Professional Documents

Culture Documents

Electric Reach Trucks Capacity 1000 - 1600 KG

Uploaded by

will wuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electric Reach Trucks Capacity 1000 - 1600 KG

Uploaded by

will wuCopyright:

Available Formats

Standard Equipment/Optional Equipment Features

Superb working environment Stability

3 Outstanding comfort and functionality 3 Chassis designed and built for maxi-

from the unique, resiliently mounted work mum strength and durability

station with an comfort seat that is fully 3 Heavy-duty design and components

Standard Equipment enhance the inherent low centre of

adjustable to the operator‘s personal pre-

ferences gravity for optimum stability and high

General: Safety: 3 Integral, adjustable control console incorpo- residual capacities

Overall width (reach legs) 1270 mm Monitoring system stops truck in the event of traction, stee- rating all operating controls 3 Linde Curve Assist for safe cornering

3 Linde Load Control: precise, effortless

Linde Load Control for lift/lower, reach, tilt and side shift ring or lift failure

fingertip control of all mast movements

Linde twin accelerator pedals Seat-actuated traction interlock

Subject to modification in the interest of progress. Illustrations and technical details could include options and not binding for actual construc-

3 High Vision armoured glass overhead guard

Comprehensive digital instrument display Linde Curve Assist top panel available as an option

Maintenance-free AC 6,5 kW drive & 14 kW lift motors Four independent braking systems (Regenerative and coun-

Linde 180º electric steering ter current braking, holding brake control with automatic

Linde Digital Control System (LDC) for smooth, precise electro- parking brake and all-wheel brake system)

nic control of all traction and hydraulic functions Automatic slowdown at end of reach travel and at max. lift

Polyurethane drive and load wheels tyres Lift height related travel speed reduction

New Standard Features: Emergency isolator

Resiliently mounted operator‘s compartment Battery lock with creep speed interlock

Fully adjustable seat with manual weight adjustment Electrical and hydraulic overload protection Precision Manoeuvrability Batteries

Integral, adjustable control console Protective polycarbonate screen between console and mast 3 Confident, seamless manouevring with 3 A short wheelbase with compact chas- 3 Capacities to suit every application:

unique Linde twin accelerator pedal sis dimensions and smooth, electric 420 Ah to 620 Ah

Generous storage compartments Electric horn

Lift height indicator above free lift zone (STD and TX) Electric Reach Trucks 3 High precision load handling with Linde

Load Control

steering ensure easy, efficient mano-

euvring and accurate straight line trac-

3 Rapid and simple battery change - eit-

her lift-out or battery on rollers

Key switch

Mast:

Capacity 1000 - 1600 kg 3 Highly responsive electric steering

3 Digital instrument display for instant

tion performance

3 Excellent all-round visibility of the load

Torsion-resistant clear view tilt standard or triplex mast R 10 B, R 12 B, R 14 B, R 16 B readout of truck status

3 Integral, adjustable operator´s control

and surrounding environment

Fork length 1150 mm console

Series 1120

tions. All dimensions subject to usual tolerances.

Optional Equipment

Torosion-resistant clear view tilt standard or triplex mast with LED working lamps

lift heights between 2930 mm and 7710 mm Rotating/flashing beacon

Side shift centering* Blue Spot™ safety light Safety

Alternative fork lengths LFM Linde Fleet management With four independent braking systems, fail-to-safe dual

Fork extensions Audible traction alarm circuitry and an impressive range of operator protection fea-

Load backrest Additional hydraulic circuit for attachments* tures, a safe and efficient working environment is assured. Linde twin accelerator pedals Linde clear view mast Servicing

Single axis joysticks for each hydraulic function Battery on rollers 3 Seamless and effortless forward/ 3 Torsion-resistant, clear view standard 3 Configurable 1120 B Linde Digital

reverse selection provides outstanding and triplex tilt masts Control system (LDC) incorporates dia-

Single accelerator pedal, automotive layout with left foot Battery roller stand Performance traction control and places minimal 3 Twin cylinder configuration for opti- gnostic technology

interlock Alternative colour schemes Powerful AC traction and lift motors combined with the demands on operator mum visibility (STD-mast), plus center 3 Easy service access

360° steering (single accelerator pedal only) renowned Linde intelligent controller to deliver seamless, Reliability 3 His left foot is safely protected within free lift cylinder on TX-mast 3 Maintenance-free AC traction, lift and

the chassis contours 3 Hydraulic hoses reeved through the steer motors

Reverse steering Other options available on request energy efficient performance for best productivity. Torsion- Durability and reliability are key elements in delivering cost

3 The operator is able to maintain high mast to enhance visibility (above 3 Up to 1000 operating hours between

PVC covered seat * Availability to be advised resistant clear view tilt standard or triplex masts ensure effective supply chain solutions. Linde reach trucks benefit levels of efficiency and productivity chains) services

High Vision armoured glass roof smooth, highly efficient storage and retrieval cycles. from the experience of over 50 years working in heavy indus-

Draught protection door trial and commercial applications. All key components are desi-

Protection frame Comfort gned and manufactured in-house to achieve these objectives.

Steel mesh profile or polycarbonate insert for overhead guard A world first sees the operator‘s work station resiliently High residual capacities also result from this knowledge.

Profiled overhead guard for drive-in racking mounted to the base chassis isolating the operator from

Side guidance wheels shocks and vibrations. An ergonomic, fully adjustable seat Productivity

Load wheel protection and integral control console housing the fingertip joystick For low to medium intensity applications requiring cost effec-

Printed in Germany 073.e.2.0414.IndA.Ki

Fan underneath overhead guard for driver comfort hydraulic levers together with a compact steering wheel tive material handling equipment, the highly competitive Linde

Radio Data Terminal bracket gives unsurpassed levels of operator comfort. The unique R10B - R16B reach truck range offers a combination of perfor-

Option bar Linde electric steering system enables effortless operation mance and low operating costs aimed at this important market

Interior light and assured manoeuvring and travelling. In this superb, sector.

Auxiliary 12 V power socket stress-free working environment, the operator is motivated

Linde Material Handling GmbH, Postfach 10 01 36, 63701 Aschaffenburg, Germany

and can fully focus on the task. Phone +49.6021.99-0, Fax +49.6021.99-1570, www.linde-mh.com, info@linde-mh.com

Technical Data according to VDI 2198

1.1 Manufacturer LINDE LINDE LINDE LINDE

1.2 Model designation R10B R12B R14B R16B

1.2a Series 1120-00 1120-00 1120-00 1120-00

Characteristics

1.3 Power unit Battery Battery Battery Battery

1.4 Operation Seat Seat Seat Seat

1.5 Load capacity/Load Q (t) 1.0 1.2 1.4 1.6

1.6 Load centre c (mm) 600 / 500 600 / 500 600 / 500 600 / 500

1.8 Axle centre to fork face x (mm) 326 1) 326 1) 360 1) 427 1)

1.9 Wheelbase y (mm) 1275 1275 1381 1453

2.1 Service weight (kg) 2825 2) 2890 2) 3270 2) 3280 2)

Weights

2.3 Axle load without load, front/rear (kg) 1750 / 1075 1770 / 1120 1950 / 1320 2015 / 1265

2.4 Axle load, fork outreached, with load, front/rear (kg) 725 / 3100 600 / 3490 580 / 4090 645 / 4235

2.5 Axle load, fork retracted, with load, front/rear (kg) 1535 / 2290 1512 / 2578 1707 / 2963 1824 / 3056

3.1 Tyres rubber, SE, pneumatic, polyurethane Polyurethane Polyurethane Polyurethane Polyurethane

3.2 Tyre size, front Ø 360 x 130 Ø 360 x 130 Ø 360 x 130 Ø 360 x 130

Wheels/Tyres

3.3 Tyre size, rear Ø 285 x 100 Ø 285 x 100 Ø 285 x 100 Ø 285 x 100

3.5 Wheels, number front/rear (x = driven) 1x / 2 1x / 2 1x / 2 1x / 2

3.6 Track width, front b10 (mm) 0 0 0 0

3.7 Track width, rear b11 (mm) 1167 1167 1167 1167

4.1 Mast/fork carriage tilt, forward/backward a/b (°) 2.0 / 2.0 2.0 / 2.0 2.0 / 2.0 2.0 / 2.0

4.2 Height of mast, lowered h1 (mm) 2524 3024 2524 2524

4.3 Free lift h2 (mm) 150 150 1857 1857

4.4 Lift h3 (mm) 3830 4830 5710 5710

4.5 Height of mast, extended h4 (mm) 4451 5451 6379 6379

4.7 Height of overhead guard (cabin) h6 (mm) 2110 2110 2110 2110

4.8 Height of seat/stand on platform h7 (mm) 910 - 1040 910 - 1040 910 - 1040 910 - 1040

4.19 Overall length l1 (mm) 2318 2) 2318 2) 2390 2) 2395 2)

4.20 Length to fork face l2 (mm) 1168 1168 1240 1245

4.21 Overall width b1/b2 (mm) 1270 1270 1270 1270

Dimensions

4.22 Fork dimensions s/e/l (mm) 40 x 80 x 1150 40 x 80 x 1150 40 x 80 x 1150 45 x 100 x 1150

4.23 Fork carriage to ISO 2328, class/type A, B 2A 2A 2A 2A

4.24 Width of fork carriage b3 (mm) 880 880 880 880

4.25 Fork spread, min/max b5 (mm) 296 / 829 296 / 829 296 / 829 296 / 829

4.26 Width between reach legs b4 (mm) 920 920 920 920

4.28 Reach travel l4 (mm) 515 515 548 612

4.31 Ground clearance, below mast m1 (mm) 90 90 90 90

4.32 Ground clearance, centre of wheelbase m2 (mm) 70 70 70 70

Clear view tilt standard mast

4.33 Aisle width with pallet 1000 x 1200 across forks Ast (mm) 2644 3) 2) 2644 3) 2) 2717 3) 2) 2740 3) 2)

R 10 B, R 12 B, R 14 B, R 16 B

4.34 Aisle width with pallet 800 x 1200 along forks Ast (mm) 2703 3) 2) 2703 3) 2) 2770 3) 2) 2780 3) 2)

Lift h3 3030 3330 3530 3730 3930 4130 4330 4530 4730 4930 5130 5330 5530 5630

4.35 Turning radius Wa (mm) 1542 4) 1542 4) 1640 4) 1710 4) Free lift h2 150 150 150 150 150 150 150 150 150 150 150 150 150 150

4.37 Length of chassis l7 (mm) 1639 1639 1737 1817 Height of mast, lowered h1 2124 2274 2374 2474 2574 2674 2774 2874 2974 3074 3174 3274 3374 3424

5.1 Travel speed, with/without load (km/h) 11 / 11 5) 6) 11 / 11 5) 6) 11 / 11 5) 6) 11 / 11 5) 6) Height of mast, extended h4 3690 3990 4190 4390 4590 4790 4990 5190 5390 5590 5790 5990 6190 6290

5.2 Lifting speed, with/without load (m/s) 0.51 / 0.57 0.45 / 0.57 0.43 / 0.57 0.4 / 0.57

Clear view tilt triplex mast

Performance

5.3 Lowering speed, with/without load (m/s) 0.55 / 0.55 0.55 / 0.55 0.55 / 0.55 0.55 / 0.55

R 10 B, R 12 B, R 14 B, R 16 B

5.4 Reach speed, with/without load (m/s) 0.16 0.16 0.16 0.16

Lift h3 4610 4760 5210 5410 5710 5860 6010 6210 6510 6660 6960 7260 7560 7710

5.8 Maximum climbing ability, with/without load (%) 10.0 / 10.0 10.0 / 10.0 10.0 / 10.0 10.0 / 10.0

Free lift h2 1457 1507 1657 1757 1857 1907 1957 2057 2157 2207 2307 2407 2507 2557

5.9 Acceleration time, with/without load (s) - - - - Height of mast, lowered h1 2124 2174 2324 2424 2524 2574 2624 2724 2824 2874 2974 3074 3174 3224

5.10 Service brake hydr./mech. hydr./mech. hydr./mech. hydr./mech. Height of mast, extended h4 5275 5425 5875 6075 6375 6525 6675 6875 7175 7325 7625 7925 8225 8375

6.1 Drive motor, 60 minute rating (kW) 6.5 6.5 6.5 6.5 Alternative lift heights are available on request.

6.2 Lift motor, rating at S3 15% (kW) 14 14 14 14 Lift height = h3 + s

6.3 Battery according to DIN 43531/35/36 A,B,C,no 43 531 / C 43 531 / C 43 531 / C 43 531 / C

Drive

6.4 Battery voltage/rated capacity (5h) (V/Ah) 48 / 420/465 2) 48 / 420/465 2) 48 / 420/465 2) 48 / 420/465 2)

6.5 Battery weight (± 5%) (kg) 750 750 750 750

6.6 Power consumption according to VDI cycle (kWh/h) upon request upon request upon request upon request

8.2 Operating pressure for attachments (bar) - - - -

Others

8.3 Oil flow for attachments (l/min) - - - -

8.4 Noise level at operator‘s ear (dB(A)) 64 64 64 64

1) - 30 mm with integrated side shifter 4) fn296 / 829

2) Alternative batteries may alter l1, Ast and sevice weight. 5) forward; backward

3) Including a 200 mm (min.) operating aisle clearance. 6) Depending on performance setting

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Empty ContainerDocument3 pagesEmpty Containerwill wuNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- CS45 KMpresDocument24 pagesCS45 KMpreswill wu100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Fantuzzi Reachstacker Cs 45 KM: Technical CharacteristicDocument9 pagesFantuzzi Reachstacker Cs 45 KM: Technical Characteristicwill wuNo ratings yet

- Hyundai Fully Converts Diesel Forklift Range To Stage IiibDocument2 pagesHyundai Fully Converts Diesel Forklift Range To Stage Iiibwill wuNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- How To Create A Better Dealer Network.Document4 pagesHow To Create A Better Dealer Network.will wuNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Electric Forklift 3.0-3.5tDocument2 pagesElectric Forklift 3.0-3.5twill wuNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Manitou M 26 M 30 M 40 M 50 ENDocument12 pagesManitou M 26 M 30 M 40 M 50 ENwill wuNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Platform Pallet Truck Capacity 2000 and 2400kgDocument6 pagesPlatform Pallet Truck Capacity 2000 and 2400kgwill wuNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Technical Book: ME POP Range 1,5 To 3 Tons Electric TrucksDocument8 pagesTechnical Book: ME POP Range 1,5 To 3 Tons Electric Truckswill wuNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Electric Man-Down Turret TruckDocument6 pagesElectric Man-Down Turret Truckwill wuNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Electric Reach Trucks Capacity 1000 - 2500 KGDocument2 pagesElectric Reach Trucks Capacity 1000 - 2500 KGwill wuNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Manitou MI 15 35 ENDocument12 pagesManitou MI 15 35 ENwill wuNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Urban Electric Pallet Truck Capacity 500 KG CiTi OneDocument2 pagesUrban Electric Pallet Truck Capacity 500 KG CiTi Onewill wuNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Electric Counterbalanced Trucks Capacity 6000 - 8000 KGDocument2 pagesElectric Counterbalanced Trucks Capacity 6000 - 8000 KGwill wuNo ratings yet

- 2015德国慕尼黑物流展展商名单Document27 pages2015德国慕尼黑物流展展商名单will wuNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Diesel and LPG Forklift Trucks Capacity 5000 - 8000 KGDocument2 pagesDiesel and LPG Forklift Trucks Capacity 5000 - 8000 KGwill wuNo ratings yet

- Battery & Charger: Lithium-IonDocument2 pagesBattery & Charger: Lithium-Ionwill wuNo ratings yet

- Service 10709790 02-18-05 ANSI EnglishDocument636 pagesService 10709790 02-18-05 ANSI EnglishKeenan100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- VOLKSWAGEN RN19UGU, Damages and MOT History CheckDocument1 pageVOLKSWAGEN RN19UGU, Damages and MOT History CheckSahib SinghNo ratings yet

- Mcculloch Parts List: 530087882 Mac Cat 335, 435 & 440 03/08/00Document3 pagesMcculloch Parts List: 530087882 Mac Cat 335, 435 & 440 03/08/00lulu3232No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Cesabb 300 B 400Document8 pagesCesabb 300 B 400BeyzaNo ratings yet

- CrankshaftDocument16 pagesCrankshaftDana RomanNo ratings yet

- GMC Hummer EV SUV 2024 Emergency Response Guide - EnglishDocument13 pagesGMC Hummer EV SUV 2024 Emergency Response Guide - EnglishShalon MeloNo ratings yet

- The Ten Forklift Safety RulesDocument10 pagesThe Ten Forklift Safety RulesAlexandra johnNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- PC 753-825 PDFDocument1,068 pagesPC 753-825 PDFMarcus DragoNo ratings yet

- BSA Bicycle TouringDocument18 pagesBSA Bicycle Touringtspinner19No ratings yet

- Active SuspensionDocument5 pagesActive SuspensionPrasad BillahalliNo ratings yet

- Audi A1, A Success Story: © CCMP 2017Document12 pagesAudi A1, A Success Story: © CCMP 2017MArieNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Tracing The Cause of Oil Mist AlarmDocument15 pagesTracing The Cause of Oil Mist AlarmrobetxNo ratings yet

- Benz Vehicle Diagnostic Report - WDDGF77X49F302514 - 2023104041502Document5 pagesBenz Vehicle Diagnostic Report - WDDGF77X49F302514 - 2023104041502leonard.otzenNo ratings yet

- Aero Design ReportDocument2 pagesAero Design ReportAdithya KothandhapaniNo ratings yet

- 22 M350 Single Spec Sheet REVISEDaDocument2 pages22 M350 Single Spec Sheet REVISEDaMichael BecherNo ratings yet

- 16074102-Triumph Daytona 675 R 2013-2016 Workshop Service ManualDocument697 pages16074102-Triumph Daytona 675 R 2013-2016 Workshop Service ManualAlfredo VillamorNo ratings yet

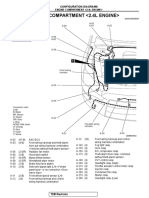

- Engine Compartment : Connector SymbolDocument11 pagesEngine Compartment : Connector Symbolskulikov191974No ratings yet

- Caterpillar Parts Book PDFDocument24 pagesCaterpillar Parts Book PDFB.HNo ratings yet

- CB103 1963 Century Selection GuideDocument131 pagesCB103 1963 Century Selection GuideApo ghasan Al shargapiNo ratings yet

- Kia Industrial SectorDocument1 pageKia Industrial SectorvgvpplNo ratings yet

- Module-Powertrain Control C1 - Black/Black (Injector) 38 WayDocument3 pagesModule-Powertrain Control C1 - Black/Black (Injector) 38 WayDavid CoboNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pneumatic Disc Break 7000Document4 pagesPneumatic Disc Break 7000Jeff MainaNo ratings yet

- Load and Trim Preparation - For PilotsDocument21 pagesLoad and Trim Preparation - For PilotsNguyễn Bình Luận100% (1)

- Safe Transition With YANMARDocument4 pagesSafe Transition With YANMARJosé Manuel PérezNo ratings yet

- Technical Presentation CAT 789c-785c 124045423-ManualDocument276 pagesTechnical Presentation CAT 789c-785c 124045423-Manualbas100% (10)

- Summary Changes For NCHRP Report 350 GuidelinesDocument28 pagesSummary Changes For NCHRP Report 350 GuidelinesrodolfoNo ratings yet

- SeaDoo 3D DI 2006 Manual PDFDocument320 pagesSeaDoo 3D DI 2006 Manual PDFRicardo Vilhena100% (3)

- Kawasaki H1 (69-76), H2 (72-75), KH500 (76-77) Service ManualDocument169 pagesKawasaki H1 (69-76), H2 (72-75), KH500 (76-77) Service ManualAndy ChrisNo ratings yet

- (2022 09) Changes in CatalogueDocument4 pages(2022 09) Changes in CatalogueamitNo ratings yet

- Disc Brake Rotor ProjectDocument9 pagesDisc Brake Rotor ProjectShobha raniNo ratings yet

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)