Professional Documents

Culture Documents

Red Cement Layer For Cable Laying

Uploaded by

Pradeep Gouda0 ratings0% found this document useful (0 votes)

17 views2 pagesOriginal Title

Red cement layer for Cable laying

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views2 pagesRed Cement Layer For Cable Laying

Uploaded by

Pradeep GoudaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

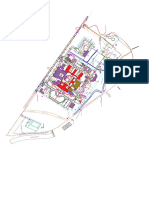

Project Seabird Phase IIA

Tender Document: Design and Construction of

Residential Buildings/Towers and Townships Along with

Related Common Facilities, Trunk Infrastructure and

Utilities Through Design Build Works Contract (DB-03)

surrounded by standing ground water for most of its functional life.

The marker posts shall be pre-cast concrete not less than C30 grade

with a mix ratio in the range 1:2:3 (Cement-Sand-Fine/Medium

Aggregate). When utilized, 6mm 43A grade steel reinforcing rods shall

be incorporated into the casting where a minimum of 10mm coverage of

concrete shall be applied around all faces.

For the fixing of the relevant marker plate (not supplied with the marker

post); 4 x 16mm diameter holes shall be drilled or precast into marker

post. The proposed location of the fixing holes, details of approximate

physical size of the route markers are to be provided by contractor.

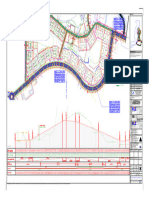

7C512.19 Cable Laying In Ducts Broad Guide Lines

Contractor shall design the duct system and obtain approval of

Engineer for the procedure to be followed for duct laying. Below are

given the broad guide lines for the same.

General Requirement for HV and LV Cable Laying

(a) Armoured Cables shall be laid in Ducts and relevant Indian / IEC

standards shall be followed for the same. In case there is any

conflict in the requirements given below the stringent clauses as

per decision of Engineer shall apply.

(b) Minimum depth below finished ground level shall be 600 mm

measured from the top of duct.

(c) Only one cable shall be laid in one duct.

(d) Outer Duct surface shall have minimum 300 mm clearance from

normal pipes of other services which shall be increased to 600

mm for very large pipelines or high pressure pipes.

(e) Minimum spacing of 75mm shall be kept between two ducts both

horizontally as well as vertically when a number of ducts are

installed. From the trench wall it shall be 100mm.

(f) The bottom bedding shall be 50mm minimum of the surround

material.

(g) HV ducts can be encased in concrete and for LT ducts unless

these are on the same route can be buried in ground as explained

below.

(h) Duct surround material thermal resistivity shall be maximum

1.0km/watt at zero percent moisture content. Only unwashed sand

graded to BS 882 or equivalent Indian Standard shall be used.

TD No. DGSB/DB-03/01 of 2018 Page 314 of 514

Project Seabird Phase IIA

Tender Document: Design and Construction of

Residential Buildings/Towers and Townships Along with

Related Common Facilities, Trunk Infrastructure and

Utilities Through Design Build Works Contract (DB-03)

This material must be compacted well around the ducts.

(i) When the ducts are laid the surround sand shall cover up to 75

mm of top of duct. After this sand cover of 75mm, a marker of

width covering the ducts below shall be placed. Then on top of this

marker backfill of Red Cement bound granular Mixture [15N after

7 days] shall be filled up to 225 mm. On it Warning tape of about

250mm shall be placed. After that the same granular mixture shall

be placed so that the marker is about 300mm below the finished

surface.

(j) Mandrel shall be passed through each duct before concreting or

covering so as to ensure that cable will not be damaged during

pulling due to incorrect duct joints. Then a 5 meter sample of

same cable can be passed and if there is any cut or damage to

cable after concreting or backfilling the ducts shall be rejected.

Typical duct drawing is enclosed in tender drawings.

7C512.20 Man Hole

7C512.20.1 General

(a) Contractor shall provide man holes for pulling the cables so that

the pulling tension of cable is not exceeded. These man holes

shall also be at cable jointing pits, cable turning, cable crossing

roads. The size will depend on the number of cables, ease in

pulling and jointing cables. It shall have provision of built in

ladders, cable supports etc. These shall be of material such as

aluminium alloy and under no condition any rusting material such

as GI or steel shall be used. All the duct ends shall be sealed for

water, gas and vermin entry including the spare ones through

proper sealing split sockets meant for this purpose so that same

can be removed when cable replacement is to be done. No

compound or foam sealing is acceptable. Sealing must be 100%

under all the operating conditions throughout the life of the cable

duct. Contractor must ensure that there is high water table at site

and this shall be taken into consideration while designing the

drainage from the manhole. In such as situation contractor may

propose to have manholes at higher level of ground.

(b) There shall be a sump hole with gravel inside with a proper size of

mesh to drain water towards the sea. All slopes in manhole shall

be towards this sump hole. It is the responsibility of contractor that

under no condition water stays inside the manhole due to rain or

TD No. DGSB/DB-03/01 of 2018 Page 315 of 514

You might also like

- Scope of Work:: Gail (India) LimitedDocument8 pagesScope of Work:: Gail (India) LimitedAnonymous sdMq4MSNo ratings yet

- 6.1 Pavement: 6.1.1 Materials - Base Course, Sub-Base, Subgrade, and Select FillDocument8 pages6.1 Pavement: 6.1.1 Materials - Base Course, Sub-Base, Subgrade, and Select FillEma WeismanNo ratings yet

- 380 KV Underground Transmission LineDocument15 pages380 KV Underground Transmission LineMohmmad NawabNo ratings yet

- Laying and Jointing Water PipesDocument15 pagesLaying and Jointing Water Pipesashish reddyNo ratings yet

- Cable laying method statementDocument11 pagesCable laying method statementSopi Labu100% (2)

- Conceal PVC Conduit in Concrete Ceiling SlabDocument2 pagesConceal PVC Conduit in Concrete Ceiling Slabfatinjamal22No ratings yet

- HDDDocument6 pagesHDDRon Cyl100% (1)

- Item SpecificationsDocument14 pagesItem Specificationssat palNo ratings yet

- Technical Specification for Sub-Station Lightning Protection and EarthingDocument4 pagesTechnical Specification for Sub-Station Lightning Protection and EarthinggaladrialNo ratings yet

- PIPEDocument10 pagesPIPEJoshua SykamNo ratings yet

- Emerson Cluj 20x30m 20cmDocument27 pagesEmerson Cluj 20x30m 20cmBenedek Rapolti VajkNo ratings yet

- TS Nit N0 578Document328 pagesTS Nit N0 578naveen prasadNo ratings yet

- Method Statement Construction & Casting of Concrete Manholes P-3Document4 pagesMethod Statement Construction & Casting of Concrete Manholes P-3a.nunezNo ratings yet

- 07131Document11 pages07131bravo deltafoxNo ratings yet

- Electrical BOQ Plot C LPSDocument5 pagesElectrical BOQ Plot C LPSAgrawal PrajaktaNo ratings yet

- Install at in CablesDocument20 pagesInstall at in Cableshashimkolan100% (2)

- Profi FOOD - CTP Bucharest ParkDocument26 pagesProfi FOOD - CTP Bucharest ParkGaftoi TicaNo ratings yet

- 26.sec.2600 (Expansion Joints)Document13 pages26.sec.2600 (Expansion Joints)aalignup arc & const. pvt ltdNo ratings yet

- Roofing p5 6Document2 pagesRoofing p5 6Ibrahim SahinNo ratings yet

- CCTV Construction MethodologyDocument12 pagesCCTV Construction MethodologyMarkNo ratings yet

- Chapter 9 - Prestressing: WJ Martin 9.1 ScopeDocument21 pagesChapter 9 - Prestressing: WJ Martin 9.1 ScopeDr. MOHAMED ALZAINNo ratings yet

- Cantilever DesignDocument8 pagesCantilever DesignJun CrisostomoNo ratings yet

- Best Practice Sheet - RenderingDocument4 pagesBest Practice Sheet - Renderingtexas_peteNo ratings yet

- ManholesDocument20 pagesManholesA.K.A. HajiNo ratings yet

- Underground Drainage Installation MethodDocument8 pagesUnderground Drainage Installation MethodUSAMANo ratings yet

- Method Statement - Cable LayingDocument5 pagesMethod Statement - Cable LayingsoubhagyaNo ratings yet

- Project - Sport CityDocument30 pagesProject - Sport CityAdmin DepartmentNo ratings yet

- Storm DrainageDocument8 pagesStorm DrainageEphrem GizachewNo ratings yet

- UG IV 3 Concrete Encased Duct Bank PDFDocument8 pagesUG IV 3 Concrete Encased Duct Bank PDFpmpeieNo ratings yet

- RTT and GBT Site ScopeDocument19 pagesRTT and GBT Site ScopeAnish RanaNo ratings yet

- General Specification For The Construction OF Elevated Water TankDocument30 pagesGeneral Specification For The Construction OF Elevated Water TankHani Ibrahim AbdoulayeNo ratings yet

- Cable Tray Fill AreaDocument20 pagesCable Tray Fill AreaNibin P SNo ratings yet

- Special Conditions of Contract For Supply Installation and Commissioning of Temporary and Permanent Cathodic Protection SystemDocument12 pagesSpecial Conditions of Contract For Supply Installation and Commissioning of Temporary and Permanent Cathodic Protection SystemsudeepjosephNo ratings yet

- SECTION 700 (Pipe Drains, Pipe Culvert, Concrete Channels)Document9 pagesSECTION 700 (Pipe Drains, Pipe Culvert, Concrete Channels)akvosmNo ratings yet

- Pipe Culverts Check ListDocument2 pagesPipe Culverts Check ListSubramanian BalakrishnanNo ratings yet

- Duct and PVC in ConcreteDocument6 pagesDuct and PVC in ConcreteAli AimranNo ratings yet

- Plumbing and Drainage 2870 2011 NotesDocument4 pagesPlumbing and Drainage 2870 2011 NotesSimon KhamalaNo ratings yet

- BD - J - WATER PROOFINGDocument13 pagesBD - J - WATER PROOFINGMuthusamy ArumugamNo ratings yet

- Section 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery ExtensionDocument3 pagesSection 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery Extensionery achjariNo ratings yet

- 16180Document9 pages16180uddinnadeemNo ratings yet

- 82 000 Cable Ducts & Manhole FinalDocument5 pages82 000 Cable Ducts & Manhole Finalrezaali.tradingNo ratings yet

- Bs5400 DesignDocument10 pagesBs5400 DesignMahesh Pokhrel67% (3)

- Diaphragm/slurry Wall SpecificationDocument27 pagesDiaphragm/slurry Wall SpecificationRoy PersonalNo ratings yet

- Substation Lightning Protection and EarthingDocument8 pagesSubstation Lightning Protection and Earthingamrit90320No ratings yet

- Chapter-9 Pipe CulvertsDocument6 pagesChapter-9 Pipe CulvertsvinuthNo ratings yet

- Checklist For Cable Trench (Indoor & Outdoor)Document4 pagesChecklist For Cable Trench (Indoor & Outdoor)Rupesh KhandekarNo ratings yet

- ApplicationsDocument15 pagesApplicationspios.helectorNo ratings yet

- Notes On Pipe Subsoil Drain Construction SpecificationDocument14 pagesNotes On Pipe Subsoil Drain Construction SpecificationSitche ZisoNo ratings yet

- 15 Laying Cable 66kvDocument8 pages15 Laying Cable 66kvprithvirajd20100% (1)

- Shotcrete Lining For Irrigation Canal LiningDocument6 pagesShotcrete Lining For Irrigation Canal LiningYosvanyNo ratings yet

- DPWH Standard Specification on Item 1013A - Corrugated Asphalt RoofingDocument5 pagesDPWH Standard Specification on Item 1013A - Corrugated Asphalt RoofingDrew B MrtnzNo ratings yet

- HB 12350Document21 pagesHB 12350Pawan Kumar PrajapatNo ratings yet

- Methodology For PQC (00) Toll Plaza L&TDocument4 pagesMethodology For PQC (00) Toll Plaza L&TDeven PatleNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionFrom EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionNo ratings yet

- District-wise Rainfall Distribution Report for India on 26-07-2022Document18 pagesDistrict-wise Rainfall Distribution Report for India on 26-07-2022Prashant VermaNo ratings yet

- Indian income tax return acknowledgment number 934515920150122Document42 pagesIndian income tax return acknowledgment number 934515920150122Pradeep GoudaNo ratings yet

- Luxury Beachfront Resort in Gokarna, IndiaDocument2 pagesLuxury Beachfront Resort in Gokarna, IndiaPradeep GoudaNo ratings yet

- P&P N11Document1 pageP&P N11Pradeep GoudaNo ratings yet

- FIDIC Lecture - EOT & Related Costs in ConstructionDocument39 pagesFIDIC Lecture - EOT & Related Costs in Constructionsomapala88No ratings yet

- Fosroc Chemicals India PVT LTD.: Presentation On Lift Pit Waterproofing SystemDocument9 pagesFosroc Chemicals India PVT LTD.: Presentation On Lift Pit Waterproofing SystemPradeep GoudaNo ratings yet

- U/ CE Xis Tin GC Ulv ErtDocument1 pageU/ CE Xis Tin GC Ulv ErtPradeep GoudaNo ratings yet

- 2639 - Rev.4 - NCC Limited - DrawingsDocument4 pages2639 - Rev.4 - NCC Limited - DrawingsPradeep GoudaNo ratings yet

- Drawings - R1 - PDF - NCC PSB DB03 AB01 DWG ST 1302 - R1Document1 pageDrawings - R1 - PDF - NCC PSB DB03 AB01 DWG ST 1302 - R1Pradeep GoudaNo ratings yet

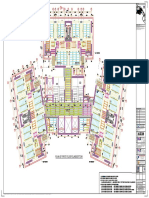

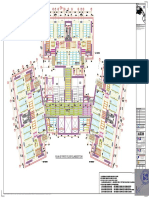

- NCC PSB Db03 Ch2a DWG Ar 1301 r0c Opt1Document1 pageNCC PSB Db03 Ch2a DWG Ar 1301 r0c Opt1Pradeep GoudaNo ratings yet

- Civilian Housing - Ch03A (Tower 2) - Design of Pile Layout & PilecapsDocument15 pagesCivilian Housing - Ch03A (Tower 2) - Design of Pile Layout & PilecapsPradeep GoudaNo ratings yet

- Drawings - R1 - PDF - NCC PSB DB03 AB01 DWG ST 1301 - R1Document1 pageDrawings - R1 - PDF - NCC PSB DB03 AB01 DWG ST 1301 - R1Pradeep GoudaNo ratings yet

- SpecificationDocument1 pageSpecificationPradeep GoudaNo ratings yet

- STP Clauses11Document1 pageSTP Clauses11Pradeep GoudaNo ratings yet

- RFP Hill Slope Stability Study 02mar16Document83 pagesRFP Hill Slope Stability Study 02mar16Pradeep GoudaNo ratings yet

- NCC PSB Db03 Ch2a DWG Ar 1301 r0c Opt1Document1 pageNCC PSB Db03 Ch2a DWG Ar 1301 r0c Opt1Pradeep GoudaNo ratings yet

- 6-65-0017 Rev 5 RockDocument12 pages6-65-0017 Rev 5 RockPradeep GoudaNo ratings yet

- SLOPE Conf - 04 - 11 - 08Document10 pagesSLOPE Conf - 04 - 11 - 08Hassan BasriNo ratings yet

- PCC - Sub ClauseDocument2 pagesPCC - Sub ClausePradeep GoudaNo ratings yet

- SFRC Report TDSDocument1 pageSFRC Report TDSPradeep GoudaNo ratings yet

- RFP Hill Slope Stability Study 02mar16Document83 pagesRFP Hill Slope Stability Study 02mar16Pradeep GoudaNo ratings yet

- Plan of First Floor Slab Bottom: Ffb1 Ffb1 Ffb1 Ffb1Document1 pagePlan of First Floor Slab Bottom: Ffb1 Ffb1 Ffb1 Ffb1Pradeep GoudaNo ratings yet

- Plan of First Floor Slab Bottom: Ffb1 Ffb1 Ffb1 Ffb1Document1 pagePlan of First Floor Slab Bottom: Ffb1 Ffb1 Ffb1 Ffb1Pradeep GoudaNo ratings yet

- Ch-Iia Plan of First Floor Beam Sides: SECTION 10-10 Section 5-5Document1 pageCh-Iia Plan of First Floor Beam Sides: SECTION 10-10 Section 5-5Pradeep GoudaNo ratings yet

- Plan of First Floor Beams Props & Tripods: Ffb2ADocument1 pagePlan of First Floor Beams Props & Tripods: Ffb2APradeep GoudaNo ratings yet

- Plan of Ch2A First Floor Beam Bottom PlatesDocument1 pagePlan of Ch2A First Floor Beam Bottom PlatesPradeep GoudaNo ratings yet

- SLOPE Conf - 04 - 11 - 08Document10 pagesSLOPE Conf - 04 - 11 - 08Hassan BasriNo ratings yet

- Civilian Housing Towers - Architectural Works: Project Area No of Structures StatusDocument12 pagesCivilian Housing Towers - Architectural Works: Project Area No of Structures StatusPradeep GoudaNo ratings yet

- Uttara Kannada PDFDocument1 pageUttara Kannada PDFPradeep GoudaNo ratings yet

- Peter Linz An Introduction To Formal Languages and Automata Solution ManualDocument4 pagesPeter Linz An Introduction To Formal Languages and Automata Solution ManualEvelyn RM0% (2)

- Section 5: Finite Volume Methods For The Navier Stokes EquationsDocument27 pagesSection 5: Finite Volume Methods For The Navier Stokes EquationsUmutcanNo ratings yet

- Human Resource Reforms in Public Administration: The Importance of The Reward SystemDocument10 pagesHuman Resource Reforms in Public Administration: The Importance of The Reward SystemElena BejanNo ratings yet

- Solar/Wind/Diesel Hybrid Energy System With Battery Storage For Rural ElectrificationDocument15 pagesSolar/Wind/Diesel Hybrid Energy System With Battery Storage For Rural ElectrificationWelde AynaleNo ratings yet

- MATH 499 Homework 2Document2 pagesMATH 499 Homework 2QuinnNgo100% (3)

- Primary Maths Dissertation ExamplesDocument8 pagesPrimary Maths Dissertation ExamplesPaperWritersAlbuquerque100% (1)

- 3.19 Passive VoiceDocument10 pages3.19 Passive VoiceRetno RistianiNo ratings yet

- LESSON PLAN On PancreasDocument4 pagesLESSON PLAN On PancreasShweta Pal100% (1)

- DEF CON 30 - Hadrien Barral - Emoji Shellcoding ?, ?, and ? - PresentationDocument141 pagesDEF CON 30 - Hadrien Barral - Emoji Shellcoding ?, ?, and ? - Presentationkumar sanjayNo ratings yet

- Boutique HotelsDocument61 pagesBoutique Hotelsnour alkhateeb100% (1)

- Lucky TextileDocument5 pagesLucky TextileSaim Bin RashidNo ratings yet

- Maximizing Emissions Control with Compact Fume ExtractionDocument9 pagesMaximizing Emissions Control with Compact Fume ExtractionS Ray Chaudhury100% (1)

- Valvula Contrabalance CBV1 10 S O A 30Document21 pagesValvula Contrabalance CBV1 10 S O A 30Judith Daza SilvaNo ratings yet

- Crisil DataDocument6 pagesCrisil DataVihang NaikNo ratings yet

- Managing An Angry PatientDocument15 pagesManaging An Angry Patientmasa.dalati.1No ratings yet

- Digital Fuel Calculation v.1Document4 pagesDigital Fuel Calculation v.1Julian ChanNo ratings yet

- TZMmanual PDFDocument8 pagesTZMmanual PDFccardenas3907No ratings yet

- Nitrogen CycleDocument15 pagesNitrogen CycleKenji AlbellarNo ratings yet

- Pages From Civil EngineeringDocument50 pagesPages From Civil EngineeringRagavanNo ratings yet

- NEM Report - IntroDocument11 pagesNEM Report - IntroRoshni PatelNo ratings yet

- The Principles Taj MahalDocument2 pagesThe Principles Taj MahalVishnuMohanNo ratings yet

- Festivals WorksheetDocument8 pagesFestivals WorksheetlurdesNo ratings yet

- Lauren Tarshis - (I Survived 05) - I Survived The San Francisco Earthquake, 1906Document66 pagesLauren Tarshis - (I Survived 05) - I Survived The San Francisco Earthquake, 1906Olga de Ramos100% (1)

- Cardio Fitt Pin PostersDocument5 pagesCardio Fitt Pin Postersapi-385952225No ratings yet

- Underwater vessels, sensors, weapons and control systemsDocument1 pageUnderwater vessels, sensors, weapons and control systemsNguyễn ThaoNo ratings yet

- Mechanics of Solids by Sadhu Singhpdf Ebook and Ma PDFDocument1 pageMechanics of Solids by Sadhu Singhpdf Ebook and Ma PDFNeeraj Janghu0% (2)

- LMV Tyre SafetyDocument19 pagesLMV Tyre SafetykarvadNo ratings yet

- Nescafe Cold CoffeeDocument24 pagesNescafe Cold CoffeeMuhammad Omer SaeedNo ratings yet

- 2-Stress-Test Your Strategy The 7 Questions To AskDocument9 pages2-Stress-Test Your Strategy The 7 Questions To AskMalaika KhanNo ratings yet

- Abstract & Concrete NounsDocument2 pagesAbstract & Concrete NounsSitifatimah92No ratings yet