Professional Documents

Culture Documents

Chapter Four: 4.8.1 Single-Slope Frames

Uploaded by

Amjad JiwaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter Four: 4.8.1 Single-Slope Frames

Uploaded by

Amjad JiwaniCopyright:

Available Formats

PRIMARY FRAMING

76 CHAPTER FOUR

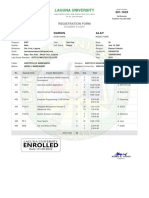

FIGURE 4.15 Lean-to framing. (Metallic Building Systems.)

4.8.1 Single-Slope Frames

Each of the five basic pre-engineered framing systems can be produced in a single-slope, rather than

gable, configuration. The single-slope feature does not significantly affect structural behavior of the

framing, its clear span capacity, or typical details. Confusing the terminology, some companies call

their single-slope rigid-frame products (Fig. 4.1h) “lean-to rigid frames.” In such cases, a picture is

truly worth a thousand words.

Single-slope framing is frequently used for office complexes and strip shopping malls, where

rainwater needs to be drained away from the parking areas or from the adjacent buildings.

4.8.2 Trussframes

Coronis Building Systems, Inc., started production of its proprietary framing line in 1956 and has

since developed over 8000 variations of the framing. A typical trussframe* resembles a tapered beam,

except for its web, which is made of truss-type members rather than being solid (Fig. 4.16). Other

trussframe varieties include multispans, cantilevered pole-type shelters, canopies, and lean-tos.

A major advantage of this system, as claimed by the manufacturer, is the absence of horizontal

reactions at the columns under gravity loads, a natural property of tapered-beam framing (or any

other simply supported straight beam, for that matter).

*Trussframe is a trademark of Coronis Building Systems, Inc.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

PRIMARY FRAMING

PRIMARY FRAMING 77

FIGURE 4.16 Trussframes. (Coronis Building Systems.)

4.8.3 Delta Joist System

Delta Joists* are unlikely to be confused with any other structure. We would have placed this system

in the next chapter, were these triangulated three-dimensional joists produced by Butler

Manufacturing Co. not conceived and sold as a complete roof-support system rather than as mere

roof purlins. The joists, which are available in 1-ft increments, have a constant depth of 251Ⲑ4 in,

regardless of loading. Their top and bottom chords are made of hot-rolled steel angles; the diagonals

consist of round bars. The joists possess a very desirable characteristic—lateral stability—which

makes them truly different, since it obviates the need for purlin bracing and perhaps even for tradi-

tional horizontal roof diaphragms.

The Delta Joist system is best suited for buildings with load-bearing masonry or precast walls,

where exterior columns and wall bracing are not needed; it can be adapted for non-load-bearing end-

walls if optional steel frames are used. The system normally provides a roof slope of 1Ⲑ4:12 and

requires the building width to be a multiple of 4 ft. The joists can span up to 60 ft, a distance nor-

mally unattainable with the secondary members traditionally used in metal building systems. The

Delta Joist system is intended to support Butler’s proprietary standing-seam roof panels; top flanges

of the joists come prepunched for attachment of the roof clips.

4.8.4 Flagpole-Type Systems and Systems with Fixed-Base Columns

Occasionally, a manufacturer proposes a system that does not look much different from the com-

peting ones but costs less. The savings can sometimes be explained by the fact that all the build-

ing columns, or the exterior columns only, are designed with fixed bases. In this design,

*Delta Joist is a trademark of Butler Manufacturing Co.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Roberson-FRIT 7236 Assessment PlanDocument13 pagesRoberson-FRIT 7236 Assessment PlanMarie RNo ratings yet

- BGP Basic in Comware 7Document8 pagesBGP Basic in Comware 7felipemunozmoraNo ratings yet

- QuickZChargerZAC DCDocument2 pagesQuickZChargerZAC DCLucaspasNo ratings yet

- Let's think step by step:- The common factor of 32, 45 and 50 is 5- 32/5 = 6.4 meters - 45/5 = 9 meters- 50/5 = 10 meters- So the best option is the 50 meter wire.b. How did you get the answerDocument59 pagesLet's think step by step:- The common factor of 32, 45 and 50 is 5- 32/5 = 6.4 meters - 45/5 = 9 meters- 50/5 = 10 meters- So the best option is the 50 meter wire.b. How did you get the answerjsphmnsycjrscribdNo ratings yet

- Kawai MP7 Owner's ManualDocument148 pagesKawai MP7 Owner's ManualMiloNo ratings yet

- B2 - PlatoDocument1 pageB2 - PlatoVeda Leigh SyNo ratings yet

- Basic Sciences: Home MCQ's DiscussionsDocument10 pagesBasic Sciences: Home MCQ's Discussionsdileep9002392No ratings yet

- PDFDocument478 pagesPDFPriyaranjan PradhanNo ratings yet

- Darius Registration Form 201 1623 2nd Semester A.Y. 2021 2022Document1 pageDarius Registration Form 201 1623 2nd Semester A.Y. 2021 2022Kristilla Anonuevo CardonaNo ratings yet

- Good Posture is Good HealthDocument4 pagesGood Posture is Good HealthJacklynlim LkcNo ratings yet

- A High Capacity Floating LNG Design by Barend - PekDocument15 pagesA High Capacity Floating LNG Design by Barend - PekShaka Shalahuddin Shantika PutraNo ratings yet

- Fast Arithmetic TipsDocument20 pagesFast Arithmetic TipsDumitru D. DRAGHIANo ratings yet

- KF2.5-200 - With-M-C - GB - 03-15 KRACHT Bomba PDFDocument8 pagesKF2.5-200 - With-M-C - GB - 03-15 KRACHT Bomba PDFJairo Andrés FA100% (1)

- Spent Caustic Recycle at Farleigh MillDocument9 pagesSpent Caustic Recycle at Farleigh MillyamakunNo ratings yet

- RGB PDFDocument35 pagesRGB PDFGestion Medios Zamba ColorsNo ratings yet

- Well Plug and Abandonment Using HwuDocument1 pageWell Plug and Abandonment Using HwuJuan Pablo CassanelliNo ratings yet

- XETEC 4g300 / 4g600Document6 pagesXETEC 4g300 / 4g600Harun ARIKNo ratings yet

- Three Phase Traffic Theory PDFDocument11 pagesThree Phase Traffic Theory PDFKocic GradnjaNo ratings yet

- PDF 20220814 211454 0000Document6 pagesPDF 20220814 211454 0000Madhav MehtaNo ratings yet

- Guided Reading Activity: The Reach of ImperialismDocument2 pagesGuided Reading Activity: The Reach of ImperialismevertNo ratings yet

- Unit4 Dbms PDFDocument66 pagesUnit4 Dbms PDFRS GamerNo ratings yet

- A2 Unit 4 Academic Skills Plus LessonDocument2 pagesA2 Unit 4 Academic Skills Plus LessonJanaNo ratings yet

- Evaluation of Different Grains Used For ProductionDocument7 pagesEvaluation of Different Grains Used For ProductionAmin TaleghaniNo ratings yet

- Contineous Assessment 2 Group BDocument11 pagesContineous Assessment 2 Group BMasnoon MidhatNo ratings yet

- The Most Efficient and Effective Ways To Address New Literacies FDocument61 pagesThe Most Efficient and Effective Ways To Address New Literacies FAlpha MoontonNo ratings yet

- Class Will and TestamentDocument4 pagesClass Will and TestamentAllan Tomas33% (3)

- Understanding the Role of Criminologists in Third World CountriesDocument4 pagesUnderstanding the Role of Criminologists in Third World Countriespaco kazunguNo ratings yet

- NB-CPR 17-722r8 - General Guidance On AVCP (Working Copy)Document25 pagesNB-CPR 17-722r8 - General Guidance On AVCP (Working Copy)halexing5957No ratings yet

- 2019 AhmadDocument73 pages2019 Ahmadaateka02No ratings yet

- VachanamruthaDocument5 pagesVachanamruthaypraviNo ratings yet