Professional Documents

Culture Documents

Lightning Test of VCS

Lightning Test of VCS

Uploaded by

Guillermo Gutierrez0 ratings0% found this document useful (0 votes)

11 views10 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views10 pagesLightning Test of VCS

Lightning Test of VCS

Uploaded by

Guillermo GutierrezCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

Final Report

Triggered Lightning Testing of a Section of Florida Gas

Transmission Pipeline and Pipeline Connectors

for

Florida Gas Transmission

University of Florida Internai Account #: 450588112

Contract dates: July 1, 2001 - November 30, 2001

Attention: Martin Winger

(martin.winger@enron.com)

Florida Gas Transinission

P. O. Box 945100

Maitland, FL 32794

by

M. A. Uman, K. J. Rambo, J. Jerauld, M. Stapleton,

and V. A. Rakov

Department of Electrical and Computer Engineering

University of Florida

216 Larsen Hall

P.O. Box 116200

Gainesville, FL 32611

nb mE BP rT BB Sf SS = SS S|

Report on Triggered Lightning Testing of a Section of Florida Gas Transmission

Pipeline and Pipeline Connectors

by

M.A. Uman, K. J. Rambo, J. Jerauld, M. Stapleton,

and V. A. Rakov

Executive Summary

At the International Center for Lightning Research and Testing at Camp Blanding, FL, a

five-stroke lightning flash was directed along pipelines and through three different

insulating joints commonly used by Florida Gas Transmission, The joints chosen for

this test were a two-inch flange with a Pikotek VCS gasket having wax poured into the

flange gap and two smaller diameter Swagelok tubing insulators encapsulated in a 3 M

epoxy underground splice kit, one of which was wrapped externally with “Trenton Wax’

tape. The gas inside the pipeline was air at atmospheric pressure. All three joints

showed significant internal damage to the pipe metal from arcing, but electrical

measurements indicated no damage to the joint insulation. The Pikotek joint had an

external flashover for one stroke only, that arcing being clearly visible on TV and 5-

msec resolution photographic film records. Hence, most of the lightning current

crossed the insulating joints via internal flashover with one stroke providing an external

flashover at one joint. It is not clear that the results obtained would have been similar if

the internal pipeline gas was maintained at its normal high pressure since higher joint

voltages would then be required for internal breakdown thus encouraging external

flashover.

1. Introduction

The University of Florida operates the International Center for Lightning Research and

Testing at Camp Blanding Army National Guard Base for the purpose of triggering

lightning from natural thunderciouds to objects on the ground. Details of that facility

and its present and past research and testing projects can be found at

www.lightning.ece.uflLedi

On August 18, 2001, a five-stroke lightning flash was triggered through four segments

of Florida Gas Transmission pipeline containing three insulating joints. Details of the

experimental set up and the results of the experiment are presented in this report. The

purpose of the experiment was to determine if the insulating joints are compromised by

lightning and if there are external flashovers of the joints that could potentially ignite any

existing mixture of pipeline gas and air.

2. The Experiment

A photograph of the vertically-mounted Florida Gas Transmission pipeline sections

containing three insulating joints is given in Figure 1. The tops of six lightning-triggering

rockets are shown mounted in launch tubes at the bottom of the photograph. A close-

2

4

up view of the lowest insulating joint, the Pikotek joint, is shown in Figure 2, and those

of the two upper joints, Swagelok joints, are shown in Figure 3. A rough drawing of the

whole pipeline and joint structure is found in Figure 4. A description of the pipeline and

joint structure follows:

At the base is a 1 foot long section of pipe of 1 % inch diameter installed

for mounting purposes. Attached above that is a 2 foot long section of 2

inch pipe and to that is connected a 2 inch flange with a Pikotek VCS

insulator gasket, wax being poured into the flange gap to fill its void

Above the flange is a 3 foot section of 2 inch pipe which is reduced down

to 3/8 inch on which is mounted a 3 foot section of 3/8 inch, .316 stainless

steel tubing, and on top of that is installed a Swagelok tubing insulator that

is encapsulated in a 3M Epoxy underground splice kit. On top of this joint

is a second section of 3/8 inch, .316 stainless steel 3 inch long tubing and

another Swagelok insulator. This top insulator was wrapped with a

“Trenton Wax’ tape product to encapsulate it. Finally, a 1 foot section of

stainless steel tubing is at the top for intercepting the lightning. All the 1%

inch and 2 inch piping was carbon steel, mechanically welded together,

while the stainless steel tubing was all screwed fittings and hand

tightened.

The Pikotek VCS insulating gasket consists of a .316 stainless steel core

to which a high strength insulating laminate is bonded to each side.

Opposing dovetail seal grooves are machined through the laminate

insulating material and into the stainless steel core. Spring-energized

PTFE (Teflon) internal face seals are then installed into these grooves to

provide pressure activated sealing. Fiberglass-reinforced epoxy insulating

sleeves and washers are used in conjunction with the VCS gasket to

provide complete electrical insulation of the flange assembly.

3. Results

‘A photograph of a triggered lightning flash to the pipeline is shown in Figure §. Current

records show that five return strokes attached to the pipeline. High speed photography

confirms that each return stroke attached to the top of the pipeline, and thus that

current flowed through each insulating joint. The current waveform of the first stroke is

found in Figure 6, measured by a resistive shunt at the base of the pipeline, An

external flashover at the Pikotek joint is evident in the TV frame shown in Figure 5 and

in other photographs of the experiment. Comparison of current and photographic

records shows that the external flashover occurred during the first return stroke which

attached to the pipeline (peak current =27 kA). After the lightning strike, the pipeline

joints were tested electrically and all were found to be still essentially open circuits. A

small arc mark was evident on a bolt of the Pikotek joint, as shown in Figure 7,

consistent with the external flashover seen in Figure 5. High-speed photography with 5

msec resolution indicates that the external flashover occurred for only the first stroke of

the five-stroke flash. The joints were disassembled to inspect for internal damage. All

joints show significant internal arc damage. Photographs of that damage are shown in

Figures 8 - 10. Visually there is not serious damage to the joint insulators, only dark

surface tracks, although clearly very large currents and charges arced internally from

pipe to pipe across the insulators.

4, Conclusions

A five-stroke lightning flash triggered through one Pikotek and two Swagelok connectors

resulted in one external flashover at the Pikotek joint for one stroke and internal

flashovers for all three joints. While there was metal damage to the pipeline interior, the

insulators of the connectors were not significantly degraded. Additional external arcing

might have occurred if the interior of the pipeline had been pressurized at 900 psi as is

the case in working pipelines rather than at atmospheric pressure. Additionally, any

internal arc damage might well have &2en different in the higher pressure environment.

Fig. 1. Four-section 4.4 m gas pipeline containing three insulating joints. Triggering

rockets in launch tubes are visible at the bottom of the photograph.

TS eee eee ene eee |

Fig. 2. Lower insulating joint of the pipeline structure.

Fig. 3. Middle and upper insulating joints of the pipeline structure.

|

|

|

|

_—_——_—_ oe

‘Swagelok Tubing Insulator

Encapsulated in "Trenton Wax" Tape

3/8" reducer

3/8" SS. Tubing I°

38"

8. Tubing 3

‘Swagelok Tubing Insulator Encapsulated

ina 3M Epoxy Underground Splice Kit

| | 38"S.S. Tubing 3°

Pikotee VCS Insulator Gasket

Fig. 4. Drawing of pipeline and joint structure.

7

I

Ui] | roe le ER

Fig. 5. Triggered lightning flash to the pipeline. Note the flashover at the lowest joint,

the Pikotek joint.

Pipeline Current Roturn Stroke 1

ete

Fig. 6. Current waveform for the first of five return strokes, the only one that produced

an external flashover.

Fig. 7. Arc marks on the exterior of the Pikotek joint. In the photograph the marks

appear as mottled silvery surfaces on the washers of the middle bolt on the left of the

flange. Photo courtesy of Martin Winger.

Fig. 8. Arc damage on the interior pipeline surface on one side of the Pikotek joint.

Photo courtesy of Martin Winger.

Fig. 9. A close-up view of the Pikotek joint shown in Fig. 8 with the insulating gasket

removed, Photo courtesy of Martin Winger.

Fig. 10. Interior arc mark on one of the Swagelok joints evident on the lower right of the

left pipe connector.

l

l 10

a

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Garlock Compression Packing: Long Term Leakage ControlDocument46 pagesGarlock Compression Packing: Long Term Leakage ControlGuillermo GutierrezNo ratings yet

- SEPCO 02 Guía de SelecciónDocument10 pagesSEPCO 02 Guía de SelecciónGuillermo GutierrezNo ratings yet

- Catálogo Dixon Bayco Dry Bulk Carga SecaDocument44 pagesCatálogo Dixon Bayco Dry Bulk Carga SecaGuillermo GutierrezNo ratings yet

- Catalogo Equipos de Camiones 1Document124 pagesCatalogo Equipos de Camiones 1Guillermo GutierrezNo ratings yet

- Lamons Capabilities Brochure 16pg WEBDocument16 pagesLamons Capabilities Brochure 16pg WEBGuillermo GutierrezNo ratings yet

- Isotek Isolation Gaskets & Kits: Sealing Global - Servicing LocalDocument3 pagesIsotek Isolation Gaskets & Kits: Sealing Global - Servicing LocalGuillermo GutierrezNo ratings yet

- GPT 1-7 - PGE Flange Isolation Kit - 11.2017 - LR - 0Document2 pagesGPT 1-7 - PGE Flange Isolation Kit - 11.2017 - LR - 0Guillermo GutierrezNo ratings yet

- Asme B1 1 PDFDocument190 pagesAsme B1 1 PDFGuillermo GutierrezNo ratings yet

- Segmented Ball Control Valve: Flow-Tek Series 19Document18 pagesSegmented Ball Control Valve: Flow-Tek Series 19Guillermo GutierrezNo ratings yet

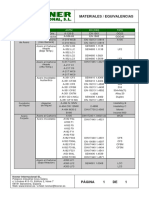

- Equivalencia MaterialesDocument1 pageEquivalencia MaterialesGuillermo GutierrezNo ratings yet