Professional Documents

Culture Documents

PPR Catalogue July 2019 31 05 2020

PPR Catalogue July 2019 31 05 2020

Uploaded by

Ratheesh Kumar0 ratings0% found this document useful (0 votes)

106 views44 pagesOriginal Title

PPR-catalogue-July-2019-31-05-2020

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

106 views44 pagesPPR Catalogue July 2019 31 05 2020

PPR Catalogue July 2019 31 05 2020

Uploaded by

Ratheesh KumarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 44

4 Polypropylene Random (PP-R)

CoG aU UL

i ee, dro-Sanitary Applications

ne ee ee ee nea

CO UNealet ea en ec eo eet ke

ees att

Nene eee cence ee eee ee Re a ee

Ce i ats ee ae evra eM uk te

Cer amen aca ae Laci)

Cee eee ae en ae ieee ecu!

eee Tee face ee ener ae ee eee ee

fabricated uPVC ancl GAP manhole aystems, Its state of the art engnoerng, cesign anc tool room feciites are full

Cee ee ea ee ete et

eee eel eek ieee ene a

Re cee een eee ee ee ger ence eee

Cee eee eee ee ce ean ce oe

eee

ieee Re Re a oe eeu eet a seen gee)

ee ee ed eee ene a)

Cer

(sone gw Cael a teh EU)

PRODUCT RANGE INCLUDES:

Maneater ane toa)

Tee eee nec a hun su eRe

Ree hee ke Cnet coo g

Cen

ee ee a ey

Cae eC oy

Cer ete eeu em ee Rea eR en aaa Us

eee a ee te Ci eR eee rel ol

ce ice eer oe ad

Cee ee eee tent

Beste MOU aaa Dg olga ae gee SC dec cue seh)

Meee ea oe i ett eee ee era eect cua

Ee ese eae eo eee Mera ee eae kel ene tT meet eel a]

Peet

IRRIGATION SYSTENS (LLDPE)

Consists of high precieon inline crip pipes and landscape and lon edging. This range algo includes ealn resistant valves,

Ce ea oe coe ean

REINFORCED THERMOPLASTIC PIPES (RTP)

Tee ae ease eee RE en eo eeac e]

Cee eee aa eld

ow

Ll LL Ya}

CONTENTS

Fields of Application 2

Features of Cosmoplast Polypropylene System 2

Mechanical & Thermal Properties of PPR 4

Pressure and Temperature 5

Regression Curve of PPR 6

Pipes Specifications

PN20 Plain PPR Pipes 7

PN16 Plain PPR Pipes 7

PN25 PPR / AL / PPR Stabi Pipes 8

PN25 PPR / AL / PE UV Resistant Pipes 8

PN20 PPR / FG / PPR Faser Pipes — 9

Longitudinal Expansion 10

Pipe Supports ——— 13

Pressure Loss —— 14

Pressure Loss Table for Pipes

PN20 & PN25 at 20°C —————_- 15

Composite Polypropylene Pipes 16

Effective Clamping Distances 18

Expansion of PPR Composite Pipes 18

Fusion Welding Process 19

Welding Composite PPR / AL / PPR Stabi and

PPR / Al / PE / UV Resistant pipes 20

Electrofusion Welding Process ——_—_. 21

Handling, Storage and Transportation ————K“ 22

Transport & Handing 23

Product Range a 24

PPR Pipes —___ 25

PPR Fittings ——$ 26

Piping System for Hydro-Sanitary Applications

Cosmopr ast PoLyPROPYLENE Pres & FITTINGS

Wilh the expertise of monulaciuring thermoplastic pipeline systems in the Gull region for more than two decades

Cosmaplast has now developed @ complete range of Polypropylene (PP-F) pipes and fitings for cold and hot water

disirbution systems

These pipes ond filings are suitable for potable water cistibution sysiems in addition to a wide range of hycro-

sanitary applications.

‘The exceptional heat stabilty of the polypropylene Random copolymer and its extraction resistance coupled with ease

of installation make the PP-R system rom Cesmoplas! e reliable piping system for ho! and cold waler oppiications

with @ sonvco lio in excors of 50 years.

Cesmoplast polypropylene system Is made from P-R granules supolied by the world’s renowned resin manufactures.

These granvles are pre-coloured and have excellent heal resistance, physical and chemical properties to suit

pplicaions such as potable wator dstibution and heating systems.

Fields of Application:

‘Tho Polypropylene system from Cesmoplast can be uted for:

+ Hot ond cold potable water piping networks in residentiol end commercial buildings. i.e. hospitals, hotels,

offices, school buildings ete.

* Chilled water networks in air conditioning systems, as an effective light weigh! and corrosion free substitute for

sieel pipes:

* Transport of wide range of chomicals in the industry.

* ligation systems for gorders.

+ Piping networks for rainwater uillzation systems.

+ Piping networks for swimming poo! faciliies,

Compressed air installations,

Cosmoplast Plumbing Systems

FEATURES OF COSMOPLAST POLYPROPYLENE SYSTEM

* Extended durability duc to the high resistance to aggressive clements.

+ A Service life in excess of 50 years

+ Smooth and porestyfree intemal surface of both pipes ond ftings thus resulting in @ very low pressure loss and

‘absence of incrustation (reduction of section due io the limestone and scaling }.

* Non-toxic and physiologically harmless material

* _ Resistonce te becterial atock thus enebling sofe potable water distribution.

+ Resistance to wide range of chemicals, therefore no corrosion in sevice lines

© High impact strength

* Heat preservation and energy -saving cbilities. The heat conductivity of PP-R pipes are much lesser than metals

‘and hence offer sianificantly lower levels of heot loss for transporting fluids.

* High ocoustic insulation agains! fluid noise. The fluid flow and hydraulic shocks within the building crosie reise

which can be avoided by use of the noise absorption ability of PP-R materials.

+ Light weight cosy fo handle material compared to the metallic piping systems ( 1/9 of the steel specific gravity).

+ Conveniont and reliable installation methods. The PP-R pipes can even be installed in suspended form under

ceiling without problems of deflection.

* Easy interconnection ever a complex network.

* No perforation coused by electrical currents, -

* Cost effective pipeline network.

+ Safe environment os PPR is 0 recyclable material

The PPR system from Cosmoplast - A safe, tough, easy ond cos affective solution for het and cold water

applications.

Piping System for Hydro-Sanitary Applications

STANDARDS:

Cosmoplast PP-R systom is producied according to the following Gorman Standards

DN 1988 Dinka water Suoey Sons

DN 8077 Polypropylene Fp: Cimeneine

DN 2078 Pyrapriene Fp: Toning Vathode

ON 15562 Polypropylene Futags: Quahy Contos ard Comectons,

on 18528 Tharmesac Pes: Pipe Comnectons

OINAIGe Sourd Inula n Bulking Costuciens

DINBO76 ‘tel Theoden Testing Maths

DN2999 ‘ur fr Figs wth Torsoded Mote nvte

vs 2206 Aegutions forthe Welding of Thomodofc Notsral

yS207 ‘Wang of Themopltc Mater by meon of Hoang Took

MECHANICAL & THERMAL PROPERTIES OF PPR

one nr

Dens of 423 len? 150 1182 0909

aiow he MER 28072,16 o/10nn 180 1198 020

ohne AR 23072 16 ert Orin WSO 118 038

isla Sin (GOne/min) Nfs komma 25

id Exoraion (G0ne/min) % 160 627/142 13

“erste E Modules (vcard ivFa Lts0 sarnz eo

Indenroe Hordes (13230) Nan? 1802039/1 w

‘Shore Hares D ce vale [on sasos 6

etched Bor Tot arc Kat DN S258 %6

aes eC Kee 1 DINEaISa @

ted Impact +29 Kin? IsO180C nd

ae oc ie iso1a0/ 160

30 Kin rors %

‘bod Imapoct 423°C Kim ISOLBO/1A 30

ee Kine isOIsGIA Bi

ees sore Ki [_soisaia 18

Vics Soling STN *c 160304 132

Temperorure YST/B/SO_ << I 180 306 oF

“Thermal Denton HOTA “Cc BO 75/1=2 3

Sebi HoT % [sorsnea 70

Longin coolio! ef ompenen nmin 59762 018

“Thermal condcivly of 3 Wak | DIN sai 024

‘Spactfic heat at 20°C K/Kak diab colorimeter 2.0

Cosmoplast Plumbing Systems

PRESSURE AND TEMPERATURE

‘The following table shows the expected lfe span of Cosmoplast Polypropylene pipes and fittings at various selected

pressures and temperatures as per DIN 8077 /8078 Standard.

Zs

yo Ee mera [sna

7 o on aa

2 a ci a

50 Mad 30.3 | 382

; a a mp

: oa a a

7 = 7 ——

5 oe a

a a a

; ra on

a a

r its oF

a =

aa a

40 135

i a

ee

a ta

5 9

n ‘ "

zs u

= 7

; a

j z

» a a

E a y

; wn on

os i a =

Piping System for Hydro-Sanitary Applications

REGRESSION CURVE OF PPR:

so)»

”

2 BI

3 ip +4

a i

z

> tt

gf .

DIAGRAM (1) a a

2 |z

S 20th

2

&

§

Zoot ash

ao} ot S

20} os

vol sob | Lt

1 100 10! 10 103 104 105 108

yeas years Soyeas

DURATION TIME (HOURS)

QUALITY CONTROL:

Cosmoplast PP-R systems are produced through a well lod I i

down process contitng of systematic inspecons on incoming le senitery anc heating stm in domes

commercial ara industial buildings

20x28 20 24

25x35 2 FF

3ax4a 2 at

40x55 10 55)

50x69 50 69.

cree a os

75x 103 75 103

90x 125 90 123

Vox 19.1 110 19.1

125x171 ra 7

T6021 160 218

Wenn

LONGITUDINAL EXPANSION:

The following schemes demonsirale some imporiani coses:

Pr

PF= Fixed Point; PS= Sliding Point

‘A. Exposed Installations:

Longitudinal expansion dapends en the famperature variction the pipes ore expesed fo. If the working

temperature of the system undergoes variations up to 10 -15°C the pipe elongotion should be evaluated ard

considered. Cold water pipes have low linear exparsion and hence can be neglected. But in case of hot water

‘and heating inscllations, the longitudinal expansion must be considered ond the installations must be planned

‘ond performed accordingly.

Thormal expansion of Folyprepylone pipes can be evaluated using tho following formula:

AL = axLlx At

Linear expansion in mm.

Cootfciont of linear exparsion = 0.18mm/mk

Intel pipe longth in m.

‘Tha diffrence between the temperature ot which the system is inscllad and tho operating temperature.

‘Compensation of Longitudinal Expansion:

For exposed installations, the length variation due lo longitudinal expansion should be compensated by a

‘calculated and planned chonge of direction.

The froe pipe length “L:” isthe langth of pipe that should be kep! free wihhout clomping s© as fo compansate

for the expansion. Its coleulated with the follawing formule:

ls=KxVdxAL

Cosmoplast Plumbing Systems

Wheee:

Ls = Free pipe lenath in mm

|AL = Linear expansion in mm

d= Exemal diameter of pipe in mm.

K = 20 Constant for the PP-R material

Exomple:

Ifa pipe of 25mm diameter with 4m length, undergoes a potential temperature variation of 50° C. The thermal

expansion calculations result the following

The variation in length:

AL = axlxAt = 0.18%4%50= 36mm

The free pipe longth

Ls KxVdxal = 20xV25x36 = 600mm

The longitudinal expansion of plain PPR pipes can be taken directly from the below table

| on ow | om | os | o7 | of | 100 | 120 | 1a

| 02 096. O72 108 1a 18 16 252 298

oe ose | toe | vee | 20 | 27 | 228 | om | aa

oa om | iw | 1% | 20 | 96 | am | som | 57

es 08 19 27 te 45 5a a 72

00 ie [aie | au | am | sa) om | 7a ~*~ von

_o 125 +| 252 | ame | soe | 60 | 740 | om | 100

08 ae ape | 4a? ‘370 72 bod 10.08 nse

| 09 102 gm | 486 oe “81 072 Vas 120

10 Li ae | 54 72 ° 108 6 aa

me) 18 72 | 08 | 1a we | 22 | me

20 sa] tae) 2 | aie | ma | wo | ae

40 72 | wa | ne | m9 | = | «2 | sa | ‘70

[ 50 T_¢ 19 7 6 5 Se oO 2

«0 wor | ze | wa | aa | aa | os | 750 | 0a

70 we | 32 | we | sa | @ | se | mee |e

- 80 wa |e | a2 | 90 | 7 roa | woe | vis2

a) 12 | ma) eo | ow | 72 | 19a | 176

[188 @ 28 se 7 * vor | 1 |

Piping System for Hydro-Sanitary Applications

The longitvdinal expansion and free pipe length can be iaken from the below

12 are?

PIPE LENGTH (m)

30140150 160170180 DI mm

DIAGRAM (2)

© 20mm

© 25mm

832mm

@40mm

PN son

@50mm

75mm

Cosmoplast Plumbing Systems

B. Concealed Installation

Concealed installations generally do not require any special consideration for linear expansion as there is

‘enough room to accommodate the expansion of the pipe as per the guidelines of installation according to DIN

1988. Where there is no room fo accommodate such expansion, the material absorbs all the siress arising

from residual exparsion

PIPE SUPPORTS:

When pipe clamping techniques are considered, two types of clamping joints must

be identfied; fixed ooin's ond siding poini, Fixed clamps hold the pipes in o rigid

manner, while a sliding point ollows the pipe fo move in the axial direction of the

pipe.

Fixed points divide the pipe network into individual sections. Given this, the possible

longitudinal exparsion and the corresponding ‘ree length from the fixed ripe points

must be calculated.

Sliding points should be located so thot the axial movernent of lorgitudinel expansion

is not influonced by the fixed conneciion points. Given this, the siding Points should not be installed on wither sida of

the fiings in order fo avoid acting as fixed poinis

Itis important, that the clomp or fastening moterial does not damage the surface ofthe pipe. The ideal fastening moterial

‘for PPR pipes ore rubber lined clamos which ensure that no mechanical damage of the pine surface can occur.

The following table shows the effective spans beeen clomps for horizontal lines ot selecied temperature

differences

Erne tee

et

2 90 “ ‘6 @ © 55 50

25 no 20 75 70 70 “s 30

2 120 %5 % 6 0 75 70

© vs v0 | 10 * 50 a 30

2 170 130 10. Tio 110 10 %

@ 170 10 40 120 0 10 700

75 210 160 160 140 730 1 10

0 zo) | 160 150 10 wo | 125

7 2080 1 170 v7 10

9 System for Hydro-Sanitary Applications

PRESSURE LOss:

The characteristics of PPR material enoble fo obtain al the exlrusion phase very smooth walls (roughness —

0.0070) which reduces the friction losses end improves the performonce of the whole system. These factors ollow

Using higher water speed in the circuits without having negative effects in the system of the case in other piping

systems,

‘The maximum allowed speed for cold water is 5 rr7s, while for hot water (higher than 70°C), itis advisable not 10

exceed 3 m/s. The pressure losses in PPR can be taken directly from following diagrams:

Pressure Loss Diagrams:

Petsreless Pom (10,000 Pas 0.1 bar = Tm. ca}

Cosmoplast Plumbing Systems

Pressure Loss Table for Pipes:

PN 20 & PN 25 at 20°C

Pe me | mans nse Jews | oa on

ac 903 [aor “000

« 0,08 0,04 09

oa core [et a

. ON C07 003

aa aml eeelee

a . 058 0,37, 0,23 O14 006 0,04 0.03,

Z we & 697 2,30 OF) 0,24 0,08 003 0,01 0,00

low rao (L/S), R- Pressure lesses(mbar/m),v Flow spord (avs)

"rescue ozs table torfinngs can be povided as per customer request

Piping System for Hydro-Sanitary Applications

COSMOPLAST COMPOSITE POLYPROPYLENE PIPES:

The technology of Composite FPR pipes has been developed due fo the increasing need for PPR pipes that can be used

in applications where the normal plain PPR pipes can not be implemented. This composite techrology could offer easy

solutions to the expansion of PPR pipes and tothe UV exposure in case of extemal installations

(A) Cosmoplast PPR / AL / PPR Stabi Pipes

‘The Polypropylene piping industry has been witnessing major

innovations in recent times and in order to cater to the need

for these innovalive producis, Cosmoplast has extended

its polypropylene product range with the addition of a new

Polypropylene (PP-R) / Aluminium (Al) composite pipe. This new

pipe syslem comprises of an aluminum loyer, inlegraled wilhin

the pelypopylone pipe structure. This innovotive produc is thus made of a unique combination of materials wth each

‘adding their own benefits fo the fincl product

‘Cosmoplast PP-R/ Aluminium/ PP-R composite pipes for hot ond cold water distibution systems ove suitable for hich

pressure potable woter disrbution systems in addition to a wide range of other hydro-sanitory applications and will

provide on operational service life in excess of over 50 years,

‘The exceptional reduction in thermal expansion of the PP-R/Al / PPR composite pipes makes this product on

‘extremely rlible and stable product for use in hot and cold water applications

‘Cosmoplast PPR/AL/PPR Stabi pipes are manufactured according tothe stondards DIN8O77 and DIN8O78 , PN25, Fipe

Series 5 2.0, SDR 5.0.

Fields OF Applications:

‘Cosmoplast composite PPR/AL/PPR pipes are used for:

= Hot and cold potable water networks in residential, industial and commercicl buildings. i.e. hospitals, hotels,

schools, offices, factories ete.

* Chilled water networks in Air Conditioning systems providing on effective light weight ond corrosion free substitute

for steel pipes.

+ Tronsportation of wide ronge of chemicals within indusiriol processes.

+ Piping networks for swimming pools facilites

+ Compressed cir installotions.

(B) Cosmoplast PPR / AL / PE Pipes, UV Resistant for External Installations

FPR pipes ore offen used fr exeinal exposed insallatons,

in which case the pipewerk hos to be istlted to avoid

dlroct exposure f UV Ligh! which may derrage tho pipes.

CCoemoplas! PPR/AL/PE UV Resistant composi pipos are

the sasy solution for e¢emal installations due to the

innovative combination between PER Aluminiym and

Polyethylene.

This technclegy is very siilar fo the Stabi FPR/AL/PPR

technology, however the edema leyor is made of

polathylene instead of FPR. This extemal FE layer

provides ha necessary proecicn to tha PPR pipe due io

Cosmoplast Plumbing Systems

Cosmoplast PPR/AL/PE UY Resistant pipes provide the same outsianding performance os FPR/AL/PPR Stoki pipes in

terms of reducing the thermal expansion, thanks to the aluminium layer inlegrated in the structure of t . Therefore

PPR/AL/PE. UV Resistant Pipes can be vsed for the same applications os ihe PPR/AL/PPR Stcbi pipes in addon to the

‘exposed external insclaions

is superior charactorisies thet enables ito resist rect exposure to sunight (UM)

‘Cosmoplast PPR/ AL/PE UV Resistant Pipes are manufactured according to the standards DIN8O77 and DIN8078 ,

PN25, Pipe Series $ 2.0, SDR 5.0.

(C) Cosmoplast PPR / FG / PPR Faser Pipes

‘Cesmoplast PPR/FG/PPR Faser pipes cre composi pipe consist of an integrated middle layer of special formulated

fibreglass [FG] impeded between on intanal and external PPR layers.

‘The presence of fibreglass layer increases the strength of the pipe in such «a way that the pipe can be produced as SDR

7-A butwit pressure rating of PN20 instead of PN16, which means bigger ID and higher flow compared io SDR 6 FN20

pipes. The expansion ofthese pipes is lso reduced 10 o almost ihe same expansion of PPR Siabi pipes.

Cosmoplast PPR/FG/PPR Faser pipes are manufoctured according to the stendards DIN8O77 ard DINBO78 , PN20,

‘SDR 7.4.

COMPOSITE-TECHNOLOGY:

‘With the PPR/AL/PPR,/Stobi and PPR/AL/PE UV resisicnt pipes the, linecr therm expansion is reduced by ot least 75%

‘when compored lo slandard PPR pipes and hence has the following cheraclerisis.

* The coeficient of linear expansion is almast identical to that of metal pipes.

+ In comparison with other plastic pipe systems the supporting clamp intervals can be increoted leoding fo ©

raducion inthe number of mounting clips being used.

* Optimum cost-perfermance ratio in compariton to metel pipes.

* Lower weight than equivalent metal pipes.

* High impact strength.

ing System for Hydro-Sanitary Applications

EFFECTIVE CLAMPING DISTANCES:

Effeciive clomping distance for Composite PPR/AL/PPR Stabi Pipe, PPR/FG/PPR Faser Pipe ond PPR/AL/PE UV resiskanl pipes.

Eero)

eee

A Se

20 13 as us 105 ves as 095

25 14s 125 12s 15 1g u 1s

2 2 15 as Z 135 3 135

ra 25 7 7 16 iB 138 as

0 24 9 135 is 175 7 1.65

6 265 2s 21 205 A is 18

5 2a 22 2.15 24 21 2 1.95

9 3 33 23 aa 2a 2

vo | eas | 25. 2a za 2 | 2 |

EXPANSION OF PPR COMPOSITE PIPES:

The expansion of companite PPR/AL/PPR Stabi Pipe, PPR/FCG/PPR Foser Pipe and PPR/AL/#

less than the normal PPR pipes. as noted in the below table.

Cake

EUV resistant pipes are 75%

oy 0.03 0.08 009, ong 015 018 021 024

02 06 012 aig 24 030) 0.36 2 08)

08 00? 018 027 096 046 os4 063 072

4 ona 024 036 os 040) on one 0,96

5 a5 0,30 45, 060) 075 090 1,05 120

06 078 0.34 054 072 0.80) 18 1.28 14a

o7 021 02 os) Oat | 1,05 1,26 1a7 148

08 024 oe oe | 096 120 wat 140 192

09 oar | 054 91 1198 1,88 1a. 18? 216

10. 030) 0.60 on | 0120 1,80. 180) 2.10) 240

20 040 1.20 1.80 2.40 3,00 3.40) 420 4,80

30 0.90 ao 270 3.60 450 540 630 720

40 v20 | 240 340 450 4,00 7.20 840 9,80

50 150 3,00 450) 6,00) 750 3.60 1950 | 1200

60 180 | 3.40 5.40 7.20 v00 | tose | 1280 | 1440

70 230 420 630 aao | 1050 | 1260 | 1470 | 1680

80 2,40 4,80 7.20 340 | 1200 | 1440 | 1660 19,20

30 270 540 310 joeo | 1380 | 1420 | 1890 | 2140

10,0 300 | 6,00 3,00 2,00, 1500 18,00 21,00 24,00

Cosmoplast Plumbing Systems

FUSION WELDING PROCESS

Cosmoplest PPR pipes and fitings are jointed using hecting

process called fusion welding. The process is very simple cn

resul in inseparable weter tight joins. I is caried out using a

cloctic fusion walding machiros thet simuteneously haat he

internal surface of the fiting and the extemal surtace of the

which ore then joined together to form inseparable water tight

joins

‘The following sections demonstrate the basic procedure for fusion

welding process for pain and composte FF pipes.

Welding Plain and PPR / FG / PPR Faser

pipes:

The folewing eps dessrto the dops ofthe welding proces:

1. Fropore the welding machine by fing itwiththe welding

dios of the diamalers to be welded. Connect the plug

to the 220 V power supply socket and wait until the

machine reaches the working temperature [260°C }.

2. Cut the pipe ot right angles fo the pipe axis using

suitable pine cuter

3. Remove any burrs or cutting chips by deburring the

‘cutting oreo,

4 Mark he welding depth on the plpe using a suitable

5. Without turning insert the end of the pipe into the

heating sleeve up fo the marked welding depth and at

the some ‘ime side without turning the fitting into the

‘other side of the heating foo! up to the stop.

. Leave the pipe ond fiting on the heating tool unil the

heating tme is elapsed.

7. Ai the end of the heaiing time, remove the

fiting from the heating tool and push them immediately

info each other up to the mark indicating the welding

depth. At this sioge the depth mark will be covered by

the welding bead. During this process, do not rolate the

pipe and fifing relative fo each other

8. Allow the join! to cool fully before using.

Piping System for Hydro-Sanitary Applications

‘Welding Composite PPR / Al / PPR Stabi and PPR / Al / PE UV Resistant pipes:

‘The welding process of composite pipes is identical to that for

plain PPR pipes. However, the external and intermediate layers

eis dt deepecantey Fhe lalon peo

The folowing stops describe the slop ofthe welding process:

Prepare the welding machine by fiting it withthe welding

dies of the diameters to be welded. Connect the plug

to the 220 V power supply socket and wait untl the

mochine reaches the working temperature (260°C |.

2. Cut the pipe at right ongles to the pipe axis using

suitable pipe cutter

3. Remove any burrs or cutting chips by deburring the

‘cutting area,

4. Use the pipe shaving toc to poo off th outer layer (PPR in

‘cate of Stab pipes 6 PE in caso of UV rosisant pipos) ond

the intormadiais ciuminum layac. This con be done by fly

pushing the end of tke composite pipe Inside the shaving

foal untl it reaches the stops inside the shaver. I is not

4 maxk ho wolding dopih at tho sop insida tho

shaving tcl sels the corect wading dopth

5. Without turing insert the end of the pipe into the

healing sleeve up to the marked welding depth and ot

the same time side without turning the fiting into the

other side of the heating tool up to the stop.

6. Leave the pipe and fiting on the heating tool until the

heating fime is elopsed.

7. At the end of the heating time, remove the pipe ond

fing from tho heeting tool and push them immeciatoly

into each other up to the mark indicating the welding

depih. AY tis stoge the depth mark will be covered by

the walding boad. During this procese, do not rotate the

pipe and fiting relative fo each other

8. Allow the joint ro cool fully before using.

ay

Level Heating time Processing Time eee

co) al oad J

20 5 4 2

Pa 7 4 2 |

2 a é 4

40 2 é 4

30 18 6 4

18 24 a é j

7: 20 8 3

0 0 8 3 j

no 20 10 8

125 © 10 2 j

Cosmoplast Plumbing Systems

Electro-fusion Welding Process

The alcrouen welding procs ua aneroocy apo or when woking hos be doe neal paces rn postions

rot extessable by he pjhston welding moc

Electofusion process is cored cut using special welding machine ond PPR Elecro-Fusion sockets. The Elbctofusion sockets

{re provided with 2 socket ends hat can be welded ina single operation,

The Eloctrofusion sockets include buit in rsietanco coin their bod, tho welding machine onde curent through tho roitonce

coil hat cause the PPR material io melt and therelore the hwo sds of the socket and the pipes are fused ogahher af the same

ime.

The elooon sola re dap on hor inal face up to which he pipe sou bo ner inl tho socket, Tse

stops cen be removed wit sharp bled in case he elachoFusion sockels ore 16 be used as ding couplers

The electro ‘union sockets have two pins onthe extemal surface, to which the welding machine is connected while perforing

the welding process. The ino incicler wil appecr during the welding process fo incieato that the welding fomperalre hot

been reached.

Ate poling he election roc, intemal aufoc lf oc cd ene fae ofthe pipe wl be hae

fegohor

Quality slacofusion joi are guaronteed only IF he socket and pipe surfaces are free from moiswre, dit and grease,

The elactrofution process is dore os dotailed below:

1. Cut the pipe at right angles to the pi

suitable pipe cuter

coxis using

2. Clean the parts of the pipe to be welded and the fiting

in order to avoid ary dust or sand that might domege

the quality of he joi

3. Remove the welding electrofusion sockets from their

protective packing and immedioiely fit the pipes ends

in the welding socket; the correct dopth of connection

is when the pipe touches the stops

4. Hold the pipes in their position during the welding

process.

5. Connect the welding machine fo the welding socket

cond start the welding machine. The springing out of

the two indicator pins indicates that the heating time

has ended.

6. Disconnect the welding machine from the welding

socket

7. When welding is completed, itis recommended not io,

‘opply cny mechanical stress (by deflections, torsions,

fractions} fo the joint for at least 20 minutes.

[Note Elacro Fusion process is applicable for gipe to pine comection only

Piping System for Hydro-Sanitary Applications

HANDLING, STORAGE AND TRANSPORTATION

ing the reslience of he

low drecions ard prec

pesca fi

PPR

Handling

+ Take all tosorak when Fondling FPR, porticulaly in vary cokl conltions when the inpac

malaria is edvesd

+ Do not how or diop pipes, or drag them elong hard sukaces,

© Donat scratch pipes ageanst hard surfaces or drag them alorg the ground

lng, ute proecive zing: ard padded eippore. Matol chaine ond hooks should not moke

direst contac withthe

dered in covered areos emeyy tom dae

ime, pipes should be stacked on a lat base o

ct expan to sunlight for long

: 2 in heir nylon packing ard fitings in heir eriginel packaging inl requied fer vse

+ Kool, stacks should contan on pe size only. Where this Is ro! pos

bose of sack

cany ilems on top ofthe pibes

© Pipes should be arg pps for welding

= While with proper shact

on fan UV,

Cosmoplast Plumbing Systems

Transport

+ Whietransoor, pies should be aronged sey on tucks voiding crossing, bending ond ove stacking

'* The pipes should also be fully supported over their ‘otal langth,

“+ Proporprtecon shoud ko provided if chains or cords oe vse to i dovm the load in axdorto avoid camaging he

Pipes

SUGGESTIONS FOR THE CORRECT HANDLING OF PP-R SYSTEM:

+ Hondle Pipes with care, and ovoid hard impacts at the ond ofthe pipes.

Use suitable sharp cutting tools fo cut the pipe with no burs.

‘+ De not twist he pipe or the Fifing altar joining together Alignment up to 5 degreas relative tothe axs of the

pipe can be done immediately after joining.

‘+ Protect the pipes from sunlight and rain during storage and on site.

+ Do notuse a flame to bend the pipes; heating with hot ar up to 140°C can be used when needed.

‘+ Use Teflon sealing tapes where necessary.

«Avoid heavy ond sharp loads on the pipes

+ Follow tho instructions for joining procass.

‘+ Follow the right techniques for exoansion compensation.

‘+ Always protect he pipes fiom direct exposure fo surlight by proper insulation or painting

«When connecting two threaded fitings, use reasonebie cuantiy of feflon sealing tope and avoid using

excess quently

Piping System for Hydro-Sanitary Applications

‘Cosmoplast PPR pipes to DIN 8077/DIN 8078 and finings to DIN 16962 PN 25

oe Cosmoplast Plumbing Systems

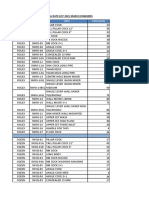

PRODUCT RANGE

PPR PIPES

eto)

COB

716/20, 20 ze

P16 /25 35 a

Pr 6/32 2 44

Piss a 35

PP 16/50. 50 $9.

Piss a Bs

P16 /75, 75 103

P10 /90 Ey wa

Wr 16/ 110 no 15.1

PIB / 125 1 ral

16/160, 160) 219

bY

20/20 20 2

20725 25 a

720/32 2 54

P20 740 Zz) oF

PP 20/50 50 $3

P20 /63 a 105,

20/75 75 125

920760 0 150)

720/110 no 123

20/125, 135 8

20/160 160 236

Leu UAL ras

P5 25/20 20 24

F525 /25 25 42

P25 /32 2 34

P2570 0 67

7525/50 50 2a

F525 783 a 105)

P3525 /75 75 125

7525/90 0 150

1325/110 he 183

Piping System for Hydro-Sanitary Applications

auld

PN 25 PPR FITTINGS

eae Ta

5025/25, | 8a

PSU 25/25 25 I AZ

[pov 5/32 2 54

P5025 Jad @ a7

EU 25 / 50 50 ca

(psu 25/63. 6 105

a Dei Damar | Wel Tk

|_rrzo20 | 20 | 28

F70.5 35 35

[pF20-32 2 4

F040 30 55

120-50 20 69

120-63 a 86

175-04 75 103

nc

PF 0.152 10 15.

Wiasa7 vas i}

reo 219 te a

me ea rye

20 800

25 sea

2 273

ra 10)

20 ©

a 7

78 2

%0 24

To %

is ’

|

Cosmoplast Plumbing Systems

Ne

Piping System for Hydro-Sanitary Applications

P-€90-20) 20 450

Poe 25, 25 20

P-90.22 2 150

Poe 40 a ”

P9060 50 0

Pot90-68 3 3

£90.75 75 2

PrERO. 50) 30 a

P-£90- 110 To 4

PERO -125 125 3

E90. 100 10 2

a

20

2

2 216

o 120

50 o

2

2

12

20 220

2 a

2 1

o a

50 36

a a

75 16

0 10

10 4

735) Z

10 2

REDUCER BUSH MxF

cae Con

7.252025 | 25x20%25 220

7252020, | 2520x206 285

P-1-252620 | _25%25x20 350

poresz20sz | 92x20532 135;

Pet-322532 | 32x25x32 126

Per ao204d | 40x20x40 100)

P--400540 | 40x25 x40 20

Por aera | 40xa2e40 20

1.502050 | 50%20x50 oo

Pore sonsso | 50x25450 20

903250 | 50x32x50 48

"508050__| 50x40 x50 ra

27083 | 6320462 44

G2s | nA a

Per603267 | 63x92x69 2

ee 22

P-1-635063 | 63x50x62 30

Pil 753275 | 75x32x75 20

754075 | 75x 40x75 20

755075 |_75x50x75 %

750975 | 75x63.x75 fa

"903790 | _90x32x90 7

=901090 | _9Ox40x90 2

79050007 | 90x50x90 2

08309 | 90x63 x90 2

507890 | 90x75x90 2

P-T-11050110 | _110x502110 e

Por ivosstie | Woxedz10 0

P-T-11075110 | 110x75x110 ‘

PaT=11ORONIO | _110x90x110 5

P-T-160110160 | 160%110x 160 2

Ast No, So

P-RB-2520 2520 ai0

PRe 3220) 3220 600

PRB 9225 32x25 480

Cosmoplast Plumbing Systems

50x40 90

48x20 0

x 20

x2 20

Bx 20

x50 «

75532 ra

75x40 @

75x50 ©

75x68 2

90x27 2

90x40 6

30x50 36

90%03 26

30575 2A

T1050 fT

V03e 20

W0x75 20

T1090 15

ris. 125110 | 125x110 10

[Deassi@no | 1e0xn10 2

95140105 | a0 125

es

7 #C-20 20 1200

tc. 98 25 612

80-3? 2 319

(pea 0 200

PeAC.50 50 140

(ca a 20

Fi 75 75 2

te-90 70 32

ec 110 no 20

[eens 135 4

PEC. 140 160 7

Piping System for Hydro-Sanitary Applications

ery

P-CR-20 20) 300

Pree 25 5 180

P-cR-32 2 100)

PoeR AO 0 a |

88.20 20 0

Pee 25 25 0 |

P0D-22 2 o

aes ay

P.SB.20, 20) 300

Pr s8-25 25 10)

P-$8-22 32 100

roy Pal Cored

P-1B-20 20 250

PoB-25 25 100

P-1B-32 2 2

Cosmopliast Plumbing Systems

Dardis

FEMALE THREADED SOCKET

RY Pl Pl

“Trresce ar BSPT mace otricie plats Eee.

Piping System for Hydro-Sanitary Applications

(Cosmoplast)

or Seaton) | y/o

PeMS20 Dx 10

Pus. 20%) aon 100

P6294 BS" v0

ewga5% | ain tan

Pens294 sexi 100

ens am) aan %

rns 22x 5

Poms 401K) a 2

Pomg-s01 sn" mi

fvs-62 | ana" 2

PoMS-750%4 Toa" 8

7-nS.903 | 90n3"

Pes 108 V0" 4

ere =

TY 20

hsm) a 150

rs 2sa¥" v0

Ps 150

PES.

ha Biog 10

18-221 wax" 7m

Pis.400h | Ma os

#8.s0i SOx Th" ™

pam aa rr

pere-7sah 753i" 3

13.903 sons" 1

PMG Oa" Z

ae Seated

PvE. nie 0

~rewe-204 | zone 0

Pome 5h | 25x 100

PME 254 | 5x0" »

Pweg | air »

Ces roe ae

P-FE20% xi"

720% Eg

Fe 25% 25 xi"

revta5% 25x

riba aaa

Tea Be

PE a2 2x0"

ei ate Ue Pa eT)

T-WE-20% Davi 100

FWE= 2516 25x 70

Pe WE-25% Bx 160

PWS. 20% xi 21

P.WG-25% 250 5

eS Si (on

PMT 20% 278 200

Fe 25%4 25H 0

FMI 25% 2x 75

FM 22 Bae so]

P-MT-379/4 mew 0

(ewer aero)

"Threads are BSPT made of ick plated Bras.

Cosmoplast Plumbing Systems

PF 20% O00" 1

ras) asa 100

Fr 204 oaN" wo

herrasu | asa |e

rotr-32h sax) «

re ae ‘0

221 mt ra

EE iol ee i dllaaal

P:P-20 20 so

rms |S 10

-ru-32 2 108

[2

9-50 0 4

rue | w

PMU-208 | x20

PoMU-2 |x|

Penu-221 na? 75

Pemysaone | iad |

ems so1m | —_Vx30 2

rwe2 | rx)

PFU=20% x20 0

ce

*.fU-221 1x32 70

Poru-an | do

~pFU-501% 0

Pee] [a

“Twenge are BSP mace otras Erase.

Piping System for Hydro-Sanitary Applications

90° ELBOW WITH UNION

BA reed

be

en)

7

P-Bu-321 x32 20

Peau -A01 er a

Pau S01” 14" x50 0

30-632 68 2

At. No. are eon

F-£U-20% 20%"

Fev 254 25x

PB. 251 25x10"

Pea xi

Pou 321M 22x 1K"

Fev 201, 20x10"

rae car) Con)

P-CU-25% 20%%"

FU 281 25x"

P-cu-201 20x"

Pogu:25%4 Be

P-CU-32h4 32x"

rons a) @y /aron

VoH-20 20 25,

reve 25 2 20

PeVCH. 32 2 5

“Theads are BSPT made fk plated Brass

Cosmoplast Plumbing Systems

1 ree

mee

—_

Eo aS

F-HAV-20

FoHAV 25

FeHwy-22

Fea 40

- F-HAV-30

FHAV. 63

F-HAV-75

LI |

Prac .95

Pac -32

Poca

—_ P3850

Prac 63

Pee Ea g ree

=) ey

P-YC-20 20 “

25 mo

2 50

ton) eee

20 0

EG 0

2 36

© 2

20) 12

a @

75 4

TRAV.90 0 a

PeenWy 110 110 2

P-8C-20 20 a

25 »

2 2

a 2

50 2

3 é

ye

F-DAV-20 20 0

__ si, a

32 D

a 16

50 10

a é

P-Dw-2s

F-DiNV-32

F-DAV=40

F-DAV- 50

P-DAV-63

Piping System for Hydro-Sanitary Applications

PEM. 1/2.3/4

Fone a7

ro Sel Cie)

P-PC-20 20 2,800

Foe 25 25 2,000)

PoPC.32 2 1,500

PPC. a0 mg 1,000

P.FC-50 50 660

Pore 8o e BO

ree ro} Oyo

P-#PC-20 20 1,100

PPC 25 5 11608

P-HPC-32 32 800

oreo « 700

PPC -50 30 400

PPC 8 30

it Se) eye

PoC 40 4 1,000

PorC-50 30 80

PoPC.63 68 450

Cosmoplast Plumbing Systems

Pa

ae

ey e

P-WM-2063, 20-63mm Induding tools 20-40rm)

PWM. 5075, 50:110mm cling

PO a Oe HE oy Cer

P-WM-2063, 2062mm (ncuding tools 20-40rm)

P-WM-5075| $0-110mm Jacluding tools SO7Smim)

P-WM110 140m flcudig feo 110-180)

F-WM- 125 125-160 (Witou tok) a)

W209

= ewias | zi

powa2 2

pw |

Pwn-s0 so

ewe |

PWi75 75

rwi9 | (90

FW 110 110

pws) 2s

ELECTRO-FUSION WELDING SOCKETS

[ee

f=

PoHRK- 9

P-EFM-20110

co Petal

P€F5.20, 20

Poets 25 25

PES. 32 2

Pe @

PEF. 50 0

Pes a

PEFS.75 75:

PL etS.90) 0

P-S-110 10

PC. 2040)

20-40

Cosmoplast Plumbing Systems

Longa}

GA eg

ere

he

20-63

7-75-1620 16-20)

PPS.2025 20-25

7-P5-3240 32.40

PPS 5088 0-88

P-15-75 75

PP5.90 90

PS. 110 110

7-0

PRESSURE TEST PUM?)

PPh

30

PoP 6B

0)

Dao

Note: Chemical Resistance Table for Polypyopylene can be provided as per customer request,

Cosmoplast Plumbing Systems

baer eS) uy

4

Cer)

www.cosmoplast.com )

Ce enone Ka

end Patel per

ero ee 5

Cee a

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Buildexpo Tanzania 2022 Sa LocDocument2 pagesBuildexpo Tanzania 2022 Sa LocRatheesh KumarNo ratings yet

- കമ്പാല മനോരമ (18)Document24 pagesകമ്പാല മനോരമ (18)Ratheesh KumarNo ratings yet

- Buildexpo Tanzania 2022 EaDocument2 pagesBuildexpo Tanzania 2022 EaRatheesh KumarNo ratings yet

- # Item Description Unit of MeasureDocument8 pages# Item Description Unit of MeasureRatheesh KumarNo ratings yet

- So, I'Ve Got Really Good News . Training + ALL of The Bonuses ONE LAST TIME!Document2 pagesSo, I'Ve Got Really Good News . Training + ALL of The Bonuses ONE LAST TIME!Ratheesh KumarNo ratings yet

- How To Launch An ISO 9001 ProjectDocument2 pagesHow To Launch An ISO 9001 ProjectRatheesh KumarNo ratings yet

- Form GST REG-06: Government of IndiaDocument3 pagesForm GST REG-06: Government of IndiaRatheesh KumarNo ratings yet

- Bid Document: Our Services IncludesDocument8 pagesBid Document: Our Services IncludesRatheesh KumarNo ratings yet

- Lines For Consesus by Uma Steel Sector MembersDocument8 pagesLines For Consesus by Uma Steel Sector MembersRatheesh KumarNo ratings yet

- Supreme Master Catalogue 2021Document92 pagesSupreme Master Catalogue 2021Ratheesh KumarNo ratings yet

- Work and Rise-About UsDocument6 pagesWork and Rise-About UsRatheesh KumarNo ratings yet

- International Supreme Price List 2021Document41 pagesInternational Supreme Price List 2021Ratheesh KumarNo ratings yet