Professional Documents

Culture Documents

Corrosion Monitoring Programs Observation

Uploaded by

Amer KhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corrosion Monitoring Programs Observation

Uploaded by

Amer KhanCopyright:

Available Formats

Corrosion control and Monitoring 3.1 to 3.1.

5:

Why other failure mode are not identified such as Hydrogen penetration monitoring and other

metallurgical modes of cracking. Associated damage mechanisms specific to each equipment

shall be clearly identified to define future NDT requirement. monitoring techniques specific to

damage mechanism greatly helps in reducing facility shutdown time and extending the life of

the asset.

3.2.3.1 TML assignment for piping:

No clear justification has been given for excluding piping circuits having NPS 2” and below. NPS

2” line could be that of hydrogen or wet H2S service !

What is TRM(Trim) and why Lines having such designations are excluded from TML assignments.

“Simplified isometrics will be developed reflecting all TMLs” an OSI isometric drawing shall

include comprehensive information such as corrosion loop#, circuit # and shall clearly identify

injection points, dead legs, pipe nipples and mixing points by use of distinct symbols, if there are

any.

Electronic copy( AutoCAD file) to be submitted along with 3D model

3.2.3.2 & 3.2.3.3 TML assignment for injection points / dead legs

TML numbering/ designation for injection points, dead legs and mixing points are not clearly

identified. Such classification greatly helps in segregation and separate monitoring.

3.2.3.7 Baseline Survey

Quantity of TMLs to be clearly identified specific to each piping circuits based on corrosion

service. What is the criteria for quantity of TMLS? ( base line survey)

3.2.3.8 Requirement for insulated items

Type and model shall be mentioned for insulation plugs in TML report

Drawing – TML orientation:

Orientation are only gathered in the TML report. TML isometric drawings shall not include the

orientations, this conflicts with statement in 3.2.3.5 where TML number and orientation are to be shown

circle.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

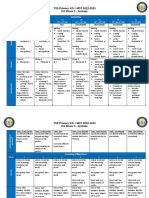

- KG1 Block 3 English Subjects MTPDocument3 pagesKG1 Block 3 English Subjects MTPAmer KhanNo ratings yet

- Boiler InspectionDocument8 pagesBoiler InspectionAmer KhanNo ratings yet

- Pressure Relief Valve Weekly Report: Appreciates All The Efforts Exerted by The Team in MaintainingDocument1 pagePressure Relief Valve Weekly Report: Appreciates All The Efforts Exerted by The Team in MaintainingAmer KhanNo ratings yet

- The Cervic Corrosion in Storage TankDocument7 pagesThe Cervic Corrosion in Storage TankAmer KhanNo ratings yet

- Deferal of Storage TankDocument14 pagesDeferal of Storage TankAmer KhanNo ratings yet

- DET4TCR2 Product SpecificationDocument3 pagesDET4TCR2 Product SpecificationAmer KhanNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)