Professional Documents

Culture Documents

Iom Apr CP 296

Uploaded by

Anonymous uEOZ7raPkz0 ratings0% found this document useful (0 votes)

23 views74 pagesAire acondicionado central

Original Title

IOM-APR-CP-296

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAire acondicionado central

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views74 pagesIom Apr CP 296

Uploaded by

Anonymous uEOZ7raPkzAire acondicionado central

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 74

ClimateMaster

EES A SA IEE AIO EET IR PS

APR CP Series

Dehumidification System

installation and Operation Reference Manual

7300 SW. 44th Street + Okiahoma City, Oklakoma 73179 + (408) 745-6000 - FAN (405) 745-6058

CP Series Installation and Operation Reference Mannal

> Ye Orr reoo_—w .

Table of Contents a

General Information Shipping Inspection

Iesodaction

Hiueling and Storage

Pte-Insalation

Pact Piping

AWA e

Installation. Connecting Ducrwork. 7

Condensate Pipiag 7

Pool Warer Heating Piping 8

Refrigerant Piping 8

Field Wiring 2

Main Power Wiring,

Operating Coniions 2

Coniot Sensors »

DDC Contras t

Pool Aedir inteteck n

Aaaliany Hea! Tatsock

Remote Air Cooled Condenser u

Start-up Belbre Startup 2

Stareap Cheeks B

Sta-op Tasrustons

Geral Strip ve

Heating Stage 1

Heating Sage 1 Hot Water Co as

Energeney. Heating» Sage Ib as

Coting Suge 1

Poo! Hoang 6

Envirosment Data B

Stareup Noses 15

GF Series Startssp Data Shoat 1

Maintenance and Memnai Fan OnlAato Swe »

Operation Opening Presses ard Temperatices 1»

Condenser Operation 8

Roigeriat Recharghng 2

Reftigernat, 2 .

Refigernt OF =

Control Sequencing Space Heating a

‘Space Cooling a

Euriaiy Contol z

Poo! Water Heating, Pa

ight Time Saback 2

ros: Protuaion am

Opeiting/Salety Couvels 21

Maintenance Monthly Mainienance 2

Angmal Maivensnce 2 :

Safe Rect z

Trevble Shooting Guide ”

2

CP Series Installation and Operation Reference Manual

_—————————$S$ —— —Or—rnronwnmns

Appendix A

AppendtsB

Appendix

AgpendiD

APPENDICES

‘Usit Dimonaion Drawings ey

WringDiggen ca

Reiigeration System Diagram BS

LCD Display “1

CP Series Installation and Operation Reference Manual

SS

Shipping Inspection

Antroduction

General Information

Upon receipt of shipenent sr the job cits, oesafully check the shipment

‘agains the bill of lading. Vevify that all units Tave been received in

‘opersting coudldou, Check the exiecior for damage and verify that all

‘intemal corponenis end coits fave aot brokea lose éxsing shipziag.

Agsnre thet the cartier makes proper aoraticn of any shonages or damage

fom all enpies af she freigit bil and that he completes a carer insposicn

Report. Concealed damage aot discovered duting uslosding aust be

reporied to the cartier within 13 days of receipt of shipment. It is the

esponsibility of the purchaser wo file all necessary claims with the cartier

Notify AFR Corporation Customer Service of afl damage within fifteen

(2S) days of shipment.

‘Tais Iustelanion and Operation Reference Manust:s applicable ty APR CP Series

Units,

‘The APR CP Series Unit is state of the art dohumidifcation end heat recovery

system designed to provide complete euvisoameatal coarol uf suclosed pool and

spa areas (Natalriam), Heat cecovered from the dehumidticacen process is used

1o eat pook water and for space Heating. Excess ‘eat is rected oeside the poo!

‘The CP Series Unit contains the following major com poreats

© Compressor: A heavy davy, multi- cylinder, servicsable compressor

with removable crankcase lester ard optionai three tage unloading

© Suction Gar Accumulator

© Hot Gar Discharge Muffler

@ Poot Water CondesseriHeater: A high efficacy coaxial eae

exchanger with cuboa steel jacket and surtoalctel ianes abe assembly

© Air Cooled Condenseridir Re-keat Col: a high efficiency

eviunced tube and fin condenser

® Evoporator: A high efficiency, anit

fin evagerator

© Thermostatic Expansion Vaives: On evaporaer clicales w control

retrlgeration system

© Sight Glass

Selenaid Valve: For pamp down

D Liguid Line Filer: Wish replaceabie coro

© Auailiary Air Heating Coil: A tigh efficiecey cahauced be and

Mo coll ommolied by a S-way modulating valve

Supply Air Blowers: Blowers driven by an open, drip-resisant motor

© Aaxiliary Poot Heater: Using stainless sisel heat exelsagert

© Optional Remote ain Cooled Condenser

@ dlr Fibers: Four 2 throwaway Siters each for the evaporalor and the

condenser

‘© Controls: Conwols on CP Series Units are integrated mlernprocessor

system isolated from the air steam in 2 seperate compartmeat on the unit

faevited enhanced woe and

CP Series Installation and Operation Reference Manual

= SS

Introduction (Con't}

Handling and Storage

General Tnformation

‘The following scrpoins are provided aad may be programmed an the DDC

Comat pene

* Space Temperamre

+ Space Relative Hinnicity

+ Poot Watt Temperatare

+ Oecupied/Unccrupied Sctmdute

‘Tre following readoms are availzbie:

@ Space Tempeeame + Space Relative Humnisicy

+ Fool Water Texpemiure + Compressor Cizuit Fault

+ Heat mode = Deiumicifcation Mode

+ Auaillary Heating Mode + Pool Water Heatteg

Blower motors and compressors are controled hp atenoe starters vith

tees leg overload prorcetion. Qverlouds are adjustable tip with push

ation resets.

See APR Direc: Die

snformation,

1 Coniroiter: Operation and Mena! ax rere

Upon xtival of cqeipment ut the jab site, immediately store unt on thes shipoing

petless in ets original sbipping maveriat in a clean, dry ae. Store uals acm

upright pesiion ara trae,

Seung

To avoid eqzipment damage while moving, DO NOT tilt or drop

its,

‘To svold equipment damage during storage, DO NOT Stack Units.

DO NOT store CP Series Tnits iu corrosive exvirouments or in

locations subject fo oxtrames of tomperature or humidity. Corrosive

‘conditions and high temperstmre or humidity during storage cam

significantly redace performance, reliability 2nd service life.

DO NOT Puncrore cardboard on the sir coil side of the equipment.

To avoid bodily harm, DO NOT attempt to move or litt CP Seri

Units withont appropriate equipment such as dalfias, hoists, hand

tucks or forks Hite. (Gee Figure & - page 5).

Cover Unit while ov the job site, Cap open ends of pipes Tn areas where

palming, plastering or the spraying of fireproof warial tas not been

completed, all dae precautions must be taken to avoid paysical damage wo

the veit and caatamination by forsign muerial. Physical damage and

contamination may prevent proper startap and may result in costly

equipment clean-up.

CP Series Installation and Operation Reference Manual

‘Handling and Storage (Cor)

Pre-Installation

General Information

An Installation and Operation Reference Maret is povided for tne OP Series

elt. Before unit scarl-up, sead al! maneals ae aacorge familiac with (he ont and is

operation,

Prepare for CP Series Unit installatisa as Fctlows

1 Select en installation site which allows adequate clearance for malasenance

and servicing of the unit. A minimum of 2 feet of clearance is requires on all

out sides of she unt.

2 Examine al pipes, Stings, valves and cemponois before iaatlling the

system, Remove any dsr foued on ot ia these corapoazuss aed assure thax all

composers ar2 secutely fined.

o

Properly size ond install supply and zetorn duerwork as zeceesary, Insulate

fall deawork whieh must be mun through eaeoaditioned areas. Saal af] duct

joins to orevent ar Heakage, Install acconding to the latest ASHRAE staz-

dae

4 Locate supply registers along outside wells. Place supply segisters eo blanket

all teas of glass and areas subject o condensation, DO NOT dizest eupply

air over poo! surface

Locate rerum sir grifes as high as possible withla the pol and spo area, De

no! allew eeturn air to deep below 70” F. Provision should be made so drain

aay condensate which might ceca.

6 On efits insalled curdoor, insulate all pipes and completely drain the saser

system

CP Series Installation and Operation Reference Manual

Pool Piping

General Information

Refer to Figure 2 below. Fipe Bool Waser according to tbe following secomumen+

dations:

1. Sasualla goo! Slker pump designed for high volume circulation of water at tow

pressure, Size the pump te accommodate the areteure drog through valves,

{Bliss axed cool wate ‘eal exchanger in the CP Series Unis and any other

nnead losoes tom axitlary agulgmeat chrough which gool water cust flow.

Consult with desiga engineer to determire total losses For installed auxibiacy

equipreent.

2 Tnotell a fine mesh strainer in the auction line of the pump with a compouad

gauge 10 indicate a plogged stalnet

Install coresion easistar, al low, ball, butterfly or gate valves 20 alow

proper servieizg of poot piging cormpenenss

o

perap as showin ia Figure 2 below: The rete line Bom the CP

‘onneete¢ to the paol rene lie epstrsam of che z00 eater,

4 Conaeet

‘Sesits Uait &

henson Sooohone eh

T

CP Sories Installation and Operation Refereuce Manual

Connecting Ductwork

Condensate Piping

Installation

Installation ofthe CP Series Unit and ell associeted components, pans and

scosssoris da make up te installation shall be in cocondance withthe regula

Mons of ALL Auchorices having jurisdiction and MUST conform to all appiteabte

Cade is the responstbiiy of the Insialling Contracior to determine an comply

‘with ALC applicable Codes ant Reguiations

Install ductwork according to crest ASHRAE guidelines, Connect

ductwork to the: CP Series Unit with approved, flexible conaecton.

Pipe the unit condensate line as follows:

1. Akach Ihe condensate drain t the eonnéetioa Lapping om the aulaide of the

eguipment

2 Connect the unit condensate drain to the bullekag eondersate draia with a

exible, non-pressure raied hose, Easure chat the sose is without kinks ‘0

‘mainsain an unobstructed How of condensate Gor the unit tothe drain.

Horizonsal rans rus: be pitched at | lack per 10 feet of deci ‘inc.

3. Yosuall a condensoce tay in the draia Tine CoUlowleg approved oraciess as

shown in Figure 3 below. Desiga tke [engta of the tap based upaa 2

‘amount of external static presauee aaticigated. As a ml:

quined for caci inch of negative pressure on the unit

Figure 3

4 Provide a means to flush or blow-out the condensate Hine

5, Provide a veat fa the draim line Ineated ster the top ia the direction of

condensate flow.

4 Taal exch unit with its own condensate rap and contention © the drain ine

when two or more writs sre inscaled,

7. On ontdoor units, wrap the condensate line with beat tape consecred 20 a

freeze oy, then inustate with 1" clored call insulatiog

CP Series Unies are eqminged with copper sweat unions for water supply and

a

CP Series Installation and Operation Reference Mannal

—_- Oe gts

Anstallation

Pool Water Heating Piping water rot. PVC can te tse for goo water urply and discharge pipiag othe

Refrigerant Piping

CP Unit

NOTE: DO NOT ase PYC pige for spa and domestic tot waver applications.

‘Use copper or iroa pipe for domestis hot waver applications and oopper or CP¥C.

for spa applications. When CPVC is used on the return siping, etal a high Umit

fagussta om the retum piping set at 130° F co prevent damage to the pipe should

water flow he interrupzed

‘The pool heat oxchaager is contrHled by the DDC which read the temperature

of he weter fora the pool, and conuols che cperation of the poot eat exchanger

to heat the pool wanes as required.

Anstell pool water Seater piping sccording to the fellewiag recorumenda.

tions,

4, Inscall pressure and vacuum gauges on the circulating pump to assare proper

amp operation and to detect lerks im the piping system,

2 Install fd low gate valves or bell valvea on the inl ine fr coral water shut

of,

3. Install 2 bypass valve herween the poo! water supply (on the fine From the

filter the C2) and rotor (om the Hine from che CP the Pool)

4, Install ball vaive on the outer pipiag

4. Insulate hot water piping to ond fom the unit wo prevent amneessary tect

less and to preven: acci¢ental hams,

Install a priming ee om the purnp watoriolet piping.

(Use a back-up wrench whea tightening or lecsening union co hold the

ground join

& Avoid high pioe curs and loose piping joints © avoid knocking and leakage

inthe piping line,

9. llmtnate all air lests inthe perp suciion 10 assure proper water crcutaiion

16, Flush out and teak test all piping grier to east up. Failure te property Alueh the

ayotem ia the primey enuse of incidental demage to CP cystems.

Rofrigetaat yiping is only necessary on split system CF Unis or wien remore

condensers are installed. Refrigerant piping is provided by the installing contrac:

tor. Referring t Figures 4 (Pages 9), pine air cooled condenser or split systene

accarding 10 prover cefrigeration practices,

CP Series Installation and Operation Reference Manual

Refrigerant Piping (con't)

Installation

eed on al joinn. The use of soft solder may void equipment warrasty.

When copper piping is installed, sl-phos, phas-copper or silver solder must

be usec on all joins. The use of soft solder may void equipment

warranty.

2 Wher baving piping, purge the ping with inert gas such as dry ulzoea 0

preven: onidatiox,

A Install an oil trap atthe haae ofall hot gas cicers. An cédtional tap ie required

‘fr avery 8.0 feet cf ine. (See Figare 4 below)

4. Pitch all efrigetst fines 12" per 10.0 feet of can Ia the ciecticn of reiger=

anc flow,

‘Assure thatthe herizoatal dimension ofthe map fas sail us possible

6 Ade 3 Maid ounces of Type 3 GS sefligeramt olf Zur each 10.0 feet of restgcr

amt ne over a tol of 35.0 feet,

Tnculate all cefrigeraat teas

FTN ome

T | Li

rover wocceu: f

Figure 4

10

CP Series Installation and Operation Reference Manual

oT

Fleld Wiring

Main Power Wiring

Operating Conditions

Control Sensors

Installation

Bs

To avoid possible injary or daath duc tn clectricel shock, open the

power supply disconnect switch and secare it in an open position

during installation.

CAUTION: Use only copper conductors for field installed electrical

wiring. Unit terminals are not dasigued to accept other types af con-

ductors.

All fick inpialled wiriag, Including electrical grouad, must comply vith

‘he Nationa! Elecmeal Code a5 sell as all appticable local codes. Yn

addition, afl fielé wirieg cust contsrm 20 Class I temperature fimizatons

Aesosibed in the NEC.

Refer to the voit wiring diagrams jachued vith the wubsoiual drawing for

Juss sizes and a sebemaie of the field comcctians whick mest G2 made by

the installing (or aleetriesl) contractor.

AT finel clecticel connections must be made with a length of flesibie

conduit to micimize vibvation and souad transmission to she building

Install Field sonnag, Refer the unit witing diagrams te ensure proper elecrticai

hookup.

Install the power supply which provides power m@ tae compressor, the rain.

‘contrals and the blower. Equip the powsr supply with a cortesty sized fused

atsconners

‘The CP Series Unit is designed far indoor of cusdoor inezallaticn,

A voliags variation of H- 10% of aamepiate atlizetion voltage is aczept-

able, Thios-phase sysieut imbalaucs showld not be allowed to exceed 27%,

‘The CP is shipsed with the following Factory instelled contel sens3is:

© Return dry bulb temperature sensor

© Return humidity sensor

© Poot water iemperasare sensor

All operating and logic conwols are factory inssalled and wired into the CP Serice

Unit. Conzois asiomatically operate delutaidifieaion, space and pool water

heating, and heat recovery based of desised conditions.

‘The CP Unit is designed ro opersce under the contmol of a DDS system.

n

CP Series Installation and Operation Reference Manual

OE

DDC Controls

Pool Heater Interlock

Auniliary Heat Interlock

Remote Air Cooled Con-

denser (Optional)

Installation

‘The DDC provided tas thos stages cf heating and a single stage cooitag. The

ire stage conzols emergency heal, The cooling stage controls the Uguil line

solenoid and the alr cooied condenser.

© Series units have normally open {N.O,}, iatelocking, dry eon for pool

pump coatrol whisk are located on the 2outel terminal stip, These costae ae

closed based on compressor operetioa. Provide an external powst source for

ese conirls

CP Series Unita have dry contacts for axillary bot water pump eonlzol whieh ate

located on the control terminal strip, Provide an extornal power source for these

eonttols

“The CP Series Unit may be supplied wiin an optional remove ait ecoled coa-

‘denser to reject excess heat outside during periods of mild weather or other times

‘then pool feat and space hest are act required. The remote ai aocled con-

donsor utilizes a combinaion of faa oveling eoato] and fun speed contral to reject

excess heat. inerlock wising aust be provided between the CP aad the remote

coacenses.

‘The remote condenser is enatgized hen space heat requirements are sacietled

sad when wither the huasidiet cals ior debumidicetion or the room thermoomt is

sot lo cooling. Pressors anitches must be set to she pressurts showa ia the chart

below.

5 260/40 (1 Fon) 270°70 (1. Fan)

4 20/40 (1 Fen) 270779 @ Fars)

2

CP Series Installation and Operation Reference Manual -

Before Start-up

Start-ap

efor Ststup, compete the flowing

1. Completely insrall the vert

2 Install all giging and strainers. CAUTION: Flush out aystom thoroughly

before making final water connections

3. Open service valves on refrigeant receivers. Valves open counter-clock-

‘wise, Replace caps on reccivers, (NOTE: seftigersat is pumped into liquie

receivers at the Factory friar lo shipping.)

4, Coan and flvoh etch vnit Refill tho unit and bleed afl ait fromthe aystem.

3. Cheek piping and componenis for leaks.

6. Install and check all ductwork

(Caeek poms: and conteol wising for proper operation. Energize power to

crankcase heaters far 2¢ hours before atetmpting to operate system

8 Tasted clean fiesh sis and return air Bltere

9. Adjast dampers. Set the fesh air damper the minienam seting required by

cee. Set dasoper lekages dor proper operation

10. Bring pect wares to 5° below operating temperane asing the anxiliary pec

heater

TL, Priene and eat ll pumps atacted to the system,

32 Adjost aquasiat tw required pool temperature

1B. Chock rotation of lower by starting end stopping fan momr. Rotation may be

changed by switching aay swo of the three moto: leads from the amagestic,

sarc the meer,

34. Check current balance of all movars including the condésser marars. Verify

that current balance between any mo legs of rach motor dacs not exceed

1.

15, ICequipmert aus: be suuned when the room is below operating coaditloas,

tan the system in beacing mode. If equipment must be strted when the rom

js nbove eptratiag temperatures, siart the system in cooling made

&

CP Series Installation and Operation Reference Manual

Start-up Checklist

Start-up

‘When te insallstion is complete and tbe system is cleamed and Qusked, check

uti system asing ue following checks.

To oxoid suurmup delays, wil trades tnvotved in che equipment instafarion

should be represesied dering startup lactating the heating contractor, a

certified air balancer, dhe elecirieal contractor, the plumbing constector,

she swimraing pool contracior and the general contractor.

202 22 oO

2S ODD ODO @ @

Etectrical/Coatrols Cheekpat

‘Wiring ie propery insialled and grosnded. Installation coruplies wish the

National Electic Code. All conductors «10 copper.

All cavipmeat fs prolecied by time defay fuses or Hype cizcatt breakers.

Conducts are properly sized 49 hold vakaye drop to below 2%

All connections in the electrical eomtal pane! are tight.

‘The control pane! is wired according to the wiring schomatic. Al) comzal

conmecitons are Aight

System contois are functioning, calibrated and sequencing §s comect

Power voltage atthe disconnest switch is within the rangs shown oa the

nameplate (4: 108

Unit Checkout

‘Unit's tastalled completely level and within ambient space, All doors ae

accessible

Blowsr belts ace edjusted #0 the proper tension. Fan and mooor sheaves are

securely tightened.

‘AIL braces and sips sre cemoved from the unit

All construction debris is removed Frere the blower eomouratent aad the

condensate pau

All blower fans tate in the comect direction

‘Refhigerant reeciver valves are open.

‘All ceftigerncr gaeges, temperature probes and sap probes on ibe sain

compressor termical ate coresty installed,

AL fiers ate instelied and ate clean

‘Tereporaurs probes are installed at the following points

+ Hot gas discharge (al compressor)

‘Liguid tine entering trermastatic expansion valve

“Suction line near fhe TXY sensing tld

+ Batesing and leaving pool water ines

+ Eutoalug and leaving space water Tees (Whea irscalled)

+ Enering and teaving DHW lines (When inscafled)

4

CP Series Installation and Operation Reference Manual

_

Start-up Instructions

irs

Start-up

General Start-up

Complore Genera! Unit Datacon Stt-ap data Set.

Pomp down anit by raning of sich

erty vat the fan rans an! tal the sntral cist ie onergized

Open all vals.

‘Tum cn cireatating yurnp and fl svsiem with pool water. Repair leaks intmedi-

ately. (Poal heat does not activate if thers is ne flow)

Verify tht the anit operating in full eecizevlation mode and thot Eres aft

damper is fully closed. (damper is not Fully closed, adjust sime clock co

noccapled mode c0 clase.)

(Cheol rogicters and verity proper ait distribution. Adjast all glee and

registers and csrvre that all grilles and zegictore are unobstructed.

‘ave exteraal stcic pressure (BSP) and CEM measured by a Certified alr

Balaaecer,

Mescure and resart on Sear-up Da Sheet operating voltage, amporage, and

anand mowt BEM.

Heating Stage 1

Replace all panels. Recotd pool siarting dara

Set consol:

minors.

to heating ceode. Test it heating wwode for al least fifteen (15)

Set syster switch 10 ON. (Hf power has been off to the ent, press RESET). Set

Diower axiteh wo ON, When the comprercor siacs, oo: the thermostat and.

snumiisat to desized room: temperature.

‘Assure Dat power is wilhia range shown cn namepce (4/- 1078).

‘Ascire that amperage drew on she compreston(s) matches nameplate,

‘Asaore that etrigeran: pressure is within operaag cenge.

Complete Heating Stage 1 Daia on Starvup Data Steet.

5

CP Series Installation and Operation Reference Manual

Start-up Instructions (Coa'®)

L

»

Start-up

Awsiliary Heating Siage Tt

Laver p00 asia tw emperters below poo! ate tam off pel

hoster. When the comprescor sins, set thecoatreller wotll stage IT auailiary

Ibcating is acivared, Test stage UI auxiliary heating for 15 minus.

‘Verify thatthe ausiliey air Keating col ts aevaued and thal the boiler mins

Complete Heartng Stage 11 Data on Stut-up Data Sheet

Kmergency Heating - Stage UI

Set the theemoetat cod ininidistatco marimar. Soc aquasterto 80°F. Testtage

emergency heating Hor 15 minutes,

‘Verify that the emergency sir Aeating electric heater come on

Complete Hear Stage I on Startup Data Sheet

Cool

Stage

‘Setshesmasiat so 5° F below sctyal cooc femperature (but ant belew 70° F), Set

aquasia: 2° below actual avo! waperamse, Set humidistat to irs lowest seming,

“Test in cooling mode for feast 15 minates.

‘Verity thatthe semote condenser (optional) functions when pool heal is

satisfied

Complete Canting Siage Date on Starcup Dats Sheet.

Pool Hesting

Sot Controller to activate pool beater. Adjust water flow inte for the conreet

temperature difference between suzply and rem water (20") and ceadjust

flow rate when operating temperztae [s ceached, Test p00] leat For at least

30 minus.

(Check circulating pump gauges for pressure aad vacuuan. Verity correce

‘water law rate, Check pumps for cavitation,

Complete Pool Heat Dasa. on Star Data Shee

Environmieat Data

Revord Environment Date ox Startup Data Sheet

‘Use this shoot 253 guide for tmubiestootng. Warrarcy will sammmoace when

fone copy of the deta shect is returned with the warsaaty registration wm AFR

(Corporstion, 7300 Seuth West 44th St, Oklehoma City, OX. 73179.

16

CP Serica Installation and Operetion Reference Manual

TS eee

Start-up ° ,

Start-ap Notes L To avoid assem frecieap during a winer arte, consplewe all phases ofthe insaiarcr

Defore scarp. Room ierpenatare mist be 70° F.

2. The second singe control for heating cnargizas heat relay (HR-2) acu

Inttates an M, O. dep contact to activate the auxiliary Heating circuit and she

oiler

‘Yo avoid invalidarfon of warranty and possible wqipment

damage, DO NOT use equipment to heat or cool geoljspa arca

whea area is under construction. DO NOT operate with dirty

Biers. DO NOT operate without Hliers.

Hfonit fle cpersce, conduct the following sheska:

Check the voltage and carrest They mus: comply with the

lzertical spectficattons described on the ramepiate

Look for wiriag errors. Check for loose terminal serous where

fro camrections Sava boon made of both the ine end iowrvcliage

vecminal beards.

3. Cheek for dirty fiters. A clogged filer may cause safery cutouts to

sop sit operation or col damage

4 Checks the supply ond return piping, Piging must be propeity

connected wo the inet ad outlet connections ow the wait

(Check the Fan. If the fin fells to opernte, verify that the blower

rotates tresly ang that che fon shearhs are firmly tghtencd. Verify that

Ge fan operates in beth Beating and cocling mode.

6 Ty equipment silt fas 10 operate, consul: Troubiesinodng Guide

(Pages 25-52) before consulting authorized service representative,

Paes

‘High voltage is present in sonte areas of the electrical panel. Fxer-

cise caution when working with energized equipment,

To prevent injury ar death due Wy elecuieal shock or contact with

moving parts, agen ualt disconnect switch before servicing unlt,

"

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Código: 984031 Motc - PANASONIC-CSC903H8K-12HP-PARALELO-: Section 1. General SpecificationsDocument13 pagesCódigo: 984031 Motc - PANASONIC-CSC903H8K-12HP-PARALELO-: Section 1. General SpecificationsAnonymous uEOZ7raPkzNo ratings yet

- Installation InstructionsDocument52 pagesInstallation InstructionsAnonymous uEOZ7raPkzNo ratings yet

- Controls, Start-Up, Operation, Service, and TroubleshootingDocument242 pagesControls, Start-Up, Operation, Service, and TroubleshootingAnonymous uEOZ7raPkzNo ratings yet

- 035-000051-001 Installation ManualDocument60 pages035-000051-001 Installation ManualAnonymous uEOZ7raPkzNo ratings yet

- Service Manual: Split InverterDocument174 pagesService Manual: Split InverterAnonymous uEOZ7raPkzNo ratings yet

- STR-A6000 Series: Off-Line PWM Controllers With Integrated Power MOSFETDocument28 pagesSTR-A6000 Series: Off-Line PWM Controllers With Integrated Power MOSFETAnonymous uEOZ7raPkzNo ratings yet

- Rotary Type Power Switch With EncoderDocument6 pagesRotary Type Power Switch With EncoderAnonymous uEOZ7raPkzNo ratings yet

- Technical & Service Manual: Sap-Krv93Eh + Sap-Crv93Eh SAP-KRV123EH + SAP-CRV123EHDocument77 pagesTechnical & Service Manual: Sap-Krv93Eh + Sap-Crv93Eh SAP-KRV123EH + SAP-CRV123EHAnonymous uEOZ7raPkzNo ratings yet

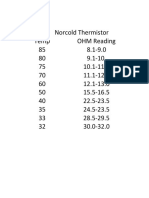

- Norcold Ohm Chart PDFDocument1 pageNorcold Ohm Chart PDFAnonymous uEOZ7raPkzNo ratings yet