Professional Documents

Culture Documents

DD1M HighwayLiveLoadsonConcretePipe

DD1M HighwayLiveLoadsonConcretePipe

Uploaded by

oz_1990Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DD1M HighwayLiveLoadsonConcretePipe

DD1M HighwayLiveLoadsonConcretePipe

Uploaded by

oz_1990Copyright:

Available Formats

Design Data 1M

Highway Live Loads on Concrete Pipe

Foreword transmitted through the pavement to the buried concrete

Thick, high-strength pavements designed for heavy pipe is usually negligible at any depth. If any culvert

truck traffic substantially reduce the pressure transmitted or sewer pipe is within the heavy duty traffic highway

through a wheel to the subgrade and consequently, to right-of-way, but not under the pavement structure, then

the underlying concrete pipe. The pressure reduction is such pipe should be analyzed for the effect of live load

so great that generally the live load can be neglected. transmission from an unsurfaced roadway, because of

In 1926, Westergaard presented a paper summarizing the possibility of trucks leaving the pavement.

the results of an extensive study of the effects of loading

conditions, subgrade support, and boundary conditions Dead Loads

on concrete pavements (1). These results formed the Various methods for analyzing soil dead loads, which

basis by which Westergaard developed a method to have been developed over the years, are presented in

calculate the stresses in concrete slabs. Based upon the the ACPA “Concrete Pipe Technology Handbook” (7) and

work of Westergaard and others, the Portland Cement the OCPA “Concrete Pipe Design Manual” (5).

Association (PCA), developed a method to determine

the vertical pressure on buried pipe due to wheel loads Surcharge Loads

applied to concrete pavements (2). The PCA method is A common type of surcharge load is additional soil

presented in the American Concrete Pipe Association, fill placed after the pipe has been installed for a period

ACPA, “Concrete Pipe Handbook” (3), “Concrete Pipe of time. If the surcharge load is a building or other

Design Manual” (4) and the Ontario Concrete Pipe surface load, the resultant uniformly distributed load

Association, OCPA, “Concrete Pipe Design Manual” (5). can be converted to an equivalent height of fill, and then

Intermediate and thin thicknesses of asphalt or evaluated as an additional soil load. When concrete pipe

flexible pavements do not reduce the pressure transmitted has been installed underground, the soil-structure system

from a wheel to the pavement subgrade to any significant will continually show an increase in load capacity. Data

degree. For these pavements, there is no generally on concrete pipe, which have been removed from service

accepted theory for estimating load distribution effects, and tested, indicate an increase in concrete strength

and, therefore, these pavements should be considered and an increase in load carrying capacity of 10 to 40

as unsurfaced roadways. percent. Settlement and consolidation will improve the

This Design Data addresses the method of soil structure surrounding the pipe, which also improves

determining the live load pressure transmitted through load carrying capacity.

unsurfaced roadways to circular and elliptical concrete

pipe in accordance with the criteria of the Canadian Live Loads

Highway Bridge Design Code, CHBDC (6). The CHBDC design loads are the CL-W Truck and

CL-625 ONT Truck (Figure 2). The average pressure

Introduction intensity caused by a wheel load is calculated by

To determine the required supporting strength of Equation 2.

concrete pipe installed under intermediate and thin The CL-W Truck and CL-625 ONT Truck design

thickness of asphalt or flexible pavements, or relatively axles are carried on dual wheels (Figure 1). The contact

shallow earth cover, it is necessary to evaluate the effect area of the dual wheels with the ground is assumed to

of live loads, such as highway truck loads, in addition to be a rectangle (Figure 1), with dimensions presented in

dead loads imposed by the soil and surcharge loads. Table 1.

Live Loads

If a rigid pavement or a thick flexible pavement

designed for heavy duty traffic is provided with a sufficient Area 1 Wheel Surface Contact Area

buffer between the pipe and pavement, then the live load

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 1

© 2012 American Concrete Pipe Association, all rights reserved. DD 1M (11/12)

maximum pressure will be developed by the fourth axle

Figure 1 CHBDC Wheel Load Surfaces wheels of two trucks in the passing mode, since at 87.5kN

Contact Area (Foot Print) each, these two wheels apply a greater load, 175kN,

than any other two wheels in passing mode (Figures 2

Wheel Load and 4). At greater depths, the maximum pressure will

be developed by wheels of axles 2 and 3 in the passing

mode, since at 62.5kN or 70kN each, the four wheels

apply the greatest load (250kN or 280kN) (Figures 2

and 5). Intermediate depths occur when the spread

area a of dual wheels of two trucks in the passing mode

overlap. Greater depths occur when the spread area b

of two single dual wheels of axles 2 and 3 in the passing

mode overlap.

Since the exact geometric relationship of individual

or combinations of surface wheel loads cannot be

0.25m b

anticipated, the most critical loading configurations along

a with axle loads and rectangular spread load area are

presented in Tables 2 and 3 for the two CHBDC design

0.60m

trucks.

Table

a(width),

1 Wheel

m Surface Contact

b(length),

Area

m DESIGN METHOD

0.60 0.25 The design method encompasses 4 steps.

1. Obtain the following project data:

IMPACT FACTORS Pipe shape, size and wall thickness.

The CHBDC applies a dynamic load allowance to Height of cover over the concrete pipe.

account for the truck load being non-static. The dynamic Design load criteria.

load allowance, IM, is determined by Equation 1: 2. Calculate the average pressure intensity of the

wheel loads on the soil plane on the outside top

IM = 0.40 (1.0 - 0.5 DE) ≥ 0.10 [1] of the pipe.

where: DE = height of earth cover over the top of the 3. Calculate the total live load acting on the pipe.

pipe, m. 4. Calculate the total live load acting on the pipe in

kN/m.

LOAD DISTRIBUTION

The surface load is assumed to be uniformly spread Project Data

on any horizontal subsoil plane. The spread load area Pipe shape and internal dimensions are shown on

is developed by increasing the length and width of the the project plans. Complete information on dimensional

wheel contact area for a load configuration as illustrated details are included in CAN/CSA-A257.1 for nonreinforced

in Figure 3 for a dual wheel; in Figure 4 for dual wheels of circular concrete pipe, CSA-A257.2 for reinforced concrete

two trucks in passing mode; and in Figure 5 for two dual circular pipe and ASTM C 507M for reinforced concrete

wheels of axles 2 and 3 in passing mode. On a horizontal elliptical pipe (8). Internal size, wall thickness and outside

soil plane, the dimensional increases to the wheel contact dimensions are presented in Tables 6 and 7 for circular

area are based on height of earth cover over the top of the and elliptical pipe.

pipe. The dimensional increase factor is 1.75H for depths The minimum earth cover over the concrete pipe can

of cover greater than 0.6 meters. CHBDC states that be obtained from the project plans.

for depths of cover less than 0.6 meters, “no distribution A decision regarding whether the CHBDC or other

beyond the footprints of the wheels shall be considered”. criteria will be used should be obtained from the project

As indicated by Figures 3, 4 and 5, the spread load authority.

areas from adjacent wheels will overlap as the height of

earth cover over the top of the pipe increases. At less

than 0.6 meters of cover, the maximum pressure will be

developed by the fourth axle dual wheel, since at 87.5kN

it applies a greater load than any other wheel (Figures 2 Average Pressure Intensity

and 3), and no dimensional increase is allowed beyond The wheel load average pressure intensity on the

the footprint of the wheel. At intermediate depths, the subsoil plane at the outside top of the concrete pipe is:

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 2

© 2012 American Concrete Pipe Association, all rights reserved. DD 1M (11/12)

Figure 2 CHBDC Wheel Loads and Wheel Spacings

CL-W TRUCK

1 2 3 4 5 Axle No.

0.04W 0.1W 0.1W 0.14W 0.12W Wheel Loads

CL-W [ 0.08W 0.2W 0.28W 0.24W Axle Loads

0.2W

25 62.5 62.5 87.5 75 Wheel Loads, kN

CL-625 [

50 125 125 175 150 Axle Loads, kN

3.6m 6.6m 6.6m

1.2m

18m

.025m

(TYP.)

2.40m 1.80m

.025m .025m

(TYP.) (TYP.)

0.60M

(TYP.)

CL-625-ONT TRUCK

1 2 3 4 5 Axle No.

25 70 70 87.5 60 Wheel Loads, kN

CL-625- NT [ 50 140 140 175 120 Axle Loads, kN

3.6m 6.6m 6.6m

1.2m

18m

C

3.00m

Curb

0.6m 1.8m 0.6m

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 3

© 2012 American Concrete Pipe Association, all rights reserved. DD 1M (11/12)

Figure 3 Spread Load Area - Single Dual Wheel

Dir

a ec b

tio

no

f T

rav

el

Wheel Load Area

H Spread Load Area

ada

Spre

Sp

rea

db

Figure 4 Spread Load Area - Two Single Dual Wheels of Trucks in Passing Mode

Wheel Load Areas

b

a

mD

1.2 ire

ctio

no

Wheel fT

Load Areas rav

a el

a

read

Sp

Sp Distributed Load Area

rea

db

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 4

© 2012 American Concrete Pipe Association, all rights reserved. DD 1M (11/12)

Figure 5 Spread Load Area - Two Single Dual Wheels of Axles 2 & 3 in Passing Mode

Wheel Load Areas

b 1.2

m

a

m b

1.2 Dire

c tio

no

Wheel fT

Load Areas rav

a el

a

read

Sp

Sp

rea

db

Distributed Load Area

Table

Table2 2 CL-W

CL-WCritical Values

Critical Values

H, meters P, kN Spread a, meters Spread b, meters Figure

H < 0.60 87.5 a b 3

0.60 ≤ H < 1.46 175 a + 1.20 + 1.75H b + 1.75H 4

1.46 ≤ H 250 a + 1.20 + 1.75H b + 1.20 + 1.75H 5

Table 3 5CL-625-ONT.

Figure Critical

Spread Load AreaValues

- Two Single Dual Wheels of Axles 2 & 3 in Passing Mode

H, meters P, kN Spread a, meters Spread b, meters Figure

H < 0.60 87.5 a b 3

0.60 ≤ H < 1.00 175 a + 1.20 + 1.75H b + 1.75H 4

1.00 ≤ H 280 a + 1.20 + 1.75H b + 1.20 + 1.75H 5

w = P(1 + IM) / A [2]

where: w = wheel load average pressure intensity,

kN/m2 From the appropriate Table 2 or 3, select the critical

P = total live wheel load applied at the wheel load and spread dimensions for the height of earth

surface, kN cover over the outside top of the pipe, H. The spread

A = spread wheel load area at the outside top live load area is equal to Spread a times Spread b. Select

of the pipe, m2 the appropriate dynamic load allowance, using Equation 1.

IM = dynamic load allowance

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 5

© 2012 American Concrete Pipe Association, all rights reserved. DD 1M (11/12)

Total Live Load WT = w L SL [3]

A designer is concerned with the maximum possible

loads, which occur when the distributed load area where: WT=total live load, kN

is centered over the buried pipe. Depending on the w=wheel load average pressure intensity, kN/m2 (at

pipe size and height of cover, the most critical loading the top of the pipe)

orientation can occur either when the truck travels L=dimension of A parallel to the longitudinal axis of

transverse or parallel to the centerline of the pipe. pipe, meters

Figure 6 illustrates the dimensions of the spread load SL=outside horizontal span of pipe, Bc, or dimension

area, A, as related to whether the truck travel is transverse of A transverse to the longitudinal

or parallel to the centerline of the pipe. axis of pipe, whichever is less, meters

Total Live Load in kN per Linear Meter

Figure 6 Spread Load Area Dimensions vs The total live load in kN per linear meter, WL, is

Direction of Truck calculated by dividing the Total Live Load, WT, by the

Effective Supporting Length, Le(See Figure 7), of the pipe:

Spread b

WL = WT / Le [4]

where: WL=live load on top of pipe, kN per linear meter

Direction of Travel

Le=effective supporting length of pipe (see Figure

7), meters

Spread b

Direction of Travel

The effective supporting length of pipe is:

Le = L + 1.75(3/4Ro) [5]

where: =outside vertical Rise of pipe, meters

Ro

Spread a

Spread a

Pipe

Pipe EXAMPLES

Centerline Four Example calculations are presented on the

following pages to illustrate the four steps of the Design

Method, and the effect of varying the depth of fill and

Unless you are certain of the pipeline orientation, the design truck. The live loads per linear meter calculated

total live load in pounds, WT, must be calculated for each in the four Examples are summarized in Table 4.

travel orientation, and the maximum calculated value

must be used in Equation 4 to calculate the live load on Table 4 Summary of Examples

the pipe in kN per meter.

Figure 7 Effective Supporting Length of Pipe

The total live load acting on the pipe is:

Wheel Surface Contact Area

H L

3R0

4 R0 Pipe Centerline

Le = L + 1.75(3/4R0)

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 6

© 2012 American Concrete Pipe Association, all rights reserved. DD 1M (11/12)

WT = 764x0.60x0.25 = 114.6 kN

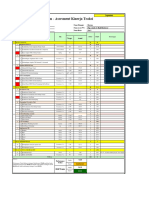

Table 4 Summary of Examples

Truck D,mm H, m P, kN Live Load, kN/m Assuming truck travel parallel to pipe centerline.

CL-W 750 0.45 87.5 74.85

Spread a=0.6 meters

CL-W 750 0.605 175 40.3 L=Spread b = 0.25 meters

CL-W 750 1.5 250 11.6 Bc=0.976m, which is greater than

Spread a, therefore

CL-625-ONT 750 1.5 280 12.93 SL=0.6 meters

EXAMPLE 1 WT = 764 x0.25 x 0.60 = 114.6 kN

Given: A 750mm diameter, C wall, concrete pipe is to

be installed as a storm drain under a flexible WT Maximum = 114.6 kN; and the truck is travelling

pavement and subjected to CHBDC highway parallel to the pipe centerline, as this gives the

loading. The pipe will be installed in a trench shortest length for the supporting length calculation.

with a minimum of 0.45m of cover over the top

of the pipe. 4. Calculate live load on pipe in kN per linear meter.

Find: The maximum live load on the pipe in kN/m

Solution: Ro=0.976m

1. Review project data.

Le=L + 1.75(3/4Ro)

A 750mm diameter, C wall, circular concrete pipe has Le=0.25 + 1.75(0.75x0.976) = 1.531 m

an I.D. of 762mm and a wall thickness of 107mm,

therefore Bc is 0.976m and Ro is 0.976m. Height of WL=WL/Le

earth cover is 0.45m. Use CHBDC CL-W loading. WL=114.6/1.531 = 74.85 kN per linear meter

2. Calculate average pressure intensity of the live load EXAMPLE 2

on the plane at the outside top of the pipe. Given: Same as Example 1, except minimum depth of

cover is 0.605m.

From Table 3, the critical load, P, is 87.5 kN and the

Spread Area is: Find: The maximum live load on the pipe in kN/m.

A=(Spread a)(Spread b) Solution:

A=(.25)(0.6) 1. Review project data.

A=0.15 m2

A 750mm diameter, C wall, circular concrete pipe has

I.M.=0.40(1.0 - 0.5H) an I.D. of 762mm and a wall thickness of 107mm,

I.M.=0.31 therefore Bc is 0.976m and Ro is 0.976m. Height of

w=P(1 + IM)/A earth cover is 0.605m. Use CHBDC CL-W loading.

w=87.5(1 + 0.31)/0.15

w=764 kN/m2 2. Calculate average pressure intensity on the plane at

the top of the pipe.

3. Calculate total live load acting on the pipe.

From Table 4, the critical load, P, is 175kN from axle 4

WT = w L SL single dual wheels in passing mode, and the Spread

Area is:

Assuming truck travel transverse to pipe centerline.

A = (Spread a)(Spread b)

L=Spread a = 0.6 meters A = (0.60 + 1.2 + 1.75x0.605)(0.25 + 1.75x0.605)

Spread b=0.25 meters A = (2.859)(1.309)

Bc=0.976m, which is greater than A = 3.74 m2

Spread b, therefore

SL=0.25 meters I.M. = 0.40(1.0 - 0.5H)

I.M. = 0. 279

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 7

© 2012 American Concrete Pipe Association, all rights reserved. DD 1M (11/12)

w = P(1 + IM)/A earth cover is 1. 5m. Use CHBDC CL-W loading.

w = 175(1 + 0.279)/3.74

w = 59.8 kN/m2 2. Calculate average pressure intensity at the outside

top of the pipe.

3. Calculate total live load acting on the pipe.

From Table 3, the critical load, P, is 250 kN two single

WT = w L SL dual wheels of axles 2 & 3 in the passing mode, and

the Spread Area is:

Assuming truck travel transverse to pipe centerline.

A = (Spread a)(Spread b)

L=Spread a = 2.859 meters A = (0.6 + 1.2 + 1.75x1.5)(0.25 + 1.2 + 1.75x1.5)

Spread b=1.309 meters A = (4.425)(4.075)

Bc=0.976 meters, which is less than A = 18.0 m2

Spread b, therefore

SL=0.976 meters I.M. = 0.40(1.0 - 0.5H)

WT=59.8 x 2.859 x 0.976 = 166.9 kN I.M. = 0. 10

w = P(1 + IM)/A

Assuming truck travel parallel to pipe centerline. w = 250(1 + 0.10)/18

w = 15.3 kN/m2

Spread a=2.859 meters

L=Spread b = 1.309 meters 3. Calculate total live load acting on the pipe.

Bc=0.976 meters, which is less than

Spread a, therefore WT = w L SL

SL=0.976 meters

Assuming truck travel transverse to pipe centerline.

WT = 59.8 x 0.976 x 1.309 = 76.4 kN

L=Spread a = 4.425 meters

WT Maximum = 166.9kN; and truck travel is transverse Spread b=4.075 meters

to pipe centerline Bc=0.976 meters, which is less than Spread b,

therefore

4. Calculate live load on pipe in kN per linear meter. SL=0.976 meters

Ro=0.976 meters WT=15.3 x 4.425 x 0.976 = 66.1 kN

Le=L + 1.75(3/4Ro) Assuming truck travel parallel to pipe centerline.

Le=2.859 + 1.75(.75x0.976) = 4.14 meters

Spread a=4.425 meters

WL=WT/Le L=Spread b = 4.075 meters

WL=166.9/4.14 = 40.3 kN per linear meter Bc=0.976 meters, which is less than Spread a,

therefore

EXAMPLE 3 SL=0.976 meters

Given: Same as Example 1, except minimum depth of

fill is 1.5 meters. WT = 15.3 x 0.976 x 4.075 = 60.85 kN

Find: The maximum live load on the pipe in kN per

linear meter. WT Maximum=66.1 kN; and truck travel is transverse to

pipe centerline

Solution:

4. Calculate live load on pipe in kN per linear meter.

1. Review project data.

Ro=0.976 meters

A 750mm diameter, C wall, circular concrete pipe has

an I.D. of 762mm and a wall thickness of 107mm, Le=L + 1.75(3/4Ro)

therefore Bc is 0.976m and Ro is 0.976m. Height of Le=4.425 + 1.75(0.75x0.976) = 5.71 meters

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 8

© 2012 American Concrete Pipe Association, all rights reserved. DD 1M (11/12)

WL=WT/Le Spread a=4.425 meters

WL=66.1/5.71 = 11.6 kN per linear meter L=Spread b = 4.075 meters

Bc=0.976 meters, which is less than Spread a,

EXAMPLE 4 therefore

Given: Same as Example 3, except design load is SL=0.976 meters

CHBDC CL-625-ONT Truck.

WT = 17.1 x 0.976 x 4.075 = 68 kN

Find: The maximum live load on the pipe in kN per

linear meter.

WT Maximum = 73.85 kN; and truck travel is transverse

Solution: to pipe centerline

1. Review project data. 4. Calculate live load on pipe in kN per linear meters.

A 750mm diameter, C wall, circular concrete pipe has Ro=0.976 meters

an I.D. of 762mm and a wall thickness of 107mm,

therefore Bc is 0.976m and Ro is 0.976m. Height Le=L + 1.75(3/4Ro)

of earth cover is 1.5m. Use CHBDC CL-625-ONT Le=4.425 + 1.75(0.75x0.976) = 5.71 meter

loading.

WL=WT/Le

2. Calculate average pressure intensity at the outside WL=73.85/5.71 = 12.93 kN per linear meter

top of the pipe.

From Table 3, the critical load, P, is 280 kN two single

dual wheels of axles 2 & 3 in the passing mode, and

the Spread Area is:

A = (Spread a)(Spread b)

A = (0.6 + 1.2 + 1.75x1.5)(0.25 + 1.2 + 1.75x1.5)

A = (4.425)(4.075)

A = 18.0 m2

I.M. = 0.40(1.0 - 0.5H)

I.M. = 0. 10

w = P(1 + IM)/A

w = 280(1 + 0.10)/18

w = 17.1 kN/m2

3. Calculate total live load acting on the pipe.

WT = w L SL

Assuming truck travel transverse to pipe centerline.

L=Spread a = 4.425 meters

Spread b=4.075 meters

Bc=0.976 meters, which is less than Spread b,

therefore

SL=0.976 meters

WT = 17.1 x 4.425 x 0.976 = 73.85 kN

Assuming truck travel parallel to pipe centerline.

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 9

© 2012 American Concrete Pipe Association, all rights reserved. DD 1M (11/12)

Table 6 Dimensions of Circular Concrete Table 7 Dimensions of Elliptical

Pipe Concrete Pipe

Equivalent Minor Major Minimum Wall

Wall A Wall B Wall C Round Size, Axis, Axis, Thickness,

Designated Actual Minimal Minimal Minimal mm mm mm mm

Internal Internal Wall Wall Wall

Diameter, Diameter, Thickness, Thickness, Thickness, 450 365 575 69

mm mm mm mm mm

600 490 770 82

300 350 44 50 69 675 550 865 88

375 381 47 57 75 750 610 960 94

450 457 50 63 82 825 670 1067 94

525 533 57 69 88 900 730 1150 113

600 610 63 75 94 975 795 1250 119

675 686 66 82 100

1050 855 1345 125

750 762 69 88 107

825 838 72 94 113 1200 975 1535 138

900 914 75 100 119 1350 1095 1730 150

1050 1067 88 117 132 1500 1220 1920 163

1200 1219 100 125 144 1650 1340 2210 175

1350 1372 113 138 157 1800 1465 2305 188

1500 1524 125 150 169 1950 1585 2495 200

1650 1676 138 163 182 2100 1705 2690 213

1800 1829 150 175 194 2250 1830 2880 225

1950 1981 163 188 207 2400 1950 3070 238

2100 2134 175 200 219 2550 2075 3265 244

2250 2286 188 213 232

2700 2195 3455 250

2400 2438 200 225 244

2550 2591 213 238 257 2850 2315 3648 263

2700 2743 225 250 269 3000 2440 3840 275

3000 3048 - 279 298 3300 2680 4225 300

3600 3658 - 330 349 3600 2925 4610 325

1. Westergaard, H.M., “Stresses in Concrete Pavements Computed by Theoretical Analysis”, Public Roads, April,

1926.

2. “Vertical Pressure on Culverts Under Wheel Loads on Concrete Pavement Slabs”, Portland Cement

Association, 1944.

3. “Concrete Pipe Handbook”, American Concrete Pipe Association, 1998.

4. “Concrete Pipe Design Manual”, American Concrete Pipe Association, 2000.

5. “Concrete Pipe Design Manual”, Ontario Concrete Pipe Association, 1997.

6. “Canadian Highway Bridge Design Code”, CAN/CSA-S6-00, CAS International-2000.

7. “Concrete Pipe Technology Handbook”, American Concrete Pipe Association, 1993.

8. ASTM Standard C 507M, “Specification for Reinforced Concrete Elliptical Culvert, Storm Drain, and Sewer

Pipe”, American Society for Testing and Materials.

American Concrete Pipe Association • www.concrete-pipe.org • info@concrete-pipe.org 10

© 2012 American Concrete Pipe Association, all rights reserved. DD 1M (11/12)

Technical data herein is considered reliable, but no guarantee is made or liability assumed.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bridgestone Truck Tire DataBookDocument122 pagesBridgestone Truck Tire DataBookRosario QuispeNo ratings yet

- AC Electric Tow Tractor: Standard FeaturesDocument2 pagesAC Electric Tow Tractor: Standard FeaturesYakupovmmNo ratings yet

- Mendoza, Michael - Deed of Sale of Motor VehicleDocument2 pagesMendoza, Michael - Deed of Sale of Motor VehicleRL AVNo ratings yet

- GPS-GSM Integration For Enhancing Public Transportation Management ServicesDocument15 pagesGPS-GSM Integration For Enhancing Public Transportation Management ServicesSekhar ReddyNo ratings yet

- MDMW Copper02Document3 pagesMDMW Copper02miningnovaNo ratings yet

- LTPP Ims User Guide 2019 v8Document216 pagesLTPP Ims User Guide 2019 v8ALEJANDRO ESTEBAN VARGASNo ratings yet

- GMN Summary Report 2017Document7 pagesGMN Summary Report 2017JCANo ratings yet

- Lec 03-1 - Directional StabilityDocument22 pagesLec 03-1 - Directional StabilityArslan MehmoodNo ratings yet

- Customised Drive Solutions For All Applications: Product Range of The VEM GroupDocument16 pagesCustomised Drive Solutions For All Applications: Product Range of The VEM Groupthiyagarajan vNo ratings yet

- Ayesha Tariq x3 PDFDocument3 pagesAyesha Tariq x3 PDFYousufNo ratings yet

- Goverdhanjee Parikrama - Nov 06 - 2010Document4 pagesGoverdhanjee Parikrama - Nov 06 - 2010prapnnachariNo ratings yet

- GSCM-18-Global Manufacturing and Materials ManagementDocument20 pagesGSCM-18-Global Manufacturing and Materials Managementabdul rehmanNo ratings yet

- Our Technology Background Framo Cargo Pumping SystemDocument199 pagesOur Technology Background Framo Cargo Pumping SystemSorescu Radu VasileNo ratings yet

- SEOT JSA For Vehicle EntryDocument3 pagesSEOT JSA For Vehicle EntryArchana SoorajNo ratings yet

- Cantilever Cataloagh Final 06 Sep 2017 Low Size PDFDocument52 pagesCantilever Cataloagh Final 06 Sep 2017 Low Size PDFVIVEK KUMAR100% (1)

- Stockholm City PlanDocument172 pagesStockholm City PlanVNo ratings yet

- Industry and Company ProfileDocument12 pagesIndustry and Company ProfileArpit KulshreshthaNo ratings yet

- Yamaha Tracer GT Owner's ManualDocument130 pagesYamaha Tracer GT Owner's ManualKenny YipNo ratings yet

- Muslim Bagh - WikipediaDocument12 pagesMuslim Bagh - WikipediaSanwal'S PoetryNo ratings yet

- International Civil Aviation Organization (ICAO)Document25 pagesInternational Civil Aviation Organization (ICAO)Anonymous abx5ZiifyNo ratings yet

- Ee2355 Dem1Document142 pagesEe2355 Dem1VXFVYNo ratings yet

- Highway - Chapter 2Document63 pagesHighway - Chapter 2Jandel kier TriaNo ratings yet

- FAQ Rim and Tyre Resizing For FB and EK HoldensDocument5 pagesFAQ Rim and Tyre Resizing For FB and EK HoldensKevin HuttonNo ratings yet

- Motorists Guide To Fighting Traffic TicketsDocument79 pagesMotorists Guide To Fighting Traffic TicketsGerardo TC0% (1)

- 2a. Performance Traksi CKMT September 2023Document109 pages2a. Performance Traksi CKMT September 2023yadiky12No ratings yet

- Bridge RuleDocument109 pagesBridge RuleArth PatelNo ratings yet

- Application No.: LLR Fresh AcknowledgementDocument1 pageApplication No.: LLR Fresh Acknowledgementakhil SrinadhuNo ratings yet

- AssignmentPGPM 33Document15 pagesAssignmentPGPM 33Santosh Thakur100% (1)

- Pre Trip InspectionDocument5 pagesPre Trip InspectionOscar TrujilloNo ratings yet