Professional Documents

Culture Documents

Admixtures Liverpool 2010

Admixtures Liverpool 2010

Uploaded by

Akshay BundhooCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Admixtures Liverpool 2010

Admixtures Liverpool 2010

Uploaded by

Akshay BundhooCopyright:

Available Formats

Admixtures for Concrete

CIVE 401- 19/02/10

Dept Civil Engineering

University of Liverpool

John Dransfield

Cement Admixtures Association

www.admixtures.org.uk

Cement Admixtures Association

Admixtures

• Admixtures are Chemicals typically consisting of

– 1 or 2 major constituents

– + 2 or 3 minor constituents

• Added to the concrete during mixing

– Usually as an aqueous solution, < 40% active chemical

• Quantity is very small

– 0.2 to 5.0% Admixture by weight on cement

– Active chemical usually less than 0.15% on the concrete

• European Standard – (BS) EN 934 parts 1 to 6 & BS 8443

• Admixtures modify the properties of the concrete in the

Plastic and / or Hardened state

Cement Admixtures Association

Cement Admixtures Association

Why use Admixtures?

• Economic - Producer

– Optimised mix design

• Placing - Contractor

– appropriate workability (consistence), compactability, cohesion,

setting and strength development

• Problem Solving – Designer / Engineer

– concrete that will meet special needs for placing or performance

• Durability - Owner

– Ensuring that concrete fulfils its design requirements for the

intended life of the structure

• Sustainability - Everyone

– helping to reduce the health and safety aspects of concrete during

placing and environmental impact during its life cycle

– www.sustainableconcrete.org.uk

Cement Admixtures Association

Current Admixture Use

• Admixtures are currently used in over 80% of all Ready Mixed and

Precast Concrete

– Admixtures are normal ingredient of concrete, together with Cement,

Aggregate, Additions and Water

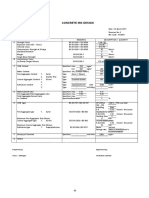

• Admixture sales by type for 2006

Plasticisers

Superplasticisers

Acc / Ret

Air Ent

Water Resistant

Other Admixtures

Mortars

Cement Admixtures Association

Admixture Types to EN 934

Normal Plasticisers (Water reducers) EN 934-2 T2

Superplasticisers (High Range WR) EN 934-2 T3

Air Entraining EN 934-2 T4

Accelerating EN 934-2 T6 & 7

Retarding EN 934-2 T8

Water Resisting (Waterproofing) EN 934-2 T9

Mortar Admixtures EN 934-3

Grout Admixtures EN 934-4

Sprayed Concrete Admixtures EN 934-5

Cement Admixtures Association

Other Admixture Types

Corrosion Inhibiting Admixtures BS 8443 T4

Foamed Concrete Admixtures BS 8443 T7

Polymer Dispersion Admixtures

Pumping Admixtures BS 8443 T5

Viscosity Modifying (Segregation Reducing) BS 8443 T6

Admixtures

Semi-Dry concrete Admixtures BS 8443

Shrinkage Reducing Admixtures BS 8443 T3

Washwater Recycling Admixtures

Anti-Washout Underwater Concrete BS 8443 T2

Admixtures

Cement Admixtures Association

Plasticisers & Superplasticisers

• 80% of all Concrete Admixture Sales

• Both types are essentially Particle Dispersants

• The difference is in the dispersing power

– But also in the secondary effects:

• Retardation

• Air entrainment

• Also known as Water Reducers / High Range

Water Reducers

Cement Admixtures Association

Particle Dispersants

• Dispersants are Polymers that adsorb onto the particle

surface by electrostatic attraction

• The polymer then repels other particles, either by

electrostatic repulsion or by steric repulsion

• This repulsion prevents particles from flocculating into

clumps which would trap water and by their size, reduce

mobility

• In a cementitious mix the effect of the dispersant is to

increase the consistance or fluidity of the mix for a given

W/C ratio

Cement Admixtures Association

Particle Dispersion

• Dispersing Effect of Plasticisers & Superplasticisers

cement flocs cement is uniformly dispersed

reduce fluidity increasing fluidity

add a plasticising

admixture

• This Can be demonstrated with a simple grout mix

Cement Admixtures Association

Dispersant Uses

• Plasticise at = Cement content & W/C

– Increased Consistence

• Water Reduce to = Consistance

– Increased Strength,

– Reduced Permeability

• Cement & Water Reduce to = W/C & Consistence

– Lower £, lower water use, lower cementitous

– Improved sustainability, lower embedded CO2

Cement Admixtures Association

Slump Test

Cement Admixtures Association

Plasticisers vs Superplasticisers

Plasticiser Superplasticiser

Main constituent Lignosulphonate Melamine Polymers SMFC

Selected Carbohydrates Naphthalene Polymers SNFC

Polycarboxylate Ethers PCE

Typical dose (40% 0.3 to 0.5% 0.6 to 1.5%

Solution)

Cost Plasticiser x 2

Not economic for cement cost

savings

Overdose Retardation Little effect till x 2 overdose

Air Entrainment Without water reduction, mix

may segregate

Water reduction 8 to 12% 16 to 30% +

Blends of superplasticiser with lignosulphonate give cost effective mid range

products with beneficial properties.

Cement Admixtures Association

Increased Consistence 1

• Add the plasticiser / superplasticiser to the concrete.

– W/C does not change so strength and durability are

unchanged, only consistence increases

• 50 to 120 mm slump for site use

– Normal Plasticiser

• 180 to 220 mm slump for flowing concrete and congested

reinforcement

– Mid range or Superplasticiser

– Pump mix

• Self Compacting Concrete for self levelling concrete, very

congested reinforcement, high quality surfaces, difficult

shapes, H&S – vibration free (reduces noise), no vibration

white finger and back problems.

– PCE Superplasticiser needed

Cement Admixtures Association

Photo 1

Cement Admixtures Association

High Flow but not quite self- compacting

Cement Admixtures Association

Water Reduction

• Normal Plasticiser – Water Reducer

– Typically 8 to 10%

– Benefit for this application limited:

• Help offset strength loss in air entrained concrete

• Reduce permeability for water resistant concrete

– Main use is to reduce cement & water to reduce cost

• May also provide some increased consistence

• Superplasticisers – High Range WR

– Typically 16 to 20% can go to over 30% with PCE

– Large strength increase, especially at early age

– Permeability reduced by an order of magnitude

– Finds extensive use for:

• Precast – early age strength, reduced need for heating

• Durability – reduced chloride penetration, carbonation etc

• Early strength on site – road & airfield repair

Cement Admixtures Association

Water Reduction and Strength

Superplasticiser

Water Reduction

Control – w/c = 0.6

30 MPa @ 28d

- 20% w/c = 0.48

42 MPa @ 28d

+ 40%

- 30% w/c = 0.42

50 MPa @ 28d

+ 67%

Cement Admixtures Association

Water Reduction on Porosity

1m3 Cement Water W/C Agg Hydration Void/Pore

Water Water

Wt 350 200 0.57 1850

Vol 110 200 700 80 120

Wt

Vol

Wt

Vol

Cement Admixtures Association

Water Reduction on Porosity

1m3 Cement Water W/C Agg Hydration Void/Pore

Water Water

Wt 350 200 0.57 1850

Vol 110 200 700 80 120

Wt 350 160 0.46 1895

(-20%)

Vol 110 160 730 80 80 (-35%)

Wt

Vol

Cement Admixtures Association

Water Reduction on Permeability

40

35

Powers

Permeability X 10-14 m/s

30

Admixtures

25

20

15

10

0

0.35 0.4 0.45 0.5 0.55 0.6

W/C

Cement Admixtures Association

Water Reduction and Chloride

Diffusion

• Water Cement ratio plays a major part in reducing

the ingress of aggressive chemicals including

chloride ions due to the use of de-icing salts or

exposure to a marine environment

Mix Cement W/C 28d Strength Chloride Diff

Mpa X 10-12 m2/sec

Control 305 PC 0.61 31.5 51.0

HRWR 305 PC 0.51 45.0 22.0

Control 375 PC 0.51 44.5 28.0

HRWR 360 PC 0.41 58.0 8.1

HRWR 450 PC 0.34 72.0 5.4

Cement Admixtures Association

Self-Compacting Concrete

Cement Admixtures Association

Self-Compacting Concrete

• SCC resulted from the development of PolyCarboxylate

Ether (PCE) Superplasticisers.

• SCC requires a combination of:

– High fluidity

– Resistance to segregation

– Resistance to blocking in congested reinforcement

• Earlier Superplasticisers could not consistently produce

concrete that exhibited all these properties.

• SCC requires greater control on constituent quality and on

production control so is not appropriate for all concrete.

Cement Admixtures Association

Use of high consistence concrete

• Pre 1970 – most concrete 50 to 120mm slump, occasionally 180mm

• 1970 – 1995 up to 220mm slump

– Based on SMF or SNF Superplasticisers

– required little vibration or compaction

• 1990 – Japan introduces SCC

• 1995 – Europe experiments with SCC

• 2003 to date – SCC use increasing

– Widely used in Precast

• Low noise

• Early strength

• Excellent surface finish

– Used on site mainly for special applications:

• Difficult access

• Difficult shapes

• Improved surface finish

Cement Admixtures Association

High Flow but not Self-Compacting

Cement Admixtures Association

SCC mix design

• High powder content

– PC + ggbs, pfa, limestone fines etc 450 to 600 kg/m3

– PCE Superplasticiser

– Sand 45 to 55% of aggregate

– Coarse aggregate normally <16mm

– Viscosity Modifying Admixture may be needed

• Mix design must 100% consistently achieve:

– Good flow

– No segregation

– Good passing ability through reinforcement /no blocking

– Appropriate viscosity / speed of flow

• SCC mix design requires an in depth knowledge of concrete mix

design and materials as well as consistently good constituents

– SCC should only be purchased from companies with a proven track

record for consistent and high quality supply of this type of concrete.

Cement Admixtures Association

Consistence by Slump Flow

• Most SCC will have a slump

flow of 660 – 750 mm

• A J-Ring or L-Box should not

significantly reduce the flow

and there should be no

height step from inside to

outside the bars.

• Coarse aggregate should be

visible at the surface and

right up to the outer edges

• There should be no

indication of bleed or grout

separation even if left to

stand.

Cement Admixtures Association

Precast – High flow & No Vibration

Cement Admixtures Association

Site – High flow & No Compaction

Cement Admixtures Association

High flow and good passing ability

Cement Admixtures Association

Cement Admixtures Association

Precast – Surface Detail

Cement Admixtures Association

Surface Quality

Cement Admixtures Association

Air Entrainment

• 1% Air reduces strength by

about 5%

• Air entrainment:

– Provides Freeze Thaw

resistance. Is a

requirement for highway

pavements

– Air increases the

apparent paste volume,

increasing cohesion,

reducing settlement and

can significantly reduce

bleed

– In low fines mixes and

semi dry concrete it

lubricates the mix,

improving compaction

Cement Admixtures Association

Freeze-Thaw

Cement Admixtures Association

Cohesion/Bleed reduction

Cement Admixtures Association

Freeze Thaw Resistance

• Occurs when saturated concrete is subjected to Freeze

Thaw action.

– Water in the capillaries freezes, generating pressure and

causing the surface to spall

• Aggravated if de-icing salts are used

– De-icing salts can increase the rate of freezing within the

concrete

– Can result in osmotic pressure due to concentration gradients

• Entrained Air:

– Does not fill with water in saturated concrete due to capillary

action

– Relieves the pressure if water in the capillaries start to freeze

– Bubble spacing needs to be small (< 0.2 mm spacing factor)

– Bubble size typically less than 0.3 mm

Cement Admixtures Association

Air Entrained Concrete

N/mm2 W/C Air

Control 58 0.50 1.3

HRWR 74 0.40 1.0

AEA 53 0.47 3.5

120

Dynamic Modulus %

100

80

60

40 Control

20 HRWR

AEA

0

0 30 60 90 120 150 800 1000

Freeze thaw Cycles

Cement Admixtures Association

Accelerating Admixtures

• Acceleration of Set or Strength?

– Most types do one or other not both.

• Sprayed Concrete accelerators

– very fast set, not covered in this talk.

• Calcium Chloride

– accelerates both set and strength.

– very cost effective

– enhances corrosion of embedded steel

• Other Accelerators

– Less effective than Calcium chloride

– Usually accelerate Set or Strength but not both

Cement Admixtures Association

Use of Accelerating Admixtures

• Superplasticisers have generally replaced strength

accelerators

• Accelerators are most effective at low temperatures

• Use accelerators for very early strength, < 12 hours

• > 12 hours strength, better to use HRWR

– 24 hour strength can be more than 200% of a control mix

– HRWR can be used with a set accelerator

– Accelerating HRWR admixtures are also available

• Use set acceleration for:

– Early finishing of floors

– Early strength for access (Pavement repairs - Roads/Airports)

Cement Admixtures Association

Retarding Admixtures

• Most retarders do not maintain the workability at the initial

level

– Some special workability retention admixtures are available

but usually need a special accelerator to initiate setting.

• Retarders delay the setting

• Setting equates to the time when two layers of concrete can

no longer be vibrated to fully remove a joint between

concrete pours.

• Retarders are often incorperated in plasticisers or

superplasticisers to give higher initial workability and

hence longer workability = Retarding Plasticisers etc

Cement Admixtures Association

Workability retention and Set retardation 1

Workability

retention

Retardation

Cement Admixtures Association

Slump Retention Normal Plasticiser

200

Control

150

Slump mm

Water

Reduced

100

Plasticised

50

0

0 30 60 90 120 150 180 210

Time after mixing, min

Cement Admixtures Association

Slump Retention Retarding Plasticiser

200

Control

150

Slump mm

Retarded

100

Plasticised

50

0

0 30 60 90 120 150 180 210 240

Time after mixing, min

Cement Admixtures Association

Workability retention and Set retardation 2

Slump

80 mm

0 slump but not set 0 mm

0 slump & setting

NO cold Joint

Cold Joint Formed

Set

Cement Admixtures Association

Water Resisting (waterproofing)

• Function:

– Reduce water absorption into the concrete surface

and / or

– Reduce passage of water through the concrete

• Action:

– Reduce number and continuity of the capillary pore

structure with a water reducer

– AND:

– Block the capillary pores

– OR:

– Line capillaries with hydrophobic material to prevent

capillary suction into the concrete

Cement Admixtures Association

Water Resisting Admixture Selection

• Hydrophobic types line

the capillary wall but are

only effective against

rain and low water

pressure

• Capillary blockers are

needed if there is water

pressure

• Many waterproofing

admixture also contain a

water reducer to reduce

the capillary continuity

Cement Admixtures Association

Corrosion Inhibiting Admixtures

• Act on embedded steel

– Increases the passivation state of the steel

– Raises Corrosion threshold potential

– Coat surface with resistant organic mono

molecular layer

• Migratory, surface applied corrosion inhibitors

are not admixtures.

Cement Admixtures Association

Corrosion Inhibitor Use

• Corrosion Inhibitors are not a substitute for good concrete

• They do provide additional protection at the end of the

structures working life.

• They work by increasing the time for corrosion to start,

after the time when chloride or carbonation reaches the

embedded steel surface

• Durable concrete design should prevent chloride or carbon

dioxide from reaching the steel within the design life of the

concrete

Cement Admixtures Association

Corrosion Inhibitor principle

• Concrete Spec

– PC 350kg/m3, W/C 0.40

– Reinforcement at 40 mm

– Chloride Diffusion Coeff 9x10-12 m2/s

• No Corrosion Inhibitor

– Chloride corrosion threshold 0.4% on cement

– Threshold reached after 30 years

• Corrosion Inhibitor added at 10 lit/m3 (30% soln)

– Chloride corrosion threshold raised to 0.8% on cement

– Threshold reached after 60 years

Cement Admixtures Association

Other Admixture Types

Corrosion Inhibiting Admixtures BS 8443 T4

Foamed Concrete Admixtures BS 8443 T7

Polymer Dispersion Admixtures

Pumping Admixtures BS 8443 T5

Viscosity Modifying (Segregation Reducing) BS 8443 T6

Admixtures

Semi-Dry concrete Admixtures BS 8443

Shrinkage Reducing Admixtures BS 8443 T3

Washwater Recycling Admixtures

Anti-Washout Underwater Concrete BS 8443 T2

Admixtures

Cement Admixtures Association

Further Information on Admixtures

• As a condition of membership CAA members all provide a

high level of Technical Support as well as supplying high

quality products

• CAA web site: www.admixtures.org.uk

– Details on CAA member companies

– Free download publications:

• ATS = 17 Admixture Technical Sheets

• AIS = 15 Admixture Information Sheets

• AES = 12 Admixture Environmental Sheets

• Guideline documents on SCC, VMA and Special Purpose

Admixtures

• Concrete Society Technical Reports:

– TR 18 Guide to admixture selection

– TR 62 Self-Compacting Concrete

Cement Admixtures Association

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Geobotanical Exploration PT V-New PDFDocument25 pagesGeobotanical Exploration PT V-New PDFmandeepgeology90% (10)

- Form - Management Review Meeting MinutesDocument6 pagesForm - Management Review Meeting Minutesshahrilzainul77No ratings yet

- Form - Management Review Meeting MinutesDocument6 pagesForm - Management Review Meeting Minutesshahrilzainul77No ratings yet

- Concrete Mix Design RC5001Document1 pageConcrete Mix Design RC5001shahrilzainul77No ratings yet

- HVOFDocument75 pagesHVOFAlan GonzalezNo ratings yet

- Particle Technology (PTY261S) : DR M AzizDocument46 pagesParticle Technology (PTY261S) : DR M AzizKyle AprilNo ratings yet

- Acceptable Rebar Rust: Concrete Construction StaffDocument4 pagesAcceptable Rebar Rust: Concrete Construction Staffshahrilzainul77100% (2)

- Crux and Reagents of Organic ChemDocument4 pagesCrux and Reagents of Organic ChemBILL RUSSO100% (5)

- WSS-M1A346-A - Calidad de ChapaDocument12 pagesWSS-M1A346-A - Calidad de ChapaDANIEL DIAZNo ratings yet

- Conducting - Charpy Impact TestDocument2 pagesConducting - Charpy Impact Testshahrilzainul77No ratings yet

- Precast ChecklistDocument1 pagePrecast Checklistshahrilzainul77100% (3)

- Eco Labelling SIRIMDocument22 pagesEco Labelling SIRIMshahrilzainul77No ratings yet

- MCQsDocument17 pagesMCQsbilal100% (1)

- NM, NP Raw Mill Semen Padang2Document272 pagesNM, NP Raw Mill Semen Padang2Emel100% (1)

- Hall: Month: Pre-Concreting Inspection - Conformance of Connection ItemsDocument1 pageHall: Month: Pre-Concreting Inspection - Conformance of Connection Itemsshahrilzainul77No ratings yet

- NCR Work FlowDocument1 pageNCR Work Flowshahrilzainul77No ratings yet

- C&S RE RTO Renewal Application Form 20172018Document6 pagesC&S RE RTO Renewal Application Form 20172018shahrilzainul7750% (2)

- Daily Report - Site Quality Maintenance Work 1Document2 pagesDaily Report - Site Quality Maintenance Work 1shahrilzainul77No ratings yet

- Water Absorption Limits On AggregatesDocument2 pagesWater Absorption Limits On Aggregatesshahrilzainul77No ratings yet

- Quality Improvement - Grout LeakageDocument1 pageQuality Improvement - Grout Leakageshahrilzainul77No ratings yet

- CGPV IBS Cube Result 2017 13.10.17Document170 pagesCGPV IBS Cube Result 2017 13.10.17shahrilzainul77No ratings yet

- Repair SOP - Rebar Loose Bonding 1Document1 pageRepair SOP - Rebar Loose Bonding 1shahrilzainul77No ratings yet

- Repair SOP - Protection of Steel Reinforcement From CorrosionDocument1 pageRepair SOP - Protection of Steel Reinforcement From Corrosionshahrilzainul77No ratings yet

- Method of Testing Determination of Resistance To FragmentationDocument3 pagesMethod of Testing Determination of Resistance To Fragmentationshahrilzainul77No ratings yet

- Repair SOP - Plank SoffitDocument1 pageRepair SOP - Plank Soffitshahrilzainul77No ratings yet

- Method of Testing Determination of Aggregates Impact Value (AIV)Document3 pagesMethod of Testing Determination of Aggregates Impact Value (AIV)shahrilzainul77No ratings yet

- Izni 202Document24 pagesIzni 202shahrilzainul77No ratings yet

- Method of Testing Determination of Aggregates Crushing Value (ACV)Document2 pagesMethod of Testing Determination of Aggregates Crushing Value (ACV)shahrilzainul77No ratings yet

- Elements Scrapped Form: No. Marking Pis Id. Type Project Requested by NCR No. (Stockyard)Document6 pagesElements Scrapped Form: No. Marking Pis Id. Type Project Requested by NCR No. (Stockyard)shahrilzainul77No ratings yet

- Elements Scrapped Form: No. Marking Pis Id. Type Project Requested by NCR No. (Stockyard)Document6 pagesElements Scrapped Form: No. Marking Pis Id. Type Project Requested by NCR No. (Stockyard)shahrilzainul77No ratings yet

- Kempf NotesDocument100 pagesKempf NoteshbadermanNo ratings yet

- Industrial Training ReportDocument43 pagesIndustrial Training ReportApurba Sarker Apu80% (10)

- Mbio 304, Lec-4, Microbial Decomposition of HemicelluloseDocument18 pagesMbio 304, Lec-4, Microbial Decomposition of Hemicellulosesahidur rahmanNo ratings yet

- A Research On Thermal Insulation Properties of Nonwovens Produced With Recycled Jute and Wool FibresDocument9 pagesA Research On Thermal Insulation Properties of Nonwovens Produced With Recycled Jute and Wool FibresAmina BenrbehNo ratings yet

- Semua Tentang BerasDocument30 pagesSemua Tentang BerasAnnisa Farhiah Wahdah HamidNo ratings yet

- Teraoka Adhesive Tapes For Electrical Insulation and Electronic Equipment 2016Document8 pagesTeraoka Adhesive Tapes For Electrical Insulation and Electronic Equipment 2016ion ionNo ratings yet

- The Facts About Fillings: Dental Materials - Advantages & Disadvantages Porcelain Fused To Metal Gold AlloyDocument4 pagesThe Facts About Fillings: Dental Materials - Advantages & Disadvantages Porcelain Fused To Metal Gold AlloyIsak Isak IsakNo ratings yet

- Chemical Thermodynamics & EnergeticsDocument22 pagesChemical Thermodynamics & Energeticsreemkhalifah786No ratings yet

- Module 2 Field Joint CoatingsDocument68 pagesModule 2 Field Joint CoatingsAbdul Wajid AliNo ratings yet

- Fandaruff (2014)Document8 pagesFandaruff (2014)Paulo DantasNo ratings yet

- Method For Coating Filter Media With Synthetic Manganese Oxide by Peter B. Merkle William R. Knocke, 2 P.E., and Daniel L. Gallagher/ P.EDocument8 pagesMethod For Coating Filter Media With Synthetic Manganese Oxide by Peter B. Merkle William R. Knocke, 2 P.E., and Daniel L. Gallagher/ P.EPiyumal PereraNo ratings yet

- 5 Heat Transfer CarranzaDocument71 pages5 Heat Transfer CarranzaChristian Rally Ramos GonzalezNo ratings yet

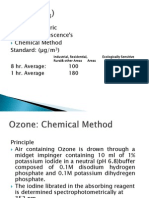

- O3Document15 pagesO3ECRDNo ratings yet

- Leidenfrost EffectDocument5 pagesLeidenfrost EffectJagdeep SekhonNo ratings yet

- Hoogsteen Base Pair PDFDocument7 pagesHoogsteen Base Pair PDFNikitaNo ratings yet

- Baterai PDFDocument4 pagesBaterai PDFK3 RS DarmoNo ratings yet

- ECH3604-1-2-1920-Topic 4 PDFDocument47 pagesECH3604-1-2-1920-Topic 4 PDFSîväñ RãjNo ratings yet

- Narayana 24-06-2022 Outgoing SR Jee Main Model GTM 19 QP FinalDocument16 pagesNarayana 24-06-2022 Outgoing SR Jee Main Model GTM 19 QP FinalShreyas VedantiNo ratings yet

- Cen/Tc 250/Sc 2/Wg 2 N 0157Document38 pagesCen/Tc 250/Sc 2/Wg 2 N 0157RobertA6100% (1)

- Question Paper Code:: Reg. No.Document2 pagesQuestion Paper Code:: Reg. No.siga_sNo ratings yet

- Modeling of High Speed Machining Processes For PDFDocument10 pagesModeling of High Speed Machining Processes For PDFAnonymous v6NXZ0No ratings yet

- Advances in Materials, MechanicalDocument762 pagesAdvances in Materials, MechanicalNikhil PimpareNo ratings yet

- MME 3518-Powder Metallurgy-1-2Document80 pagesMME 3518-Powder Metallurgy-1-2Mohammed GhisheerNo ratings yet