he canal nousng over he canst ston covesponing

the cylinder concer

‘Tne pump housing is atached tothe camshaft housing by studs and

ruts

‘The square base of the fuel pump housing is provided wih a groove to

receive any leakage ol, which is subsequently drained of threugh a

rain pipe.

In the base, a bore is provided for at toothed rack, Le. the regulating

guide, which controls the quantity of fue ol delvered by he punp.

Furthermore, forthe VIT-1ype fuel pump, another boris provided above

the bore for the regulating guide. This bore Is provided with a rack, Le

the ting guide, which controls tne engine timing

[AL he top, the pump housing is closed by a top cover.

“The top cover is provided with a suction valve and a puncture valve

‘These two valves are on some engine types combined ito one unit

‘The pump housing contains the plunger and barrel. The plunger and bar-

‘el are matched paris, and must rot be replaced individually,

‘The pump plunger is provided witha guide block designed to travel In

the miled keyway in the regulating guide. At the boltom it has a foot

which rests on a steel dsc in he Bayonet int at the roller guide neck.

JRlesrance ot approx. 0.1 mn between the plunger foot and the roler

guide permits tuning ofthe plunger in the roller guide

The regulating guide is able to tur nthe bottom ofthe pump housing

‘On the ouside the regulating guide has 2 toothed rim to! mesh with the

above-mentioned toothed rack atthe base of the pump housing. The.

toothed rm and toothed rack are marked with Ines enabing the parts

to be positioned cortecty after dsassembly. The toothed rack Is linked

togetver withthe regulating gear ofthe engine through a spring-loades

connection. Thus, inthe eventat a scking pump plunger, the regulating

‘90a for he remaining Wel pumps wil not be blockes.

‘The pump baralis provided with ollcu-off holes, which are covered and

‘uncovered dung the travel ofthe plunger within the barrel. This fune-

tion, in conjunction with the turning ofthe plunger eltected by the regu-

lating gear, serves 10 regulate the amount o all injected into the engine

cylinder

‘Two screw plugs ae ited in the pump housing opposite the cut-lf holes

ofthe barrel. The ol jets which are ejectod through the cut-off holes at

{he end ofthe delivery stroke wil hit the stew pluge, which can be re

placed when they are eroded

age (6)

uM

Description

‘89030-0001

Injaction timing

Puncture valve

Page 244),

Engine Types 35-98MC tee

Fel pumps without VIT (Variable Injection Timing)

“The pump barel is attached 10 the top cover by means of screws.

‘The lowe pat ofthe barrel is guided in the bore ofthe pump housing

‘Two sets ot O-rings and back-up rings are ited in grooves On the out

side of he bane and the pur cover to Seal betwee pump barre/pump

‘over and housing,

‘A number of semi-ceula shims are inserted between the top cover and

the pump housing. 8y removing o inserting such shims, the pump barrel

Can be sight lowered oF raised in relation tothe plunger, ana in nis

‘way the inal moment of fue ol injection into the engine cylinder can

be acjustes, andthe maximum, combustion pressure thus changed.

Refer to Volume Il, Chapter 908, regarding adjustment ofthe maxamum

‘combustion pressure.

\iTsype tue pumps:

‘The pump bare is guided a the top and battom ot the pumnp housing

Low ction sealing fings are fited in grooves inthe barel to seal be:

‘ween barrel and rousing. The Barcel is provides with a dain bore be-

{ween the sealing rings atthe lower end,

‘The pump barre has a threaded lower end wich fits into the internal

threads of the timing gude

‘The timing guide has a gear rim to mesh with the upper toothed rack at

the base of tne pump hovsing. The gear rim and toothed rack are marked

ith ines enabling the pars tobe positioned correct ater disassembly

‘The toothed racks inked to a serve-ar cylinder which ie controlled m

chanically or electronicaly in elation to the engine load The position of

the upper toothed rack cetermines the verical postion of the Darel rel-

aive to the plunger through the teased connection,

In this manner the initia! moment of uel ol injection into the cylinder can

be agusied by @ servoair eyinder

‘The pump barrel is prevented trom turing by a guide Screw mounted in

the pump housing

In the top cover of th sump, a puncture vaive is ited, The puncture

valve consists ofa piston which communicates wit the contol alr sys-

tem o the engin. nthe event af actuation of the shut-down system,

land when STOP is actvated, compressed ait supplied tothe top of

the piston, causing the piston wy pin io be pressed downward and keep

the suction valve inthe open poston. Ths wl puneture’ tne ol flow to

the fue valve, As ong ae the puncte valve i activate, the fue ols

reluined through bores fe the pump heusing, and no injection takes

place.

nen retring to his fxt, please quote Description AB00%0 Eatin 0001

Pry

MAN Baw

Fuel Ol Injection

‘Shock absorber

Fuel Pump

‘Actuating Gear

Fuel Oil High-

Pressure Pipes

Fuel Ol! Leakage

Alarm

8:

Description

Engine Types 35-98MC =~

During the suction stroke, the springfoaded suction valve opens and the

dalvery chamber is iled wih ol. As Soon as the plunger has coveres

the cut-off holes during ts upward movement inthe pump barrel, the in-

[ection commences through the fuel valves. Th injection wil last unt

the cutoff holes are uncovered bythe oblique cut-off edges ofthe plung-

€,fllowing which the os forced though two miled groves a the side

‘ofthe plunger and out trough the cutoff oles ofthe barrel during the

Fest ofthe delivery stroke.

{shock absorber is installed on each pump hovsing or inthe main fuel

pipe to take up pressure variations.

‘The camshaft housing contains the fuel pump and exhaust valve acti

ating gear for each eyinder,

‘Tho uel pump is actuated by a camon the camshall. The movement is

‘wansmited through the roller gues tothe plunger in the barrel of the

pump housing which ~ through ie high-pressure pipes ~ is connected

‘with the fuel valves on the cylinder cover.

Reversible engines:

“The roler guide of each‘uel pump incorporates an angular dsplaceable

reversing lnk

Raversing is achieved by shifting the roller inthe fuel pump drive mech:

nism at each eynder. The ik connecting the raller guide and role ie

Provided with a eversing arm, and a plot fs mounted at the top end of

the reversing am. The pivot tavels ina reversing guide connected to

an air cylinder. The link is se.locking in ther the AHEAD oF ASTERN po-

Sion withcut the sia of exteral forces, Each cylinder is reversed ind

vidual, and the reversing mechanism is activated by compressed ait

‘Tho ravrsing arrangement may incorporate a damper in order to reduce

the mechanical stresses.

Alhigh-pressure pipes inthe system are provided wih a protective outer

Pipe. The space between the pipe and the protective outer pipe commu-

iates through bores inthe union nipples witha dain bore Inthe pump

top cover.

‘uel ol leakage alarm is required for Unattended Machinery Spaces,

ows.

35.966

Each fuel pump is, via dain pipes, connected to @ common drain tank,

which incorporates a level swch, The drain tank i also equipped with

fan overiow pip, which has a small drain bore below, whereby ol from

Small leakages can be drained tothe oulet, without actuating the level

‘wth

len referring otis te please vote Desertion 490030 Eaton 0001 Page (4)

WS

Description

‘90030-0001

Fuel Vaive

Funetioning

Page 444)

ry

Engine Types 35-98MC AN BBW

Inthe event of pipe fractures or maor leakages in the system, the above

‘mentioned bore wil nol be large enough ta allow the increased oll quan-

Ii to pass, andthe ol level the drain tank will ge un reaches the

level ofthe overtow pipe. The rising ok level wil cause the level switch

to set off an alarm,

s0.90MC:

Altenatvey to the common drain tank, the drain pipes on 50-88MC en-

fines can Be connected to a diaphragm valve, which sets off an alarm

‘and actvaies the punctute valve in order to stop tne Wel eil Pow rom

the pertaining pump

(On 60-906 engines, whien ate provided with pneumatcally cperated

{ual pump role guide iting gear, automatic acvaton of tne iting gear

by the daphragm valve can be arranged inorder to sop the uel el ow

{tom the pertaining pump.

‘The fuel valve consists ofa valve head and a valve housing. Fitted within

the valve housing isa non-return valve and a spindle and spindle guide

win a pressure spring, and a nozzle

‘Te spindle may be provided with a cutoff slide. When the fuel valve is

{ite inthe eyinder cover, the valve parts are tightened together bythe

pressure Irom the securing nuts

‘The functioning ofthe tel valve Isa follows:

“The electrical fet ol primary pump circulates preheated ol through the

{uel pump and fuel valve. The fuel ol passes through the ful valve, lea

Ing through a creation bore andthe reluin oll pipe on the valve head

‘When the pressure atthe begining of the Tuel pump’s

has

ery stroke

ached the predetermined pressure, he circulating bores is closed.

\inen the pressure has reacted the predetermined opening value for the

{uel valve, the spinde will be Hed and ol injected through the nazzle

into the engine eylinder

‘On completion of the ful purp's delivery stroke, the valve spindle ie

pressed against its seat and injection now ceases. Then the circulating

bore is uncovered, and oll starts to recrculate through the valve.

When rofeng to his text please quote DeserptionAB0080 Eston C001

——

Plate 90901-0203

Een) Fuel Pump

ed

Page 12)

When rforing to his page, please quote Pate Peds Eaton C203

Plate 90901-0203

Fuel Pump

es

‘tem Description

tem Description

ov

519

stud

Nut

Dise

Phug

Packing

lug serow

Guide pin

Guide bushing

Plug serow

Toothed bar

shim

Pump housing

Guide pin

FRogulating guide

Packing

hug scrow

Stoatball,

Screw

Screw

Sealing ing

Backup ring

Plinger

Union

Point

Fottring

“Top cover

Guida pin

Sealingring

Back-up ring

Sealing

Pump barel

Nut

Rostiction pg

Serew

Screw

Sealing ting

Sealing ring

‘Spring

Housing

Sealing ring

Serew

Pug

Air piston

Sealing ing

Housing

Sealingring

Conical ring in 22

Cone

Spring

oe

mm

7

mm

Spindle

Housing

Pum bare, compote

‘Pump bare ane fp cover, complete

Puncture valve, completa

‘Suction valve, complete

Combined puncture and sucton valve,

complete

Me

Pd mn

HARES Fuc! Pump Gear ate 90902-116

‘SSOMC-C (

Plate 90902-116 Fuel Pump Gear

ar

[tem

No

Part Desciation

tom

Part Description

012

028

036

48

061

073

85

097

107

120

148

156

181

193

215

227

240

252

266

276

288

323

335

347

350

360

372

34

396

a8

431

443

455

467

479

492

514

525

538

551

563

587

599

609

610

522

834

66

67

Fuck pn ee oid, compete

Shatin or ink

Ee

5

Stop soon

see

Bushing

Dre

Bhatia or roter

ican

st sae

Pole gle

Bushing

Pin

trv

Pin °

tie pin

tis Bock

Seren

tice pin

Bushing

Ftange

Sus

Sealing bush

Bushing for raler guide

Nut

Cap

Settoekng nut

Serew

Serpe ng, axl

Scraper eng

Flange

oer tor srapr

Locking wire fern

Seow

Nat

Pimp base

Packing

Packeg

cover

Screw

Dee

Sts

Stas

Sprig, internal

Spring extrnal

Dee

Die

Seating ring

680_| Seltiocking nut

“er

Plate 90905-12 Reversing Mechanism

Tom = tat

ma Part Deseritor i Part Description

019 | Shatt

a

tee | Disenco pe

Oa. Saioong nt

oie [oun

tee [Siow

or |eover

403 |Saew

8 |r

12r | Pange oa pina

150 |ovotang meta, compete

‘82 |Seew

jee [acm

128 | iner

2 [See

2 |nen

235 | Resting socket

a7 [Balan

259 non

(Ee.

Fuel Valve

Pry

ed

Plate 90910-0145

When refering to this page,please quote Pate 90910 Eaton 0145,

CBr

Plate 90910-0145, Fuel Valve

Hem item ce

PS ltem Description ra em Descriptio

016 Thrust pece

041 Cutoft shat

053 Spindle guide

065 | Nozzle

077 | Spindle guide, compete

80 | O-ring

080 | Holder, complete

100 | Guide pin

112. | Union nut

124 | Ong

148 | o-ring

151 | Vale head

173. | Guide pin

185. | spring|

197 | Non-return vate, complete

219 | Thrust spine

220 | spring

232 | Spring guide

244 | Thrust foot

950° | Dise

* Optional extras

|__| optional extras

“Ze

Er

ery Meh-Pressure Pipes Plate 90913-97

‘SEOMO-C

Pinte 90919-97 High-Pressure Pipes

ee Part Description ne Part Description

012 | High-pressure pipe, compote

(036 | Thrust bushing

(088 | Union nipple

061 | Oxing

(073 | Union out

107 | Flexible hose, complete

120 [High-pressure pipe

382 | Union nipple

144 lovrng

168 High-pressure pipe, complate

203 | High-pressure pipe

(24

Prey)

M Fuel Oil System

fd I syst Plate 0918.49

‘S50MC-C

Plate 0914-43, Fuel Oil System

(255

Tem

a Part Daseripton

tom

No.

Part Deseripion

218 | Ratu ol sip, Las

031 |Contal aiepipe,

043 Pipe, L650

055 | Fuel of inet pipe

078 | Retum ol pipe, L=600

080 | Retumn oi pipe, L=1050

(082 |Bal vaio

102 | Fuel of inlt pine

(£6

Pry

HORII Fol Oil System Plate 89914.24

'S5OMC-C

oon |

102

s

Plate s0914-48 Fuel Oll System

Tern Tem

re Part Description fe Part Description

018 | Retum ot pipe

031 | Contol air pipe, L-800

042 | Pipe

067 | Fuol ol init pipe

090 | Retum oil pipe

102 | Rotum oll pipe

114 | Ball valve

126 | Fuel alinet pipe

Prey

HOOP Fe! Oil Systom - Details Plate sosts-24

‘SSOMC-C C

Plate 90815-24 Fuel oil System - Details

cried:

tom

No.

Part Description

tem

No.

Patt Description

013

025

07

50

062

086

108

21

133

145

169

182

196

216

241

253

265

277

269

230

300

312

328

348

61

373

305

297

407

420

Oring

Piston

Spring

Cup point screw

Nut

Oxing

Housing

Valve housing

Spring que

Valve cover

[Over fow valve, complete

Level switch

Drain box

Drain box, complete

Packing

Serew

Wearing ring

Sealing ring

Packing

Lock washer

Nut

stus

Spring guide

Housing

Piston

Spring

Stud

Flange

Soring

Shock absorber, complete

INDEX

730

CYLINDER COVER

PISTON WITH ROD AND STUFFING BOX

CYLINDER LINER AND

CYLINDER LUBRICATION

‘CROSSHEAD WITH CONNECTING ROD

CRANKSHAFT, THRUST BEARING

‘AND TURNING GEAR

MECHANICAL CONTROL GEAR

‘STARTING AIR COMPONENTS

EXHAUST VALVE,

FUEL OIL SYSTEM

‘TURBOCHARGER SYSTEM

SAFETY EQUIPMENT

ASSEMBLY OF LARGE PARTS

Air System of Engine

(Regarding the turbocharger, see the

producer's special instnctons)

‘The engine is supplied with scavenge air

from one turbocharger mounted at the aft

feng ofthe engine.

Alternatively, one or two turbochargers may

be located on the exhaust side,

The angine exhaust gas drives the turbine

wheel of the turbocharger and, through &

common shaft, the turbine whee! dives the

comprassor wheel.

The compressor draws alr trom the engine

room, through the air fiters. From the com

‘pressor outlot, the alr passes through te

Charging air pipe to the charging alr cooler

(Plate $1005) where the air is cooled down,

The charging air pipe, with compensator, Is

Jngulated and can be clad internally with @

‘sound-absorbing material

The air cooler Is designed to separate con-

2

ao a

= - :

278 z

a i

a = =

a

A in

Pe-90216 181d

aay

(63

Plate 91206-74 Chain Wheel Frame with Covers

tom | tem

he Part Description a Part Description

023 | Packing

095 | Flange

047 |stue

059 |Nut

072 | Seow

096 [Stud

118 [Cover

143. | Guide pin

167 |Cover

179 |Seraw

192 | stud

214 | stu

238 |Scrow

251 | Chain whee) frame, upper

275 | Stud

287 | Distance pipe, L-25

299 |Nut

309 | Screw

322 [Stud

394 | Distance pipe, L-70

4s | Not

art [Plug

‘205 [Distance pipe, L-s0

4405. | Scraw

429 [Locking wie

430 | Screw

454 |Gaskot

486 | Cover

491 | Top guara

501 | Gasket

513 | Cover

525 | Screw

849 |Sccow

882 | Screw

574 | Rail for sealing

586 | Packing, rather

608 | Distance pipe, Lass

621 | Guide pin

4g

Pry

PROPIN Arrangement of Piston Cooling

‘S5OMC-C

on

023 B-B

van

Plate 91207-61

es

Plate 91207-81 Arrangement of Piston Cooling

ten _ tem an Destton

017 | Screw

029 | Locking wire

042 | Slotted pipe

058 | Screw

066. | Settlocking nut

078 | Washer

091 | Drain pine

119 {Sight glass

125 | Drain box

149 [Bracket

150 |Screw

174 | Clamp

186 | Settiocking nut

Bedplate Plate 91210-108,

Plate 91210-108 Bedplate

Cer

tem

No.

Part Deseription

a5

Part Description

013

097

050

ose

086

098

108

121

145,

187

Nut

‘Stud

‘Sorow

Bedplate

Main bearing cap

Spring pin

Main Dearing, upper shell

Main bearing, lower shell

Screw

Grate

Plate 91211-55 Axial Vibration Damper

“er

tem

No.

Part Desctiation

tem

No.

Part Description

ong

020

048

056

08

093

403

wer

139

140

164

176

308

an

235

259

260

2re

Serna

Sor

Serow

Fetticson for damper

Pestrin for damger

esto fo camper

Seren

seat in 22

Oi seat 22

Side pin

Nut

Nut

Sua

Stud

Ail vibration damper housing,

complete

Damper housing, upper part

‘Suse in

Damper housing, lower par

170

Perr

PROPIA Holding-Down Bolts and End-Chock Bolts Plate 9125-50

‘SSOMC-C.

098

08s:

"17

SSSSMT ESS

ZA ize

SIGS

166

178

“7

Plate 91215-50 Holding-Down Bolts and End-Chock Bolts

Item 7] Item

te art Desciton te an Destoton

010 | Grub screw

022 | Liner, pot side

(034 | Liner, starboord side

048 | Liner

058. | Spherical washor

071 | Spherical washer

083 Nut

095. | Protecting cap

117 |oistance pipe

129 | Epoxy chocks

180 | Spherical washer

142. | Spherieal nut

154 |Holaing down

188. | Nur

178 Stud for end chock bolt, MS2xS

201 | Protecting cap

MBx8

Goleviation of Top Grazing Length

edie iduat fangth

In order to determinate #

UnoP Eaen Pop ar aeing bore

Wren the length

Deisactartatag. angel

80 Si parme Fon tne engine

= 60 BF 5e08'S°Gn the engine

gigegente tine

ane

+

cantee tine on

oT

j

Egy

‘ioe

ove

+

:

-

‘io [as [o _s50v6-0 BF (02 | ABB

Ie ae eet

w

eygane

‘8

‘Ebelael aes

= pe

baton

thi

Bolts tor top bracing are to be tightened by meons of

S°torque wranen: :

The bolts ot, the engine sige are to be tightened to

476 Nin. ‘ine bolte'at the mul! eet are tovbe Trantened

10°18 Ne

When during th

teiol trip the

ures the two" bot

Peis praceddra 's Vol be cor

top beecing:

Moke sure thot the veoms ore supported in the vertical

Traction diving tnis operat ion

Ihe tightening should be checked o

Ghees fh

dette ble eae Praaee gs beige

TR React ae at i Sat aes

1° tha engin

bracing might become ineffective r

2 Piet tgang 1ghte

enecking

| -ssowe/ssone-c [31 (01 | ABN

EEEETE| 324618 TOP_BRACING INSTRUCTIONS [A14-166630-4]

ea

ee

Tronsverse top brocing

Forces from engine ond

Engine bore { o?] P| inant cogs say

ENON

3 248 230

30 209 210

80. 165} 190

©): Force per brocin

70 126 {170 ot specified number

60. 93-[ 140)

50 Sa 170] b): Minimum horizonte!

46. 351110 rigidity a

a2 <5 {100 Tonto! the Tops

35 321-85

brocing is required.

Fe] JPR efirtemect oe a war

Saree q

=f 6

nao +

oH 3|

+H A

oH i

a ior ent o

Ka-syucyc-c__ [81 (01 | ABONIRAD |:

384616 Top bracing-forces 14-166600-8

Ses SUREECST

N

B. OVERSEAS NETWORK

178

rey

OVERSEAS NETWORK

SEUNG HONG KONG.

om No, 806 1 Tower, Landmark Sp ‘Sutue 5201-2, Great Eagl Carte, 28 Hatour

{Nr Dengsartusn Road Chaoyang Dist Fad, Wancha, Hong Kong

Satng 100008, Cara Tot 85231065600 Fax 852-8106 552/605

Yar ee 1065060677-8

Fax 06 1OESOO ESSA HOUSTON

BEUING 100 Breas, Sut 110, Park Ten Contr

Houston, Towa 77086 USA

Being Hyun traheng Conston Marinaty al .201.578.7087 | Fax, 1281-578 0017

es He 2 a Cngen Fe

Tot 85.1088 83447994795 LONDON

Fax. 00 1a 1950479 Fi, 8 Marrs House 1 Hammers Grove