Professional Documents

Culture Documents

MHT410 Moisture, Hydrogen and Temperature Transmitter: For Online Transformer Condition Monitoring

Uploaded by

Andrew SetiawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MHT410 Moisture, Hydrogen and Temperature Transmitter: For Online Transformer Condition Monitoring

Uploaded by

Andrew SetiawanCopyright:

Available Formats

MHT410 Moisture, Hydrogen and

Temperature Transmitter

For online transformer condition monitoring

Features and benefits

• Measures moisture and hydrogen

directly in transformer oil

• Compatible with mineral oil,

natural ester oil, synthetic ester

oil, and silicone oil

• Easy to install

• Provides early warning on

potential transformer faults

• Unique probe design allows for

direct measurement in oil

• 5-year standard warranty

• Robust design providing reliable

operation and no false alarms

• Maintenance-free operation

• No cross-sensitivity to other

gases

• Indigo520 compatible, with easy

access to measurement data

Vaisala MHT410 Moisture, Hydrogen and Temperature Transmitter provides reliable

online monitoring of insulating oil in power transformers.

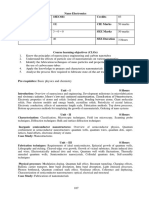

Real-time measurement MHT410 is also compatible with the 334

132 202

Vaisala Moisture, Hydrogen and Vaisala Indigo500 series transmitters. 94.5

Temperature Transmitter MHT410 With its local graphical display,

provides an accurate real-time Indigo520 is a great addition to MHT410.

50

74

36

38.5

measurement result for critical It helps you to identify data trends at the

20.6

parameters measured in oil, enabling site, as well as power the MHT410 with a

reliable conclusions on the transformer's single-wire solution. 51 25.5 1.5” NPT

condition. With its unique probe design, 76.5

MHT410 delivers accurate measurement Robust and maintenance-free

150

and trend data about the health of the operation 125

transformer in real time. MHT410 is designed for ease of use in

demanding environments. It has

Enabling proactive undergone extensive testing to ensure it

maintenance decisions withstands wide temperature changes,

All of the transmitter's measured vibration, and harsh outdoor conditions.

222

270

parameters are available through digital The transmitter has no consumables or

and analog outputs, providing moving parts that could break, and is

information on transformer fault encased in an IP66-rated metal housing

situations and enabling timely, proactive equipped with a weather shield.

maintenance decisions to minimize Every unit is individually tested for a

expensive service shutdowns and pressure of at least 10 bar and also

outages. withstands vacuum conditions. Special mm

attention has been given to EMC

tolerance: for example, all electrical

connections are isolated. MHT410 can

also tolerate short-term power outages.

Technical data

Measurement performance Mechanical specifications

Hydrogen Mechanical connection on transmitter 1.5" NPT (male)

Measurement range (in oil) 0 … 5000 ppmv Cable gland (optional, for use with M20×1.5 for cable diameter 5 … 9 mm

Indigo520) (0.20 … 0.35 in)

Accuracy 1) 2) ±10 % of reading or ±15 ppmv

(whichever is greater) Cable gland (optional) M20×1.5 for cable diameter 8 … 11 mm

(0.31 … 0.43 in)

Repeatability ±10 % of reading or ±15 ppmv

(whichever is greater) Cable gland (optional) M20×1.5 for cable diameter

11 … 14.5 mm (0.43 … 0.57 in)

Minimum detection limit 15 ppmv

Conduit fitting (optional) 1/2" NPT

Typical long-term stability 3 % of reading / year

Interface cable (optional, pre- 5 m (16 ft 5 in), 9.2 mm (0.36 in) outer

Cross sensitivity to other gases < 2 % (CO2, C2H2, C2H4, CO) assembled) diameter

Response time 63 % of full response: 2 h (when Interface cable (optional) 10 m (33 ft), 9.2 mm (0.36 in) outer

sensor is not in reference cycle) diameter

Warm-up time 2 h, 12 h for full specification Interface cable (optional, for use with 10 m (33 ft), 6.2 mm (0.24 in) outer

Indigo520) diameter

Sensor Catalytic palladium-nickel alloy film

solid-state sensor Housing material AlSi 10 Mg

Moisture in oil IP rating IP66

Measurement range (in oil) 0 … 100 %RS / aw 0 … 1 Transmitter weight without cables 4.1 kg (9.04 lb)

Response time (90 % of full response at 10 min Self-diagnostics indication Status LEDs, analog output, Modbus

+20 °C (+68 °F) in still oil) Integrated data logging capabilities Non-volatile memory, up to 44 years'

Sensor HUMICAPâ 180L2 storage with default logging

Accuracy (including non-linearity, hysteresis, and repeatability): Individual functional test reports Calibration test reports for moisture,

hydrogen, and temperature; probe

0 … 90 %RS ±2 %RS (aw ± 0.02) leak test report (5 bara nominal)

90 … 100 %RS ±3 %RS (aw ± 0.03) Factory warranty 5 years

Temperature

Measurement range −40 … +120 °C (−40 … +248 °F)

Operating environment

Accuracy at +20 °C (+68 °F) ±0.2 °C (0.36 °F)

Oil type Mineral oil / Natural ester oil /

Sensor Pt1000 RTD Class F0.1 IEC 60751

Synthetic ester oil / Silicone oil

1) The accuracy specified is the accuracy during calibration against gas in oil standard. Field performance Oil temperature −20 … +75 °C (−4 … +167 °F)

may be affected, for example, by variation in hydrogen solubility (partition coefficients) between

different mineral oils. Operating temperature (electronics) −40 … +60 °C (−40 … +140 °F)

2) The accuracy specified is applicable in the oil temperature specified (−20 … +75 °C (−4 … +167 °F)).

Storage temperature −40 … +60 °C (−40 … +140 °F)

Operating humidity 0 … 100 %RH, condensing

Inputs and outputs

Pressure tolerance (probe, short-term) Max. 10 bara

Operating voltage 15 … 30 VDC, 24 VAC (±15 %) (power Pressure tolerance (probe, continuous) Max. 4 bara

supply input is galvanically isolated) 1)

Temperature tolerance, sensor head −40 … +120 °C (−40 … +248 °F)

Power consumption Typical 4 W, maximum 12 W

Integrated protection for short power >3s

Analog output (current) 1) outages

Channels 3 isolated 4 … 20 mA (loop-powering)

External load Max. 500 Ω

Compliance

Error status indication in case of device 3.5 mA default, user-configurable for

error each channel EU directives EMC, RoHS

mA output accuracy at +20 °C (+68 F) ±0.125 % full scale EMC compatibility EN 61326‑1, industrial environment

Temperature dependence of the analog ±0.006 % / °C full scale CISPR 32 / EN 55032, Class B

outputs (when DC powered)

Electrical safety EN 50581:2012

Digital outputs 1)

Fulfills the requirements of

Interfaces Isolated RS-485 half-duplex EN 61000-6-5 in the following tests:

RS-485 (Service Port, non-isolated) • EN 61000-4-2, EN 61000-4-3,

Protocols Modbusâ RTU, DNP3, serial ASCII EN 61000-4-4, EN 61000-4-5,

EN 61000-4-6, EN 61000-4-8,

Screw terminals Wire size AWG 22-14 EN 61000-4-11, EN 61000-4-12,

Single wire (solid) 1.5 mm2

EN 61000-4-16, EN 61000-4-17

Stranded wire (flex.) 1.0 mm2

Recommended wire torque 0.4 Nm Compliance marks CE, EAC, RCM, WEEE

1) Max. isolation voltage 1.5 kV DC.

Published by Vaisala | B211484EN-G © Vaisala 2021

All rights reserved. Any logos and/or product names are trademarks of Vaisala or its individual partners.

www.vaisala.com Any reproduction, transfer, distribution or storage of information contained in this document is strictly

prohibited. All specifications — technical included — are subject to change without notice.

You might also like

- Moisture, Hydrogen, and Temperature Transmitter MHT410: For Online Transformer Condition MonitoringDocument2 pagesMoisture, Hydrogen, and Temperature Transmitter MHT410: For Online Transformer Condition MonitoringAndrew SetiawanNo ratings yet

- BC435084501801en 000101Document22 pagesBC435084501801en 000101Felipe Doria RibeiroNo ratings yet

- Schneider EM RelaysDocument16 pagesSchneider EM RelaysMuneer MPNo ratings yet

- Om025 Om050Document9 pagesOm025 Om050Khairul UmamNo ratings yet

- Hydro-Mix VI: Product Information SheetDocument4 pagesHydro-Mix VI: Product Information Sheetkrishna kumarNo ratings yet

- SEW Eurodrive MOVITRAC LT InvertersDocument2 pagesSEW Eurodrive MOVITRAC LT InverterscealrofaNo ratings yet

- Monitor de Transformador-Ap-M09-08l-01en - 506 - VTM - 507 - ItmDocument4 pagesMonitor de Transformador-Ap-M09-08l-01en - 506 - VTM - 507 - ItmFernando RodriguezNo ratings yet

- 95C-10828 - VC6800, VC6900 Series Floating Control Valves - Product Data - 001750Document6 pages95C-10828 - VC6800, VC6900 Series Floating Control Valves - Product Data - 001750Cuajinike1No ratings yet

- Hydro Power Synchronous GeneratorsDocument8 pagesHydro Power Synchronous GeneratorsPritam SinghNo ratings yet

- Dual Hi-Lo Pressure SwitchesDocument16 pagesDual Hi-Lo Pressure SwitchesfreddyheavymetalNo ratings yet

- Fieldvue DVC6200 Series Digital Valve Controller: A Single Instrument Solution Across Your FacilityDocument16 pagesFieldvue DVC6200 Series Digital Valve Controller: A Single Instrument Solution Across Your FacilityLimuel EspirituNo ratings yet

- Linear Globe Valve: ActuatorsDocument40 pagesLinear Globe Valve: ActuatorsLuis AngelNo ratings yet

- Kongsberg Electronic Hand ControlDocument4 pagesKongsberg Electronic Hand ControltstkupdhNo ratings yet

- Relayaux: Auxiliary Relays For Tripping and Control ApplicationsDocument28 pagesRelayaux: Auxiliary Relays For Tripping and Control ApplicationsKuenley TiNy OndeNo ratings yet

- Viscopro 2000: Monitoring and Control For Single-Line Process EnvironmentsDocument4 pagesViscopro 2000: Monitoring and Control For Single-Line Process EnvironmentsLuz Stella Calixto GomezNo ratings yet

- Portable Vibration Calibrator: Lab Accuracy To The FieldDocument2 pagesPortable Vibration Calibrator: Lab Accuracy To The Fieldenghemo89No ratings yet

- Hydraulic Rock Breaker: Variable Range OverviewDocument4 pagesHydraulic Rock Breaker: Variable Range OverviewRidha AbbassiNo ratings yet

- Hydran M2: GE Grid SolutionsDocument2 pagesHydran M2: GE Grid SolutionsLaurentiuNo ratings yet

- Hydranm2 Gea 12934a HRDocument2 pagesHydranm2 Gea 12934a HRMarcus SiaNo ratings yet

- RotaMASS 3 Series Coriolis Mass Flow & Density Meter PDFDocument36 pagesRotaMASS 3 Series Coriolis Mass Flow & Density Meter PDFJerico AnchetaNo ratings yet

- VCTDS 0036 EN Web PDFDocument8 pagesVCTDS 0036 EN Web PDFAbdul RahimNo ratings yet

- General Specifications: 3 Series Coriolis Mass Flow and Density MeterDocument36 pagesGeneral Specifications: 3 Series Coriolis Mass Flow and Density MeterMartha Lozada NavarroNo ratings yet

- Trident Fused Oil Ring Main Unit Up To 15.5kV: Providing Intelligent SolutionsDocument4 pagesTrident Fused Oil Ring Main Unit Up To 15.5kV: Providing Intelligent SolutionsmealysrNo ratings yet

- WPS Direct Drive BrochureDocument8 pagesWPS Direct Drive BrochureGerardo Del CarpioNo ratings yet

- ModelZSeriesRotaryValveMonitor Datasheet VCTDS 02774 enDocument8 pagesModelZSeriesRotaryValveMonitor Datasheet VCTDS 02774 enRon Don jrNo ratings yet

- Lower Your Total Cost of Ownership: HelicalDocument12 pagesLower Your Total Cost of Ownership: Helicalankit58497No ratings yet

- Underground Coring Drill: Technical OverviewDocument8 pagesUnderground Coring Drill: Technical OverviewLuis AparcanaNo ratings yet

- Hydran201ti Gea 12933 A4 HRDocument2 pagesHydran201ti Gea 12933 A4 HRLaurentiuNo ratings yet

- Industrial Flame Monitoring IFM Brochure 67 7148Document11 pagesIndustrial Flame Monitoring IFM Brochure 67 7148swapnil28.08 kNo ratings yet

- Dual Channel Hour Meter & Maintenance Monitor Module MODEL 759Document3 pagesDual Channel Hour Meter & Maintenance Monitor Module MODEL 759Ewerton BianchiNo ratings yet

- 9110D Portable Vibration Calibrator Datasheet DS 0103Document2 pages9110D Portable Vibration Calibrator Datasheet DS 0103Adhitya ReNo ratings yet

- Medidores Liquid ControlsDocument16 pagesMedidores Liquid ControlsbrijaldofelixNo ratings yet

- Rccx3 Medidor de Flujo CoriolisDocument36 pagesRccx3 Medidor de Flujo Coriolisfabio amayaNo ratings yet

- Hoja de Especificaciones RL94 InteriorDocument2 pagesHoja de Especificaciones RL94 InteriormrspokebcsNo ratings yet

- Generator Health Monitoring Fact SheetDocument2 pagesGenerator Health Monitoring Fact SheetTalha NizamiNo ratings yet

- Trane YCDDocument72 pagesTrane YCDTerrence ReddNo ratings yet

- Bed Level Sensor - RoyceDocument8 pagesBed Level Sensor - RoyceKishore AsuriNo ratings yet

- Divisora de MasaDocument4 pagesDivisora de MasaNicolas Astudillo MaldonadoNo ratings yet

- Joslyn Hi-Voltage Overhead Reclosers and Switches PDFDocument46 pagesJoslyn Hi-Voltage Overhead Reclosers and Switches PDFFlogisto79No ratings yet

- Polysonics DCT6088Document2 pagesPolysonics DCT6088Fadjar TandabawanaNo ratings yet

- EIM Product Selection GuideDocument6 pagesEIM Product Selection GuidesalemNo ratings yet

- MC Propeller Flow Meters: Municipal Water, Agriculture, IrrigationDocument4 pagesMC Propeller Flow Meters: Municipal Water, Agriculture, IrrigationJamesh BabuNo ratings yet

- 730series Catalog enDocument21 pages730series Catalog enOussama SridiNo ratings yet

- Iguard BDocument2 pagesIguard Bpabloperezmtz1No ratings yet

- Hydran 201ti (Mark IV) Essential DGA Monitoring For TransformersDocument2 pagesHydran 201ti (Mark IV) Essential DGA Monitoring For Transformerslxd.hepNo ratings yet

- CoreTec 4 - Transformer Monitoring PlatformDocument2 pagesCoreTec 4 - Transformer Monitoring PlatformJaime Vicuña CubillosNo ratings yet

- Brochure BiRotor Plus For Crude Oil R03Document4 pagesBrochure BiRotor Plus For Crude Oil R03eka pramudia santosoNo ratings yet

- EPM Valve Automation TechnologiesDocument8 pagesEPM Valve Automation TechnologiesWahyu YuliadiNo ratings yet

- 3000025ENDocument4 pages3000025ENDavid Antonio Vargas RuizNo ratings yet

- Partially Owned by Ansaldo Sistemi Industriali S.p.A.: Answer Drives S.R.LDocument14 pagesPartially Owned by Ansaldo Sistemi Industriali S.p.A.: Answer Drives S.R.LMohamed AlkharashyNo ratings yet

- Potenciómetro de AceleraciónDocument4 pagesPotenciómetro de AceleraciónVictor HernandezNo ratings yet

- Trident Brochure Oil RMUDocument4 pagesTrident Brochure Oil RMUrajeshNo ratings yet

- Efficient Solutions For Important Environments: Multi-DENCODocument12 pagesEfficient Solutions For Important Environments: Multi-DENCOJeghiNo ratings yet

- Raise Borer EpirocDocument8 pagesRaise Borer EpirocDiego Ignacio VelizNo ratings yet

- LMV5... Linkageless Burner Management System: Combustion ControlsDocument4 pagesLMV5... Linkageless Burner Management System: Combustion ControlsRafael CalleNo ratings yet

- Bifmi 0036 Us PDFDocument43 pagesBifmi 0036 Us PDFRaúl R Rojas TorresNo ratings yet

- Grundfosliterature 1891259Document4 pagesGrundfosliterature 1891259Mohammad ZeeshanNo ratings yet

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- DM70 Datasheet B010162ENDocument3 pagesDM70 Datasheet B010162ENAndrew SetiawanNo ratings yet

- VIM G Continuous Monitoring System Services - B211313EN DDocument10 pagesVIM G Continuous Monitoring System Services - B211313EN DAndrew SetiawanNo ratings yet

- CMS Validation GXP Products Service Brochure B211475ENDocument6 pagesCMS Validation GXP Products Service Brochure B211475ENAndrew SetiawanNo ratings yet

- 80pk-9 DatasheetDocument3 pages80pk-9 DatasheetAndrew SetiawanNo ratings yet

- DL2000 Datasheet B211055EN EDocument2 pagesDL2000 Datasheet B211055EN EAndrew SetiawanNo ratings yet

- 80pk-11 Iseng0100Document2 pages80pk-11 Iseng0100Andrew SetiawanNo ratings yet

- PFT - 401CEF: PFT Series - AC High Voltage Dielectric Test SetDocument1 pagePFT - 401CEF: PFT Series - AC High Voltage Dielectric Test SetAndrew SetiawanNo ratings yet

- SICOM3024P: 24+4G Port Layer 2 Managed Rack Mountable SwitchesDocument6 pagesSICOM3024P: 24+4G Port Layer 2 Managed Rack Mountable SwitchesAndrew SetiawanNo ratings yet

- 80pk-11 DatasheetDocument4 pages80pk-11 DatasheetAndrew SetiawanNo ratings yet

- Kyland SICOM3028GPT Datasheet enDocument13 pagesKyland SICOM3028GPT Datasheet enAndrew SetiawanNo ratings yet

- Kyland Ruby3A Datasheet ENDocument7 pagesKyland Ruby3A Datasheet ENAndrew SetiawanNo ratings yet

- Cable Test Vans and Systems: Prepared For AnythingDocument20 pagesCable Test Vans and Systems: Prepared For AnythingAndrew SetiawanNo ratings yet

- DANEO 400: Hybrid Signal Analyzer For Power Utility Automation SystemsDocument16 pagesDANEO 400: Hybrid Signal Analyzer For Power Utility Automation SystemsAndrew SetiawanNo ratings yet

- Multifunction Substation Test SetDocument28 pagesMultifunction Substation Test SetAndrew SetiawanNo ratings yet

- DS - VLF Test System - PHG 70 - PHG 80 - Portable - BAUR - En-GbDocument3 pagesDS - VLF Test System - PHG 70 - PHG 80 - Portable - BAUR - En-GbAndrew SetiawanNo ratings yet

- TANDO 700: High-Precision Measuring and Analysis System For Dissipation/power Factor and CapacitanceDocument8 pagesTANDO 700: High-Precision Measuring and Analysis System For Dissipation/power Factor and CapacitanceAndrew SetiawanNo ratings yet

- DS - DC HV Tester - PGK 25 - BAUR - En-GbDocument2 pagesDS - DC HV Tester - PGK 25 - BAUR - En-GbAndrew SetiawanNo ratings yet

- DS - AC - DC HV Test Set - PGK 260 HB - BAUR - En-GbDocument3 pagesDS - AC - DC HV Test Set - PGK 260 HB - BAUR - En-GbAndrew SetiawanNo ratings yet

- CIBANO 500 Ordering Information ENUDocument18 pagesCIBANO 500 Ordering Information ENUAndrew SetiawanNo ratings yet

- Analog and Digital ComputerDocument2 pagesAnalog and Digital ComputerMikiyas MikaNo ratings yet

- System/Battery Type Emerson Narada 12NDT100A Narada 12NDT180 Vision CT12 180XDocument2 pagesSystem/Battery Type Emerson Narada 12NDT100A Narada 12NDT180 Vision CT12 180XBysNo ratings yet

- HF-320 스미토모 인바타 메뉴얼 PDFDocument259 pagesHF-320 스미토모 인바타 메뉴얼 PDFAmith PrasannaNo ratings yet

- STIL - File (Autosaved) (Copy)Document17 pagesSTIL - File (Autosaved) (Copy)Praveen SakrappanavarNo ratings yet

- Portable Air Conditioner Climatiseur Portatif Acondicionador de Aire PortatilDocument38 pagesPortable Air Conditioner Climatiseur Portatif Acondicionador de Aire Portatilantony2288No ratings yet

- Bvp151 Led240 NW Psu 200w SWB g2 GMDocument2 pagesBvp151 Led240 NW Psu 200w SWB g2 GMQasim ZAHEERNo ratings yet

- Asus X555LD (Repair Guide) PDFDocument7 pagesAsus X555LD (Repair Guide) PDFMrOne260No ratings yet

- Ssic2020 Classification StructureDocument38 pagesSsic2020 Classification StructurejohnNo ratings yet

- SEM600 1988 Resonant Mode ConverterTopologiesDocument14 pagesSEM600 1988 Resonant Mode ConverterTopologiesjuanNo ratings yet

- Power Electronics Homework SolutionsDocument5 pagesPower Electronics Homework Solutionsafnabzdmfiefxr100% (1)

- 08 DetectingDocument88 pages08 DetectingStanley PolancoNo ratings yet

- Specifications: - : User'S Operating Manual For Pid Digital Temperature ControllerDocument9 pagesSpecifications: - : User'S Operating Manual For Pid Digital Temperature ControllerAnjum ParkarNo ratings yet

- Human HumaCount - 5L Brochure - ENDocument4 pagesHuman HumaCount - 5L Brochure - ENPopovNo ratings yet

- Oneline DiagramDocument20 pagesOneline DiagramAgus FebriansyahNo ratings yet

- BA10339FVDocument5 pagesBA10339FVPot GeeAdmitNo ratings yet

- Heater & Air Conditioning Control System: SectionDocument164 pagesHeater & Air Conditioning Control System: SectionPablo CoronelNo ratings yet

- F2740eac PDFDocument26 pagesF2740eac PDFcontrol remote02No ratings yet

- IPL-50Series F - L Flow Meter For Open Channels ENGDocument6 pagesIPL-50Series F - L Flow Meter For Open Channels ENGIgnatius Albert Shan HandokoNo ratings yet

- Rpcppe 2023 - PpeDocument21 pagesRpcppe 2023 - PpeJeur CasioNo ratings yet

- Viper Pro Rapid - Wiring DiagramDocument1 pageViper Pro Rapid - Wiring DiagrammickNo ratings yet

- k2968 PDFDocument6 pagesk2968 PDFtinhmuaNo ratings yet

- Vsmgear GPIOBox User Manual V40 1Document15 pagesVsmgear GPIOBox User Manual V40 1Johann HENRYNo ratings yet

- Indicators Series: Max 420 BarDocument6 pagesIndicators Series: Max 420 BarЫфтнфNo ratings yet

- Powerware 9135 Two-in-One UPS 5000/6000 VA User's GuideDocument37 pagesPowerware 9135 Two-in-One UPS 5000/6000 VA User's Guideseemann27No ratings yet

- ANTENTOP-01 - 2014 # 018 Antenna UA6AGW in Experimenters by RU1OZDocument2 pagesANTENTOP-01 - 2014 # 018 Antenna UA6AGW in Experimenters by RU1OZLucian RobNo ratings yet

- Group-10 Mini Project Report 22Document23 pagesGroup-10 Mini Project Report 22Lohith MNo ratings yet

- Serial Communications PDFDocument33 pagesSerial Communications PDFminastirNo ratings yet

- x2000 AC Drives Comprehensive CatalogueDocument82 pagesx2000 AC Drives Comprehensive CatalogueAmit KumarNo ratings yet

- What Is ImpedanceDocument11 pagesWhat Is ImpedancejuangasaNo ratings yet

- Nanoelectronics 18EC661 SyllabusDocument3 pagesNanoelectronics 18EC661 SyllabussmkeshkamatNo ratings yet