Professional Documents

Culture Documents

Theory, Timber

Theory, Timber

Uploaded by

hazel0 ratings0% found this document useful (0 votes)

10 views7 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views7 pagesTheory, Timber

Theory, Timber

Uploaded by

hazelCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

THEORY OF STRUCTURES

DETERMINACY OF STRUCTURES

>

»

2

»

>

>

FI

r<3S — unstable structure

r=3S determinate (either unstable or stable structure)

r>3S indeterminate, stable structure at n" degree

SSES:

bér<2j unstable structures

b+r = 2j determinate (either unstable or stable structure)

b+r>2j Indeterrinate, stable structure at n"" degree

Where; r= sum of reactions, internal roller, hinge or pin, ete.

$ = total number of segments

b = total number of bars

J = total number of joints (including support joints)

DETERMINATE STRUCTURES FOR BEAM

SPANDREL AREA AND CENTROID LOCATION:

bh

Area An aq ¥

b

xlocation Xo" ee

ylocation yq= fi*4 (ny

Where: n#-2 moment applied n=0 uniform load

n#.-1 concentrated load n=1 triangular load

DOUBLE INTEGRATION METHOD:

>

Moment, M = y” Syr= SF onrey

> Slope, 0 = y’ = dy/dx eo) = J Ey =f (Mx+ 1)

2

> Deflection, 5=y EN) * Elly) = (M s + C1x + C2)

>» Boundary Conditions (solve C, and C2):

4. Deflection, 5 = y = 0 at the SUPPORT.

2. Slope, 6 = y’ = dy/dx = 0 at the FIXED SUPPORT,

AREA MOMENT METHOD:

>» THEOREM I:

> THEOREM Il;

El(8as) * Areaas

El(tes) * Areaas (Xa)

El(twa) * Areaas (Xe)

CONJUGATE BEAM METHOD:

» The SHEAR OF THE CONJUGATE BEAM (or FICTITIOUS

BEAM) is equal to the SLOPE of the actual beam,

» The MOMENT OF THE CONJUGATE BEAM is equal to the

DEFLECTION of the actual beam.

INDETERMINATE STRUCTURES FOR BEAM

MOMENT DISTRIBUTION METHOD:

> Beam Stiffness, K:

1. Absolute K=4 EI/L

2. RelativeKeI/L

Modified K = For continuous beams with hinge or roller ends, the

final moment at that end is ZERO. The distribution of moment

become easier if we multiply the beam stiffness K of the span

containing that support by 3/4, which would eliminate any

further distribution of moment on that support, Do not do this

for fix-end support,

K

oF=—

xK

1, DF = 0 for Fixed End Support.

2, DF = 1 for Hinge or Roller End Support.

>» Distribution Factor:

» © T. .

4, FEMas = -Pab?/ 1?

FEMea = +Patb / L?

2. FEMan = -wh?/12

FEMea = +wh?/12

3, FEMas = -wh?/30

FEMpa = wl? / 20

Pab?

For any loading: FEMs.=—~ [ Te

2,

FEMsa= + f [Pe

THREE MOMENT EQUATION METHOD:

Mala + 2Mp(L1tL2) + McLo + (6Aa/L)s + (BAD/L)2 = GEI (ha/Lrthcfl.2)

» Ifthere’s no settlement, ha = he = 0, Therefore,

Maka + 2Me(LytLa) + McL2 + (6Aall.), + (GAb/L)2 = 0

4. 6AalL = P(a)(L?- a4 /L

BAb/L = P(b)(L% b4)/ L

2 6Aa/L=wh'/4

ADIL = wh / 4

3. 6Aa/L = SwL?/ 60

GAbIL = 7wL? / 60

For any Joadinag: oR a J [Pa A “y

6Ab i [= by

i L

SUPER-POSITION (or SUPERIMPOSED) METHOD:

>» Formulating equations and/or relationships using deflection

formulas.

>» DEFLECTION AT FREE-END OF CANTILEVER BEAM

EI(6)= aie

A. Moment applied (n # -2) = ENS) # ML2/2

B. Concentrated load (n = -1) — ENS) = PL?/3

CG, Uniform joad (n= 0) — ENS) # wh) 8

D. Triangular load (n = 1) + ENS) = wit) 30

> FLECT! TT ID-SPAN OF :

* A. SIMPLY SUPPORTED BEAM:

a. Uniformly loaded + EA(6) = 6wL4 / 334

b. Concentrated loads at

quarter points of beam + BIS) = 19PL?/ 384

c. Concentrated loads at

middle thirde of beam « ENS) = 23PL?/ 648

d. Single concentrated

load at the midspan + ENG) = PL? /48

B. FIXED-ENDED BEAM:

a. Uniformly loaded + ENS) = wht / 384

b. Concentrated loads at

quarter points of beam « BI(8) = PL? /96

c. Concentrated loads at

middle thirds of beam + EMS) = SPL?/ 648

d. Single concentrated

load at the midspan « ENG) * PL? /192

> MAXIMUM MOMENT OF A SINGLE SPAN BEAM:

A. AT MIDSPAN OF SIMPLY SUPPORTED BEAM:

a. Uniformly loaded Minox = WL? 8

b. Concentrated loads at

quarter points of beam Minx * PL / 2

c. Concentrated loads at

Middle thirds of beam + Minox * PL / 3

d. Single concentrated

load at the midspan Min ® PL / 4

B. AT SUPPORT OF FIXED-ENDED BEAM:

a, Uniformly loaded + Minox WL? 42

b, Concentrated loads at

quarter points of beam + Max ® 6PL / 16

c. Concentrated loads at

Middle thirds of beam = Mm 2PL/9

d, Single concentrated

load at the midspan = Max * PL/8

ROLLER SUPPORT OF A PROPPED BEAM:

aa

Where: P= ydx

asx

FRAME STRUCTURES

» Frame Structure Problems can be best solved also using

Three Moment Equations and Moment Distribution Method!

VIRTUAL WORK METHOD FOR TRUSSES

» Truss Deflection or Displacements:

‘SUL.

ABy RE. « deflection due to actual loads

UAL

Gey TE. « deflection due to unit load

» $tress of the Redundant Member (for indeterminate truss):

P, _ 1unit force

ae

PORTAL AND CANTILEVER METHOD

>» PORTAL METHOD: *

@. The frame Is divided into independent portals.

b. Point of inflection occurs at mid-height of each column.

¢. Point of inflection occurs at mid-span of each beam or girder.

4. Horizontal shear at a given story is distributed among the

columns such that each interlor column resists twice as

much as each exterior column.

» GANTILEVER METHOD: |

@. Point of inflection occurs at the mid-span of each beam or

girder,

b. Point of inflection occurs at mid-height of each column.

¢. The axial force in each column Is directly proportional to its

distance from the center of gravity of all columns on that

level.

INFLUENCE DIAGRAMS

» INFLUENCE DIAGRAM FOR REACTION * formulate equation by

assuming a unit load of variable distance “x” from left end of the

beam. The solver must identify the critical distances and obtain

their corresponding ordinates of influence diagram.

>» INFLUENCE DIAGRAM FOR SHEAR = isolate the beam from left

énd to the point that requires influence diagram for shear. Obtain

‘the corresponding shear reactions of the point considered after

applying a unit load at all critical points. For the point in

consideration, obtain the shear ordinate of influence diagram by

applying a unit load on the nearest left and nearest right of the

point. Note that the point considered for shear has abrupt change

in the ordinate of Its influence diagram.

>» INELUENCE DIAGRAM FOR MOMENT = solve for the moment

values of the beam subject for shear. To avoid confusion with

regards to the sign (either + or -), it is advisable to draw the shear

and moment diagram of each conditions. Mostly, the result of

influence diagram for shear and moment at the point considered is

opposite in sign!

END OF THEORY OF STRUCTURES FORMULAS **

TIMBER DESIGN (2010 NSCP) |

BENDING AND SHEARING STRESS

> BENDING STRESS f= me)

For rectangular section: fo,max = ul

ig! i fo, rma pay?

> HORIZONTAL SHEAR STRESS ie

3V_4.6V

For rectangular section: Frame te a

ANALYSIS OF PURLINS

Pufwind toad)

P (sin 6)

> Wind Load (Duchemin’s Formula) Pr® ce

Wind Pressure (in kPa): P = 0,0000473(v)?

V = velocity (In kph)

Where; Pitch « 2 Tang = t= at

>» Bending stress relationships fo ™ foqny + Foyt)

>» Shearing stress relationships 7 = fugy? + fun?

HORIZONTAL SHEAR IN NOTCHED BEAMS

» Horizontal shear force for rectangular section

2

Vs 3 (Fvyb)(h)

as (ad + notched at tension side

2 d= e(dnotcH/d') < notched at compression side

Where: a?" d= duotcn

d = depth of the rectangular section

@ = distance notch extends Inside the inner edge of

the support (limitation: ed’)

ADJUSTMENTS FOR THE ALLOWABLE STRESSES OF

BEAMS AND COLUMNS IN TIMBER DESIGN

A, SIZE FACTOR ADJUSTMENTS FOR BEAMS

19

cre (*) Ifd>300 mm

Fy’ = Fo(Cr) + Adjusted allowable bending stress

NOTES:

41, The width of beam, b is 125mm or thicker

2, For circular beam (greater than 340mm diameter) and

square beams (300mm or larger) loaded in the plane

diagonal, use equivalent square beam of equal cross-

sectional area,

3. Size factor adjustments are cumulative with form factor

adjustments, except for lumber I-beams and box beams,

but are not cumulative with the slenderness factor

adjustments,

B. SLENDERNESS FACTOR ADJUSTMENT FOR BEAMS

cae

ee

CONDITIONS:

a, IfGg<10 Fp’ ® Fp + No adjustments!

E

b. If10 60!

TYPE OF BEAM SPAN AND ed

NATURE OF LOAD . LENGTH, Le

Single-span beam, load concentrated at the Senter 161tu

Single-span beam, uniformly distributed load 1.92tu

Single-span beam, equal end moments 1.84tu

Cantilever bear, load concentrated at unsupported end 1.69tu

Cantilever beam, uniformly distributed load 1,06tu

Cantilever beam, uniformly distributed load with

concentrated load ai cantilever end 1.69

Single-span or cantilever beam, any other load 192tu

ty = unsupported length of beam, mm

C. SLENDERNESS FACTOR ADJUSTMENT FOR COLUMNS

Slenderness Ratio, SR * Ke(L) /d

Where: L = unsupported length of the column

d= depth of the column

Ky = buckling factor obtained in the table below:

!

Buckling Modes

Design buakling factor, Ke

owhen ideal conditions are

elie 0 | 20 | 30 | 2m | a |

| Rotstion fixed, tranalation fixed

Rotations irae, translation flxed

ondition code ¥

Ete od tp | Rotation tixed, translation tree

@ | Rotation tree, translation tree

User Note: Le = Ko(L)

COLUMN CLASSIFICATIONS:

4. Simple Solid-Wood Columns ~ simple column consist of a

single piece or of pieces properly glued together to form a

single member.

K

Spaced Column, Connector Joined ~ spaced columns are

formed of two or more individual members with thelr

longitudinal axes parallel, separated at the ends and middle

points of their length by blocking and joined at the ends by

timber connectors capable of developing the required shear

resistance,

3. Built-up Columns ~ built-up columns, other than connector-

joined spaced columns and glued-laminated columns, shall

not be designed as simple solid columns,

4, Glulam Columns — Glulam columns shall be composed of at

least four laminations, with thelr grains essentially parallel.

Foe

on Foe

often [Ata? oo

Footsie Mar) pe | os

c

20.80 — for sawn lumber.

= 0,86 — for round timber plles.

Ken(E) ;

Fer = (eRe = Euler's critical buckling stress for columns

FG = tabulated compression design values multiplied by all

of the applicable adjustment factors.

Kes 30,30 — for visually graded lumber,

= 0,418 for products such as machine stress-rated

sawn lumber.

TAPERED COLUMNS

hep * Grin + (noe Chin) a~0.18 (1~ $!)]

dmin = the minimum dimension, d, for that face of the column

dinax =the maximum dimension, d, for that face of the column

Support Condition:

Large end fixed, small end unsupported: a=0.70

Small end fixed, large end unsupported: a=030

Both ends simply supported;

Tapered toward one end a=0.50,

Tapered toward both ends a=0.70

tl onditions:

1

+ Grp * Amin + 3 max = min)

The design of a column of round cross-section shall be based on the design

calculations for a square column of the same cross-sectional area having the

same degree of taper.

COMBINED STRESSES IN TIMBER DESIGN

A. FLEXURE AND AXIAL TENSION

te $10

Fr FL

and

= tabulated bending design value multiplied by all applicable

adjustment factors except bear stability factor, C..

= Fo(Co)(Cm)(Ci)(Cr)(Cx)(Ci) for Sawn lumber

= Fy(Co)(Cm)(C.)(Cv) for Glulam lumber

F,, = tabulated bending design value multiplied by all applicable

adjustment factors except volume factor, Cv.

® Fy(Co)(Gm(C1)(Cr)(Gr)(Cx(Gi) for Sawn lumber

® Fe(Co)(Cm)(C,)(C.) for Glularn lumber

Fy = allowable tension design value parallel to the grain

f = actual unit stress in tension parailal to the grain

fp = actual unit stress for extrame fiber in bending

B. FLEXURE AND AXIAL COMPRESSION

t fia

ot eee

Fo Rost)

Je Leon Limitation: 05/5 1.0

K= 0,674

ctio Ti Is

Cp = Load duration factor Ci = Inclising factor

Cm = Wet service factor C= Temperature factor

Cr ® Size factor Cr = Repetitive member factor

C; = Form factor Cp = Column stability factor

Cm = Flat use factor C. = Beam stability factor

Cy = Support factor Cy = Volume factor

COMPRESSION AT AN ANGLE TO GRAIN

> HAKINSON'S FORMULA:

Fi Fey Fes)

"Fey (Bin 8)? + Feu. (cos 0)?

Allowable values Fc shall be adjusted for duration of load before

using Hakinson’s Equation. Values of Fn and Fo. are not subjected

to duration of load modifications.

COMPOSITE AND LAMINATED SECTIONS

>» imply transform the given composite section into an

equivalent homologous section using their modular (or

modulus) ratio, n to be multiplied to their corresponding

width,

> In laminated sections, the laminated surface (or the surface to

be joined) usually is said to be the critical surface for

horizontal shear, thus given more attention.

+ END OF TIMBER DESIGN FORMULAS **

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hydraulics Module CDocument5 pagesHydraulics Module ChazelNo ratings yet

- HYDRAUGEODocument15 pagesHYDRAUGEOhazelNo ratings yet

- Answer: 250Mm, 0.74mpa, 2.75M: Reinforced Concrete - Lecture03 - August2019Document5 pagesAnswer: 250Mm, 0.74mpa, 2.75M: Reinforced Concrete - Lecture03 - August2019hazelNo ratings yet

- Surveying 2019bDocument30 pagesSurveying 2019bhazel100% (1)

- Surveying Lec2Document6 pagesSurveying Lec2hazelNo ratings yet

- Welded Simple Connection: Based On Block Shear Capacity ofDocument12 pagesWelded Simple Connection: Based On Block Shear Capacity ofhazelNo ratings yet

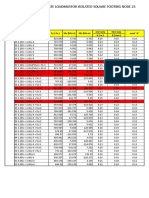

- Tabulation of Ultimate Loadingsfor Isolated Square Footing Node 23Document12 pagesTabulation of Ultimate Loadingsfor Isolated Square Footing Node 23hazelNo ratings yet

- IEEE CE Sample Lightweight Concrete Bricks Produced From Industrial and Agricultural Solid WasteDocument5 pagesIEEE CE Sample Lightweight Concrete Bricks Produced From Industrial and Agricultural Solid WastehazelNo ratings yet

- Fluids Quiz Questions PDFDocument10 pagesFluids Quiz Questions PDFhazelNo ratings yet

- 17lo-0074: Concreting of Mati-Tarragona Bypass Road (Lucatan-Tagabakid Road), Including ConstructionDocument6 pages17lo-0074: Concreting of Mati-Tarragona Bypass Road (Lucatan-Tagabakid Road), Including ConstructionhazelNo ratings yet

- College of Engineering Education: Hon. Rolando T. TrajeraDocument2 pagesCollege of Engineering Education: Hon. Rolando T. TrajerahazelNo ratings yet