Professional Documents

Culture Documents

Technical Information Screws, Nuts: Clamping Force and Tightening Torques

Technical Information Screws, Nuts: Clamping Force and Tightening Torques

Uploaded by

jbsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Information Screws, Nuts: Clamping Force and Tightening Torques

Technical Information Screws, Nuts: Clamping Force and Tightening Torques

Uploaded by

jbsCopyright:

Available Formats

24000

Technical Information

Screws, Nuts

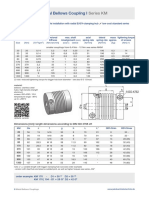

The values for clamping forces Fsp and

26000

Clamping force and tightening torques

tightening torques Msp specified in the Set screws Set screws

table apply to standard metric thread Stan- µges* clamping force Fsp tightening torque Msp Stan- µges* clamping force Fsp tightening torque Msp

according to DIN 13 and head contact dard = µG in kN in Nm dard = µG in kN in Nm

surfaces according to thread = µK in quality class thread = µK in quality class

DIN 912, 931-934, 6912, 7984, 7990. 8.8 10.9 12.9 8.8 10.9 12.9 8.8 10.9 12.9 8.8 10.9 12.9

27000

0,08 4,40 6,40 7,5 2,2 3,2 3,8 0,08 59,0 86,7 101,0 97 143 167

0,10 4,20 6,20 7,3 2,5 3,7 4,3 0,10 56,9 83,6 97,8 113 165 194

M4 M14

The Fsp clamping force values result 0,12 4,05 6,00 7,0 2,8 4,1 4,8 0,12 54,7 80,4 94,1 127 186 218

0,14 3,90 5,70 6,7 3,1 4,5 5,3 0,14 52,6 77,2 90,3 139 205 239

in a 90% utilisation of yield point σ

0.2 (DIN 267 pg. 3) subject to the 0,08 7,16 10,50 12,3 4,3 6,3 7,3 0,08 81,0 119,0 139,0 147 216 253

0,10 6,90 10,10 11,9 4,9 7,2 8,5 0,10 78,2 115,0 134,0 172 252 295

respective coefficient of friction in M5 0,12 6,63 9,74 11,4 5,5 8,1 9,5 M16 0,12 75,3 111,0 130,0 194 285 333

threads. 0,14 6,36 9,34 10,9 6,0 8,9 10,4 0,14 72,4 106,0 124,0 214 314 367

28000

0,08 10,10 14,90 17,4 7,4 10,9 12,7 0,08 131,0 186,0 218,0 298 424 496

0,10 9,74 14,30 16,7 8,5 12,5 14,7 0,10 126,0 180,0 210,0 347 494 578

It can be inferred from the table which M6 0,12 9,35 13,70 16,1 9,5 14,0 16,4 M20 0,12 121,0 173,0 202,0 392 558 653

screw with which quality is required 0,14 8,97 13,20 15,4 10,4 15,3 17,9 0,14 117,0 166,0 194,0 431 615 719

for a particular coefficient of friction 0,08 18,50 27,20 31,9 17,9 26,2 30,7 0,08 188,0 268,0 313,0 512 730 854

in thread in order to apply a given FM M8 0,10 17,90 26,20 30,7 20,6 30,3 35,5 M24 0,10 182,0 259,0 303,0 597 850 995

0,12 17,20 25,20 29,5 23,1 34,0 39,7 0,12 175,0 249,0 291,0 673 959 1122

assembly force (Fsp >= FM).

29000

0,14 16,50 24,20 28,3 25,3 37,2 43,6 0,14 168,0 239,0 280,0 742 1057 1237

0,08 29,50 43,30 50,7 36,0 53,0 61,0 0,08 300,0 430,0 500,0 1000 1450 1700

The Msp tightening torques are M10 0,10 28,40 41,80 48,9 41,0 61,0 71,0 M30 0,10 290,0 415,0 485,0 1190 1700 2000

calculated based on the Fsp clamping 0,12 27,30 40,20 47,0 46,0 68,0 80,0 0,12 280,0 400,0 465,0 1350 1900 2250

0,14 26,20 38,50 45,1 51,0 75,0 88,0 0,14 270,0 358,0 450,0 1500 2100 2500

forces assuming µG = µK = µges.

0,08 43,00 63,10 73,9 61,0 90,0 105,0 0,08 440,0 630,0 730,0 1750 2500 3000

0,10 41,40 60,90 71,2 71,0 104,0 122,0 0,10 425,0 600,0 710,0 2100 3000 3500

31000

M12 M36

Determination of the Msp tightening 0,12 39,90 58,50 68,5 80,0 117,0 137,0 0,12 410,0 580,0 680,0 2350 3300 3900

0,14 38,30 56,20 65,8 87,0 128,0 150,0 0,14 395,0 560,0 660,0 2600 3700 4300

torque at 90 % yield point utilisation

for a screw specified in size and

quality is made according to the table

at the right subject to the underhead Screw stability according to DIN ISO 20898 T 1 (4.92)

friction occurring (µK), irregardless of a

32500

coefficient of friction in thread deviating quality classes 5.8 6.8 8.8 10.9 12.9

from it.

Minimum tensile strength Rm N/mm2 500 600 800 1000 1200

Minimum yield point Re N/mm2 400 480 640

900 1080

To attain the applicable rated load

torque it is still necessary to reduce half 0.2-proof stress Rp0,2 N/mm2 – – 640 900 1080

33000

the spread of the designated torque Test stress Sp N/mm2 364 440 582 792 950

wrench by the particular tightening 10 8 12 9 8

Failure strain A5 %

torque Msp.

Impact strength (ISO test piece) Nm/cm2 – – 60 40 30

Calculation of the table values and

information for applications according The respective quality classes have the following meaning (demonstrated using the example 8.8):

95000

to VDI guideline 2230.

minimum tensile strength Rm

First number 8. = = 800 N/mm2

100

minimum yield point Re

96000

Second number .8 = · 10 = 640 N/mm2 (80 % of Rm)

minimum tensile strength Rm

Nut stability according to DIN ISO 20898 T 2 (2.94)

Quality class classification numbers 5 6 8 10 12

97000

Test stress Sp Sp N/mm2 500 600 800 1000 1200

The quality classes have the following meaning (demonstrated using the example 10):

test stress Sp

10 =

100

This test stress is equal to the minimum tensile strength of a screw that can be loaded when

pairing with the corresponding nut up to the minimum yield point of the screw.

A-Z

1287

technische Daten_en_fr.indd 1287 03.12.2012 16:03:15

Technical Information

Screws, Nuts

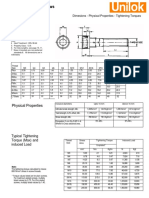

The coefficients of friction (see table) Coefficient of friction μG in the thread (according to Strelow or VDI 2230)

fluctuate over a wide range. They

fluctuate even when tightening and by

production run of the same screws. mG Thread External thread (screw)

Because µG and µK are generally Material Steel

of different sizes a wide range of

black tempered or phosphated galvanized galvanized cadmium- adhesive

tightening torques arise as a result. Surface

(Zn6) plated (Cd6)

Calculation is performed using various Tapping machine-

rolled machine-cut or rolled

coefficients of friction in accordance cut

with VDI guideline 2230. By contrast

Material

natural Surface

Thread

Tapping

Lubrica- dry lubricated MoS2* lubricated dry lubricated dry lubricated dry

Illgner/Blume in their „Schrauben tion

Vademecum“ calculate using a

finish

coefficient of friction µges = µG = µK. 0,12 0,10* 0,08 0,10 – 0,10 – 0,08 0,16

Here it proceeds according to VDI

methods. However if µG and/or µK

Steel

cadmium-plated 0,10 – – – 0,12 0,10 – – 0,14

are unknown, µG = 0,12 or µK = 0,12

Internal thread (nut)

galvanized

would typically be used. machine-cut

dry

0,08 – – – – – 0,12 0,12 –

GJL/GJMB

natural

finish

– 0,10 – 0,10 – 0,10 – 0,08 –

natural

finish

AlMg

– 0,08 – – – – – – –

* Molybdenum disulfide

Coefficient of friction μK on the head or nut engaging surface (according to Strelow or VDI 2230)

mK Support suface Screw head

Material Steel

black tempered or phosphated galvanized galvanized cad-

Surface (Zn6) mium-plated (Cd6)

Support suface

Manufac- pressed turned smoothed pressed

ture

Material

Surface

Manuf-

smoothed acture

Lubrica- dry lubricated MoS2* lubricated MoS2*dry lubricated dry lubricated dry lubricated

tion

– 0,16 – 0,10 – 0,16 0,10 – 0,08 –

natural

finish

0,12 0,10 0,08 0,10 0,08 – 0,10 0,08 0,08

Steel

machined

cadmium-plated

0,10 – 0,10 – 0,10 0,16 0,10 – –

galvanized

Counter support

dry

0,08 – – 0,12 0,12

smoothed

– 0,10 – – – 0,10 bis 0,18 0,08 –

GJL/GJMB

natural

finish

– 0,14 – 0,10 – 0,14 0,10 0,10 0,08 –

machined

AlMg

– 0,08 – – – – –

* Molybdenum disulfide

1288

technische Daten_en_fr.indd 1288 03.12.2012 16:03:16

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Torque Details-Hex Bolt DIN 933Document2 pagesTorque Details-Hex Bolt DIN 933coolkaisy100% (3)

- MTO Hymn BookDocument284 pagesMTO Hymn BookEcosqin Beauty92% (12)

- Beam On Elastic Foundation-Finite ElementDocument29 pagesBeam On Elastic Foundation-Finite ElementrymacNo ratings yet

- Online Admission SystemDocument157 pagesOnline Admission Systemmikkijain100% (1)

- Base Plate & Anchor Bolt - BP1Document20 pagesBase Plate & Anchor Bolt - BP1munishant1No ratings yet

- Anki Guide For Medical StudentsDocument6 pagesAnki Guide For Medical StudentspchamessNo ratings yet

- Fire DynamicsDocument11 pagesFire DynamicsSelvakumar BalachandranNo ratings yet

- Farm Structure NotesDocument150 pagesFarm Structure NotesAnnebo Tayebwa96% (25)

- Tightening Torques PDFDocument1 pageTightening Torques PDFlaweenceNo ratings yet

- Setting Time - Vicat Needle ASTM C 191Document10 pagesSetting Time - Vicat Needle ASTM C 191alex_g00dy100% (1)

- Cpar M2Document64 pagesCpar M2Allan AñonuevoNo ratings yet

- Module 1 Assessment in Learning 2 A RivadDocument20 pagesModule 1 Assessment in Learning 2 A RivadAshley Delmundo100% (1)

- Moment Strangere InoxDocument1 pageMoment Strangere Inoxtracam500100% (1)

- Din 933Document2 pagesDin 933Sugumar0% (1)

- High Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)Document2 pagesHigh Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)jaison jacobNo ratings yet

- NutsDocument8 pagesNutsGerry Dan ChanliongcoNo ratings yet

- Datasheet KMDocument1 pageDatasheet KMFrancisco SanchezNo ratings yet

- Metal Bellows Coupling I: Series KMDocument1 pageMetal Bellows Coupling I: Series KMIsmael RiosNo ratings yet

- Combined Bearing/Freewheel - CSK - CSK..2RS - Stieber ClutchDocument2 pagesCombined Bearing/Freewheel - CSK - CSK..2RS - Stieber ClutchborischechenkoNo ratings yet

- Socket Head Cap ScrewDocument4 pagesSocket Head Cap ScrewsarbiniNo ratings yet

- BEL - Confirmation - 130420 WITH QUANTITYDocument4 pagesBEL - Confirmation - 130420 WITH QUANTITYSHUBHAM SHUKLANo ratings yet

- 0-00-000-0048-50 R SCW/PHD/COMBI/M2.5x6/MS/ZBP 2 0 M110016BO0A R Screw Allen M4 X 16 ZP 8 0 4 0 0 0 0 0 0 0 0 0 0 0 0Document4 pages0-00-000-0048-50 R SCW/PHD/COMBI/M2.5x6/MS/ZBP 2 0 M110016BO0A R Screw Allen M4 X 16 ZP 8 0 4 0 0 0 0 0 0 0 0 0 0 0 0SHUBHAM SHUKLANo ratings yet

- Stieber CSK35-M-C5Document2 pagesStieber CSK35-M-C5Johnatas GamaNo ratings yet

- 5 Dicharge End 4 Burning Zone 1 Feed End 2 Preheating Zone 3 Calcining ZoneDocument1 page5 Dicharge End 4 Burning Zone 1 Feed End 2 Preheating Zone 3 Calcining ZoneJOELMAX10111No ratings yet

- Bearings For Screw DrivesDocument10 pagesBearings For Screw DrivesTravis DavisNo ratings yet

- Es PM FW0009 2016Document5 pagesEs PM FW0009 2016陳相如No ratings yet

- 06-STRUTURAL BOLT & NUT As Per A490MDocument1 page06-STRUTURAL BOLT & NUT As Per A490MSaravan KumarNo ratings yet

- Parafuso Cabeça Cilíndrica Com Sextavado Interno - Série Métrica PDFDocument1 pageParafuso Cabeça Cilíndrica Com Sextavado Interno - Série Métrica PDFOliver OliveiraNo ratings yet

- Parafuso Cabeça Cilíndrica Com Sextavado Interno - Série Métrica PDFDocument1 pageParafuso Cabeça Cilíndrica Com Sextavado Interno - Série Métrica PDFOliver OliveiraNo ratings yet

- HSFG Part II Bolt & NutDocument1 pageHSFG Part II Bolt & NutvpjagannaathNo ratings yet

- Beam On Elastic Foundation-Finite ElementDocument29 pagesBeam On Elastic Foundation-Finite ElementamindammakNo ratings yet

- τεχνικά χαρακτηριστικά τριφασικών ασύγχρονων κινητήρων βραχυκυκλωμένου δρομέα (κέλυφος χυτοσιδήρου) (Κατάλογος Βαλιάδη)Document32 pagesτεχνικά χαρακτηριστικά τριφασικών ασύγχρονων κινητήρων βραχυκυκλωμένου δρομέα (κέλυφος χυτοσιδήρου) (Κατάλογος Βαλιάδη)jkgrNo ratings yet

- Installation Instructions Input/Output Chokes (FSD To FSF)Document2 pagesInstallation Instructions Input/Output Chokes (FSD To FSF)Uno MariconNo ratings yet

- Beam On Elastic Foundation-Finite ElementDocument29 pagesBeam On Elastic Foundation-Finite ElementHHTNo ratings yet

- TIEIG 2023 - Twin Washers & Disc SpringsDocument24 pagesTIEIG 2023 - Twin Washers & Disc SpringsHülya Kula ÇİÇEKÇİNo ratings yet

- Carbon Hollow Bar ST 52Document2 pagesCarbon Hollow Bar ST 52JeganeswaranNo ratings yet

- Datasheet KMDocument1 pageDatasheet KMAlexander DíazNo ratings yet

- Nicolas Cavalcante - ProtendidoDocument20 pagesNicolas Cavalcante - ProtendidoNicolas CavalcanteNo ratings yet

- Beam On Elastic Foundation-Finite ElementDocument29 pagesBeam On Elastic Foundation-Finite ElementMd. Mahmudle HassanNo ratings yet

- Spring Lock Washer Dimensions-DIN-128-A-ENDocument1 pageSpring Lock Washer Dimensions-DIN-128-A-ENivanNo ratings yet

- Wa0001Document6 pagesWa0001Jony RodriguezNo ratings yet

- Hex NutsDocument10 pagesHex Nutsjaskaran singhNo ratings yet

- Mv. Adriani: Bulk CarrierDocument33 pagesMv. Adriani: Bulk CarrierHazemy putraNo ratings yet

- 04-Strutural Bolt & Nut As Per A325mDocument1 page04-Strutural Bolt & Nut As Per A325mSaravan KumarNo ratings yet

- High Tensile Bolts TechnicalDocument6 pagesHigh Tensile Bolts Technicalventhan_kalaiNo ratings yet

- DIN 7980 - Saibe Grower PDFDocument1 pageDIN 7980 - Saibe Grower PDFCorciu ValentinNo ratings yet

- Holding Down Bolts BS 7419 (Square Square) : Grade 4.6 & 8.8Document2 pagesHolding Down Bolts BS 7419 (Square Square) : Grade 4.6 & 8.8Thilan SenarathneNo ratings yet

- Stieber Type Csk-Csk2rs-EnDocument2 pagesStieber Type Csk-Csk2rs-Ena04205No ratings yet

- 1587 4 PDFDocument1 page1587 4 PDFQA QCNo ratings yet

- Hexagon Domed Cap Nuts: High TypeDocument1 pageHexagon Domed Cap Nuts: High TypeQA QCNo ratings yet

- Load Vs Settlement-12.xlsx - GroupDocument4 pagesLoad Vs Settlement-12.xlsx - GroupNeelakantamNo ratings yet

- Tugas Uji Tarik FixDocument15 pagesTugas Uji Tarik FixANDINTA MUDA YUSUFNo ratings yet

- Muermann b4 Fork End Connector Pin Gusset Plate 460Document1 pageMuermann b4 Fork End Connector Pin Gusset Plate 460Nargis KhanNo ratings yet

- JIS KIS Flange Product Range CatalogueDocument8 pagesJIS KIS Flange Product Range CatalogueAsep DarojatNo ratings yet

- Appendix Technical Data & Dimensions: Multistrand Post-TensioningDocument18 pagesAppendix Technical Data & Dimensions: Multistrand Post-TensioningCamilo Andres TorresNo ratings yet

- Catalog Standard Motor LTS PDFDocument20 pagesCatalog Standard Motor LTS PDFYogesh BadheNo ratings yet

- Datasheet KPPDocument1 pageDatasheet KPPRogelio LiceaNo ratings yet

- Nyy 0,6/1 KV Technical - DataDocument24 pagesNyy 0,6/1 KV Technical - DataDavi RumusNo ratings yet

- HDAP-OFDM Dimming PDFDocument1 pageHDAP-OFDM Dimming PDFRashed IslamNo ratings yet

- Blower - TrundeanDocument5 pagesBlower - Trundeanwaterlink.faysalNo ratings yet

- Hardy Cross Method Solved ExampleDocument4 pagesHardy Cross Method Solved ExamplejajajajNo ratings yet

- Hydro BonjeanDocument34 pagesHydro Bonjeanarqhab walzthyNo ratings yet

- PIP-10346044 2022/ 02/21 21:14: 18-05: 00 SSNR3130 © 2022 Ca Terpi Llar Inc - Caterpi Llar: Confi Dentia L Gre enDocument3 pagesPIP-10346044 2022/ 02/21 21:14: 18-05: 00 SSNR3130 © 2022 Ca Terpi Llar Inc - Caterpi Llar: Confi Dentia L Gre enJuan Ricardo Bolivar PilcoNo ratings yet

- Cpi STD Eam 20Document24 pagesCpi STD Eam 20RajendraNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- School-Based Management (SBM) Validation: Division of BukidnonDocument20 pagesSchool-Based Management (SBM) Validation: Division of BukidnonMarcus JuanNo ratings yet

- Lesson 5 - Value of ResearchDocument10 pagesLesson 5 - Value of ResearchAiko CunananNo ratings yet

- 1.000 Sentence Buiding - Thi Chuyên HSG L P 9, 10...Document63 pages1.000 Sentence Buiding - Thi Chuyên HSG L P 9, 10...Xoăn TrầnNo ratings yet

- JHS LCP English Grade 7 10Document25 pagesJHS LCP English Grade 7 10Daryl RiveraNo ratings yet

- Tech SeminarDocument22 pagesTech SeminarSINCHANA H CNo ratings yet

- Emperor OS New Features v2Document27 pagesEmperor OS New Features v2Saqib HussainNo ratings yet

- Wa0003 PDFDocument15 pagesWa0003 PDFMuntandwe georgeNo ratings yet

- Computing Fundamentals: Dr. Muhammad Yousaf HamzaDocument62 pagesComputing Fundamentals: Dr. Muhammad Yousaf HamzaAr rehmanNo ratings yet

- PRC Form DAVEDocument1 pagePRC Form DAVEDave Sayson33% (3)

- Technology TimelineDocument2 pagesTechnology TimelineEllarie RyalsNo ratings yet

- Art History Research PosterDocument10 pagesArt History Research Posterapi-259714129No ratings yet

- Future Comunication Infrastructure EctlDocument18 pagesFuture Comunication Infrastructure Ectlyasuni1000No ratings yet

- Syllabus of 2nd Year LMD English at ENS Algeria Semster 4Document363 pagesSyllabus of 2nd Year LMD English at ENS Algeria Semster 4belbachir100% (1)

- Case Study On BoeingDocument12 pagesCase Study On BoeingshahraashidNo ratings yet

- Steam Iron: MM 433: Manufacturing Processes SeminarDocument35 pagesSteam Iron: MM 433: Manufacturing Processes SeminarPrasoon MeenaNo ratings yet

- Shrink FittingDocument26 pagesShrink FittingmaheshkbandariNo ratings yet

- 4 Using Gaussian Elimination: Column Space, Nullspace, Rank, Nullity, Linear Independence, Inverse MatrixDocument14 pages4 Using Gaussian Elimination: Column Space, Nullspace, Rank, Nullity, Linear Independence, Inverse Matrixmcs mNo ratings yet

- 영상센서신호의잡음분석을이용한위성용전자광학탑재체의신호대잡음비개선방법Document11 pages영상센서신호의잡음분석을이용한위성용전자광학탑재체의신호대잡음비개선방법최지웅No ratings yet

- Digital MarketingDocument8 pagesDigital MarketingYounus ahmedNo ratings yet

- Front Elevation: 760 M.M Above Roof SurfaceDocument1 pageFront Elevation: 760 M.M Above Roof SurfaceAbid AyubNo ratings yet

- Identical ParticlesDocument11 pagesIdentical ParticlesShams ShamsNo ratings yet

- Cobox Dinrail: Installation GuideDocument43 pagesCobox Dinrail: Installation GuideXaoc KabataNo ratings yet