Professional Documents

Culture Documents

Week4 02411840000017 A Kilang

Uploaded by

KilangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Week4 02411840000017 A Kilang

Uploaded by

KilangCopyright:

Available Formats

Manufacturing System Laboratory

Study Guide Industrial Engineering

lnstitut Teknologi Sepuluh

Department

Nopember

Manufacturing System I Tl 184414

Week (4)

Topic (MATERIAL HANDLING, QUALITY INSPECTIONS, AND

PACKAGING CONCEPTS)

Please answer the following questions and include the references.

1. Please answer the following questions below:

• What is material handling, mechanical material handling, and manual material

handling and explain the differences from one another?

• Explain the factors that influence the selection of material handling equipment?

• What are the indicators of safe manual material handling?

• Explain the different types of material handling equipments and how each of them

work

2. Find the journal or relevant source about the Celluveyor! Don't forget to write down your

sources (such as journal, books, etc) using the Harvard Referencing Systems at the last page

of the report.

• Explain the problem background!

• Analyze the case using 5W+1H!

• What is the difference between a celluveyor and a conventional conveyor!

3. Please choose one example of a type of product packaging (it can be a small or large product),

explain the application of the chosen example, and explain the aspects of the quality

dimensions that are included!

4. Quality inspection can be divided into 3 types of inspection, there are off-line inspection, on-

line inspection and on-line/post process inspection. Describe the differences between the

three types of inspection and provide examples of their application!

Contact Person: #188 #191

Copyright Manufacturing System Assistant Team 2020

ANSWER :

1. Material Handling : Process of moving materials in a form raw materials, semi-finished good, finished good

product to a desired place. This moving work is just carried in a small area like a factory

Manual Material Handling : Process of moving materials with manual method like lifting, carrying, pushing, pulling, etc.

Mechanical Material Handling : Process of moving materials with help of machine like conveyor, lift truck, cranes, hoist etc

Factors that influence the selection of material handling equipment

Properties of materials

Building layout

Production Flow

Cost Considerations

Engineering Factors, etc.

Indicators of safe manual material handling

-To find how safe the process of manual material handling. It can use REBA and RULA

Different types of material handling equipments and how each of them work

Storage and handling equipment : designed to utilize vertical space so the warehouse can hold more items. Bins, drawers,

stacking frames, flow racks, cantilever racks, and mezzanines are also included in this category.

Bulk Material handling equipment : this is, the storing, transportation and control of materials in loose bulk form. If there’s a

lot of material all together, you’re probably using bulk material handling equipment.

Industrial Trucks : These are vehicles or equipment that move materials. Sometimes workers run them, and sometimes

they are automatic. Automated Guided Vehicles (AGVs) fall under both engineered systems and industrial trucks.

Engineered Systems : This type of material handling equipment involves more complicated systems with multiple

components, usually automated

2. F

3. Rigid Box

A rigid box is made out of highly condensed paperboard that is 4 times thicker than the paperboard used in the construction of a

standard folding carton. The easiest real-world example of rigid boxes are the boxes that hold Apple’s iPhones and iPads,

which are 2 piece setup rigid boxes.Compared to paperboard and corrugated boxes, rigid boxes are definitely among the most

expensive box styles. The rigid boxes usually do not require dies that are expensive or massive machinery and are often hand-

made. Their non-collapsible nature also gives them a higher volume during shipping, which easily incurs higher shipping fees.

These boxes are commonly used in merchandising cosmetics, jewelry, technology, and high-end luxury couture. It is easy to

incorporate features such as platforms, windows, lids, hinges, compartments, domes, and embossing in a rigid box.

4. Offline inspection : In off-line inspection, the inspection equipment is usually dedicated and does not make any

physical contact with machine tools. There is always a time delay between production and inspection. The disadvantage of

offline inspection is that the parts have already been made by the time poor quality is detected. Sometimes by default a

defective part may not be included into the sample. A coordinate measuring machine (CMM) is an example of off-line

inspection. CMM is discussed in detail in the next section.

Online inspection : If the task of inspection is done as the parts are manufactured, then it is called as online inspection.

There are two variations of on-line inspection. If the inspection is performed during the manufacturing operation, it is called on-

line/in-process inspection. If the inspection is performed immediately following the production process, it is called on-line/post-

process inspection

Reference :

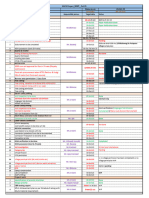

DesignConveyorSystems. 2019. The 4 Types of Material Handling Equipment. [Online] Available at :

https://www.designedconveyor.com/2019/11/04/the-4-types-of-material-handling-equipment/

Rajak. 2020. Factors Affecting the Selection of Material Handling equipment. [Online] Available at : https://hmhub.me/types-of-

material-handling-equipments/

Velarga. 2017. 7 Packaging Types to Consider. [Online] Available at ; https://www.packagingstrategies.com/blogs/14-packaging-

strategies-blog/post/89440-packaging-types-to-consider

You might also like

- A Study On Supply Chain and Logistics Managemernt For K.M.B GraniteDocument50 pagesA Study On Supply Chain and Logistics Managemernt For K.M.B GraniteRaja Thrisangu100% (1)

- Introduction To Materials Handling PDFDocument8 pagesIntroduction To Materials Handling PDFhijzain75% (4)

- Material Handling Equipment: RAFIULLAH KHAN MSC PROJECT REPORT PDFDocument46 pagesMaterial Handling Equipment: RAFIULLAH KHAN MSC PROJECT REPORT PDFrafimarwat67% (12)

- Attention and Effort. (1973)Document253 pagesAttention and Effort. (1973)Robert C. CasasNo ratings yet

- Fritz Springmeier InterviewDocument59 pagesFritz Springmeier InterviewCzink Tiberiu100% (4)

- (Material Handling, Quality Inspections, and Packaging Concepts)Document4 pages(Material Handling, Quality Inspections, and Packaging Concepts)Raynathan PrajnadiNo ratings yet

- Material Handling NewDocument70 pagesMaterial Handling Newphilo minaNo ratings yet

- Materials HandlingDocument6 pagesMaterials HandlingRose LopezNo ratings yet

- Materials HandlingDocument18 pagesMaterials HandlingJessica SaballeroNo ratings yet

- Material Handling Equipment - Dr. Eng. Daniel KitawDocument313 pagesMaterial Handling Equipment - Dr. Eng. Daniel KitawBîñïåm ËñdàlåmàwNo ratings yet

- Material Handling SystemsDocument16 pagesMaterial Handling Systemschris_clifford_2No ratings yet

- Material HandlingDocument17 pagesMaterial HandlingJessica SaballeroNo ratings yet

- Iyyappan Chapter 1 DONEDocument14 pagesIyyappan Chapter 1 DONEPriya dharshiniNo ratings yet

- DistmnDocument73 pagesDistmnJuvie Mangana Baguhin TadlipNo ratings yet

- Chapter 1Document12 pagesChapter 1Priya dharshiniNo ratings yet

- MH Chapter 1Document20 pagesMH Chapter 1nurhussen nureNo ratings yet

- Operation AnalysisDocument22 pagesOperation AnalysisJahmmil A RamastaNo ratings yet

- MH Lect Chapter 1Document19 pagesMH Lect Chapter 1Kuma AlexoNo ratings yet

- Material Handling 2009Document45 pagesMaterial Handling 2009FarhinNo ratings yet

- Iare PL&MH PptsDocument47 pagesIare PL&MH PptsdheenathayalNo ratings yet

- Chp.7 Material HandlingDocument26 pagesChp.7 Material HandlinganfaalNo ratings yet

- UNIT 1 - Introduction To Material Handling EquipmentsDocument20 pagesUNIT 1 - Introduction To Material Handling EquipmentsAdugna GosaNo ratings yet

- Ergonomics AssignmentDocument13 pagesErgonomics AssignmentDame TolossaNo ratings yet

- Chapter 1 Introduction To MH - AregawiDocument32 pagesChapter 1 Introduction To MH - AregawiBeke derejeNo ratings yet

- Definition: Materials Handling Equipment (MHE) : Benefits/ Objectives of Good Materials Handling System Reduce CostDocument2 pagesDefinition: Materials Handling Equipment (MHE) : Benefits/ Objectives of Good Materials Handling System Reduce CostTilahun WoretawNo ratings yet

- School of Mechanical, Chemical and Material Engineering: Dep't:-Manufacturing EngineeringDocument25 pagesSchool of Mechanical, Chemical and Material Engineering: Dep't:-Manufacturing EngineeringHenok HailuNo ratings yet

- IARE PPC Lecture NotesDocument65 pagesIARE PPC Lecture NotesJaveed802No ratings yet

- Rpa Assg1Document4 pagesRpa Assg1Anushka LukeNo ratings yet

- Material HandlingDocument26 pagesMaterial HandlingRohit AroraNo ratings yet

- Material HandlingDocument12 pagesMaterial Handlingseid negashNo ratings yet

- Operations Process: UNIT II OPERATIONS PROCESS: Process Analysis - Process Flow ChartingDocument77 pagesOperations Process: UNIT II OPERATIONS PROCESS: Process Analysis - Process Flow ChartingSenthil RokeshNo ratings yet

- Material HandlingDocument41 pagesMaterial HandlingmjbicaldoNo ratings yet

- Material HandlingDocument55 pagesMaterial HandlingNishaThakuri100% (2)

- Material Handling in Textile Industries PDFDocument15 pagesMaterial Handling in Textile Industries PDFUmair AshrafNo ratings yet

- Unit 2 NotesDocument75 pagesUnit 2 NotesrajeeevaNo ratings yet

- Material Handling Equipment Selection: New Classifications of Equipments and AttributesDocument9 pagesMaterial Handling Equipment Selection: New Classifications of Equipments and Attributesabdul ghoniNo ratings yet

- WINSEM2021-22 MEE1018 TH VL2021220503069 Reference Material I 11-04-2022 Module6Document57 pagesWINSEM2021-22 MEE1018 TH VL2021220503069 Reference Material I 11-04-2022 Module6Harsh VermaNo ratings yet

- Abe 214 Lecture NoteDocument46 pagesAbe 214 Lecture Noteemmanueladah147No ratings yet

- Lesson 3Document16 pagesLesson 3Princess Czarina Delas AlasNo ratings yet

- Introduction To Material HandlingDocument27 pagesIntroduction To Material HandlingKevin Ferrer FNo ratings yet

- Lesson 5 in Introduction To I.E PDFDocument5 pagesLesson 5 in Introduction To I.E PDFRanah Pauolynne LintanNo ratings yet

- A Review Paper of Various Industrial Material Handling SystemsDocument5 pagesA Review Paper of Various Industrial Material Handling SystemsRINKAL LOUNGANINo ratings yet

- Material HandlingDocument20 pagesMaterial HandlingMitali KolambekarNo ratings yet

- Mid-Term Assignmen, Group 2WF., Alaa AboualiDocument5 pagesMid-Term Assignmen, Group 2WF., Alaa AboualiAlaa AboaliNo ratings yet

- Oh I Ou 1183469771Document130 pagesOh I Ou 1183469771Rowena Matte FabularNo ratings yet

- Role of Material Handling Equipment at Fulfillment Center: Managing E-Business OperationsDocument5 pagesRole of Material Handling Equipment at Fulfillment Center: Managing E-Business OperationsHimanshu SagarNo ratings yet

- Automation in Manufacturing 301Document57 pagesAutomation in Manufacturing 301MsNo ratings yet

- Types of Material Handling EquipmentDocument7 pagesTypes of Material Handling EquipmentWilly K. Ng'etichNo ratings yet

- Material Handling Systems in ConstructionDocument7 pagesMaterial Handling Systems in Constructionramyatan SinghNo ratings yet

- Selection of Material Handling EquipmentDocument6 pagesSelection of Material Handling EquipmentAkif ZubairNo ratings yet

- Non-Traditional Machining and Automation: B.Tech. (4 Sem) Spring 2021 Department of Mechanical Engineering NIT SrinagarDocument18 pagesNon-Traditional Machining and Automation: B.Tech. (4 Sem) Spring 2021 Department of Mechanical Engineering NIT SrinagarJatin prasad TandanNo ratings yet

- Material Handling SystemsDocument15 pagesMaterial Handling SystemsShreyas JyothishNo ratings yet

- Material Handling Equipment PPT Chap 1.0Document50 pagesMaterial Handling Equipment PPT Chap 1.0eyukaleb4No ratings yet

- MACHINEDocument9 pagesMACHINEJONAS VIMBANENo ratings yet

- A Review Paper of Various Industrial Material Handling SystemsDocument5 pagesA Review Paper of Various Industrial Material Handling SystemsMUKUL VIPATNo ratings yet

- 137 Introduction To Materials Handling Sidphartha Ray Edisi 1 2008Document150 pages137 Introduction To Materials Handling Sidphartha Ray Edisi 1 2008JyNo ratings yet

- Draft Project Report Dhiraj ChavanDocument63 pagesDraft Project Report Dhiraj ChavanMayuri PotdarNo ratings yet

- Operation ManagementDocument26 pagesOperation ManagementNavinkumarNo ratings yet

- Introduction of Material HandlingDocument14 pagesIntroduction of Material HandlingsankasturkarNo ratings yet

- Plant Layout and Facility Design: Course Code: Greg 4181 Target Group: 4 Year GEDDocument90 pagesPlant Layout and Facility Design: Course Code: Greg 4181 Target Group: 4 Year GEDEndashaw YohannesNo ratings yet

- Guide: StudyDocument4 pagesGuide: StudyKilangNo ratings yet

- Delivery Performance Improvement Using Six Sigma Method: A Case Study at FMC Agricultural ManufacturingDocument12 pagesDelivery Performance Improvement Using Six Sigma Method: A Case Study at FMC Agricultural ManufacturingKilangNo ratings yet

- Weekly Report AutomationDocument1 pageWeekly Report AutomationKilangNo ratings yet

- Cycle Time Dept 3Document2 pagesCycle Time Dept 3KilangNo ratings yet

- Week4 - 02411840000017 - Kilang Roba - ADocument1 pageWeek4 - 02411840000017 - Kilang Roba - AKilangNo ratings yet

- Week1 - 02411840000017 - Kilang Roba - ADocument1 pageWeek1 - 02411840000017 - Kilang Roba - AKilangNo ratings yet

- (Automatic Identification and Data Capture) : I 1 e OpicDocument3 pages(Automatic Identification and Data Capture) : I 1 e OpicKilangNo ratings yet

- Week2 02411840000017 Kilang Roba Wanadri ADocument1 pageWeek2 02411840000017 Kilang Roba Wanadri AKilangNo ratings yet

- Say's Law of Market and Quantity Theory of MoneyDocument19 pagesSay's Law of Market and Quantity Theory of MoneyBHANU TYAGINo ratings yet

- Landscape Architecture: Elements of Garden DesignDocument7 pagesLandscape Architecture: Elements of Garden Designtwinkle4545No ratings yet

- Separation of Powers - WikipediaDocument15 pagesSeparation of Powers - WikipediaSacredly YoursNo ratings yet

- Solar Geometry FinalDocument17 pagesSolar Geometry Finalsarvesh kumarNo ratings yet

- 850 SQ MM AAC Conductor PDFDocument1 page850 SQ MM AAC Conductor PDFSamyak DeoraNo ratings yet

- Prog Copywriting Exercise 10Document3 pagesProg Copywriting Exercise 10azertyNo ratings yet

- Hach - MWP (Plan Vs Actual) Status - 22 Oct-1Document1 pageHach - MWP (Plan Vs Actual) Status - 22 Oct-1ankit singhNo ratings yet

- Presentation On Modal Auxiliary VerbsDocument18 pagesPresentation On Modal Auxiliary VerbsAbdelhafid ZaimNo ratings yet

- Junior 3 Future-Passive VoiceDocument1 pageJunior 3 Future-Passive VoiceJonathan QNo ratings yet

- First Responder ManualDocument69 pagesFirst Responder ManualCristina Joy Vicente Cruz100% (3)

- Pattern, Price and Time - Using Gann TheoryDocument29 pagesPattern, Price and Time - Using Gann TheoryRohitOhri44% (9)

- Once Upon A Time A Hawk Feels in Love With A HenDocument2 pagesOnce Upon A Time A Hawk Feels in Love With A HenJeffri Aritonang100% (1)

- Evija - Lotus Cars Official WebsiteDocument5 pagesEvija - Lotus Cars Official WebsiteluyuanNo ratings yet

- Indira Gandhi Apprentice FormDocument3 pagesIndira Gandhi Apprentice FormDevil Gamer NeroNo ratings yet

- ASA 105: Coastal Cruising Curriculum: Prerequisites: NoneDocument3 pagesASA 105: Coastal Cruising Curriculum: Prerequisites: NoneWengerNo ratings yet

- Fforde Economic StrategyDocument29 pagesFforde Economic StrategyDinhThuyNo ratings yet

- Ankit Pathak: Business AnalystDocument3 pagesAnkit Pathak: Business AnalystBibhuPrakashDasNo ratings yet

- Music For BandDocument143 pagesMusic For BandTedTerroux604No ratings yet

- WWDC 2020 Viewing GuideDocument13 pagesWWDC 2020 Viewing GuidejuniorNo ratings yet

- UNIT-5 ppspNOTESDocument29 pagesUNIT-5 ppspNOTESEverbloom EverbloomNo ratings yet

- Biology-Activity-3 - Growth and Development of PlantDocument3 pagesBiology-Activity-3 - Growth and Development of PlantnelleoNo ratings yet

- NPJH50465Document3 pagesNPJH50465Samuel PerezNo ratings yet

- Friday HeatsDocument29 pagesFriday HeatsTGrasley6273No ratings yet

- Task Performance EuthenicsDocument3 pagesTask Performance EuthenicsKimberly MarquezNo ratings yet

- Basic Electrical Engg Kee 101Document3 pagesBasic Electrical Engg Kee 101SHIVAM BHARDWAJNo ratings yet

- Vibration Control Technology Industry (Freudenberg Schwab)Document111 pagesVibration Control Technology Industry (Freudenberg Schwab)ismailNo ratings yet

- Applied Business Tools and Technologies: A. Activation of Prior KnowledgeDocument12 pagesApplied Business Tools and Technologies: A. Activation of Prior KnowledgeClaire CarpioNo ratings yet