Professional Documents

Culture Documents

Dupont Ion Exchange Resins Preventing Silica Fouling of Weak Base Anion Resins

Dupont Ion Exchange Resins Preventing Silica Fouling of Weak Base Anion Resins

Uploaded by

jilujOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dupont Ion Exchange Resins Preventing Silica Fouling of Weak Base Anion Resins

Dupont Ion Exchange Resins Preventing Silica Fouling of Weak Base Anion Resins

Uploaded by

jilujCopyright:

Available Formats

Tech Fact

DuPont Ion Exchange Resins

Preventing Silica Fouling of Weak Base Anion Resins

Silica Fouling Occasionally, some plants experience weak base anion resin which clumps together

due to silica polymerization. Common operating symptoms include short run

length, increased pressure drop and high WBA effluent conductivity during the run

(due to channeling), and the inability to backwash the bed. When the vessel is

opened and samples are taken, the resin beads will be clumped together and a

gummy substance may even be present. This document is an explanation of the

most probable cause, and ideas on how to correct the problem.

Most demineralizers that use weak base anion resins for water treatment also use

strong base anion resins. In order to minimize the amount of caustic used to

regenerate the resins, a technique known as thoroughfare regeneration is generally

used. Thoroughfare regeneration is the use of waste caustic from the SBA vessel to

regenerate the WBA resin. Since WBA resins regenerate very efficiently, even waste

caustic will return the resin to the free base form.

The primary concern with a thoroughfare regeneration is ensuring that most of the

impurities from the SBA resin are dumped to the drain before the thoroughfare

begins. If significant amounts of silica are present when the thoroughfare begins, it

may polymerize upon contacting the acidic WBA resin, leading to the problems

described above.

First, the problem needs to be corrected. Generally, the first third of the regenerant

from the SBA vessel is discarded to the drain. A variety of changes in SBA operating

conditions may have caused the silica peak to shift, including changes in caustic

concentration, caustic temperature, or installation of new SBA resin. Correcting the

situation is usually accomplished by discarding additional caustic to the drain before

the thoroughfare regeneration begins. To be confident that the right amount is

discarded, an elution study can be performed. Using a two step caustic injection, for

example 2% and 4% NaOH, gives another alternative to dilute the silica peak.

Layered bed configurations with SBA and WBA resins in the same vessel generally

operate with lower caustic concentrations and more uniform flow rates and so they

tend to be less prone to silica precipitation.

Finally, the weak base anion resin needs to be cleaned. A series of hot caustic soaks

should remove most of the polymerized silica and allow continued operation. In

some extreme cases, the weak base anion resin may need to be replaced.

Note that WBA resin clumping can also be caused by organics build-up on the resin

or a combination of organics and silica.

Page 1 of 2 Form No. 45-D01097-en, Rev. 1

November 2019

Have a question? Contact us at: All information set forth herein is for informational purposes only. This information is general information and may differ from that

based on actual conditions. Customer is responsible for determining whether products and the information in this document are

www.dupont.com/water/contact-us

appropriate for Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with

applicable laws and other government enactments. The product shown in this literature may not be available for sale and/or

available in all geographies where DuPont is represented. The claims made may not have been approved for use in all countries.

Please note that physical properties may vary depending on certain conditions and while operating conditions stated in this

document are intended to lengthen product lifespan and/or improve product performance, it will ultimately depend on actual

circumstances and is in no event a guarantee of achieving any specific results. DuPont assumes no obligation or liability for the

information in this document. References to “DuPont” or the “Company” mean the DuPont legal entity selling the products to

Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. No freedom from infringement of any patent or

trademark owned by DuPont or others is to be inferred.

DuPont™, the DuPont Oval Logo, and all trademarks and service marks denoted with ™, ℠ or ® are owned by affiliates of

DuPont de Nemours Inc. unless otherwise noted. © 2020 DuPont.

Page 2 of 2 Form No. 45-D01097-en, Rev. 1

November 2019

You might also like

- BSDA - Guide To Good Bottled Water Standards - 2002Document66 pagesBSDA - Guide To Good Bottled Water Standards - 2002LMNAVANo ratings yet

- Irish Grammar BookDocument224 pagesIrish Grammar BookBarrio Arias David100% (12)

- Settleability Problems and Loss of Solids in the Activated Sludge ProcessFrom EverandSettleability Problems and Loss of Solids in the Activated Sludge ProcessNo ratings yet

- Balance StatementDocument5 pagesBalance StatementNayeem RiyazNo ratings yet

- VOC Compliant 2K PUR Coatings in Low ... - Bayercoatings - deDocument32 pagesVOC Compliant 2K PUR Coatings in Low ... - Bayercoatings - desriatul2006No ratings yet

- Planning For Health PromotionDocument55 pagesPlanning For Health Promotionsweetsai05No ratings yet

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- Section 5.1 Soap SticksDocument7 pagesSection 5.1 Soap SticksManuel ChNo ratings yet

- Galleon - September 2009 ExposureDocument14 pagesGalleon - September 2009 Exposuremarketfolly.comNo ratings yet

- Produced Water OverviewDocument86 pagesProduced Water Overviewsigit cahyonoNo ratings yet

- Drilling Fluids SelectionDocument16 pagesDrilling Fluids SelectionRashid Ali SheikhNo ratings yet

- S&P Based ETPDocument41 pagesS&P Based ETPamnoman17No ratings yet

- 7.operational Problems PDFDocument42 pages7.operational Problems PDFDeva VaraNo ratings yet

- BSP Camp-O-Ral GSP Encampment 2018 ProgramDocument3 pagesBSP Camp-O-Ral GSP Encampment 2018 ProgramJhun Bautista100% (10)

- Antiespumantes AshlandDocument28 pagesAntiespumantes AshlandEmilio TafurNo ratings yet

- Final Report On Meezan BankDocument72 pagesFinal Report On Meezan Bankmubasherkhan83% (6)

- Completion Fluid 2Document45 pagesCompletion Fluid 2Waled Fekry100% (2)

- Tata Full Corporate Offer (FCO) 7000++Document2 pagesTata Full Corporate Offer (FCO) 7000++Sharma Sanjeev KumarNo ratings yet

- Size CO Liquid: Technical InformationDocument0 pagesSize CO Liquid: Technical InformationMuhammad Aasim HassanNo ratings yet

- IER Operating Profiles TechFact 45 D01095 enDocument3 pagesIER Operating Profiles TechFact 45 D01095 enegyptian_scientistNo ratings yet

- Cuidado de La Recina LechosDocument3 pagesCuidado de La Recina LechosGustavo Ernesto Guridi RamosNo ratings yet

- Use of Concrete Admixtures in Self-Compacting Cementitious SystemsDocument45 pagesUse of Concrete Admixtures in Self-Compacting Cementitious SystemsAmmad AlizaiNo ratings yet

- 812 00353 01 Acumer 9210 Dispersant Polymer For Mineral Slurries TdsDocument5 pages812 00353 01 Acumer 9210 Dispersant Polymer For Mineral Slurries TdsAhmed ElgendyNo ratings yet

- Flocon 260Document2 pagesFlocon 260Mehri ImaniNo ratings yet

- FILMTEC™ Membranes Water Chemistry and Pretreatment: Scale ControlDocument2 pagesFILMTEC™ Membranes Water Chemistry and Pretreatment: Scale ControlAhsan HabibNo ratings yet

- Water Chemistry and Pretreatment Biological Fouling PreventionDocument3 pagesWater Chemistry and Pretreatment Biological Fouling PreventionAbdiel AlonsoNo ratings yet

- Biosolids Technology Fact Sheet: Gravity ThickeningDocument10 pagesBiosolids Technology Fact Sheet: Gravity ThickeningRahmi Arslan100% (1)

- Sika Bond LA SubmittalDocument17 pagesSika Bond LA SubmittalmkNo ratings yet

- 27 2957 01 Acusol Prime 1 PolymerDocument4 pages27 2957 01 Acusol Prime 1 Polymerdiana patricia rosero clavijoNo ratings yet

- Sikabond LaDocument3 pagesSikabond Laecc.trust.minaNo ratings yet

- Alphaflow Bind ItDocument2 pagesAlphaflow Bind ItJulio VechimNo ratings yet

- Operator Reference Sheet MathDocument5 pagesOperator Reference Sheet MathPrashant RukmangadNo ratings yet

- Dow Corning IE 2404 Emulsion Product Data 1127013Document2 pagesDow Corning IE 2404 Emulsion Product Data 1127013ShambhatiaNo ratings yet

- TDS-DOWSIL™ GP SHP 60 PlusDocument3 pagesTDS-DOWSIL™ GP SHP 60 Plus刘龙生No ratings yet

- Unit 2 SummaryDocument22 pagesUnit 2 SummaryPutu HermayaniNo ratings yet

- Sika Retarder LiquidDocument3 pagesSika Retarder LiquidSmári ValgarðssonNo ratings yet

- FILMTEC Membranes Water Chemistry and Pretreatment: Colloidal and Particulate Fouling PreventionDocument2 pagesFILMTEC Membranes Water Chemistry and Pretreatment: Colloidal and Particulate Fouling PreventionSandeep RazdanNo ratings yet

- Dowex Practical Guidelines LDocument8 pagesDowex Practical Guidelines LAyman FawzyNo ratings yet

- Us 2952639Document7 pagesUs 2952639khoiri 787No ratings yet

- Facile Preparation of Loess-Coated Membranes For Multifunctional Surfactant-Stabilized Oil-In-water Emulsion Separation - 149 - 2019Document10 pagesFacile Preparation of Loess-Coated Membranes For Multifunctional Surfactant-Stabilized Oil-In-water Emulsion Separation - 149 - 2019eng.ali.nomanNo ratings yet

- Silo - Tips - Problem Solving ForumDocument5 pagesSilo - Tips - Problem Solving ForumMax DraggerNo ratings yet

- Sudan III.1390Document2 pagesSudan III.1390Joko JokoNo ratings yet

- CompletionDocument62 pagesCompletionavanishNo ratings yet

- Is Your Sodium Zeolite Water Softener Resin in Good Condition?Document3 pagesIs Your Sodium Zeolite Water Softener Resin in Good Condition?nermeen ahmedNo ratings yet

- US2942991Document3 pagesUS2942991Kerem BNo ratings yet

- Advances in Functionalized Nanoparticles Based Drilling Inhibitors For Oil ProductionDocument12 pagesAdvances in Functionalized Nanoparticles Based Drilling Inhibitors For Oil ProductionMario Valentino DioNo ratings yet

- Pegamento para TuberiaDocument4 pagesPegamento para TuberiaJesus RoaNo ratings yet

- US UK Avista PDS Vitec 3000 FinalDocument1 pageUS UK Avista PDS Vitec 3000 FinalEmin MešićNo ratings yet

- Coagulation and FlocculationDocument8 pagesCoagulation and Flocculationgauravalok85No ratings yet

- StabilizeDocument4 pagesStabilizeARHNo ratings yet

- Operational Procedures: 7.05 Wellbore StabilityDocument4 pagesOperational Procedures: 7.05 Wellbore Stabilityciucalata88No ratings yet

- Sika Plastocrete-05.pt - enDocument2 pagesSika Plastocrete-05.pt - enarizqolmahbubNo ratings yet

- 0901 B 803808 EcadfDocument3 pages0901 B 803808 EcadfMohammad Doost MohammadiNo ratings yet

- Fecl3 CoagulationDocument8 pagesFecl3 Coagulationebin_thankachan1988No ratings yet

- Caustic Soda Solution (Naoh 50%)Document5 pagesCaustic Soda Solution (Naoh 50%)Nurhidayat71No ratings yet

- TDS-61 How To Prepare Aqueous Dispersions of Carbopol PDFDocument2 pagesTDS-61 How To Prepare Aqueous Dispersions of Carbopol PDFKirk BorromeoNo ratings yet

- 3y - Margraffy: April 9, 1968Document11 pages3y - Margraffy: April 9, 1968JorgeWashiHuamanChjutalliNo ratings yet

- Bolto (2009) - Crosslinked Poly (Vinyl Alcohol) MembranesDocument13 pagesBolto (2009) - Crosslinked Poly (Vinyl Alcohol) MembranesViraj EdirisingheNo ratings yet

- SPE 155123 TOTAL's Industrial Experience in Sea Water DesulfationDocument8 pagesSPE 155123 TOTAL's Industrial Experience in Sea Water DesulfationLê BìnhNo ratings yet

- Coagulation and Disinfection ManualDocument25 pagesCoagulation and Disinfection ManualOxfamNo ratings yet

- ACUSOL™ 420N Polymer ACUSOL™ 420NG Polymer: Features & BenefitsDocument4 pagesACUSOL™ 420N Polymer ACUSOL™ 420NG Polymer: Features & BenefitsNONo ratings yet

- 1 s2.0 S0141813019399428 MainDocument6 pages1 s2.0 S0141813019399428 Mainmohamed.alkadour96No ratings yet

- ATS 6 Water ResistingDocument3 pagesATS 6 Water ResistingGia GuallarNo ratings yet

- VapproVCI-749 ElectrolubeDocument2 pagesVapproVCI-749 ElectrolubeAbdulrehmanNo ratings yet

- Water Resisting (Waterproofing) Admixtures: Admixture Sheet - ATS 6Document3 pagesWater Resisting (Waterproofing) Admixtures: Admixture Sheet - ATS 6chandan paulNo ratings yet

- BFG Gas LineDocument12 pagesBFG Gas LinejilujNo ratings yet

- 4 Quick Fixes For Your Sleep Problems: Doctor Formulated SupplementsDocument12 pages4 Quick Fixes For Your Sleep Problems: Doctor Formulated SupplementsjilujNo ratings yet

- DM Plant Chemicals CalculationDocument2 pagesDM Plant Chemicals CalculationjilujNo ratings yet

- A Adjust As Necessary I Inspect and Correct. Replace If Worn Out or Faulty R Replace L Lubricate C CleanDocument2 pagesA Adjust As Necessary I Inspect and Correct. Replace If Worn Out or Faulty R Replace L Lubricate C CleanjilujNo ratings yet

- Small Intestinal Bacterial Overgrowth: A Primary Care ReviewDocument6 pagesSmall Intestinal Bacterial Overgrowth: A Primary Care ReviewjilujNo ratings yet

- Invoice SampleDocument2 pagesInvoice SampleHong VineseNo ratings yet

- Factories Act Cap 126 L F N 1990 Cap f1 L F N 2004Document121 pagesFactories Act Cap 126 L F N 1990 Cap f1 L F N 2004Empere Oyinkeprebi RobertNo ratings yet

- Plato Idea of JusticeDocument2 pagesPlato Idea of JusticeZeeshanmirzaaNo ratings yet

- IXIA and IDirect Issues UpdatesDocument23 pagesIXIA and IDirect Issues Updatesrob challerayNo ratings yet

- Grammar T.3 (N - Cardinales, Ordinales, Cantidades, Con Nombres)Document6 pagesGrammar T.3 (N - Cardinales, Ordinales, Cantidades, Con Nombres)Alejandro Gamarra CascalesNo ratings yet

- The 12 Investment Club - ICEA UGANDA MONEY MARKET FUNDDocument2 pagesThe 12 Investment Club - ICEA UGANDA MONEY MARKET FUNDChrispus MutabuuzaNo ratings yet

- Major Biomes of The World WSDocument17 pagesMajor Biomes of The World WShorne.legaci6826No ratings yet

- Case Study 3Document1 pageCase Study 3Babu babuNo ratings yet

- Accounting Ratios PDFDocument22 pagesAccounting Ratios PDFumerceoNo ratings yet

- Apple Iphone SWOTDocument20 pagesApple Iphone SWOTericdbrittoNo ratings yet

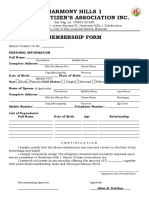

- Harmony Hills 1 Senior Citizen Association Inc Membership FormDocument2 pagesHarmony Hills 1 Senior Citizen Association Inc Membership FormRoxanne Tiffany Dotillos Sarino100% (1)

- FISD Online ResourcesDocument6 pagesFISD Online ResourcesSushma Reddy VNo ratings yet

- Important GD TopicsDocument6 pagesImportant GD TopicsMohammed ShaiqNo ratings yet

- Automated Vehicle Security System Using ALPR and Face DetectionDocument9 pagesAutomated Vehicle Security System Using ALPR and Face Detectionakinlabi aderibigbeNo ratings yet

- ESP Modular Distance Learning Modality & RBB AccomplishmentDocument24 pagesESP Modular Distance Learning Modality & RBB AccomplishmentJulius BayagaNo ratings yet

- Advertising Budgeting, Media, and Media PlanningDocument45 pagesAdvertising Budgeting, Media, and Media PlanningAbesheik HalduraiNo ratings yet

- Gr. Sonatrach Sinopec - Tender No.006 - GSS - 2018 - Provision of Running Tubular ServicesDocument2 pagesGr. Sonatrach Sinopec - Tender No.006 - GSS - 2018 - Provision of Running Tubular ServicesOussama AmaraNo ratings yet

- Beyoncé and WaterDocument8 pagesBeyoncé and WaterkgazooNo ratings yet

- Aqap 4107 Eng en DataDocument22 pagesAqap 4107 Eng en Data신동득No ratings yet

- Mil M8Document5 pagesMil M8Eya Kayte C. ReblandoNo ratings yet

- Sir Shapoor Reporter and 1953 Coup in Iran 1Document17 pagesSir Shapoor Reporter and 1953 Coup in Iran 1ashakow8849No ratings yet

- Indian History - Chronology of India's Freedom StruggleDocument16 pagesIndian History - Chronology of India's Freedom StrugglemsmgectNo ratings yet