Professional Documents

Culture Documents

Applied Mineral Inventory Estimation Techniques

Uploaded by

Erland PrasetyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Applied Mineral Inventory Estimation Techniques

Uploaded by

Erland PrasetyaCopyright:

Available Formats

2 APPLIED MINERAL INVENTOR Y ESTIMATION

being mined and processed (i.e., improved grade con- Limit of Sample

trol during mining). This can be accomplished by mineralization site

increasing the grade for the same tonnage, increas-

ing the tonnage while maintaining the same average

R

grade, or some combination that involves improved

selection of ore versus waste. Improved grade control

arguably offers the best return for the least invest-

ment because of the leverage that grade mined has on

revenue.

The three undertakings – ore estimation, mine

planning, and grade control – are complementary in Discretization

an efficient mining operation and are natural progres- of deposit

as an array

sions. The integration of these three endeavors is im- of blocks

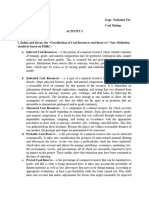

portant because the grade control system must bal- Figure 1.1: A two-dimensional representation of the gen-

ance with the ore reserve as well as with the final eral situation in mineral inventory estimation. A mineralized

products of the operating plant, and both estimation zone/deposit defined by geology is discretized by a number

and grade control are influenced by planned opera- of blocks (commonly of uniform size, but not necessarily

tional procedures. If this balance is not achieved, the so). Each block is to be estimated using nearby data within

a search area (volume), in this case defined by a circle

original investment may be in jeopardy. Reappraisals

centered on the block to be estimated. Small black dots

of mineral inventories may be necessary many times are sample sites (for which there would be grade values)

prior to and during the life of a mine. within the deposit; small open circles are samples outside

the limits of the deposit.

1.2: MINERAL INVENTORY ESTIMATES

Mineral inventories are a formal quantification of nat- Quantification of a resource/reserve is to a level

urally occurring materials, estimated by a variety of of confidence (subjective or statistical) appropriate to

empirically or theoretically based procedures. Inven- the available data and the stated needs of the estimate.

tories that are based on an economic feasibility study Volumes, tonnages, grades, and quantities of metals

are commonly classed as reserves; inventories that or minerals are the common attributes that are quan-

are less well established are considered resources. tified. Their estimation must be optimal in the sense

These resource/reserve estimates, commonly deter- that they must be unbiased and the random error must

mined from a two- or three-dimensional array of not exceed an acceptable quality criterion. Mineral

assayed samples, are applied to mineralized rock vol- inventory estimates are used to determine economic

umes that total many orders of magnitude larger than viability that is relatively assured in the case of re-

the total sample volume (Fig. 1.1). Thus, errors of es- serves. Volume (or tonnage) of ground classed as re-

timation can be viewed as errors of extension (i.e., sources generally has not been evaluated rigorously

errors made in extending the grades of samples to a for economic viability or has been found to lack im-

much larger volume [tonnage] of rock). For purposes mediate economic potential. Estimation procedures

of establishing a mineral inventory, a mineral deposit can differ substantially for deposits to be mined un-

generally is discretized into an array of blocks, and derground compared with deposits to be mined by sur-

the average value of each block is estimated in some face pits. Similarly, methodology can vary depending

manner from the nearby data. Thus, a mineral inven- on whether the mineral inventory in question is for

tory can be viewed as a detailed breakdown of blocks short-term or long-term production planning.

whose individual sizes, locations, and grades are well Mineral inventories are determined at various

established. times in the exploration, evaluation, and production of

You might also like

- Principles of Mining: Valuation, Organization and AdministrationFrom EverandPrinciples of Mining: Valuation, Organization and AdministrationNo ratings yet

- Time Lapse Approach to Monitoring Oil, Gas, and CO2 Storage by Seismic MethodsFrom EverandTime Lapse Approach to Monitoring Oil, Gas, and CO2 Storage by Seismic MethodsNo ratings yet

- Mining Geology Note PDFDocument57 pagesMining Geology Note PDFgetasew89% (9)

- General SOP ProceduresDocument8 pagesGeneral SOP ProceduresHabelNo ratings yet

- Block Size Selection and Its Impact On Open-Pit Design and Mine PlanningDocument7 pagesBlock Size Selection and Its Impact On Open-Pit Design and Mine PlanningmapykNo ratings yet

- Ore Reserve/Resource Estimation: Ore Reserve Estimates Are Assessments of The Quantity andDocument16 pagesOre Reserve/Resource Estimation: Ore Reserve Estimates Are Assessments of The Quantity andBrunno AndradeNo ratings yet

- KBPL Mining Recovery and DilutionDocument6 pagesKBPL Mining Recovery and Dilutionaris goldieNo ratings yet

- Istilah-Istilah Analisa CadanganDocument16 pagesIstilah-Istilah Analisa CadanganRilySabanaNo ratings yet

- Mineral Resources Classification of A Nickel Laterite Deposit Comparison Between Conditional Simulations and Specific AreasDocument12 pagesMineral Resources Classification of A Nickel Laterite Deposit Comparison Between Conditional Simulations and Specific Areasjeha kunramadiNo ratings yet

- Net PayDocument10 pagesNet PaySanty RamirezNo ratings yet

- Geostatistics As A T o o L To D e F I N e Various Categories of Resources 1Document13 pagesGeostatistics As A T o o L To D e F I N e Various Categories of Resources 1cmollinedoaNo ratings yet

- MROR: Mineral Resources and Ore Reserves ClassificationDocument4 pagesMROR: Mineral Resources and Ore Reserves ClassificationLeonardo Madriaga AgodillaNo ratings yet

- MCCARTHY - Mining Dilution and Losses in Mining PDFDocument4 pagesMCCARTHY - Mining Dilution and Losses in Mining PDFAshanti Utahel100% (1)

- Review of Mineral Reserve Classification and Estimation Methods in BrazilDocument12 pagesReview of Mineral Reserve Classification and Estimation Methods in BrazilRogerio Andrade100% (1)

- Geological Reserves - Cut-Off GradesDocument4 pagesGeological Reserves - Cut-Off GradespaulogmelloNo ratings yet

- 101 106Document6 pages101 106mrputaxelputaxNo ratings yet

- Activity 5 - DAHUYLA, Jef Michael L.Document11 pagesActivity 5 - DAHUYLA, Jef Michael L.Jef Michael L. DahuylaNo ratings yet

- 1973 XXXXXXXXXDocument22 pages1973 XXXXXXXXXSelamet ErçelebiNo ratings yet

- Optimizing Ore-Waste Dig-Limits As Part of Operational Mine Planning Through Genetic AlgorithmsDocument13 pagesOptimizing Ore-Waste Dig-Limits As Part of Operational Mine Planning Through Genetic AlgorithmsErland PrasetyaNo ratings yet

- 300 000 052 772 - ReconciliationDocument8 pages300 000 052 772 - ReconciliationLuis RojasNo ratings yet

- Resource EstimationDocument32 pagesResource EstimationRohit KumarNo ratings yet

- Jara RMDocument8 pagesJara RMMamita TsilaitraNo ratings yet

- INTRODUCTIONDocument8 pagesINTRODUCTIONKangkan DasNo ratings yet

- UBC Surface Mining Lecture on Sampling TheoryDocument44 pagesUBC Surface Mining Lecture on Sampling TheoryMartin JanuaryNo ratings yet

- Dilution and Losses in Underground MiningDocument4 pagesDilution and Losses in Underground MiningConstanza Díaz Fuentes100% (2)

- Actividad Virtual 1-Dilution - and - Losses (3) WordDocument4 pagesActividad Virtual 1-Dilution - and - Losses (3) WordCyovana Perez100% (1)

- Opening A Mine StepsDocument5 pagesOpening A Mine StepsSourabh SharmaNo ratings yet

- Channel Sampling: Channel Sampling Is Laborious, Tedious, Time Consuming and ExpensiveDocument7 pagesChannel Sampling: Channel Sampling Is Laborious, Tedious, Time Consuming and ExpensivelovelyNo ratings yet

- Ore Reserve EstimationDocument4 pagesOre Reserve EstimationdeshmukhgeolNo ratings yet

- Mining Grade ControlDocument6 pagesMining Grade Controlminerito221175% (8)

- 2003 116 Smuselect PDFDocument16 pages2003 116 Smuselect PDFDavid HalomoanNo ratings yet

- Curso de EdumineDocument19 pagesCurso de EdumineMax Hubert QNo ratings yet

- Mining Geometrical Modelling Approach For The Estimation of Cut-Off Grade of Open-Pit Mines, Through Maximization of The Net Present ValueDocument14 pagesMining Geometrical Modelling Approach For The Estimation of Cut-Off Grade of Open-Pit Mines, Through Maximization of The Net Present ValueSirri BlessingNo ratings yet

- Page 27Document1 pagePage 27YeimsNo ratings yet

- Ore Reserve Estimation Method - 911 MetallurgistDocument24 pagesOre Reserve Estimation Method - 911 MetallurgistAvinash BarsaNo ratings yet

- Planning For Narrow Vein Mines: G GemellDocument4 pagesPlanning For Narrow Vein Mines: G GemellBendigo BanksNo ratings yet

- Istilah-Istilah Analisa CadanganDocument17 pagesIstilah-Istilah Analisa CadanganTatsuo Saor FanaetuNo ratings yet

- Bench and Pilot Plant ProgramsDocument10 pagesBench and Pilot Plant ProgramsNataniel LinaresNo ratings yet

- A Simple and Accurate Method For Ore Reserve Estimation in SLC MinesDocument15 pagesA Simple and Accurate Method For Ore Reserve Estimation in SLC MinesRalain NgatchaNo ratings yet

- Resource Estimation and Valuation of Alluvial Diamond DepositsDocument8 pagesResource Estimation and Valuation of Alluvial Diamond DepositsLuis Miguel La TorreNo ratings yet

- Block Size Selection and Its Impact On Open-Pit Design and Mine PlanningDocument8 pagesBlock Size Selection and Its Impact On Open-Pit Design and Mine PlanningKevin RiosNo ratings yet

- Design and Dimensioning of Sublevel Stoping For ExDocument6 pagesDesign and Dimensioning of Sublevel Stoping For ExJóse AntonioNo ratings yet

- MarioERossi and ClaytonVDeutsh - Mineral Resource Estimation-62-76Document15 pagesMarioERossi and ClaytonVDeutsh - Mineral Resource Estimation-62-76ArielEstebanZúñigaSanMartín100% (1)

- SPE-97113-MS Use of DST For Effective Dynamic Appraisal - Case Studies From Deep Offshore West Africa and Associated Methodology - APKO PDFDocument23 pagesSPE-97113-MS Use of DST For Effective Dynamic Appraisal - Case Studies From Deep Offshore West Africa and Associated Methodology - APKO PDFLawNo ratings yet

- Sgs Min Tp2002 04 Bench and Pilot Plant Programs For Flotation Circuit DesignDocument10 pagesSgs Min Tp2002 04 Bench and Pilot Plant Programs For Flotation Circuit DesignevalenciaNo ratings yet

- 2015 WCSB7 Placer Gold SamplingDocument8 pages2015 WCSB7 Placer Gold SamplingDirceu NascimentoNo ratings yet

- Eng GeoDocument1 pageEng GeoErland PrasetyaNo ratings yet

- Bruce WDocument12 pagesBruce WJuan Carlos Gonzalez LNo ratings yet

- Mining Grade Control — Past, Present and FutureDocument6 pagesMining Grade Control — Past, Present and FutureYenefer Irene VillanuevaNo ratings yet

- Comparative Economic Elements of Mineral Resources in The Context of International ManagementDocument10 pagesComparative Economic Elements of Mineral Resources in The Context of International ManagementJoinNo ratings yet

- 235-242 MarquesDocument8 pages235-242 MarquesKiko LoureiroNo ratings yet

- Reserve EstimationDocument5 pagesReserve EstimationSunnyNo ratings yet

- Chap 1-IntroDocument111 pagesChap 1-IntroaliNo ratings yet

- CO2 Storage Capacity Estimation Issues and DevelopmentDocument7 pagesCO2 Storage Capacity Estimation Issues and DevelopmentJulian De BedoutNo ratings yet

- Understanding Your Ore for Improved Mineral ProcessingDocument4 pagesUnderstanding Your Ore for Improved Mineral Processingvernando pratamaNo ratings yet

- adequacy_of_sampling_for_acid_mine_drainageDocument16 pagesadequacy_of_sampling_for_acid_mine_drainagesyalsaNo ratings yet

- IOP Conference Series: Materials Science and Engineering - Sensitivity Analysis of Net Present Value due to Optimal Pit LimitDocument12 pagesIOP Conference Series: Materials Science and Engineering - Sensitivity Analysis of Net Present Value due to Optimal Pit LimitMaría Alejandra Vera BurauNo ratings yet

- 2022 Chapter 3 Mine Valuation & EconomicsDocument28 pages2022 Chapter 3 Mine Valuation & EconomicsOUMAR PATHE BARRYNo ratings yet

- Andina PreconditionDocument5 pagesAndina PreconditionEli SilvaNo ratings yet

- New Approach To Flexible Open Pit Optimisation and SchedulingDocument7 pagesNew Approach To Flexible Open Pit Optimisation and SchedulinghamidNo ratings yet

- Geometallurgy of Battery MineralsDocument19 pagesGeometallurgy of Battery MineralsErland PrasetyaNo ratings yet

- GeodotDocument1 pageGeodotErland PrasetyaNo ratings yet

- GeosatDocument1 pageGeosatErland PrasetyaNo ratings yet

- GeosbangDocument2 pagesGeosbangErland PrasetyaNo ratings yet

- Simplified Geological Map of SumatraDocument2 pagesSimplified Geological Map of SumatraErland PrasetyaNo ratings yet

- TSF Amendment Executive SummaryDocument21 pagesTSF Amendment Executive SummaryErland PrasetyaNo ratings yet

- Geoape Loe Ape LoeDocument2 pagesGeoape Loe Ape LoeErland PrasetyaNo ratings yet

- Using Trade Policy To Drive Value Addition-Lessons From Indonesia's Ban On Nickel ExportsDocument33 pagesUsing Trade Policy To Drive Value Addition-Lessons From Indonesia's Ban On Nickel ExportsErland PrasetyaNo ratings yet

- Numerical Groundwater Modelling ReportDocument110 pagesNumerical Groundwater Modelling ReportErland PrasetyaNo ratings yet

- GeowereDocument4 pagesGeowereErland PrasetyaNo ratings yet

- What Is Unfolding and When To Use ItDocument2 pagesWhat Is Unfolding and When To Use ItErland PrasetyaNo ratings yet

- Ref GeoDocument1 pageRef GeoErland PrasetyaNo ratings yet

- ISATIS-Narrow Vein Modeling and Narrow Vein Modeling and Resource EstimationDocument49 pagesISATIS-Narrow Vein Modeling and Narrow Vein Modeling and Resource EstimationErland PrasetyaNo ratings yet

- GeosmiminDocument2 pagesGeosmiminErland PrasetyaNo ratings yet

- Mine and Mining Project Site Visit Guidelines: A Practical ApproachDocument16 pagesMine and Mining Project Site Visit Guidelines: A Practical ApproachErland Prasetya100% (1)

- Applied Sciences: Review of GIS-Based Applications For Mining: Planning, Operation, and Environmental ManagementDocument25 pagesApplied Sciences: Review of GIS-Based Applications For Mining: Planning, Operation, and Environmental Managementebrahim payamNo ratings yet

- Eng GeoDocument1 pageEng GeoErland PrasetyaNo ratings yet

- Applied Mineral Inventory Estimation: R R R RDocument1 pageApplied Mineral Inventory Estimation: R R R RErland Prasetya100% (1)

- Ref GeoDocument1 pageRef GeoErland PrasetyaNo ratings yet

- GeooDocument1 pageGeooErland PrasetyaNo ratings yet

- ISATIS-Narrow Vein Modeling and Narrow Vein Modeling and Resource EstimationDocument49 pagesISATIS-Narrow Vein Modeling and Narrow Vein Modeling and Resource EstimationErland PrasetyaNo ratings yet

- Optimizing Ore-Waste Dig-Limits As Part of Operational Mine Planning Through Genetic AlgorithmsDocument13 pagesOptimizing Ore-Waste Dig-Limits As Part of Operational Mine Planning Through Genetic AlgorithmsErland PrasetyaNo ratings yet

- Geo YesDocument1 pageGeo YesErland PrasetyaNo ratings yet

- Minerals: Incorporation of Geometallurgical Attributes and Geological Uncertainty Into Long-Term Open-Pit Mine PlanningDocument26 pagesMinerals: Incorporation of Geometallurgical Attributes and Geological Uncertainty Into Long-Term Open-Pit Mine PlanningGonzaloNo ratings yet

- C O - P M: Anadian PEN IT InesDocument62 pagesC O - P M: Anadian PEN IT InesJorge Gastelum Piña100% (5)

- 17897V1 MGT501 Assessment2Document16 pages17897V1 MGT501 Assessment2bitet100% (1)

- Pom 1Document37 pagesPom 1anuj_mythNo ratings yet

- CV of Rifat 26 Nov 2014Document9 pagesCV of Rifat 26 Nov 2014sjkdaNo ratings yet

- Attachment "A" - Property ListDocument6 pagesAttachment "A" - Property ListBrian Gillespie75% (12)

- Oracle Financials Cloud EbookDocument25 pagesOracle Financials Cloud EbookMariel A. Russo MNo ratings yet

- SAP Application AreasDocument100 pagesSAP Application AreasLodewijk BorsboomNo ratings yet

- Isfi Nuraida - Anggaran KasDocument86 pagesIsfi Nuraida - Anggaran KasGhinaNo ratings yet

- Assets Management Policy and Strategies. ICPAK PDFDocument39 pagesAssets Management Policy and Strategies. ICPAK PDFNassir CeellaabeNo ratings yet

- MetroDocument16 pagesMetroabdakbar100% (3)

- ACC Working Capital ManagementDocument12 pagesACC Working Capital ManagementSourabh DhimanNo ratings yet

- Profit Planning, Activity-Based Budgeting, and E-Budgeting: Answers To Review QuestionsDocument73 pagesProfit Planning, Activity-Based Budgeting, and E-Budgeting: Answers To Review QuestionsMJ YaconNo ratings yet

- 2022 - Appendix 66 Rcpi Marikaban Integrated School CorrectedDocument15 pages2022 - Appendix 66 Rcpi Marikaban Integrated School CorrectedErnie LahaylahayNo ratings yet

- Chapter 8 Kieso Accounting For IntermediateDocument48 pagesChapter 8 Kieso Accounting For IntermediateYenita Febriani100% (2)

- Penerapan Modul Inventory Dalam Penyajian Laporan Persediaan Bahan BakuDocument11 pagesPenerapan Modul Inventory Dalam Penyajian Laporan Persediaan Bahan BakuGedeon Budi PrasetyoNo ratings yet

- Basics of Supply Chain Management: Practice QuestionsDocument21 pagesBasics of Supply Chain Management: Practice Questionsshivam_dubey4004No ratings yet

- EIC Analysis of FMCG SectorDocument37 pagesEIC Analysis of FMCG SectorBig BullsNo ratings yet

- Business Plan PDFDocument10 pagesBusiness Plan PDFMasiko JamesNo ratings yet

- Retail ManagementDocument10 pagesRetail ManagementNaveenNo ratings yet

- 2015.12 2016.01 Q&A P2 Eng FinalDocument32 pages2015.12 2016.01 Q&A P2 Eng FinalKxlxm KxlxmNo ratings yet

- Iocl Final ReportDocument57 pagesIocl Final ReportSuhail DastanNo ratings yet

- Sap Press Product Lifecycle ManagementDocument103 pagesSap Press Product Lifecycle ManagementSheikh Umer25% (4)

- CH 06Document92 pagesCH 06Noheul KimNo ratings yet

- Supply Chain & Value-Creation: Zubin PoonawallaDocument18 pagesSupply Chain & Value-Creation: Zubin PoonawallaNaresh KumarNo ratings yet

- Chads Creative Concepts Case StudyDocument5 pagesChads Creative Concepts Case StudyJoe Nathaniel100% (1)

- Problem No. 1 Average Method Equivalent Production Inputs: Materials Conversion CostDocument4 pagesProblem No. 1 Average Method Equivalent Production Inputs: Materials Conversion CostJune Maylyn MarzoNo ratings yet

- Hotel Linen Room - How To Supply Linen and Linen Control ProceduresDocument4 pagesHotel Linen Room - How To Supply Linen and Linen Control ProceduresArjun SinghNo ratings yet

- 2606Document5 pages2606Pranil DwivediNo ratings yet

- Internship Report Analysis of Sonex TilesDocument83 pagesInternship Report Analysis of Sonex TilesMuhammad Qasim0% (1)

- Costco2-Quiz End-TermDocument4 pagesCostco2-Quiz End-TermmhikeedelantarNo ratings yet

- 01 Full CH Cost and Management Accounting Chapter 1 Copy 1Document200 pages01 Full CH Cost and Management Accounting Chapter 1 Copy 1sabit hussenNo ratings yet