Professional Documents

Culture Documents

The Faltering Factory

Uploaded by

Abhishek JainOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Faltering Factory

Uploaded by

Abhishek JainCopyright:

Available Formats

The Faltering Factory

An engineer with a flair of production management was the principle owner and founder of a

company in Los Angeles. He had a special talent for working with airplane manufacturers, taking

their designs of various small devices and subcontracting component parts, and producing them

on a contract basis. He operated a small facility where he completed the assembly operations,

purchased outside and tested and shipped the complete assemblies.

Subsequently, to meet competition that sprang up, he decided to manufacture his own parts, which

represented the greater part of the total value of his products. To have a favorable labor market

and a climate that was good for his type of manufacturing, he located his new plant in Arizona,

several hundred miles from Los Angeles. Not only did he set up the parts manufacturing there, but

he moved the testing and assembling operations there as well. The owner, however, remained in

Los Angeles, in his executive headquarters, with a small group of sales engineers. This permitted

him to maintain the same close contacts with his customers that had made him successful.

A qualified factory manager had been put in charge of the new plant. During the starting-up period,

the owner made frequent trips to the plant, keeping in touch with what was going on and providing

leadership and motivation to the local management. But as time went on, these trips became less

and less frequent as the complexity of his personal activities made his continuous presence in Los

Angeles more and more compelling. Accordingly, the time came when full responsibility for the

factory operation had been shifted to the manager, with the owner depending completely on the

manager’s activities and results.

Soon the owner began to hear from several of his customers that some of his prices were not

competitive, some deliveries were seriously late, and quality was not up to the expected high

standard. The owner began to develop a sense of disquietude. His uneasiness reached a point

where he procured the services of a consulting industrial engineer.

On his introductory trip through the plant, the consultant got the impression that a rather slow

working tempo prevailed. This led him to review the payroll recorder. Here he learned that for

several months, workers’ productivity had been slipping. An investigation showed that it was due

to delays and slowing down of workers caused by an uneven flow of work. When this was explored

more deeply, the cause of the uneven flow proved to be a combination of substandard materials

and inadequate machine maintenance. Working backward, the consultant unearthed the root of

this difficulty – poor control of materials. Purchased materials were not up to the original

standards. At first this caused low productivity, which increased labor costs. Then, to compensate

for this, a drive toward overhead cost reduction ensued, which included a cutback in maintenance

personnel. The result only lowered productivity still more. All this resulted in high overall cost,

lower capacity and poor quality, which showed up later in customer complaints.

A meeting of the owner, factory manager, and the consultant revealed that deterioration in

purchase materials and parts was because of a misguided program on the part of the factory

manager to reduce production costs by saving on purchases. The use of substitute materials

created other cost increases that overbalanced several times the slight saving on purchases.

Discuss the case in terms of production functions and decision making in a production system.

You might also like

- Lean-based Production Management: Practical Lean ManufacturingFrom EverandLean-based Production Management: Practical Lean ManufacturingNo ratings yet

- Manufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesFrom EverandManufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesRating: 4.5 out of 5 stars4.5/5 (3)

- Faltering FactoryDocument1 pageFaltering FactoryRatul MondalNo ratings yet

- The Case of The Faltering FactoryDocument1 pageThe Case of The Faltering FactoryPrashant BarsingNo ratings yet

- The Case of The Faltering FactoryDocument1 pageThe Case of The Faltering Factorynicero88No ratings yet

- The Case of The Faltering FactoryDocument1 pageThe Case of The Faltering FactoryANKITNo ratings yet

- Faltering Factory Mini CaseDocument1 pageFaltering Factory Mini CaseVidhi VermaNo ratings yet

- OM Case StudiesDocument9 pagesOM Case StudiesAbhiroop VermaNo ratings yet

- Vickers Ohama Plant - 0181Document4 pagesVickers Ohama Plant - 0181narenkNo ratings yet

- Glovia Lean ManufacturingDocument16 pagesGlovia Lean ManufacturingALEJANDRANo ratings yet

- MM ZG537 Assignment 1Document7 pagesMM ZG537 Assignment 1Akhil KarthikeyanNo ratings yet

- Ch. 10,11,12,13 TestDocument11 pagesCh. 10,11,12,13 TestCarlos PresasNo ratings yet

- Assignment 2 - The Goal EssayDocument4 pagesAssignment 2 - The Goal EssayAnonymous e994HRfJNo ratings yet

- Operation Management Case StudyDocument8 pagesOperation Management Case StudyArsalan HaiderNo ratings yet

- Edgar F AnalysisDocument4 pagesEdgar F AnalysisChelcy MangloNo ratings yet

- Donner CompanyDocument35 pagesDonner CompanyZunaira GullNo ratings yet

- Operation ManagementDocument45 pagesOperation ManagementJersey RamosNo ratings yet

- Measuring The Cost of Quality: Executive SummaryDocument6 pagesMeasuring The Cost of Quality: Executive Summaryمحمد زرواطيNo ratings yet

- Mazlow New StoryDocument6 pagesMazlow New Storynaser shamsNo ratings yet

- Unit 5-Business OperationsDocument10 pagesUnit 5-Business Operationsvshtyt52swNo ratings yet

- Cost of QualityDocument7 pagesCost of QualityLepokkumzuk JamirNo ratings yet

- Business Unit 2 Part 2Document45 pagesBusiness Unit 2 Part 2Twaiba AdmaniNo ratings yet

- Hank Kolb CaseDocument3 pagesHank Kolb CaseflmcollantesNo ratings yet

- Chapter 1 Operation ManagementDocument9 pagesChapter 1 Operation ManagementOnline EducationNo ratings yet

- CQV #2 Like-For-Like Change ProblemsDocument7 pagesCQV #2 Like-For-Like Change Problemswindli2012No ratings yet

- Optimizing Efficiency: FabricationDocument7 pagesOptimizing Efficiency: FabricationVivek Kumar SinghNo ratings yet

- Final English 311 PaperDocument10 pagesFinal English 311 Paperapi-272625771No ratings yet

- Final Essay - Managing QualityDocument6 pagesFinal Essay - Managing QualityTom BeaulieuNo ratings yet

- Module 3 SKILLS FOR IMPROVING WORK PROCESSDocument25 pagesModule 3 SKILLS FOR IMPROVING WORK PROCESSMamatha NUNo ratings yet

- Nuclear Tube Assembly Room CaseDocument7 pagesNuclear Tube Assembly Room CaseSoniaNo ratings yet

- OM Chapter 4Document14 pagesOM Chapter 4abdulwahab kemalNo ratings yet

- Group 10 - Section B - Hank Kolb Case - TQMDocument4 pagesGroup 10 - Section B - Hank Kolb Case - TQMJYOTI TALUKDARNo ratings yet

- Quality Assurance in China: Best Practices: Practical Advice For Importers Who Want To Avoid The Traps of China SourcingDocument10 pagesQuality Assurance in China: Best Practices: Practical Advice For Importers Who Want To Avoid The Traps of China SourcingFagalNo ratings yet

- Chapter 5 Operations Human Resource ManagementDocument7 pagesChapter 5 Operations Human Resource Managementnielisa dejanNo ratings yet

- S23 MGMT 6139 Module 10 BrightView Plumbing and Heathing - A New Buisness ModelDocument10 pagesS23 MGMT 6139 Module 10 BrightView Plumbing and Heathing - A New Buisness ModelVino DhanapalNo ratings yet

- AISC Shop InspectionDocument19 pagesAISC Shop InspectionkblaxtonNo ratings yet

- Operations Management IntroductionDocument44 pagesOperations Management IntroductionSiddharth SalgaonkarNo ratings yet

- The Order To Delivery Cycle: Quick Response Is Essential: Cause and EffectDocument4 pagesThe Order To Delivery Cycle: Quick Response Is Essential: Cause and EffectjustingordanNo ratings yet

- Lean Accounting VGDocument11 pagesLean Accounting VGpeter358No ratings yet

- Director Production Operations Manufacturing in Columbus OH Resume Todd BejsovecDocument2 pagesDirector Production Operations Manufacturing in Columbus OH Resume Todd BejsovecToddBejsovecNo ratings yet

- Job-Order Costing Project: Group Presentation MA-100đDocument22 pagesJob-Order Costing Project: Group Presentation MA-100đTHUỶ NGUYỄN THỊ XUÂNNo ratings yet

- Effectiveness and Efficiency-MBA 631Document22 pagesEffectiveness and Efficiency-MBA 631Manasseh Abimaje100% (1)

- 12 Manufacturing MetricsDocument6 pages12 Manufacturing MetricsWendy SarriaNo ratings yet

- Hvac Installer ResumeDocument5 pagesHvac Installer Resumeafiwhyqrv100% (2)

- RES 341 Week 1 Individual Paper Ethics in BusinessDocument4 pagesRES 341 Week 1 Individual Paper Ethics in BusinessGleynne MilloradaNo ratings yet

- 5 Ways For Lead Time ReductionDocument5 pages5 Ways For Lead Time ReductionYamini ShamiNo ratings yet

- Power EconomicsDocument33 pagesPower EconomicsGoogleadscourse111No ratings yet

- Westover Case StudyDocument2 pagesWestover Case StudyMohamad ELyas100% (2)

- Optimization of A Plant Layout and Materials Handling System For A Furniture Manufacturing CompanyDocument6 pagesOptimization of A Plant Layout and Materials Handling System For A Furniture Manufacturing Companyashti gosineNo ratings yet

- 7 Wastes 5s LeanDocument12 pages7 Wastes 5s LeanJulio Cesar Gonzalez MendezNo ratings yet

- 7 Lean Manufacturing 1 1 Five S and Visual ControlDocument44 pages7 Lean Manufacturing 1 1 Five S and Visual Controlmax hopus100% (1)

- Case Studies in Engineering EthicsDocument8 pagesCase Studies in Engineering EthicsMitsui Konttori100% (2)

- By: Berdon, Elsha Mica D. Chua, Christian T. Taguba, John Elmer Ticsay, Januel BDocument50 pagesBy: Berdon, Elsha Mica D. Chua, Christian T. Taguba, John Elmer Ticsay, Januel BChris ChuaNo ratings yet

- Balraj KuntalDocument2 pagesBalraj KuntalSid GuptaNo ratings yet

- Standard CostingDocument52 pagesStandard CostingSunday Oluwole0% (1)

- Brainstorm Brainsteering New Product DevelopmentDocument9 pagesBrainstorm Brainsteering New Product DevelopmentMaliha KhanNo ratings yet

- Cost Reduction in A Manufacturing Business - BEDocument3 pagesCost Reduction in A Manufacturing Business - BEsonali sonalNo ratings yet

- Nestle Case StudyDocument4 pagesNestle Case StudyOmair ShaikhNo ratings yet

- Chapter FiveDocument28 pagesChapter FiveBahredin AbdellaNo ratings yet

- Cover Letter Format For Resume For Marine EngineerDocument8 pagesCover Letter Format For Resume For Marine Engineerpqdgddifg100% (1)

- SAE AS4059F Table1Document2 pagesSAE AS4059F Table1CherryNo ratings yet

- The First Two Years of Operational Experience With The Sikorsky S-61Document6 pagesThe First Two Years of Operational Experience With The Sikorsky S-61Floyd PriceNo ratings yet

- Analytical ChemistryDocument7 pagesAnalytical ChemistryNia RukmanNo ratings yet

- MU e MT - CUSTOM BIOGENIC SYSTEMS 2100 - 2101 CONTROLLED RATE FREEZER SET-UP & TECHNICAL MANUALDocument10 pagesMU e MT - CUSTOM BIOGENIC SYSTEMS 2100 - 2101 CONTROLLED RATE FREEZER SET-UP & TECHNICAL MANUALRenato MouraNo ratings yet

- Stomatognathic SystemDocument71 pagesStomatognathic SystemRaj Singh83% (6)

- Republic Act 8749 Salient FeaturesDocument34 pagesRepublic Act 8749 Salient Featuresdenr02legal88% (8)

- Compound Plamar GanglionDocument4 pagesCompound Plamar Ganglionchinmayghaisas100% (2)

- Capgemini TestsDocument50 pagesCapgemini TestsObli Narasimha RajanNo ratings yet

- Overall Efficiency Evaluation of Commercial Distillation Columns With Valve and Dual Ow TraysDocument8 pagesOverall Efficiency Evaluation of Commercial Distillation Columns With Valve and Dual Ow TraysArioston JúniorNo ratings yet

- BookDocument182 pagesBookSebastian Aguayo FritzNo ratings yet

- 2 and Lehr Panzerdivison PDFDocument38 pages2 and Lehr Panzerdivison PDFLeonte Daniel100% (1)

- Manalaysay JPT Thesis With Approval PDFDocument103 pagesManalaysay JPT Thesis With Approval PDFTheresa Marie PrestoNo ratings yet

- Test B2: Example: O A Because of B As For C Since D As A ResultDocument5 pagesTest B2: Example: O A Because of B As For C Since D As A ResultAgrigoroaiei IonelNo ratings yet

- 09 Husserl - The Encyclopaedia Britannica Article - Draft EDocument19 pages09 Husserl - The Encyclopaedia Britannica Article - Draft EAleksandra VeljkovicNo ratings yet

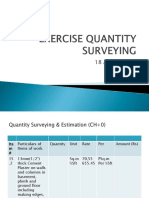

- Quantity Surveying & Estimation-2Document17 pagesQuantity Surveying & Estimation-2Engr Nissar KakarNo ratings yet

- Board of Technical Education: "Design & Analysis of Highway Pavement"Document43 pagesBoard of Technical Education: "Design & Analysis of Highway Pavement"Bharath SrinivasreddyNo ratings yet

- Worksheet 8: Language HandbookDocument2 pagesWorksheet 8: Language HandbookMrs BeyNo ratings yet

- Chapter 5Document22 pagesChapter 5Aftab AhmedNo ratings yet

- Rohm Bu2090Document12 pagesRohm Bu2090Alberto Carrillo GuerreroNo ratings yet

- Immoreev, I. - Active Transmitting Phased Antenna ArraysDocument14 pagesImmoreev, I. - Active Transmitting Phased Antenna ArraysDhimas AfihandarinNo ratings yet

- Martin HeideggerDocument29 pagesMartin HeideggerAljon AniesNo ratings yet

- K3M 2008 - Form 6Document15 pagesK3M 2008 - Form 6SeanNo ratings yet

- GAT - Subject (Electronics)Document14 pagesGAT - Subject (Electronics)Muhammad Sarmad Hafeez100% (3)

- T1001W6F011Document1 pageT1001W6F011Asim SaleemNo ratings yet

- Product Service Manual and Parts List BM# 3266/005 (M8LKFX-912Y)Document30 pagesProduct Service Manual and Parts List BM# 3266/005 (M8LKFX-912Y)Castañeda JacvNo ratings yet

- Recipe For BPP Ncii UaqteaDocument11 pagesRecipe For BPP Ncii UaqteaPJ ProcoratoNo ratings yet

- Typical Malfunctions of BWMSDocument2 pagesTypical Malfunctions of BWMSPyaeSoneHtunNo ratings yet

- Qapco-Tank Method Statement2-11-05-19Document30 pagesQapco-Tank Method Statement2-11-05-19Bibhas Das100% (2)

- Pathe Projector Pathe Baby User ManualDocument23 pagesPathe Projector Pathe Baby User ManualzakskenNo ratings yet

- Seidel's TestDocument13 pagesSeidel's TestFahcrezaNo ratings yet