Professional Documents

Culture Documents

IDS1000-A40 Container Data Center V200R002 Product Manual Draft A (40 FT)

Uploaded by

Marco SilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IDS1000-A40 Container Data Center V200R002 Product Manual Draft A (40 FT)

Uploaded by

Marco SilvaCopyright:

Available Formats

IDS1000-A40 Container Data Center

V200R002

Product Manual (40 ft)

Issue Draft A

Date 2014-05-23

HUAWEI TECHNOLOGIES CO., LTD.

Copyright © Huawei Technologies Co., Ltd. 2014. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://www.huawei.com

Email: support@huawei.com

Huawei Proprietary and Confidential

Issue Draft A (2014-05-23) i

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) About This Document

About This Document

Purpose

This document describes the IDS1000-A40 container data center (All-in-one for short) in

terms of its overview, benefits, components, and typical application scenarios.

Intended Audience

This document is intended for:

Sales engineers

Technical support engineers

System engineers

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Symbol Description

Indicates an imminently hazardous situation which, if

not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in equipment damage, data loss,

performance deterioration, or other unanticipated results.

NOTICE is used to address practices not related to

personal injury.

Calls attention to important information, best practices

and tips.

NOTE is used to address information not related to

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential ii

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) About This Document

Symbol Description

personal injury, equipment damage, and environment

deterioration.

Change History

Issue Draft A (2014-05-23)

This issue is used for first office application (FOA).

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential iii

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) Contents

Contents

About This Document .................................................................................................................... ii

1 Overview......................................................................................................................................... 1

1.1 Product Model .............................................................................................................................................................. 1

1.2 Positioning .................................................................................................................................................................... 2

1.3 Specifications ................................................................................................................................................................ 3

2 Benefits............................................................................................................................................ 6

3 Container ........................................................................................................................................ 8

3.1 Container Exterior ........................................................................................................................................................ 9

3.1.1 Front View of the Container ...................................................................................................................................... 9

3.1.2 Rear View of the Container...................................................................................................................................... 11

3.1.3 Left View of the Container ...................................................................................................................................... 13

3.1.4 Right View of the Container .................................................................................................................................... 14

3.2 Container Interior........................................................................................................................................................ 14

3.3 Container Reliability ................................................................................................................................................... 16

4 Power Supply and Distribution System ................................................................................. 18

4.1 Overview .................................................................................................................................................................... 18

4.2 Layout ......................................................................................................................................................................... 19

4.3 Configuration and Port Description ............................................................................................................................ 20

4.4 Routing Power Cables ................................................................................................................................................ 26

5 Temperature Control System .................................................................................................... 27

5.1 Overview .................................................................................................................................................................... 27

5.2 Layout ......................................................................................................................................................................... 27

5.3 Routing Power Cables for Air Conditioners ............................................................................................................... 29

6 Monitoring System ..................................................................................................................... 30

6.1 Overview .................................................................................................................................................................... 30

6.2 Layout ......................................................................................................................................................................... 32

6.3 Routing Monitoring Cables ........................................................................................................................................ 33

7 Fire Extinguishing System ........................................................................................................ 35

7.1 Overview .................................................................................................................................................................... 35

7.2 Layout ......................................................................................................................................................................... 36

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential iv

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) Contents

7.3 Routing Fire Extinguishing Cables ............................................................................................................................. 39

8 Surge Protection and Grounding ............................................................................................. 40

8.1 Surge Protection.......................................................................................................................................................... 40

8.2 Grounding ................................................................................................................................................................... 40

9 Lighting System........................................................................................................................... 42

10 Integrated Cabling .................................................................................................................... 44

11 Typical Application Cases ....................................................................................................... 46

A Container Dimensions, Ground Points, and Ports .............................................................. 48

B Component Introduction .......................................................................................................... 50

B.1 Cabinet ....................................................................................................................................................................... 50

B.2 Power Supply and Distribution System ..................................................................................................................... 51

B.3 Air Conditioner .......................................................................................................................................................... 60

B.4 Monitoring System ..................................................................................................................................................... 62

B.5 Fire Extinguishing System ......................................................................................................................................... 66

B.5.1 CE Type................................................................................................................................................................... 66

B.5.2 Standard Type .......................................................................................................................................................... 69

B.6 Lighting System ......................................................................................................................................................... 71

C Acronyms and Abbreviations .................................................................................................. 74

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential v

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 1 Overview

1 Overview

1.1 Product Model

Figure 1-1 shows the model of the All-in-one. Table 1-1 describes the model.

Figure 1-1 Model

Table 1-1 Model description

No. Category Definition

1 Series Container data center

2 Hyphen -

3 Product type A: All-in-one

4 Container type M: 40-ft All-in-one

S: 20-ft All-in-one

5 Power system A: 380 V, 50 Hz

B: 380 V, 60 Hz

C: 480 V, 60 Hz

6 Container feature X: basic type

C: CE type

H: for T3 working

conditions

7 Tier level D: Tier II

8 Optional configuration X: basic configurations,

without the very early

smoke detection

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 1

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 1 Overview

No. Category Definition

apparatus (VESDA) or

non-monitoring

PDU2000s

V: with the VESDA and

non-monitoring

PDU2000s

M: without the VESDA,

but with monitoring

PDU2000s

S: with the VESDA and

monitoring PDU2000s

9 Actual power density 05: 5 kW

1.2 Positioning

The All-in-one, in which various service units can be configured, functions as a foundation for

cloud computing in enterprise data centers. It meets the requirements of telecom operators and

Internet service providers for environmental protection, energy conservation, and fast

deployment. In addition, it has distinct advantages in scenarios such as disaster relief

operations, military operations, oil exploration, and enterprise data management.

The All-in-one is located at the bottom layer of a data center and provides basic physical

construction for full-service operation in the data center. Figure 1-2 shows the All-in-one

architecture.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 2

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 1 Overview

Figure 1-2 All-in-one architecture

1.3 Specifications

Table 1-2 lists the key All-in-one specifications.

Table 1-2 Key All-in-one specifications

Item Specifications

Power supply and Power input Two 250 A inputs of

distribution three-phase, five-wire,

380 V AC, 50 Hz or 60

Hz

Two 250 A inputs of

three-phase, five-wire,

480 V AC, 60 Hz

Surge protection level Class B, 100 kA

(external)/60 kA (PDU8000)

Rack power density 6 kW

UPS Rack-mounted 20 kVA UPS

(UPS2000-G)

UPS configuration 80 kVA; 3+1 backup

Backup time ≥ 7 minutes

Air-cooled in-row precision Cooling capacity 20 kW for each air

air conditioner conditioner; 3+1 backup

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 3

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 1 Overview

Item Specifications

Refrigerant R410A

Operating specifications Temperature in the cold 10–30°C

aisle

Humidity range 20%–80% RH

Environmental requirements Ambient temperature –15°C to +52°C

Ambient humidity 5%–100% RH

Altitude ≤ 3000 m; When the altitude

exceeds 1000 m, the output

power derates.

Structure Container 40-ft ISO marine container

(H x W x D: 9.5 ft x 8.5 ft x

40 ft)

Container heat insulation Overall coefficient of heat

performance transfer: ≤ 0.41 W/(m2 x K)

at the container top; ≤ 0.7

W/(m2 x K) at the container

sides; ≤ 0.1 W/(m2 x K) at

the container bottom

Integrated cabling Power cables and signal

cables are routed separately.

Pipe routing Pipes are routed under the

floor.

Protection level IP56

Lighting 300 lux

Installation mode The All-in-one is installed

on four 300 mm high steel

bases that are connected to

the concrete pad using M16

bolts.

Dimensions External dimensions (H x W 2896 mm x 2438 mm x

x D) 12,196 mm

Total IT load power 48 kW

All-in-one weight Empty container (without IT

equipment): 12 t;

fully-configured container:

< 20 t

Typical cabinet capacity Nine 45 U cabinets (380

V input scenario)

Eight 45 U cabinets (480

V input scenario)

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 4

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 1 Overview

Item Specifications

Fire extinguishing Type Fire extinguishing system

with the automatic fire

detection and emergency

gas release functions

Alarm Audible and visual alarm

with automatic monitoring

and detection

Monitoring The analog addressable

system releases gas if a

composite fire alarm is

generated.

Extinguishing agent Heptafluropropane (standard

Type); FM200 (CE Type)

Fire extinguishing rating Overall fire resistance

duration of 50 minutes

Security Access control Access control system

IP camera Standard dual-resolution IP

cameras are installed in the

hall and cold aisles.

Management Management functions The NetEco monitors the

temperature and humidity

control system, fire

detection and control

system, access control

system, and cooling system

inside the All-in-one in real

time.

The NetEco supports

monitoring over emails and

Simple Network

Management Protocol

(SNMP) short messages.

Backup power systems

access the UPS and diesel

generator (D.G.) over

programmable dry contacts.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 5

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 2 Benefits

2 Benefits

The All-in-one is an integrated and compact data center that features high security and

reliability, fast deployment, low cost, high energy efficiency, and intelligent management.

High Security and Reliability

The two-porch design prevents wind and sand from entering the equipment compartment

when doors are open for maintenance.

The All-in-one features good security performance.

− The All-in-one is properly grounded and has good anti-electromagnetic interference

capability. The electromagnetic compatibility (EMC) of the All-in-one meets Class A

requirements of the CISPR22/EN55022 standard.

− The All-in-one uses the ISO668 standard container. The container uses

industry-leading welding technologies, tapping screws, and waterproof sealing rubber

strips to ensure that dustproof and waterproof performance of the containers reaches

IP56.

− The All-in-one uses materials and coating protection for the ISO668 standard

container. The service life of the outdoor All-in-one is up to 15 years.

− The All-in-one uses an intelligent access control system and mechanical locks to

ensure safety.

− The container interior is decorated with fire-resistant and heat insulation materials

with an overall fire resistance duration of 45 minutes. The container exterior is coated

with fireproof paint of different thicknesses and can withstand fires up to 1 or 2

hours.

− The container uses the HFC-227ea FM-200 fire extinguishing system, which features

high-reliability, clean, insulation, and environmental-protection. The fire

extinguishing system ensures that a fire can be put out efficiently and securely

without damaging IT equipment.

Fast Deployment

The All-in-one adopts streamlined manufacturing, professional division of labor, and

good construction conditions to ensure that the All-in-one and its modules can be

produced fast. The product quality is easy to be controlled and improved, and the

production efficiency is improved. The manufacturing period is less than 6 weeks.

Infrastructures such as the cooling equipment, power supply equipment, and racks are

preinstalled before delivery. You only need to provide network cables, power cables, and

water pipes for commissioning.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 6

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 2 Benefits

System commissioning is complete in factories, and therefore onsite engineering and

equipment room commissioning take less than 7 days.

Mature delivery mode, modular structure, and low transportation costs of the container

ensure fast deployment of the All-in-one, low and phase-by-phase investments, and

simple and convenient expansion and upgrade.

Only the concrete pad and mains are required in the initial period.

Low Cost and High Energy Efficiency

The container integrates the cooling system, power distribution system, monitoring

system, and security system that are installed and pre-commissioned before delivery. The

All-in-one goes through the trial run before delivery. You are welcome to check and try

the product in factory.

Civil engineering is simple when the All-in-one is deployed outdoors. It starts to work

after it is installed on a concrete pad and connects to the humidifier, water, mains supply,

and networks.

The All-in-one features easy migration and can be transported on level two roads. It

applies to various scenarios such as dynamic data service deployment, military affairs,

disaster relief, and field operations.

The All-in-one is energy-efficient. The hot and cold aisles are separated in the equipment

compartment to ensure high cooling efficiency.

Intelligent Management

The NetEco manages infrastructures of the All-in-one in a unified manner.

The NetEco monitors equipment efficiently and in real time.

The NetEco monitors environments in real time to identify potential risks.

The NetEco provides various methods of collecting and analyzing power consumption

data. Such data is fundamental to improve the power usage effectiveness (PUE). You can

customize the data collection and analysis methods.

The NetEco offers a robust security mechanism to protect equipment and ensures a

proper environment.

The All-in-one provides standard network management system (NMS) interfaces. The

NetEco provides SNMP ports to communicate with third-party NMSs.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 7

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 3 Container

3 Container

Introduction

As an integrated and compact small-capacity data center, the All-in-one uses a standard 40 ft

container. Figure 3-1 shows its appearance.

Figure 3-1 Appearance

Features

The container uses a standard 40 ft container, complying with GB/T1413-1998, GB/

T1836-1997, ISO1161:1984, and ISO1496-1:1990. The container supports marine

transportation and has been certified by the classification society.

The container is painted using the same techniques as those for standard containers. The

container and its doors are specially protected in surfaces to work in harsh environments.

The container interior is decorated with fire-resistant and heat insulation materials with

an overall fire resistance duration of 50 minutes. The container exterior is coated with

fireproof paint to withstand fire up to 1 or 2 hours (depending on the paint thickness).

External ports are on the rear end wall. To be specific, feeder windows are in the upper

part of the end wall, and pipe inlets in the lower part. All ports are protected to IP56.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 8

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 3 Container

An outward opening door is installed at one end of the container for maintaining outdoor

units, and the other end is configured with an outward/inward opening door as the

entrance to the container. An inward opening door is designed on one container side for

device installation.

The entrance dimensions (H x W) are 2150 mm x 900 mm. The device installation door

dimensions (H x W) are 2150 mm x 1200 mm.

The container has a shock absorbing system that absorbs the impact of physical

movement on internal components.

Steel reinforcing beams are welded under the original bottom plate, steel frames are

welded for side walls and end walls, and steel parts are added to end doors to improve

the stiffness and strength of the container.

− Column strength: Columns at the four corners withstand 86,400 kg stress.

− Top panel strength: 1500 kg/m2

− Side panel strength: 1200 kg/m2

− Floor strength: 1500 kg/m2

3.1 Container Exterior

The container uses 2 mm thick steel plates on the exterior and is painted in the same way as

standard containers. Parts such as the lock rods, handles, hinges, lock brackets are made of

stainless steels, and the container body and doors are especially protected in surfaces to

withstand the 1000-hour salt spray test.

The container uses industry-leading welding technologies, tapping screws, and waterproof

sealing rubber strips to ensure that dustproof and waterproof performance of the containers

reaches IP56.

3.1.1 Front View of the Container

Figure 3-2 shows the front view of the container.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 9

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 3 Container

Figure 3-2 Front view of the container (with doors closed)

(1) End door (for maintaining outdoor units) Two in total

(2) Lock rod Three in total

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 10

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 3 Container

Figure 3-3 Front view of the container (with doors open)

(1) Outdoor unit Four in total

3.1.2 Rear View of the Container

Figure 3-4 shows the rear view of the All-in-one.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 11

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 3 Container

Figure 3-4 Rear view of the All-in-one (with doors closed)

(1) Emergency door release button (2) End door (main entrance)

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 12

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 3 Container

Figure 3-5 Rear view of the All-in-one (with doors open)

(1) Hall (2) Battery compartment

3.1.3 Left View of the Container

Figure 3-6 shows the left view of the container.

Figure 3-6 Left view of the container

(1) Ventilation window of the Two in total

outdoor unit compartment

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 13

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 3 Container

(2) Container ground point Four in total

(3) Ports for the condensate One for each pipe. The condensate drainpipe is delivered

drainpipe and water refill pipe with the container and the water refill pipe provides a 1/2

inch inner thread connector.

(4) Device installation One in total

door/emergency door

(5) Container feeder window For routing cables

(6) Port reserved for customer Two in total (diameter: M25; configured with waterproof

services end connectors)

(7) Monitoring optical fiber Two in total (diameter: M50; configured with waterproof

upstream port end connectors)

(8) Power cable port Two in total (diameter: M76; configured with waterproof

power cable metal connectors)

3.1.4 Right View of the Container

Figure 3-7 shows the right view of the container.

Figure 3-7 Right view of the container

(1) Container ground point (2) Ventilation window of the outdoor unit compartment

3.2 Container Interior

The container interior has been decorated to feature thermal insulation. The interior

decoration is harmonious in style and hue. All decorative materials feature environmental

protection, electrostatic discharge (ESD) protection, and long life cycles, and release no toxic

gas. Figure 3-8 shows the interior layout of the container.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 14

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 3 Container

Figure 3-8 Interior layout of the container

(1) Outdoor unit compartment (2) Indoor unit (3) Server cabinet

(four in total)

(4) Hot aisle (5) Cold aisle (6) UPS installation

cabinet (one in total)

(7) Server cabinet (configured with a (8) Sealing plate (9) Battery compartment

transformer in the 480 V scenario)

(10) Hall

Heat Insulation System

The container exterior is made of 2 mm thick steel plates. The insulation system of the

container is made of connecting mechanical parts, heat insulation filling materials, and

sandwich insulation panels. The container interior uses the rock wool sandwich panels for

heat insulation. The rock wool sandwich panel is made of 0.5 mm thick color steel plates

stuffed with polyurethanes. Sandwich panels of 40 mm are installed respectively for container

sides and container top using screws or rivets.

Figure 3-9 Heat insulation system inside the container

Floor and Support

Equipment inside the container is installed on the raised floor. The distance between the

container bottom and the surface of the raised floor is 200 mm. The floor supports under

the raised floor are secured to beams of the steel chassis using screws.

Removable tiles are installed on all or part of floor supports. You can adjust the

installation positions of these tiles based on configurations and port locations. The tiles

feature easy and secure installation and safe transportation.

Cold aisles consist of lip-resistant aluminum panels and square steel supports covered

with tiles, and hot aisles consist of vented floor tiles.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 15

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 3 Container

The compression strength of both the raised floor and floor supports is greater than 1500

kg/m2.

Cold aisles use the ESD square plates or lip-resistant aluminum panels and structural steel

skeleton. These tiles are aligned with each other and combined using battens at both ends.

The hot aisles use aluminum panels with holes and vented floor tiles of square steels. The

ventilation rate is greater than 25%. These tiles are aligned with each other and combined

using battens at both ends.

Suspended Ceiling

A suspended ceiling is installed on the top of the container to beautify the container and

isolate the cold aisles from hot aisles. The distance between the top heat insulation panel

and the suspended ceiling sheet is 200 mm.

The ceiling uses sheet metal and square steel skeleton. the sealing plate is installed with

humidity and temperature sensors and cameras.

The top heat insulation panel, square steel framework, and heat insulation panels for side

walls and end walls connect to the container steel structure over connecting kits,

ensuring secure and reliable connections.

3.3 Container Reliability

Table 3-1 describes reliability of the container.

Table 3-1 Container reliability

Item Description

Maintenance door Features the dual-antitheft design with

mechanical locks and the access control

system. The security of the door meets

Class B GB17565 requirements.

Mechanical lock Features high reliability, easy operation, and

waterproof and anti-corrosion designs. The

security of the mechanical lock meets Class

B GA/T73-94 requirements.

Access control system Allows you to assign permission of different

levels. It monitors door status and generates

alarms.

Ventilation The container uses ventilation ports of

standard containers that feature good

security and ventilation designs. The area of

ports is 700 mm2.

Surge protection and grounding Grounding bars are installed in the container

for equipment and the container. Surge

protection measures are taken for power

ports and network ports to ensure security of

the All-in-one.

Video surveillance system Monitors the protection area in real time.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 16

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 3 Container

Item Description

Wind resistance strength 30 m/s wind speed during operation.

Shockproof level The fully configured container complies

with the outdoor earthquake-resistant

requirements (equivalent to greater than

McIntosh 9 intensity) specified in ETSI EN

300 019-2-4.

Service life 15 years.

Fireproof performance Fireproof performance of the decorative

materials complies with the Code for Fire

Protection Design of Interior Decoration of

Buildings (GB50222-95) of China. The

materials can withstand fires for 50 minutes

or longer.

Heat insulation The overall coefficient of heat transfer is

less than or equal to 0.41 W/(m2 x K) at the

container top, 0.7 W/(m2 x K) for container

sides, and 0.1 W/(m2 x K) at the container

bottom.

Water resistance and dust proof levels All ports are protected to IP56

(weather-tightness test) of the

GB4208/IEC529 standard.

Anti-corrosion performance in salt mists The container uses weathering steels and

surface treatment and passes the 1000-hour

salt spray test.

Antifungal performance The container passes the 24 hours, 28 days

long mould growth test.

The weather-tightness test is conducted according to GB/T 5338-2002 and GB 17770. The

nozzle has an inner diameter of 12.5 mm and is 1.5 m away from the container surface, as

shown in Figure 3-10. Water with the pressure of 100 kPa and running speed of 100 mm/s is

supplied, which is equivalent to a 10 m water spout. No water penetrates into the container.

Figure 3-10 Weather-tightness test

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 17

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 4 Power Supply and Distribution System

4 Power Supply and Distribution System

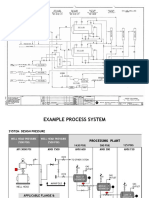

4.1 Overview

The power distribution system supports the 220 V power system and 277 V Latin American

power system. Figure 4-1 and Figure 4-2 show the general power supply and distribution

solution.

Figure 4-1 General power distribution solution for a 380 V scenario

Details about the power distribution solution for a 380 V scenario are as follows:

Supports two three-phase 380 V, 400 V, or 415 V power inputs. The backup power

source can be the mains or diesel generator (D.G.).

Two power inputs connect to the PDU8000, converge on an AC transfer switch (ATS),

and then are distributed to the UPSs, precision air conditioners, and other loads.

Power outputs from the UPS pass through the parallel UPS PDU5000 and UPS output

PDU5000, and then enter two server cabinet PDU5000s which provide two backup

power outputs to server cabinets.

The UPS output PDU5000 supplies power to door status sensors, monitors, and fans.

The PDU8000 supplies power using a bypass circuit breaker when the UPS is in the

maintenance period. In normal cases, the bypass circuit breaker is locked using a

padlock.

The UPSs are configured with one battery string and provide 10-minute backup power.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 18

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 4 Power Supply and Distribution System

Figure 4-2 General power distribution solution for a 480 V scenario

Details about the power distribution solution for a 480 V scenario are as follows:

Supports two 480 V power inputs. The backup power source can be the mains or D.G.

Two power inputs are combined by an ATS in the PDU8000, and the power is

transformed into 380 V by a 160 kVA transformer. The 380 V power is later distributed

to the UPSs, precision air conditioners, and other loads.

Power outputs from the UPS pass through the parallel UPS PDU5000 and UPS output

PDU5000, and then enter two server cabinet PDU5000s which provide two backup

power outputs to server cabinets.

The UPS output PDU5000 supplies power to door status sensors, monitors, and fans.

The PDU8000 supplies power using a bypass circuit breaker when the UPS is in the

maintenance period. In normal cases, the bypass circuit breaker is locked using a

padlock.

The UPSs are configured with one battery string and provide 10-minute backup power.

4.2 Layout

The power supply and distribution system consists of the PDU8000, parallel UPS PDU5000,

UPS output PDU5000, server cabinet PDU5000, UPS, battery, and rack PDU2000. Figure 4-3

shows the layout of the power supply and distribution system.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 19

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 4 Power Supply and Distribution System

Figure 4-3 Layout of the power supply and distribution system

(1) UPS installation Only one. It houses the UPS and PDU5000.

cabinet

(2) Server cabinet Install a transformer in this cabinet in the 480 V scenario.

(3) PDU8000 Only one. It supports two power inputs (active and standby) to the

container.

(4) Battery It houses batteries. In the case of mains or D.G. power failures,

compartment batteries work with the UPS to supply power to the All-in-one.

4.3 Configuration and Port Description

Configuration

Table 4-1 describes configurations of the power supply and distribution components in the

All-in-one.

Table 4-1 Configurations of the power supply and distribution components

Component Configuration

PDU8000 1 PCS

Parallel UPS PDU5000 1 PCS

UPS output PDU5000 1 PCS

Server cabinet PDU5000 2 PCS

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 20

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 4 Power Supply and Distribution System

Component Configuration

UPS 3+1 backup

Battery Forty 50 Ah batteries

Ports

Table 4-2 describes ports on the power supply and distribution components in the All-in-one.

Table 4-2 Port description

Component Input Output Circuit Breaker

Specifications Specifications No./Equipment

Label

PDU8000 (380 V One 4-pole 250 A One 4-pole 160 QF1: controls the

scenario) PC Class A circuit breaker maintenance

three-section ATS Five 3-pole 32 A bypass input to

circuit breakers the UPS.

QF2–QF5:

Five 3-pole 63 A

circuit breakers control input to

the UPS.

Five 1-pole 10 A

QF6–QF9:

circuit breakers

control inputs to

Four 1-pole 10 A indoor units.

circuit breakers

QF10 and QF11:

One 10 A reserved

residual current

QF12 and QF17:

device (RCD)

control normal

lights.

QF13: controls

emergency

lights.

QF14: controls

sockets.

QF15: controls

the fire control

box.

QF16 and QF18:

reserved

QFS: controls

SPDs.

PDU8000 (480 V One 4-pole 250 A One 3-pole 250 A QF: controls

scenario) PC Class MCCB input to the

three-section ATS transformer

QFS: controls

SPDs.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 21

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 4 Power Supply and Distribution System

Component Input Output Circuit Breaker

Specifications Specifications No./Equipment

Label

Transformer One 3-pole 250 A 4-pole 320 A 1QF: controls the

MCCB circuit breaker 380 V output.

4-pole 160 A 2QF: RCD

circuit breaker QF1: controls the

Residual current transformer

device (RCD) output PDU5000

Transformer output Reserved input Five 3-pole 32 A QF1–QF4:

PDU5000 wiring terminals circuit breakers control input to

Five 3-pole 63 A the UPS.

circuit breakers QF5–QF8:

Four 3-pole 10 A control inputs to

circuit breakers indoor units.

QF9–QF12:

Four 1-pole 10 A

circuit breakers control inputs to

outdoor units.

QF14 and QF17:

control normal

lighting.

QF15: controls

emergency

lighting.

QF16: controls

the fire control

box.

QF19: controls

fans.

QF13, QF18, and

QF20: reserved

Parallel UPS Four 4-pole 63 A One 3-pole 100 A QF1-QF4:

PDU5000 circuit breakers circuit breaker control input to

One UPS the UPS.

maintenance QF5: controls

bypass outputs of the

UPS.

UPS output One 3-pole 100 A Two 3-pole 80 A 1QF: controls

PDU5000 circuit breaker circuit breakers input to the UPS.

Six one-pole 10 QF1: controls

A circuit route A output of

breakers the UPS.

QF2: controls

route B output of

the UPS.

QF3: controls the

access control

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 22

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 4 Power Supply and Distribution System

Component Input Output Circuit Breaker

Specifications Specifications No./Equipment

Label

system.

QF4: controls the

monitoring

system.

QF5: controls

fans.

QF6: reserved

Server cabinet One 3-pole 100 A Nine 1-pole 32 A QF1:

PDU5000 circuit breaker circuit breakers corresponds to

One 3-pole 16 A A1-I* in the

circuit breaker PDU8000.

QF2:

Three 1-pole 10

A circuit corresponds to

breakers A2-I in the

PDU8000.

QF3:

corresponds to

B1-I in the

PDU8000.

QF4:

corresponds to

B2-I in the

PDU8000.

QF5:

corresponds to

C1-I in the

PDU8000.

QF6:

corresponds to

C2-I in the

PDU8000.

QF7:

corresponds to

D1-I in the

PDU8000.

QF8:

corresponds to

D2-I in the

PDU8000.

*: Routes A and B of the server cabinet PDU5000 correspond to routes I and II respectively.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 23

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 4 Power Supply and Distribution System

Figure 4-4 Circuit breakers in the 380 V PDU8000

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 24

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 4 Power Supply and Distribution System

Figure 4-5 Circuit breakers in the 480 V PDU8000

Figure 4-6 Circuit breakers in the Parallel UPS PDU5000

Figure 4-7 Circuit breakers in the UPS output PDU5000

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 25

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 4 Power Supply and Distribution System

Figure 4-8 Circuit breakers in the server cabinet PDU5000

4.4 Routing Power Cables

For cables on the top of the container, route power cables along the cable trays near side walls

and route signal cables along the cable trays near cabinets. For power cables under the floor,

route them near cabinets, and bind them to each beam.

Figure 4-9 Power cable routes for server cabinets in the container

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 26

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 5 Temperature Control System

5 Temperature Control System

5.1 Overview

The All-in-one uses air-cooled in-row precision air conditioners as the cooling system:

In the All-in-one, air conditioners and server cabinets form hot and cold contained aisles

to isolate hot air from cold air. Air flows in from the front and out from the rear. Air

conditioners cool hot air from servers and generate cold air for servers.

Horizontal flow air conditioners are placed near heat sources, which greatly shortens the

air supply distance and improves cold air utilization.

The PDU8000, UPS, and IT equipment are deployed in one compartment. Four precision

air conditioners work in 3+1 backup mode. The hot aisles are contained and connected

by ventilation floors (600 mm x 600 mm). The outdoor units, located at the end of the

container, are separate from the IT equipment compartment.

5.2 Layout

The All-in-one uses precision air conditioner in 3+1 backup mode. Figure 5-1 shows the

layout of the cooling system.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 27

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 5 Temperature Control System

Figure 5-1 Layout of the cooling system

(1) Indoor unit Four in total (in 3+1 backup mode)

(2) Outdoor unit Four in total (in 3+1 backup mode)

Figure 5-2 shows the routes of refrigerant pipes. Figure 5-3 shows the routes of the water

refill pipe and condensate drainpipe to the humidifier.

Figure 5-2 Routes of refrigerant pipes

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 28

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 5 Temperature Control System

Figure 5-3 Routes of the water refill pipe and condensate drainpipe

(1) Route of the condensate drainpipe (2) Route of the water refill pipe to the humidifier

5.3 Routing Power Cables for Air Conditioners

Power cables for air conditioners in the container are routed out from the bottom of the air

conditioners, and then along the air conditioner supports under the air conditioners, and

finally through the cable hole on the partition wall to connect to the power distribution cabinet

in the hall. Bind the cables to cable bridges when routing cables.

Figure 5-4 Power cable routes for air conditioners in the container

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 29

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 6 Monitoring System

6 Monitoring System

6.1 Overview

The All-in-one uses an independent and complete monitoring system. The monitoring system

consists of a centralized management platform and multiple scattered monitoring devices, as

shown in Figure 6-1.

Figure 6-1 Monitoring system

NetEco

The NetEco is a new data center management system developed by Huawei to manage the

real-time data, status, and alarms for the power supply, environment, videos, and access

control components of data center infrastructures.

The NetEco adopts the policy of layered management, local control, and remote detection.

Information from infrastructures such as power distribution components, access control

components, closed-circuit televisions (CCTVs), and sensors are converged on collectors or

switches, which forms a local management module. The NetEco deletes, selects, and

processes data from this module based on user requirements, and sends the data in the form

specified by the user to the NMS or terminals through the Internet.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 30

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 6 Monitoring System

Equipment at the bottom layer can easily connect to the NetEco over Modbus, SNMP, and

Transmission Control Protocol/Internet Protocol (TCP/IP). Table 6-1 lists the monitoring

subsystems and equipment.

Table 6-1 Monitoring subsystems and equipment

Subsystem Equipment Monitored Item Working Principle

Power supply Precise air Running status and The equipment connects to

monitoring conditioner parameters, faults, and a data collector over RS485

subsystem alarms. ports. The collector

UPS connects to the NetEco over

Operating parameters

that can be monitored a network. Then the NetEco

Power

remotely displays faults and

distribution

generates alarms in real

cabinet

time.

ATS

Environment Water sensor Parameters such as the The equipment connects to

monitoring water leakage in the a data collector over dry

subsystem All-in-one contact. The collector

connects to the NetEco over

a network. Then the NetEco

displays faults and

generates alarms in real

time.

Security Camera Real-time status of the Cameras connect to a

protection All-in-one and its switch over fast Ethernet

monitoring modules (FE) ports. The switch

subsystem connects to the NetEco over

a network. Then the NetEco

displays faults and

generates alarms in real

time.

Access Access control Access controllers connect

controller information and rights to the NetEco over TCP/IP.

about the All-in-one and Then the NetEco displays

Card reader its modules. faults and generates alarms

in real time.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 31

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 6 Monitoring System

Figure 6-2 NetEco web user interface (WebUI)

6.2 Layout

Figure 6-3 shows the layout of monitoring components.

Figure 6-3 Layout of monitoring components

(1) Camera Two in total, with one in the cold aisle and the other in the hall. It

monitors maintenance aisles and supports network functions and

day/night mode.

Key specifications: The camera uses the 1/2.7 inch high performance

complementary metal-oxide-semiconductor (CMOS) that features

progressive scanning, maximum resolution of 1280x720, maximum

frame rate of 30, and output videos in BNC format.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 32

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 6 Monitoring System

(2) Water Only one. It monitors liquid leakage in the container, transmits data to the

sensor remote monitoring host, and works with monitoring software to generate

alarms for water intrusion.

(3) UPS Only one. It houses the collector, switch, server, and network video

installation recorder (NVR).

cabinet

The collector, switch, server, and NVR are installed in the UPS installation cabinet, as shown

in Figure 6-4.

Figure 6-4 Installation positions of monitoring components

(1) Collects monitoring signals.

Collector

(2) Switch Serves as the convergence layer for accessing the monitoring system. It can be

used to construct a highly reliable ring network between the switch and the

monitoring system.

(3) Server Processes and backs up data reported by monitoring modules.

(4) NVR Manages, stores, and transfers data over streaming media.

6.3 Routing Monitoring Cables

Monitoring cables in the container are routed along the top of the container within the space

for routing L1 signal cables. They are preinstalled before delivery.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 33

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 6 Monitoring System

Figure 6-5 Routing cables for cameras and water sensors

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 34

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 7 Fire Extinguishing System

7 Fire Extinguishing System

7.1 Overview

The fire extinguishing system uses the gas fire extinguishing equipment that consists of an

extinguishing agent vessel, an inlet pipe, a pressure annunciator, and a solenoid valve driver.

When the All-in-one catches fire, a lot of smoke is generated and the temperature rises. The

smoke detector and heat detector send fire signals to the fire extinguishing controller, which

then generates a large current to start the solenoid valve of the gas fire extinguishing

equipment. Then the valve of the extinguishing agent vessel opens automatically, and

extinguishing agents are released to the protection area.

Figure 7-1 and Figure 7-2 show the conceptual diagrams of the fire extinguishing system.

Figure 7-1 Conceptual diagram of the standard fire extinguishing system

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 35

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 7 Fire Extinguishing System

Figure 7-2 Conceptual diagram of the CE fire extinguishing system

7.2 Layout

Figure 7-3 shows the layout of the standard fire extinguishing system.

Figure 7-3 Layout of the standard fire extinguishing system

(1) Gas Only one in the PDU8000. It controls the release of gas and generates

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 36

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 7 Fire Extinguishing System

extinguishing fire alarms.

controller

(2) Gas release Only one. When fire occurs in the container, the fire extinguishing

indicator equipment releases extinguishing agent into the protection area and the

gas release indicator displays "DON'T ENTER" to warn onsite

personnel.

(3) Audible and Two in total, with one in the cold aisle and the other in the hall. In case

visual alarm of fire, the audible and visual alarm generates obvious flash signals

and shrill audible signals to remind onsite personnel to evacuate the

site immediately.

(4) Emergency Only one. When fire occurs in the container, the emergency start/abort

start/abort switch switch starts or stops the gas fire extinguishing equipment in

emergency. The device is usually installed outside the door of the

protection area. If you press the glass plate to start fire extinguishing in

emergency, the red indicator lights up.

(5) Heat detector Four in total, deployed in each aisle and the battery compartment. It

monitors the onsite ambient temperature in real time. When it works in

monitoring mode, the red indicator blinks. When the ambient

temperature exceeds the alarm threshold, it enters the alarm mode and

the red indicator is steady on.

(6) Smoke Four in total, deployed in each aisle and the battery compartment. It

detector monitors the onsite smoke density in real time. When it works in

monitoring mode, the red indicator blinks. When the smoke density

exceeds the alarm threshold, it enters the alarm mode and the red

indicator is steady on.

(7) Alarm bell Only one. When an accident occurs, the alarm bell produces clear and

consistent sounds to remind onsite personnel to evacuate the site

immediately.

(8) Fire The fire extinguishing pipe goes through the entire container and

extinguishing provides nozzles for each cold aisle and hot aisle and the battery

pipe compartment to spray extinguishing agent to the entire protection area.

(9) Gas fire Only one. The gas fire extinguishing equipment is a fire cylinder that

extinguishing consists of an extinguishing agent vessel, an inlet pipe, a pressure

equipment annunciator, and a solenoid valve driver.

Fire extinguishing equipment of the standard fire extinguishing system has been installed before

delivery.

Figure 7-4 shows the layout of the CE fire extinguishing system.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 37

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 7 Fire Extinguishing System

Figure 7-4 Layout of the CE fire extinguishing system

(1) Gas Only one in the PDU8000. It controls the release of gas and

extinguishing generates fire alarms.

controller

(2) Gas release Only one. When fire occurs in the container, the fire extinguishing

indicator equipment releases extinguishing agent into the protection area and

the gas release indicator displays "DON'T ENTER" to warn onsite

personnel.

(3) Audible and Two in total, with one in the cold aisle and the other in the hall. In

visual alarm case of fire, the audible and visual alarm generates obvious flash

signals and shrill audible signals to remind onsite personnel to

evacuate the site immediately.

(4) Emergency One for each. When fire occurs in the container, the emergency

shutdown button and startup button starts the gas fire extinguishing equipment in

emergency startup emergency. When fire is put out, the emergency shutdown button

button stops the gas fire extinguishing equipment. The devices are usually

installed outside the door of the protection area. If you press the

glass plate to start fire extinguishing in emergency, the red indicator

lights up.

(5) Heat detector Four in total, deployed in each aisle and the battery compartment. It

monitors the onsite ambient temperature in real time. When it

works in monitoring mode, the red indicator blinks. When the

ambient temperature exceeds the alarm threshold, it enters the alarm

mode and the red indicator is steady on.

(6) Smoke detector Four in total, deployed in each aisle and the battery compartment. It

monitors the onsite smoke density in real time. When it works in

monitoring mode, the red indicator blinks. When the smoke density

exceeds the alarm threshold, it enters the alarm mode and the red

indicator is steady on.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 38

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 7 Fire Extinguishing System

(7) Buzzer Only one. When an accident occurs, the buzzer produces consistent

sounds to remind onsite personnel to evacuate the site immediately.

(8) Fire The fire extinguishing pipe goes through the entire container and

extinguishing pipe provides nozzles for each cold aisle and hot aisle and the battery

compartment to spray extinguishing agent to the entire protection

area.

(9) Gas fire Only one. The gas fire extinguishing equipment is a fire cylinder

extinguishing that consists of an extinguishing agent vessel, an inlet pipe, a

equipment pressure annunciator, and a solenoid valve driver.

Fire extinguishing equipment of the CE fire extinguishing system has been installed before delivery,

except that the fire cylinder needs to be locally assembled and charged with purchased gas.

7.3 Routing Fire Extinguishing Cables

Signal cables are routed on the top of an aisle along the cable trays near the cabinet side and

are bound to each beam. All surface-mounted fire control cables are routed through metal

hoses. The hose ends are protected with grommets to prevent damage in case of a fire. Fire

control cables are routed and used separately to ensure secure and reliable power supply to the

fire extinguishing system.

Figure 7-5 Routing cables for the fire extinguishing system

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 39

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 8 Surge Protection and Grounding

8 Surge Protection and Grounding

The surge protection and grounding system protects the container and AC power distribution

equipment to ensure equipment security and reliability.

8.1 Surge Protection

Power Ports

Class I surge protective devices (SPDs) with the maximum discharge current (Imax) of

100 kA (8/20µs) are installed at AC power ports.

An SPD with the maximum discharge current of 60 kA (8/20µs) is installed for the input

power distribution cabinet.

Signal Ports

Indoor signal ports are protected to 1 kV for common mode.

Signal ports for routing cables out of the container pass the 3 kA impulse current test.

8.2 Grounding

Internal Grounding

The main earthing terminal (MET) is installed in the container and connects to the external

ground grid over ground downleads.

Equipment in the container connects to the ground busbar over ground cables and are

insulated from other metal parts.

External Grounding

Ground points in the shape of M12 bolts are evenly located on the container exterior. Ensure

that at least two diagonal ground points are connected to the ground grid. Figure 8-1 shows

the four ground points on the container exterior. The ground resistance is less than or equal to

10 ohms.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 40

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 8 Surge Protection and Grounding

Figure 8-1 Ground point of the container (unit: mm)

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 41

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 9 Lighting System

9 Lighting System

Introduction

Lighting devices are installed on the ceiling. The layout details are as follows:

Each ceiling on the hot and cold aisles is configured with two 220 V two-tube

fluorescent lights.

Each side aisle plate is configured with five 220 V two-tube fluorescent lights.

One emergency light is available on the side aisle ceiling close to the air conditioner

compartment.

Figure 9-1 shows the lighting system layout.

Figure 9-1 Lighting system layout

(1) Aisle light 14 in total

(2) Light on the side aisle plate 5 in total

(3) Emergency light 1 in total

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 42

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 9 Lighting System

Cable Routes for Lights in the Container

Power cables for lights in the container are routed along the ends of lights and connect to the

PDU8000 in the hall.

Cables for emergency lights and normal lights are routed separately.

Figure 9-2 Cable routes for lights in the container

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 43

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 10 Integrated Cabling

10 Integrated Cabling

Cables for the All-in-one are routed at the top and bottom of the container. Power cables and

signals cables are routed separately at the top along the container sides. A sufficient distance

is reserved between the two types of cables at cross points to prevent electromagnetic

interference. The distance between parallel power cables and signal cables must be greater

than 200 mm. L2 signal cables (network cables or optical fibers) are routed under the floor

within the specified space (W x D: 400 mm x 40 mm) to facilitate future cable routing.

The integrated cabling system supports upgrades of customer servers and smooth upgrades of

the All-in-one.

Figure 10-1 Integrated cabling system (unit: mm)

(1) Power cable (2) L1 signal cable

(3) Air conditioner power cable (4) L2 signal cable

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 44

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 10 Integrated Cabling

Route optical fibers from the internal optical distribution frame, along the cable-routing board

on the rear right side of the cabinet interior, then to the bottom of the cabinet and finally out of

the cabinet through the right cable hole.

Figure 10-2 Optical fiber route inside the cabinet

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 45

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 11 Typical Application Cases

11 Typical Application Cases

The All-in-one integrates UPSs, air conditioners, and server cabinets. The All-in-one operates

immediately after it connects to the power supply and network.

The All-in-one is used when customers can hardly predict the required network capacity or

plan infrastructures at a time. The All-in-one is mobile, maximizes return on investment (ROI),

and facilitates expansion.

Figure 11-1 Mobile All-in-one

Remove IT equipment and batteries before moving the All-in-one.

The All-in-one can be located near the customer location and used as a small-scale integrated

data center (IDC) in enterprise markets to meet special application requirements such as

service influxes and capacity expansion.

Compared with traditional civil data centers, the All-in-one is preferred when a data center

must be quickly constructed and deployed due to urgent service requirements.

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 46

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) 11 Typical Application Cases

Figure 11-2 All-in-one in an enterprise park

The All-in-one also applies to outdoor scenarios such as interim exhibitions, large-scale

games, fairs, disaster relief, military exercises, and surveys.

Figure 11-3 All-in-one in harsh environments

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 47

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) A Container Dimensions, Ground Points, and Ports

A Container Dimensions, Ground Points,

and Ports

Figure A-1 Dimensions and ground points of the container

W1. Container width: 12,192 mm W2. Container ground point: 11,390 mm

W3. Container ground point: 1940 mm W4. Width of the outdoor unit compartment:

1450 mm

W5. Width of the equipment compartment: D1. Container depth: 2438 mm

9365 mm

Figure A-2 Side view of the container

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 48

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) A Container Dimensions, Ground Points, and Ports

H1. Container height: 2896 mm H2. Feeder window height: 2269 mm

W1. Distance between the container left end and W2. Width of the panel for the

the panel for the condensate drainpipe and water condensate drainpipe and water refill

refill pipe: 1826 mm pipe: 288 mm

W3. Distance between the container left end and W4. Distance between the container

the center of the maintenance door: 7143 mm right end and the container ground

point: 800 mm

W5. Distance between the container right end and -

the feeder window: 324 mm

Figure A-3 Feeder window dimensions

H1.75 mm H2.150 mm

W1.475 mm W2.275 mm

W3.100 mm W4.50 mm

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 49

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) B Component Introduction

B Component Introduction

B.1 Cabinet

A server cabinet in the All-in-one is a dual-cabinet and houses IT equipment.

Appearance

Figure B-1 shows a server cabinet.

Figure B-1 Server cabinet (unit: mm)

(1) Cable hole at the top of the cabinet (2) Cable hole at the bottom of the cabinet

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 50

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) B Component Introduction

Structural Features

A server cabinet conforms to IEC297 and is suitable for 19 inch wide equipment. It has the

following structural features:

Is welded with structural steel, without front or rear doors.

Provides installation ports at the top and bottom for easy installation and removal.

Provides fasteners on both sides at its rear for securing PDU2000s and cables.

Is compatible with IT and CT equipment.

Specifications

Table B-1 lists the server cabinet specifications.

Table B-1 Server cabinet specifications

Item Specifications

Dimensions (H x W x D) 2100 mm x 1120 mm x 1000 mm

Available space 45 U

Weight ≤ 120 kg

Loading capability 500 kg per cabinet (static load)

Number of cables 100 network cables

B.2 Power Supply and Distribution System

PDU8000

The PDU8000 distributes power for 380 V and 480 V scenarios.

The 380 V PDU8000 supports two power inputs (active/standby). Two power inputs

enter the PDU8000, converge on the AC transfer switch (ATS), and then are distributed

to the UPS and other loads.

The 480 V PDU8000 also supports two power inputs (active/standby). Two power inputs

enter the PDU8000, converge on the AC transfer switch (ATS), then are converted into

380 V power over a 160 kVA transformer, and finally distributed to the UPS and other

loads.

Figure B-2 shows a PDU8000.

Figure B-2 PDU8000

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 51

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) B Component Introduction

The PDU8000 supplies power to the entire All-in-one. Table B-2 lists the PDU8000

specifications.

Table B-2 PDU8000 specifications

Item Specifications

Power distribution scenario 380 V 480 V

Rated input operating 380 V AC, 400 V AC, or 480 V AC (three-phase,

voltage 415 V AC (three-phase, four-wire, and PE)

four-wire, and PE)

Rated input operating 50 Hz or 60 Hz 60 Hz

frequency

Output circuit breaker One 4-pole 160 A One 3-pole 250 A MCCB

MCCB

Five 3-pole 32 A circuit

breakers

Five 3-pole 63 A circuit

breakers

Five 1-pole 10 A circuit

breakers

Four 1-pole 10 A circuit

breakers

One 1-pole 10 A RCD

Input ATS One 4-pole 250 A PC Class three-section ATS

Surge protection level Class I with a maximum surge current of 60 kA

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 52

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) B Component Introduction

Item Specifications

Shell protection level IP20

Cabling Routed in from the top and out from the bottom

Installation mode Wall-mounted

Dimensions (H x W x D) 1600 mm x 1070 mm x 280 mm

Transformer

A transformer is optional. For a 480 V scenario, the transformer is installed inside a

dual-cabinet. Three circuit breakers are configured for transformer outputs and six fans for

transformer heat dissipation, as shown in Figure B-3.

Figure B-3 Transformer

Table B-3 lists the transformer specifications.

Table B-3 Transformer specifications

Item Specifications

Output 4-pole 320 A circuit breaker

4-pole 160 A circuit breaker

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 53

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) B Component Introduction

Item Specifications

RCD

Capacity 160 kVA

Number of phases Three phases

Frequency 60 Hz

Materials Winding: copper

Magnetic core: silicon steel

Primary rated voltage 480 V

Primary rated current 170 A

Rated output no-load or load voltage 1 380 V

Rated output no-load or load voltage 2 208 V

Vector group Dyn11

Efficiency ≥ 96% (fully configured)

Protection level IP20

Dimensions (H x W x D) 500 mm x 350 mm x 800 mm

PDU5000

There are four types of PDU5000s: Parallel UPS PDU5000, UPS output PDU5000, server

cabinet PDU5000, and transformer output PDU5000, as shown in Figure B-4, Figure B-5,

Figure B-6, and Figure B-7.

The PDU5000 possesses the following features:

The PDU5000 is made of cold-rolled steel, rack-mounted, maintained from front or rear,

and supports overhead cabling.

Supplies input and output power.

Figure B-4 Parallel UPS PDU5000

Figure B-5 UPS output PDU5000

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 54

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) B Component Introduction

Figure B-6 Server cabinet PDU5000

Figure B-7 Transformer output PDU5000

Table B-4 lists the PDU5000 specifications.

Table B-4 PDU5000 specifications

Item Specifications

Type Parallel UPS UPS output Server cabinet Transformer

PDU5000 PDU5000 PDU5000 output PDU5000

Input Four 4-pole One 3-pole 100 One 3-pole 100 Reserved input

63 A circuit A disconnector A disconnector wiring terminals

breakers:

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 55

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) B Component Introduction

Item Specifications

for outputs

of four

UPSs

One UPS

maintenanc

e bypass

input

Output One 3-pole 100 Two 3-pole Nine 1-pole Five 3-pole

A circuit 80 A circuit 32 A circuit 63 A circuit

breaker: for the breakers: for breakers: breakers

UPS output the server eight for Five 3-pole

PDU5000 cabinet single-phase 32 A circuit

PDU5000 PDU2000s, breakers

Six 1-pole 10 and one

Four 3-pole

A circuit serving as a

standby 10 A circuit

breakers: for breakers

door status circuit

breaker Four 1-pole

sensors,

monitoring One 3-pole 10 A circuit

devices, and 16 A circuit breakers

fans breaker:

serving as a

standby

circuit

breaker

Three 1-pole

10 A circuit

breakers:

serving as

standby

circuit

breakers

Smart meter N/A PD510 N/A N/A

Dimensions 130 mm (3 U) x 430 mm x 635 mm 260 mm (6 U) x

(H x W x D) 430 mm x 635

mm

Rated input 380 V AC, 400 V AC, or 415 V AC

voltage

Rated input 50 Hz or 60 Hz

frequency

Shell IP20

protection

level

Cabling Routed in and out from the rear

Installation Mounted in a 19-inch rack

mode

Issue Draft A (2014-05-23) Huawei Proprietary and Confidential 56

Copyright © Huawei Technologies Co., Ltd.

IDS1000-A40 Container Data Center

Product Manual (40 ft) B Component Introduction

UPS

The UPS supplies power to server cabinets each with a maximum power of 6 kW when the

D.G. and mains power supplies are disconnected.

The UPS provides a capacity of 20 kVA, works in 3 +1 backup mode, uses one battery

string, and provides 10-minute power backup.

The UPS supports wide input voltage and frequency ranges to apply to poor power grids.

It has an excellent loading capacity.