Professional Documents

Culture Documents

MC68HC912/9S12 FLASH/EEPROM Programmer User's Guide: Engineering Technical Laboratory

Uploaded by

Roger SegoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MC68HC912/9S12 FLASH/EEPROM Programmer User's Guide: Engineering Technical Laboratory

Uploaded by

Roger SegoCopyright:

Available Formats

Engineering Technical Laboratory Rev.

MC68HC912/9S12 FLASH/EEPROM Programmer

User’s Guide

© ETL 2004-2006 Microcontroller Development Tool

TABLE OF CONTENTS

1. PREFACE ...................................................................................................................................... 3

2. CHECKLIST AND REQUIREMENTS ........................................................................................ 3

3. INSTALLATION AND USE ........................................................................................................ 4

3.1 PROGRAMMER CHECK AND CONNECTION TO PC...................................................... 5

3.2 PROGRAMMER FIRMWARE UPDATE.............................................................................. 5

4. INTERFACE TYPES .................................................................................................................... 6

4.1 IN-CIRCUIT PROGRAMMING ............................................................................................ 6

4.2 ON-BOARD PROGRAMMING ............................................................................................. 6

5. WORKING WITH TARGET MCU.............................................................................................. 7

5.1 MC68 HC912 Devices............................................................................................................. 7

5.1.1 In-Circuit EEPROM/FLASH reading example ................................................................ 7

5.1.2 In-Circuit EEPROM/FLASH programming example....................................................... 7

5.1.3 On-Board EEPROM/FLASH reading example ................................................................ 8

5.1.4 On-Board EEPROM/FLASH programming example ...................................................... 8

5.2 MC 9S12 Devices .................................................................................................................... 9

5.2.1 Features of MC9S12xx128 Devices with 0L85D/1L85D masksets ................................. 9

6. FILE OPERATIONS ................................................................................................................... 11

6.1 LOAD FILE INTO BUFFER ................................................................................................ 11

6.2 SAVE FILE FROM BUFFER ............................................................................................... 11

7. ERRORS AND TROUBLESHOOTING .................................................................................... 12

8. WARRANTY STATEMENT...................................................................................................... 14

9. APPENDIX.................................................................................................................................. 15

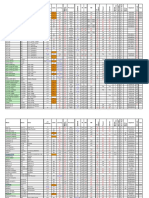

Figure 2. In-Circuit programming schematic diagram for HC912/9S12 MCU............................... 15

Figure 3. In-Circuit wiring diagram for MC68HC912B32, 80-PIN QFP Package ......................... 16

Figure 4. In-Circuit wiring diagram for MC68HC912D60/DG128, 112-PIN TQFP Package........ 17

Figure 5. In-Circuit wiring diagram for MC68HC912D60A/DG128A, 112-PIN LQFP Package.. 18

Figure 6. In-Circuit wiring diagram for MC68HC(9)12D60, 80-PIN QFP Package ...................... 19

Figure 7. In-Circuit wiring diagram for MC68HC912D60A, 80-PIN QFP Package ...................... 20

Figure 8. In-Circuit wiring diagram for MC9S12Dx64/Dx128/Dx256, 80-PIN QFP Package ...... 21

Figure 9. In-Circuit wiring diagram for MC9S12Dx64/Dx128/Dx256, 112-PIN LQFP Package.. 22

Figure 10. In-Circuit wiring diagram for MC9S12H-Family 112-PIN LQFP Package .................. 23

Figure 11. In-Circuit wiring diagram for MC9S12H-Family 144-PIN LQFP Package .................. 24

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 2

1. PREFACE

This manual will guide you through the installation and operation of the ETL

MC68HC912/9S12 Programmer, referenced hereafter as the HC912-Programmer.

The HC912-Programmer has been designed for Reading, Programming of FLASH,

EEPROM contents of the next Motorola Microcontroller Unit (MCU):

9 MC68HC912 DC128A (3K91D) 9 MC9S12 DG128B (0L85D)

9 MC68HC912 DC128 (0K50E) 9 MC9S12 DT128B (0L85D)

9 MC68HC912 DG128 (5H55W) 9 MC9S12 A128B (0L85D)

9 MC68HC912 DG128A (3K91D) 9 MC9S12 DB128B (0L85D)

9 MC68HC912 D60A (2K38K) 9 MC9S12 DT128B (1L85D)

9 MC68HC912 D60 (0K75F) 9 MC9S12 DG256C (2K79X)

9 MC68HC912 D60 (0K13J) 9 MC9S12 DT256C (2K79X)

9 MC68HC912 D60 (4F73K) 9 MC9S12 DP256C (2K79X)

9 MC68HC912 B32 (4J54E) 9 MC9S12 DP512 (1L00M)

9 MC68HC912 B32 (9H91F) 9 MC9S12 D64 (2L86D)

9 MC9S12 DT128B (3L40K)

9 MC9S12 H128 (1K78X)

9 MC9S12 H256 (1K78X)

& Note: Most number of devices can be programmed in two operating modes In-

Circuit and On-Board.

& Note: On-Board programming must be used when device secured or BDM

module disabled only. See Section 4.2 for details.

& Note: Devices that not mentioned above in list can’t be guaranteed of correct

reading, programming by HC912-Programmer.

2. CHECKLIST AND REQUIREMENTS

The following describes what items are supplied with the HC912-Programmer and the

system requirements if used by a PC.

9 HC912-Programmer – supplied

9 Two HC912 QFP112 Adaptors – supplied

9 Two MC9S12 112QFP Adaptors– supplied

9 Cable -A DB9 “straight-thru” cable - supplied

9 HC912-Programmer PC software on CD-ROM – Optional Extra

Desktop PC and a free Serial Communication Port (COM1...8)

Memory - Minimum 32 Mbytes

Display - Color SVGA display recommended

Power supply 12 Volt/500 mA linear power supply source

OS -MS-Windows (Win98, Win2000/XP/2003)

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 3

3. INSTALLATION AND USE

The HC912-Programmer includes two LED’s and mode jumper (Figure 1).

Color LED’s indicates programmer state and external power supply voltage (Table 1, 2).

GREEN HC912-Programmer is ready.

GREEN Flashing HC912-Programmer is busy.

RED Error occurred while operation.

DARK Voltage applied to HC912-Programmer lower than 6 Volt.

Table 1. LED D1 color meaning

GREEN Motorola device powered on.

DARK Motorola device powered off.

Table 2. LED D4 color meaning

Jumper-1 (JP1) is intended for HC912-Programmer mode selection (see Table 3).

JP1 Shorted Normal operation. Motorola device EEPROM/FLASH

Reading/Programming.

JP1 Opened Service mode. HC912-Programmer firmware update.

Table 3. HC912-Programmer operation modes

& Note: When Service mode selected LED D1 will be RED.

JP1 1-Pin Key

Serial Port Connector

D4 D1

COM 1...8

Motorola Device Socket for

On-Board Programming

P5

12V

BKGD GND

Power

Connector RES

VDD

BDM ICP

Figure 1. The HC912-Programmer board layout

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 4

3.1 PROGRAMMER CHECK AND CONNECTION TO PC

Connect the power supply source to HC912-Programmer (an external 12 V DC power

supply source is required).

Attach a COM port cable to the 9-pin connector on the programmer and to a COM port

on the PC.

Insert jumper JP1 (see Figure 1).

Remove any adaptor from Motorola device socket.

Turn On power supply source and make sure that LED D1 appear green.

Start HC912-Programmer software.

After few seconds you should see on display message: “MC68HC912 Programmer Ver-

X.X detected”.

In case when you should see message: “MC68HC912 Programmer Ver-X.X not

found”, change COM port number. To do that select “Tools” menu item and than select

“Comm Port Options”. Select new COM port number. After pressing “OK” button the

new setting will be applied and software reattempts connection with programmer.

Now HC912-Programmer ready to operate.

& Note: To speed up connection between HC912-Programmer and PC

communication port baud rate must be set to maximum value.

& Note: Update HC912-Programmer firmware if required (see Section 3.2).

3.2 PROGRAMMER FIRMWARE UPDATE

This section describes how to update firmware (ATMEGA and XILINX) of HC912-

Programmer.

Remove JP1 (see Figure 1).

Turn On power supply; make sure that LED D1 appears red.

Start HC912-Programmer software.

Compare firmware version “MC68HC912 Programmer Ver-X.X detected” and version

specified in “Help>About” menu item.

If versions not coincide, follow next steps to update firmware.

Select menu item “Tools>Firmware Update”.

After message box “Firmware Update” appeared, press “OK” button.

After firmware update completed, turn Off power supply, close HC912-Programmer

software.

Insert JP1.

Turn On power supply. Make sure that LED1 appear green.

Start HC912-Programmer software on PC. New firmware version “MC68HC912

Programmer Ver-X.X detected” will appear.

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 5

4. INTERFACE TYPES

This section describes two interfaces, In-Circuit Programming (ICP) and On-Board

Programming (OBP) of HC912-Programmer.

4.1 IN-CIRCUIT PROGRAMMING

In-Circuit programming interface is basic for HC912-Programmer. With this interface HC912-

Programmer automatically detects target MCU bus speed. Ceramic resonator connected to target

MCU must be in range from 2 MHz to 16 MHz. If target MCU secured (9S12 devices) or BDM

module disabled (912 devices) there is no way to establish connection between MCU and HC912-

Programmer.

& Note: ECLK Pin on target MCU must be connected to circuit via resistor

1Kohm or higher to avoid damaging of this pin.

& Note: When using In-Circuit programming interface remove adaptor from

Motorola device socket (see Figure 1).

4.2 ON-BOARD PROGRAMMING

On-board programming interface designed for establishing connection with target device when

MCU secured (9S12 devices) or BDM module disabled (912 devices). This interface allows

Read/Program EEPROM/FLASH without any restrictions. To work with this interface type MCU

must be mounted to the corresponding QFP adaptor supplied with HC912-Programmer.

& Note: When target adaptor with MCU mounted, check contacts careful to avoid

short circuit. Otherwise target MCU can be damaged!

& Note: When On-board programming interface used, remove cable from BDM

ICP connector (see Figure 1).

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 6

5. WORKING WITH TARGET MCU

This section contains overall information about Motorola MCUs supported by HC912-

Programmer. When HC912-Programmer successfully installed (see Section 3) target devices can

be read, program and verify.

5.1 MC68 HC912 Devices

This section describes basic rules working with next devices:

9 MC68HC912 DC128A (3K91D)

9 MC68HC912 DC128 (0K50E)

9 MC68HC912 DG128 (5H55W)

9 MC68HC912 DG128A (3K91D)

9 MC68HC912 B32 (4J54E)

9 MC68HC912 D60A (2K38K)

FLASH/EEPROM memory for these devices can be read, program in both OBP and ICP

interfaces.

& Note: On-Board programming interface not implemented for MC68HC912B32

device.

Extra care must be taken when working with EEPROM Shadow Word/Byte in ICP interface.

If BDM Lockout bit (NOBDML) programmed to zero, further access to MCU will be blocked after

next reset. The only one way to grant access to locked MCU is mount MCU on corresponding

adaptor and use On-Board programming interface.

5.1.1 In-Circuit EEPROM/FLASH reading example

Connect required pins to board with target MCU (see Appendix Figure 2).

Remove any adaptor from Motorola device socket (see Figure 1).

Apply power to HC912-Programmer. LED D1 became to green light (see Table 1).

Select corresponding device in HC912-Programmer software (“Device” button).

Select “Read Sequence” panel in HC912-Programmer software.

Press “EEPROM/FLASH” button.

Press “Start” button.

LED D4 on HC912-Programmer became to green light. That means that +5 voltage

regulator switched on and VCC applied to target MCU.

Now HC912-Programmer automatically detects MCU bus speed.

When LED D1 on HC912-Programmer became permanent green, reading completed.

Target MCU powered off.

After read sequence successfully completed it is necessarily to save memory dump to

file (see Section 6.2).

If some errors appeared during reading process refer to Section 7.

5.1.2 In-Circuit EEPROM/FLASH programming example

Connect required pins to board with target MCU (see Appendix Figure 2).

Remove any adaptor from Motorola device socket (see Figure 1).

Apply power to HC912-Programmer. LED D1 became to green light (see Table 1).

Select corresponding device in HC912-Programmer software (“Device” Button).

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 7

Load EEPROM/FLASH data from file (see Section 6.1) or enter data to Hex Editor.

Select “Program Sequence” panel in HC912-Programmer software.

Press “EEPROM/FLASH” button.

Press “Start” button.

LED D4 on HC912-Programmer became to green light. That means that +5 voltage

regulator switched on and VCC applied to target MCU.

Now HC912-Programmer automatically detects MCU bus speed.

When LED D1 on HC912-Programmer became permanent green, programming

completed. Target MCU powered off.

If some errors appeared during programming process refer to Section 7.

& Note: Extra care must be taken when programming the EEPROM Shadow

Word/Byte.

& Note: Strongly recommended before EEPROM/FLASH programming, for a first

time, read EEPROM/FLASH contents and save it to file.

5.1.3 On-Board EEPROM/FLASH reading example

Mount target MCU on corresponding QFP adaptor.

Insert adaptor to Motorola Device Socket on HC912-Programmer in according to 1 pin-

key (see Figure 1).

Remove cable from BDM ICP connector (see Figure 1).

Apply power to HC912-Programmer.

Select device in HC912-Programmer software (“Device” Button).

Select “Read Sequence” panel in HC912-Programmer software.

Press “EEPROM/FLASH” button.

Press “Start” button.

LED D4 on HC912-Programmer became to green light. That means that +5 voltage

regulator switched on and VCC applied to target MCU.

When LED D1 on HC912-Programmer became permanent green light, reading

completed.

When read sequence successfully completed it is necessarily to save memory dump to

file (see Section 6.2).

If some errors appeared during reading process refer to Section 7.

& Note: When target MCU mounted on adaptor check contacts careful to avoid

short circuit. Otherwise target MCU can be damaged!

& Note: During removing the adaptor with target MCU HC912-Programmer must

be powered off to avoid damaging of programmer and target MCU!

5.1.4 On-Board EEPROM/FLASH programming example

Mount target MCU on corresponding QFP adaptor.

Insert adaptor to Motorola Device Socket on HC912-Programmer in according to 1 pin-

key (see Figure 1).

Remove cable from BDM ICP connector (see Figure 1).

Apply power to HC912-Programmer.

Select device in HC912-Programmer software (“Device” Button).

Load EEPROM/FLASH data from file (see Section 6.1) or enter data to Hex Editor.

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 8

Select “Program Sequence” panel in HC912-Programmer software.

Press “EEPROM/FLASH” button.

Press “Start” button.

LED D4 on HC912-Programmer became to green light. That means that +5 voltage

regulator switched on and VCC applied to target MCU.

When LED D1 on HC912-Programmer became permanent green light, programming

completed.

If some errors appeared during programming process refer to Section 7.

& Note: When target MCU mounted on adaptor check contacts careful to avoid

short circuit. Otherwise target MCU can be damaged!

& Note: During removing the adaptor with target MCU HC912-Programmer must

be powered off to avoid damaging of programmer and target MCU!

& Note: Extra care must be taken when programming the EEPROM Shadow

Word/Byte.

& Note: Strongly recommended before EEPROM/FLASH programming, for a first

time, read EEPROM/FLASH contents and save it to file.

5.2 MC 9S12 Devices

This section describes basic rules working with next devices:

9 MC9S12 D64 (2L86D)

9 MC9S12 DG128B (0L85D)

9 MC9S12 DT128B (0L85D)

9 MC9S12 A128B (0L85D)

9 MC9S12 DB128B (0L85D)

9 MC9S12 DT128B (1L85D)

9 MC9S12 DG256C (2K79X)

9 MC9S12 DT256C (2K79X)

9 MC9S12 DP256C (2K79X)

9 MC9S12 DP512 (1L00M)

FLASH/EEPROM memory for these devices can be read, program in both OBP and ICP

interfaces.

& Note: Use On-Board programming interface only if target MCU secured.

Extra care must be taken when working with FLASH Option/Security byte in ICP interface. If

MCU not erased (all EEPROM and FLASH bytes not equal to $FF) and FLASH Security byte not

equal to XXXXXX10B, further access to MCU will be blocked after next reset. To grant access to

MCU device must be mounted on corresponding adaptor and On-Board programming interface

must be used.

In all other respects EEPROM/FLASH programming technique similar to MC68HC912

devices (See sections 5.1.1-5.1.4)

5.2.1 Features of MC9S12xx128 Devices with 0L85D/1L85D masksets

This section describes specific behavior of MC9S12xx128 (0L85D/1L85D) devices when In-

Circuit programming interface is used. In according to Motorola errata relative to this devices there

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 9

is some problem exists with running of Sector Erase and Program Commands when MCU secured.

Only Bulk Erase of FLASH and EEPROM command possible. In many cases this problem can be

solved by disabling of security via Backdoor Access Key. HC912-Programmer automatically read

this key and passes the security sequence. But if Backdoor Access Key disabled there is no

possibilities to disable security. To solve this problem the second method of security disabling

must be used. After erasing FLASH and EEPROM, target MCU can be accessed in Special Single

Chip mode (HC912-Programmer In-Circuit interface). Follow instructions below:

Read full EEPROM and FLASH contents in On-Board programming interface.

First of all, when link with MCU completed it is necessarily to read all FLASH and

EEPROM contents and save it to File. For more information see sections 5.1.3 On-

Board EEPROM/FLASH reading example. It is obligatory to save EEPROM and

FLASH contents to file (see Section 6.2).

Erase EEPROM and FLASH.

Press Erase FLASH and EEPROM buttons on Program Sequence panel. Also, press

Verify EEPROM and FLASH buttons to perform erase check.

Press Start button.

When LED D1 on HC912-Programmer became permanent green light, erasing

completed.

Disconnect power from HC912-Programmer.

Remove target MCU from programmer and solder it back to board.

Prepare target MCU for In-Circuit Programming.

Connect required pins to board with target MCU (see Appendix Figure 2).

Remove any adaptor from Motorola device socket (see Figure 1).

Apply power to HC912-Programmer. LED D1 became to green light (see Table 1).

Select corresponding device in HC912-Programmer software (“Device” Button).

Load EEPROM/FLASH data from previous saved file.

Change value of FLASH Security byte, $7BF0F Address to $FE in Hex Editor. That

mean that device will be unsecured after programming. Also, some changes in

EEPROM and FLASH areas are possible.

If further access to MCU is not required, FLASH Security byte not need to be changed.

Press “EEPROM/FLASH” button on Program Sequence Panel.

Press “Start” button.

LED D4 on HC912-Programmer became to green light. That means that +5 voltage

regulator switched on and VCC applied to target MCU.

When LED D1 on HC912-Programmer became permanent green, programming

completed. Target MCU powered off.

If some errors appeared during programming process refer to Section 7.

& Note: There is no way to restore EEPROM and FLASH contents after erasing.

That is strongly recommended read EEPROM and FLASH contents and save it

to file before erasing.

& Note: When target MCU mounted on adaptor check contacts careful to avoid

short circuit. Otherwise target MCU can be damaged!

& Note: During removing the adaptor with target MCU HC912-Programmer must

be powered off to avoid damaging of programmer and target MCU!

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 10

6. FILE OPERATIONS

This section describes basic rules working with files. Memory dump from Hex Editor (Buffer)

can be load/save from/to hard disk. Also short descriptions such as project name, MCU type and

memory cell assignment can be done for future fast remind. HC912-Programmer accepts tree types

of file formats:

9 BIN (Binary format)

9 Motorola S-Record (4 byte address)

9 Motorola S-Record (6 byte address)

9 EEF (Extended ETL Format)

6.1 LOAD FILE INTO BUFFER

Select “File>Open” menu item.

Press “Browse” button.

In File Open Dialog window, select file witch need to be open.

Press “Open” button.

Than opposite “Auto Format Detected:” text, select correct file format. Note that software

try automatically detects file format, but unknown records in file will fail this detection.

“Load Entire file” check box must be checked if automatically loading procedures

required.

Than press “OK” button.

Sometimes load data from file to specific buffer allocations required. For Example if required

load buffer from $0400 address from binary file beginning from $0000 address follow next steps:

Select “File>Open” menu item.

Press “Browse” button.

In File Open Dialog window, select file which need to be open.

Press “Open” button.

Than, opposite “Auto Format Detected:” select Binary format.

Uncheck “Load Entire File” check box.

In field “Offset Value to Place Data to Buffer:” enter 0x0400.

Than press “OK” button.

Now data placed to Hex Editor Buffer from the beginning of 0x0400 address.

If more complicated operations with files required, for example load Hex Editor Buffer from

many files “Lowest Address From File To Load”, “Highest Address From File To Load” and

“Clear Buffer Before Loading File” options are available.

6.2 SAVE FILE FROM BUFFER

Select “File>Save” menu item.

Press “Browse” button.

Select directory in which file will be saved.

Type file name, for example “test1”

Press “Save” button.

Than select format in which file will be saved*.

Press “OK” button.

& Note: Use EEF Format for future “Load File Into Buffer” automatically

processing. Also, only in EEF Format Project Description, Device Name and

Memory Cells attributes can be saved.

& Note: Use Motorola S-Record (6 byte address) Format to save all FLASH

memory contents.

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 11

7. ERRORS AND TROUBLESHOOTING

This section describes most recently encountered problems, errors and fixing solutions.

Problem: LED D1 (see Figure 1) Dark.

Causes: This problem can accrue when external power supply connected to HC912-

Programmer is damaged or connected in wrong polarity.

Solutions: Check voltage on HC912-Programmer power clamps. It must be 12 V +/- 1V.

Problem: LED D1 (see Figure 1) Red.

Causes: These problem can appear in two cases: if HC912-Programmer is in the service

mode (JP1 removed) and if some error accrue while operation of HC912-

Programmer.

Solutions: Insert jumper JP1 (see Figure 1), remove adaptors from Motorola device socket

and cable from ICP connector, turn-off and than turn-on power supply connected

to HC912-Programmer. If LED D1 still red contact ETL technical support.

Error Message: MC68HC912 Programmer not found

Causes: This message can appear when HC912-Programmer software couldn’t

establish connection with HC912-Programmer board.

Solutions: Check connection of COM port cable from PC to HC912-Programmer

board. Apply power from external power supply to HC912-Programmer. In

menu item “Tools>Comm Port Options” select correct COM port number.

Error Message: Communication Error

Causes: This message can appear when Communication between HC912-

Programmer and PC is broken.

Solutions: Try to decrease communication baud rate in “Tools>Comm Port Options”

dialog window. Also this message can appear when COM port cable has

poor contact with DB-9 connectors.

Error Message: RESET Line must be in 'high' state

Causes: This message can appear when MCU Reset pin connected to ground through

external components or no oscillation on EXTAL, XTAL pins.

Solutions: Check MCU reset pin resistance relatively to VSS pin, and if it too low

check passive and active components connected. Or check integrity of

ceramic resonator and passive components connected to EXTAL, XTAL

pins.

Error Message: BKGD Line must be in 'high' state

Causes: This message can appear when MCU BKGD pin connected to ground

through external components.

Solutions: Cut any component from pin.

Error Message: Pin Tester Errors:

Causes: This message can appear in On-Board programming interface when some

pins has poor contact with QFP adaptor, or pins are damaged.

Solutions: Clean pins from colophony. Check contacts between adaptor and target

MCU pins. Check short circuits between pins to pins, pins to GND and pins

to VCC.

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 12

Error Message: BDM Speed Auto Detection failed

Causes: This message can appear in In-Circuit programming interface if target MCU

not connected correctly to HC912-Programmer or MCU secured.

Solutions: Check contacts between HC912-Programmer and MCU pins. If this error

not disappeared, place MCU on corresponding QFP adaptor and use On-

Board programming interface.

Error Message: BDM Activation Error

Causes: This message can appear when wrong Device selected.

Solutions: Select correct device type; take attention on MCU maskset.

Error Message: No clock on ECLK pin

Causes: This message can appear in On-Board programming interface when wrong

Device selected.

Solutions: Select correct device type; take attention on MCU maskset.

Error Message: Parallel Boot Failed

Causes: This message can appear in On-Board programming interface when wrong

Device selected.

Solutions: Select correct device type; take attention on MCU maskset.

Error Message: Monitor Loader time-out Error

Causes: This message can appear when wrong Device selected.

Solutions: Select correct device type; take attention on MCU maskset.

Error Message: Monitor Check-sum Error

Causes: This message can appear after monitor firmware loaded into target MCU

with errors.

Solutions: Try to reconnect to target MCU. If this error not disappeared, possible target

MCU has damaged RAM.

Error Message: Monitor Heap Check-sum Error

Causes: This message can appear after monitor firmware transferred data into target

MCU RAM with errors.

Solutions: Try to reconnect to target MCU. If this error not disappeared, possible target

MCU has damaged RAM.

Error Message: BDM active status or monitor firmware time-out Error

Causes: This message can appear if target MCU “hangs up”.

Solutions: Try to reconnect to target MCU. If this error not disappeared, check contacts

between HC912-Programmer and MCU pins, power supply voltage on VCC

pins.

Error Message: Parallel Bus active status or monitor firmware time-out Error

Causes: This message can appear if target MCU “hangs up”.

Solutions: Try to reconnect to target MCU. If this error not disappeared, check contacts

between HC912-Programmer and MCU pins, power supply voltage on VCC

pins.

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 13

Error Message: Device still locked

Causes: This message can appear in On-Board programming interface when target

MCU secured.

Solutions: Check accuracy of device type selected; take attention on MCU maskset.

Try to reconnect to target MCU.

Error Message: Device can't be unsecured

Causes: This message can appear in In-Circuit programming interface when MCU

EEPROM/FLASH erased (all data equal to $FF) and accordingly device

still secured.

Solutions: Check voltage on VCC pins. Try to reconnect to target MCU.

Error Message: Voltage on VFP pin is below normal programming voltage level

Causes: This message can appear when no or low voltage applied to VFP pin.

Solutions: Apply specified by Motorola voltage to VFP pin.

Error Message: On-Board Programming Interface not supported for the Device

Causes: This message can appear when wrong Device selected.

Solutions: Select correct device type; take attention on MCU maskset.

Error Message: External power supply must be disconnected from BDM ICP connector

Causes: This message can appear in On-Board programming interface when

external voltage applied to BDM ICP connector (see Figure 1).

Solutions: Disconnect cable from BDM ICP connector.

Error Message: Vreg Overcurrent Protection

Causes: This message can appear when current consumption from built-in power

supply grater than 500 mA.

Solutions: Check target MCU power pins on short circuit.

Error Message: Vreg Output Voltage out of range

CYPRESS IIC BUS Busy

CYPRESS IIC Protocol Failed

CYPRESS Frequency out of range

Wrong Subroutine call

Causes: These messages can appear when fatal problems with HC912-Programmer

hardware accrued.

Solutions: Contact ETL technical support.

& Note: HC912-Programmer has Log Window which can be stored to file. To

perform this operation right clicks on Log Window. Than click on “Save to

hc912prog.log file“ menu item. Now this file can be found in the same

directory as HC912-Programmer software. Log File can be send by E-mail to

techsupport@etlweb.net for non described problem solution.

8. WARRANTY STATEMENT

ETL warrants that Product delivered shall conform to applicable. Report any defects for a 45

days period, from the applicable data on invoice.

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 14

9. APPENDIX

HC912 Programmer

HC912/9S12 MCU

BKGD 1 BKGD

Gnd 2 VSS

Gnd

RESET 4 RESET

P5 VDD 6 VDD

1K Logic level on this pin must be “LOW”

MODA

1K Logic level on this pin must be “LOW”

Gnd MODB

External circuit *

>1 K

ECLK

Note: To avoid damaging of ECLK pin

it must be connected to external circuit EXTAL

via resistor equal or grater than 1 Kohm.

XTAL

2...16 MHz

Figure 2. In-Circuit programming schematic diagram for HC912/9S12 MCU

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 15

PS5 / SDO/MOSI

PDLC0 / DLCRx

PDLC1 / DLCTx

PS4 / SDI/MISO

PS7 / CS /SS

PS6 / SCK

PS0 / RxD

PS1 / TxD

PDLC2

PDLC3

PDLC4

PDLC5

PDLC6

VDDX

VSSX

PS3

PS2

PP7

PP6

VFP

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

PP5 1 60 VSSA

PP4 2 59 VDDA

PW3 / PP3 3 58 PAD7 / AN7

PW2 / PP2 4 57 PAD6 / AN6

PW1/ PP1 5 56 PAD5 / AN5

PW0/ PP0 6 55 PAD4 / AN4

IOC0 / PT0 7 54 PAD3 / AN3

IOC1 / PT1 8 53 PAD2 / AN2

IOC2 / PT2 9 52 PAD1 / AN1

VDD 10 MC68HC912B32 51 PAD0 / AN0

VSS 11 50 VRL

80 QFP 49

IOC3 / PT3 12 VRH

IOC4 / PT4 13 48 VSS

IOC5 / PT5 14 47 VDD

IOC6 / PT6 15 46 PA7 / DATA15 / ADDR15

PAI / IOC7 / PT7 16 45 PA6 / DATA14 / ADDR14

BKGD SMODN / TAGHI/ BKGD 17 44 PA5 / DATA13 / ADDR13

ADDR0 / DATA0 / PB0 18 43 PA4 / DATA12 / ADDR12

ADDR1 / DATA1 / PB1 19 42 PA3 / DATA11 / ADDR11

ADDR2 / DATA2 / PB2 20 41 PA2 / DATA10 / ADDR10

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

ADDR3 / DATA3 / PB3

ADDR4 / DATA4 / PB4

ADDR6 / DATA6 / PB6

IRQ / PE1

ADDR5 / DATA5 / PB5

DBE / PE7

R/W / PE2

XIRQ / PE0

ADDR8 / DATA8 / PA0

ADDR9 / DATA9 / PA1

VSSX

VDDX

MODB / IPIPE1 / PE6

MODA / IPIPE0 / PE5

ADDR7 / DATA7 / PB7

XTAL

LSTRB / TAGLO / PE3

RESET

ECLK / PE4

EXTAL

GND

VDD

RESET

Figure 3. In-Circuit wiring diagram for MC68HC912B32, 80-PIN QFP Package

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 16

PS 5/SDO/MOSI

PS 4/SDI/MISO

External +12V for FLASH Programming

PS 2/RxD1

PS 0/RxD0

PS 3/TxD1

PS 1/TxD0

PIB6/SDA

PIB7/SCL

PP 3/PW3

PK 0/PIX0

PK 1/PIX1

PK 2/PIX2

PK 7/ECS

PS 6/SCK

RxCAN0

RxCAN1

TxCA N0

TxCA N1

PS 7/SS

VDDX

VDDA

VSSX

VSSA

VRH1

PIB4

PIB5

VRL1

VFP*

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

PW2/PP2 1 84 PAD17/AN17

PW1/PP1 2 83 PAD07/AN07

PW0/PP0 3 82 PAD16/AN16

IOC0/PT0 4 81 PAD06/AN06

IOC1/PT1 5 80 PAD15/AN15

IOC2/PT2 6 79 PAD05/AN05

IOC3/PT3 7 78 PAD14/AN14

KWJ7/PJ7 8 77 PAD04/AN04

KWJ6/PJ6 9 76 PAD13/AN13

KWJ5/PJ5 10 75 PAD03/AN03

KWJ4/PJ4 11 74 PAD12/AN12

VDD 12 73 PAD02/AN02

PK3 13 MC68HC912 D60/DG128 72 PAD11/AN11

VSS 14 71 PAD01/AN01

IOC4/PT4 15 112TQFP 70 PAD10/AN10

IOC5/PT5 16 69 PAD00/AN00

IOC6/PT6 17 68 VRL0

IOC7/PT7 18 67 VRH0

KWJ3/PJ3 19 66 VSS

KWJ2/PJ2 20 65 VDD

KWJ1/PJ1 21 64 PA7/ADDR15/DATA15/DATA7

KWJ0/PJ0 22 63 PA6/ADDR14/DATA14/DATA6

BKGD SMODN/TAGHI/BKGD 23 62 PA5/ADDR13/DATA13/DATA5

ADDR0/DATA0/PB0 24 61 PA4/ADDR12/DATA12/DATA4

ADDR1/DATA1/PB1 25 60 PA3/ADDR11/DATA11/DATA3

ADDR2/DATA2/PB2 26 59 PA2/ADDR10/DATA10/DATA2

ADDR3/DATA3/PB3 27 58 PA1/ADDR9/DATA9/DATA1

ADDR4/DATA4/PB4 28 57 PA0/ADDR8/DATA8/DATA0

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

V SSPLL

IRQ/P E1

VDDPLL

VS TBY

KWH4/PH4

DBE/CAL/P E7

MODB/IPIPE1/P E6

EX TAL

MODA/IPIPE0/PE5

ECLK /P E4

XTAL

K WH3/PH3

KWH2/PH2

KWH1/PH1

XIRQ /PE 0

RESET

XFC

VSSX

VDDX

ADDR5/DATA5/PB5

ADDR6/DATA6/PB6

ADDR7/DATA7/PB7

KWH0/PH0

LSTRB /TAGLO/PE3

R/W /PE2

KWH7/PH7

KWH6/PH6

KWH5/P H5

GND

VDD

RESET

Figure 4. In-Circuit wiring diagram for MC68HC912D60/DG128, 112-PIN TQFP Package

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 17

PS5/SDO/MOSI

PS4/SDI/MISO

PS2/RxD1

PS0/RxD0

PS3/TxD1

PS1/TxD0

PIB6/SDA

PIB7/SCL

PP3/PW3

PK0/PIX0

PK1/PIX1

PK2/PIX2

PK7/ECS

PS6/SCK

RxCAN0

RxCAN1

TxCAN0

TxCAN1

PS7/SS

TEST

VDDX

VDDA

PIB4

PIB5

VSSX

VSSA

VRH1

VRL1

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

PW2/PP2 1 84 PAD17/AN17

PW1/PP1 2 83 PAD07/AN07

PW0/PP0 3 82 PAD16/AN16

IOC0/PT0 4 81 PAD06/AN06

IOC1/PT1 5 80 PAD15/AN15

IOC2/PT2 6 79 PAD05/AN05

IOC3/PT3 7 78 PAD14/AN14

KWJ7/PJ7 8 77 PAD04/AN04

KWJ6/PJ6 9 76 PAD13/AN13

KWJ5/PJ5 10 75 PAD03/AN03

KWJ4/PJ4 11 74 PAD12/AN12

VDD 12 73 PAD02/AN02

PK3

V SS

13

14

MC68HC912 D60A/DG128A 72

71

PAD11/AN11

PAD01/AN01

IOC4/PT4 15 112 LQFP 70 PAD10/AN10

IOC5/PT5 16 69 PAD00/AN00

IOC6/PT6 17 68 VRL0

IOC7/PT7 18 67 VRH0

KWJ3/PJ3 19 66 VSS

KWJ2/PJ2 20 65 VDD

KWJ1/PJ1 21 64 PA7/ADDR15/DATA15/DATA7

KWJ0/PJ0 22 63 PA6/ADDR14/DATA14/DATA6

BKGD SMODN/TAGHI/ BKGD 23 62 PA5/ADDR13/DATA13/DATA5

ADDR0/DATA0/PB0 24 61 PA4/ADDR12/DATA12/DATA4

ADDR1/DATA1/PB1 25 60 PA3/ADDR11/DATA11/DATA3

ADDR2/DATA2/PB2 26 59 PA2/ADDR10/DATA10/DATA2

ADDR3/DATA3/PB3 27 58 PA1/ADDR9/DATA9/DATA1

ADDR4/DATA4/PB4 28 57 PA0/ADDR8/DATA8/DATA0

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

KWH1/PH1

XIRQ /PE0

V DDPLL

V SSPLL

CGMTST/MODB/IPIPE1/PE6

EXTAL

KWH3/PH3

KWH0/PH0

LSTRB /TAGLO /PE3

R/W /PE2

IRQ /PE1

VSSX

ECLK /DBE/CAL/PE7

KWH2/PH2

RESET

VSTBY

V DDX

XFC

ADDR5/DATA5/PB5

ADDR6/DATA6/PB6

ADDR7/DATA7/PB7

KWH7/PH7

KWH5/PH5

KWH4/PH4

ECLK/PE4

XTAL

MODA/IPIPE0/PE5

KWH6/PH6

GND

VDD

RESET

Figure 5. In-Circuit wiring diagram for MC68HC912D60A/DG128A, 112-PIN LQFP Package

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 18

External +12V for FLASH Programming

PS5/SDO/MOSI

PCAN0/RxCAN

PCAN1/TxCAN

PS4/SDI/MISO

PS2/RxD1

PS0/RxD0

PS3/TxD1

PS1/TxD0

PP3/PW3

PS6/SCK

PS7/SS

VDDAD

VSSAD

VFP*

VDDX

VSSX

PP4

PP5

PP6

PP7

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60 PAD07/AN07

PW2/PP2 1

59 PAD06/AN06

PW1/PP1 2

58 PAD05/AN05

PW0/PP0 3

57 PAD04/AN04

IOC0/PT0 4

56 PAD03/AN03

IOC1/PT1 5

55 PAD02/AN02

IOC2/PT2 6

54 PAD01/AN01

IOC3/PT3 7

53 PAD00/AN00

KWG4/PG4 8

52 VRL0

VDD 9

MC68HC(9)12D60 51 VRH0

VSS 10

80 QFP 50 VSS

IOC4/PT4 11

49 VDD

IOC5/PT5 12

48 PA7/ADDR15/DATA15/DATA7

IOC6/PT6 13

47 PA6/ADDR14/DATA14/DATA6

IOC7/PT7 14

46 PA5/ADDR13/DATA13/DATA5

BKGD SMODN/TAGHI/BKGD 15

45 PA4/ADDR12/DATA12/DATA4

ADDR0/DATA0/PB0 16

44 PA3/ADDR11/DATA11/DATA3

ADDR1/DATA1/PB1 17

43 PA2/ADDR10/DATA10/DATA2

ADDR2/DATA2/PB2 18

42 PA1/ADDR9/DATA9/DATA1

ADDR3/DATA3/PB3 19

41 PA0/ADDR8/DATA8/DATA0

ADDR4/DATA4/PB4 20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

EXTAL

RESET

XTAL

ADDR6/DATA6/PB6

ADDR7/DATA7/PB7

VDDPLL

VSSPL L

XFC

R/W/PE2

ECLK/PE4

IRQ/PE1

XIRQ/PE0

ADDR5/DATA5/PB5

KWH4/PH4

MODA/IPIPE0/PE5

VSSX

VDDX

ECLK /DBE/CAL/PE7

CGMTST/MODB/IPIPE1/PE6

LSTRB/TAGLO/PE3

GND

VDD

RESET

Figure 6. In-Circuit wiring diagram for MC68HC(9)12D60, 80-PIN QFP Package

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 19

PS5/SDO/MOSI

PCAN0/RxCAN

PCAN1/TxCAN

PS4/SDI/MISO

PS2/RxD1

PS0/RxD0

PS3/TxD1

PS1/TxD0

PP3/PW3

PS6/SCK

PS7/SS

VDDAD

VSSAD

TEST

VDDX

VSSX

PP4

PP5

PP6

PP7

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60 PAD07/AN07

PW2/PP2 1

59 PAD06/AN06

PW1/PP1 2

58 PAD05/AN05

PW0/PP0 3

57 PAD04/AN04

IOC0/PT0 4

56 PAD03/AN03

IOC1/PT1 5

55 PAD02/AN02

IOC2/PT2 6

54 PAD01/AN01

IOC3/PT3 7

53 PAD00/AN00

KWG4/PG4 8

52 VRL0

VDD 9

MC68HC912D60A 51 VRH0

VSS 10

80 QFP 50 VSS

IOC4/PT4 11

49 VDD

IOC5/PT5 12

48 PA7/ADDR15/DATA15/DATA7

IOC6/PT6 13

47 PA6/ADDR14/DATA14/DATA6

IOC7/PT7 14

46 PA5/ADDR13/DATA13/DATA5

BKGD SMODN/TAGHI/BKGD 15

45 PA4/ADDR12/DATA12/DATA4

ADDR0/DATA0/PB0 16

44 PA3/ADDR11/DATA11/DATA3

ADDR1/DATA1/PB1 17

43 PA2/ADDR10/DATA10/DATA2

ADDR2/DATA2/PB2 18

42 PA1/ADDR9/DATA9/DATA1

ADDR3/DATA3/PB3 19

41 PA0/ADDR8/DATA8/DATA0

ADDR4/DATA4/PB4 20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

EXTAL

RESET

XTAL

ADDR6/DATA6/PB6

ADDR7/DATA7/PB7

IRQ/PE1

VDDPLL

VSSPLL

ADDR5/DATA5/PB5

R/W/PE2

XIRQ/PE0

ECLK/PE4

XFC

KWH4/PH4

MODA/IPIPE0/PE5

VSSX

VDDX

ECLK /DBE/CAL/PE7

CGMTST/MODB/IPIPE1/PE6

LSTRB /TAGLO/PE3

GND

VDD

RESET

Figure 7. In-Circuit wiring diagram for MC68HC912D60A, 80-PIN QFP Package

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 20

PJ6/KWJ6/RXCAN4/SDA/RXCAN0

PJ7/KWJ7/TXCAN4/SCL/TXCAN0

PM2/RXCAN1/RXCAN0/MISO0

PM4/RXCAN0/RXCAN4/MOSI0

PM5/TXCAN0/TXCAN4/SCK0

PM3/TXCAN1/TXCAN0/SS0

PM0/RXCAN0/RXB

PM1/TXCAN0/TXB

PP4/KWP4/PWM4

PP5/KWP5/PWM5

PP7/KWP7/PWM7

PS2//RXD1

PS0/RXD0

PS3/TXD1

PS1/TXD0

VREGEN

VDDX

VSSX

VSSA

VRL

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

SS1/PWM3/KWP3/PP3 1 60 VRH

SCK1/PWM2/KWP2/PP2 2 59 VDDA

MOSI1/PWM1/KWP1/PP1 3 58 PAD07/AN07/ETRIG0

MISO1/PWM0/KWP0/PP0 4 57 PAD06/AN06

IOC0/PT0 5 56 PAD05/AN05

IOC1/PT1 6 MC9S12 D64/DG64 55 PAD04/AN04

IOC2/PT2 7 MC9S12 DT128/DG128/DJ128/DB128 54 PAD03/AN03

IOC3/PT3 8 MC9S12 DT256/DG256/DJ256/DB256 53 PAD02/AN02

VDD1 9 52 PAD01/AN01

VSS1 10 51 PAD00/AN00

IOC4/PT4 11 50 VSS2

IOC5/PT5 12 80 QFP 49 VDD2

IOC6/PT6 13 48 PA7/ADDR15/DATA15

IOC7/PT7 14 47 PA6/ADDR14/DATA14

BKGD MODC/TAGHI/BKGD 15 46 PA5/ADDR13/DATA13

ADDR0/DATA0/PB0 16 45 PA4/ADDR12/DATA12

ADDR1/DATA1/PB1 17 44 PA3/ADDR11/DATA11

ADDR2/DATA2/PB2 18 43 PA2/ADDR10/DATA10

ADDR3/DATA3/PB3 19 42 PA1/ADDR9/DATA9

ADDR4/DATA4/PB4 20 41 PA0/ADDR8/DATA8

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

ADDR5/DATA5/PB5

ADDR6/DATA6/PB6

ADDR7/DATA7/PB7

EXTAL

XTAL

XCLKS/NOACC/PE7

VSSR

VDDR

XFC

MODA/IPIPE0/PE5

RESET

TEST

R/W/PE2

XIRQ/PE0

MODB/IPIPE1/PE6

ECLK/PE4

VDDPLL

VSSPLL

LSTRB/TAGLO/PE3

IRQ/PE1

GND

VDD

RESET

Figure 8. In-Circuit wiring diagram for MC9S12Dx64/Dx128/Dx256, 80-PIN QFP Package

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 21

PM4/BF_PSYN/RXCAN0/RXCAN4/MOSI0

PM5/BF_PROK/TXCAN0/TXCAN4/SCK0

PM2/RX_BF/RXCAN1/RXCAN0/MISO0

PM3/TX_BF/TXCAN1/TXCAN0/SS0

PJ6/KWJ6/RXCAN4/SDA/RXCAN0

PJ7/KWJ7/TXCAN4/SCL/TXCAN0

PM6/BF_PERR/RXCAN4

PM7/BF_PSLM/TXCAN4

PM0/RXCAN0/RXB

PK7/ECS/ROMCTL

PM1/TXCAN0/TXB

PP4/KWP4/PWM4

PP5/KPW5/PWM5

PP6/KWP6/PWM6

PP7/KWP7/PWM7

PS5/MOSI0

PS4/MISO0

PS2/RXD1

PS0/RXD0

PS6/SCK0

PS3/TXD1

PS1/TXD0

VREGEN

PS7/SS0

VDDX

VSSX

VSSA

VRL

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

SS1/PWM3/KWP3/PP3 1 84 VRH

SCK1/PWM2/KWP2/PP2 2 83 VDDA

MOSI1/PWM1/KWP1/PP1 3 82 PAD15/AN15/ETRIG1

MISO1/PWM0/KWP0/PP0 4 81 PAD07/AN07/ETRIG0

XADDR17/PK3 5 80 PAD14/AN14

XADDR16/PK2 6 79 PAD06/AN06

XADDR15/PK1

XADDR14/PK0

7

8

MC9S12 D64/DG64 78

77

PAD13/AN13

PAD05/AN05

IOC0/PT0 9 MC9S12 DT128/DG128/DJ128/DB128 76 PAD12/AN12

IOC1/PT1 10 75 PAD04/AN04

IOC2/PT2 11

MC9S12 DT256/DG256/DJ256/DB256 74 PAD11/AN11

IOC3/PT3 12 MC9S12 DP512 73 PAD03/AN03

VDD1 13 72 PAD10/AN10

VSS1 14 71 PAD02/AN02

IOC4/PT4 15 70 PAD09/AN09

IOC5/PT5 16 69 PAD01/AN01

IOC6/PT6 17 112LQFP 68 PAD08/AN08

IOC7/PT7 18 67 PAD00/AN00

XADDR19/PK5 19 66 VSS2

XADDR18/PK4 20 65 VDD2

KWJ1/PJ1 21 64 PA7/ADDR15/DATA15

KWJ0/PJ0 22 63 PA6/ADDR14/DATA14

BKGD MODC/TAGHI/BKGD 23 62 PA5/ADDR13/DATA13

ADDR0/DATA0/PB0 24 61 PA4/ADDR12/DATA12

ADDR1/DATA1/PB1 25 60 PA3/ADDR11/DATA11

ADDR2/DATA2/PB2 26 59 PA2/ADDR10/DATA10

ADDR3/DATA3/PB3 27 58 PA1/ADDR9/DATA9

ADDR4/DATA4/PB4 28 57 PA0/ADDR8/DATA8

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

ADDR5/DATA5/PB5

ADDR6/DATA6/PB6

ADDR7/DATA7/PB7

XCLKS/NOACC/PE7

EXTAL

XTAL

VSSR

VDDR

XFC

MODB/IPIPE1/PE6

VSSPLL

MODA/IPIPE0/PE5

ECLK/PE4

VDDPLL

LSTRB/TAGLO/PE3

R/W/PE2

IRQ/PE1

XIRQ/PE0

RESET

TEST

KWH7/PH7

KWH6/PH6

KWH5/PH5

KWH4/PH4

SS1/KWH3/PH3

SCK1/KWH2/PH2

MOSI1/KWH1/PH1

MISO1/KWH0/PH0

GND

RESET

VDD

Figure 9. In-Circuit wiring diagram for MC9S12Dx64/Dx128/Dx256, 112-PIN LQFP Package

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 22

PA7/ADDR15/D ATA15/FP15

PA6/ADDR14/D ATA14/FP14

PA5/ADDR13/D ATA13/FP13

PA4/ADDR12/D ATA12/FP12

PA3/ADDR11/D ATA11/FP11

PA2/ADDR10/D ATA10/FP10

PE7/NOACC/XCLKS/FP22

PE3/LSTRB/TAGLO/FP21

PK7/ECS/ROMONE/FP23

PA1/ADDR9/D ATA9/FP9

PA0/ADDR8/D ATA8/FP8

PB7/ADDR7/D ATA7/FP7

PB6/ADDR6/D ATA6/FP6

PT3/IOC3/FP27

PT2/IOC2/FP26

PT1/IOC1/FP25

PT0/IOC0/FP24

PE2/R/W/FP20

PT7/IOC7

PT6/IOC6

PT5/IOC5

PT4/IOC4

PL3/FP19

PL2/FP18

PL1/FP17

PL0/FP16

VDD X1

VSSX1

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

M0C0M/PU0 1 84 PB5/ADDR5/DATA5/FP5

M0C0P/PU1 2 83 PB4/ADDR4/DATA4/FP4

M0C1M/PU2 3 82 PB3/ADDR3/DATA3/FP3

M0C1P/PU3 4 81 PB2/ADDR2/DATA2/FP2

VDDM1 5 80 PB1/ADDR1/DATA1/FP1

VSSM1 6 79 PB0/ADDR0/DATA0/FP0

M1C0M/PU4 7 78 PK0/XADDR14/BP0

M1C0P/PU5 8 77 PK1/XADDR15/BP1

M1C1M/PU6 9 76 PK2/XADDR16/BP2

M1C1P/PU7 10 75 PK3/XADDR17/BP3

M2C0M/PV0 11 74 VLCD

M2C0P/PV1 12 73 VSS1

M2C1M/PV2 13 72 VDD1

M2C1P/PV3 14 MC9S12H-Family 71 PAD07/AN07

VDDM2 15 112 LQFP 70 PAD06/AN06

VSSM2 16 69 PAD05/AN05

M3C0M/PV4 17 68 PAD04/AN04

M3C0P/PV5 18 67 PAD03/AN03

M3C1M/PV6 19 66 PAD02/AN02

M3C1P/PV7 20 65 PAD01/AN01

M4C0M/PW0 21 64 PAD00/AN00

M4C0P/PW1 22 63 VDDA

M4C1M/PW2 23 62 VRH

M4C1P/PW3 24 61 VRL

VDDM3 25 60 VSSA

VSSM3 26 59 PE0/XIRQ

M5C0M/PW4 27 58 PE4/ECLK

M5C0P/PW5 28 57 PE6/IPIPE1/MODB

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

R ESET

TEST

M5C1P/PW7

TXD0/PS1

M5C1M/PW6

PWM0/PP0

PWM1/PP1

R XD0/PS0

VSS2

VDDX2

VSSX2

VSSPLL

VDDR

MODC/TAGHI/BKGD

VDDPLL

XFC

EXTAL

XTAL

MOSI/PS5

IRQ/PE1

RXCAN0/PM2

TXCAN0/PM3

RXCAN1/PM4

TXCAN1/PM5

MODA/IPIP0/PE5

MISO/PS4

SCK/PS6

SS/PS7

GND

VDD

RESET

BKGD

Figure 10. In-Circuit wiring diagram for MC9S12H-Family 112-PIN LQFP Package

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 23

PA7/ADDR15/DATA15/FP15

PA6/ADDR14/DATA14/FP14

PA5/ADDR13/DATA13/FP13

PA4/ADDR12/DATA12/FP12

PA3/ADDR11/DATA11/FP11

PA2/ADDR10/DATA10/FP10

PE7/NOACC/XCLKS/FP22

PK7/ECS/ROMONE/FP23

PE3/LSTRB/TAGLO/FP21

PA1/ADDR9/DATA9/FP9

PA0/ADDR8/DATA8/FP8

PB7/ADDR7/DATA7/FP7

PB6/ADDR6/DATA6/FP6

PT3/IOC3/FP27

PT2/IOC2/FP26

PT1/IOC1/FP25

PT0/IOC0/FP24

PE2/R/W/FP20

PJ 3/KWJ 3

PJ 2/KWJ 2

PJ 1/KWJ 1

PJ 0/KWJ 0

PT7/IOC7

PT6/IOC6

PT5/IOC5

PT4/IOC4

PL7/FP31

PL6/FP30

PL5/FP29

PL4/FP28

PL3/FP19

PL2/FP18

PL1/FP17

PL0/FP16

VDDX1

VSSX1

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

M0C0M/PU0 1 108 PB5/ADDR5/DATA5/FP5

M0C0P/PU1 2 107 PB4/ADDR4/DATA4/FP4

M0C1M/PU2 3 106 PB3/ADDR3/DATA3/FP3

M0C1P/PU3 4 105 PB2/ADDR2/DATA2/FP2

VDDM1 5 104 PB1/ADDR1/DATA1/FP1

VSSM1 6 103 PB0/ADDR0/DATA0/FP0

M1C0M/PU4 7 102 PK0/XADDR14/BP0

M1C0P/PU5 8 101 PK1/XADDR15/BP1

M1C1M/PU6 9 100 PK2/XADDR16/BP2

M1C1P/PU7 10 99 PK3/XADDR17/BP3

KWH0/PH0 11 98 VLCD

KWH1/PH1 12 97 VSS1

KWH2/PH2 13 96 VDD1

KWH3/PH3 14 95 PAD15/AN15

M2C0M/PV0 15 94 PAD07/AN07

M2C0P/PV1 16 93 PAD14/AN14

M2C1M/PV2 17 MC9S12H-Family 92 PAD06/AN06

M2C1P/PV3

VDDM2

18

19 144 LQFP 91

90

PAD13/AN13

PAD05/AN05

VSSM2 20 89 PAD12/AN12

M3C0M/PV4 21 88 PAD04/AN04

M3C0P/PV5 22 87 PAD11/AN11

M3C1M/PV6 23 86 PAD03/AN03

M3C1P/PV7 24 85 PAD10/AN10

KWH4/PH4 25 84 PAD02/AN02

KWH5/PH5 26 83 PAD09/AN09

KWH6/PH6 27 82 PAD01/AN01

KWH7/PH7 28 81 PAD08/AN08

M4C0M/PW0 29 80 PAD00/AN00

M4C0P/PW1 30 79 VDDA

M4C1M/PW2 31 78 VRH

M4C1P/PW3 32 77 VRL

VDDM3 33 76 VSSA

VSSM3 34 75 PE0/XIRQ

M5C0M/PW4 35 74 PE4/ECLK

M5C0P/PW5 36 73 PE6/IPIPE1/MODB

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

TEST

XTAL

M5C1M/PW6

M5C1P/PW7

VDDPLL

VSSPLL

EXTAL

SDA/PM0

SCL/PM1

PWM0/PP0

PWM1/PP1

PWM2/PP2

PWM3/PP3

PWM4/PP4

PWM5/PP5

RXD0/PS0

TXD0/PS1

RXD1/PS2

TXD1/PS3

VSS2

VDDX2

VSSX2

RXCAN0/PM2

TXCAN0/PM3

RXCAN1PM4

TXCAN1/PM5

MODA/IPIPE0/PE5

MISO/PS4

MOSI/PS5

SCK/PS6

SS/PS7

IRQ/PE1

MODC/TAGHI/BKGD

VDDR

XFC

RESET

GND

VDD

RESET

BKGD

Figure 11. In-Circuit wiring diagram for MC9S12H-Family 144-PIN LQFP Package

©ETL 2004-2006 MC68HC912/9S12 Programmer User’s Guide 24

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Chrysler Scan Tool Flash Availability - 09 March 2015Document589 pagesChrysler Scan Tool Flash Availability - 09 March 2015Roger SegoNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- DRB 3 Features Menus PDFDocument140 pagesDRB 3 Features Menus PDFRoger Sego100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Pinout TCMDocument3 pagesPinout TCMRoger SegoNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 01m Adaptation Basic SettingDocument4 pages01m Adaptation Basic SettingEmma MummyNo ratings yet

- BMW Power Systems Supply E87Document5 pagesBMW Power Systems Supply E87Roger SegoNo ratings yet

- BMW Power Systems Supply E87Document5 pagesBMW Power Systems Supply E87Roger SegoNo ratings yet

- Ecus Pin Out Elimentaciones de Emuladores PDFDocument8 pagesEcus Pin Out Elimentaciones de Emuladores PDFRoger SegoNo ratings yet

- Installation of Peugeot Planet System 2000: Insert The USB Interface-Cable Only Into The Computer After The InstallationDocument18 pagesInstallation of Peugeot Planet System 2000: Insert The USB Interface-Cable Only Into The Computer After The InstallationRoger SegoNo ratings yet

- MagnetiMarelli WorkshopEquipment 2014 PDFDocument66 pagesMagnetiMarelli WorkshopEquipment 2014 PDFRoger SegoNo ratings yet

- Diagrama 1 PDFDocument2 pagesDiagrama 1 PDFRoger SegoNo ratings yet

- Infineon TLE6209R DS v03 02 enDocument30 pagesInfineon TLE6209R DS v03 02 enRoger SegoNo ratings yet

- BSM Peugeot Can Bus PDFDocument5 pagesBSM Peugeot Can Bus PDFRoger SegoNo ratings yet

- File SafeDocument1 pageFile SafeRoger SegoNo ratings yet

- JARM - Extension Board Manual 16/12/2010Document17 pagesJARM - Extension Board Manual 16/12/2010செல்வம் முத்துராமன்No ratings yet

- Chapter 19 - FBs-4DA - 2DA Analog Output ModuleDocument10 pagesChapter 19 - FBs-4DA - 2DA Analog Output ModuleJoako FilipovichNo ratings yet

- Desktop Management With JP1-10finalDocument39 pagesDesktop Management With JP1-10finalThanakom SiriwatanapakornNo ratings yet

- Operators Manual: Doc #P10226 Rev 1.8Document32 pagesOperators Manual: Doc #P10226 Rev 1.8Christopher DaMatta BarbosaNo ratings yet

- PD78 Series Microcontroller EEPROM Programmer User's Guide: Engineering Technical LaboratoryDocument14 pagesPD78 Series Microcontroller EEPROM Programmer User's Guide: Engineering Technical LaboratoryUbaldo BritoNo ratings yet

- Installation Manual MARINE RADAR FR-8062/8122/8252Document56 pagesInstallation Manual MARINE RADAR FR-8062/8122/8252Douglas LimaNo ratings yet

- Holes : Model Brand Name Cable Learning Processor IR RM KM Signature Year JP1 ConnectorDocument9 pagesHoles : Model Brand Name Cable Learning Processor IR RM KM Signature Year JP1 Connectormokracipa69100% (1)

- PD78 Series Microcontroller EEPROM Programmer User's Guide: Engineering Technical LaboratoryDocument14 pagesPD78 Series Microcontroller EEPROM Programmer User's Guide: Engineering Technical LaboratoryDaniel Norberto DemariaNo ratings yet

- MC68HC912/9S12 FLASH/EEPROM Programmer User's Guide: Engineering Technical LaboratoryDocument24 pagesMC68HC912/9S12 FLASH/EEPROM Programmer User's Guide: Engineering Technical LaboratoryRoger SegoNo ratings yet

- 8062 InstDocument52 pages8062 InstСергей ЗNo ratings yet

- Manual Programming - 9xx Commands - JP1 RemotesDocument11 pagesManual Programming - 9xx Commands - JP1 RemotesGermán BlandoNo ratings yet

- LayadCircuits Saleng GSM v1 1 PDFDocument15 pagesLayadCircuits Saleng GSM v1 1 PDFEdward Amoyen AbellaNo ratings yet

- 2.4 Control UnitDocument4 pages2.4 Control UnitPhuocTranThienNo ratings yet

- Building A Serial Interface For JP1.2 and JP1.3Document2 pagesBuilding A Serial Interface For JP1.2 and JP1.3Yo YoNo ratings yet

- ProntoDocument6 pagesProntomatti-xNo ratings yet