Professional Documents

Culture Documents

Discrete Data - Attribute R&R

Discrete Data - Attribute R&R

Uploaded by

Berk BircanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Discrete Data - Attribute R&R

Discrete Data - Attribute R&R

Uploaded by

Berk BircanCopyright:

Available Formats

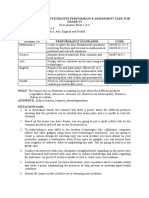

MSA for Attribute or Categorical Data

MSA Example:

Attribute or

Categorical Data

All Rights Reserved, Juran Institute, Inc. 1 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Definitions

Accuracy: Overall agreement of the measured value with the true value (which may be an

“expert” value). Bias plus precision.

Attribute Data: Discrete qualitative data.

Attribute Measurement System: Compares parts to a specific set of criteria and accepts the

item if the criteria are satisfied.

Bias: A systematic difference from the true value. Revealed in the differences in averages from

the true value.

Precision: Variation in the measurement process.

R&R: Repeatability and Reproducibility. Two elements of precision.

Repeatability: The variation observed when the same operator measures the same item

repeatedly with the same device.

Reproducibility: The variation observed when different operators measure the same parts using

the same device, sometimes it can be the same operator using different devices.

The list provides a quick reference for key terms used in Measurement System Analysis.

All Rights Reserved, Juran Institute, Inc. 2 #### XXXX.#### vx

MSA for Attribute or Categorical Data

The Fundamental MSA Question

“Is the variation (spread) of the measurement system

too large to study the current level of process

variation?”

Variation

Product Variability in the (Observed Variability)

Process Variability measurement Total Variability

process

+ =

MSA for Continuous Processes 3 .PPT All Rights Reserved, Juran Institute, Inc.

Quantifying Variation

Like all processes, the measurement process has CTQs. The graph above lists

some of the most common CTQs used for the measurement process. MSA

quantifies the amount of variation for:

Accuracy

Repeatability

Reproducibility

Stability (this is typically covered in the Black Belt workshop)

Linearity (covered in Black Belt workshops)

All Rights Reserved, Juran Institute, Inc. 3 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Bias

True

Value or Possible Causes of Bias

Standard

Sensor not properly

calibrated

Bias

Improper use of sensor

Unclear procedures

Observed

Average Human limitations

MSA for Continuous Processes 4 .PPT All Rights Reserved, Juran Institute, Inc.

Bias

Bias is the difference between the observed average of measurements and the true

average. Validating accuracy is the process of quantifying the amount of bias in the

measurement process. Experience has shown that bias and linearity are typically

not major sources of measurement error for continuous data, but they can be.

In service and transaction applications, evaluating bias most often involves testing

the judgment of people carrying out the measurements.

¾Example

A team wants to establish the accuracy of its process to measure defects in

invoices. First, they gather a “standard” group of invoices and have an “expert”

panel establish the type and number of defects in the group. Next, they have the

standard group of invoices measured by the “normal” measurement process.

Differences between averages the measurement process came up with, and what

the known defect level was from the expert panel represented the bias of the

measurement process.

All Rights Reserved, Juran Institute, Inc. 4 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Repeatability

Possible Causes of Poor

Repeatability

Equipment

Gage instrument needs

maintenance

The gage needs to be more

rigid

People

Environmental conditions

Repeatability (lighting, noise)

Physical conditions (eyesight)

MSA for Continuous Processes 5 .PPT All Rights Reserved, Juran Institute, Inc.

Repeatability

Repeatability is the variation in measurements obtained when one operator uses

the same measurement process for measuring the identical characteristics of the

same parts or items.

Repeatability is determined by taking one person, or one measurement device, and

measuring the same units or items repeatedly. Differences between the repeated

measurements represent the ability of the person or measurement device to be

consistent.

Possible causes of the lack of repeatability are listed on the slide.

All Rights Reserved, Juran Institute, Inc. 5 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Reproducibility

Mean of

the measurements Possible Causes of Poor

of Operator B Reproducibility

Mean of

the measurements Measurement procedure is not

of Operator A clear

Operator is not properly trained

in using and reading gage

Operational Definitions not

established

Reproducibility

MSA for Continuous Processes 6 .PPT All Rights Reserved, Juran Institute, Inc.

Reproducibility

Reproducibility is very similar to repeatability. The only difference is that instead of

looking at the consistency of one person, you are looking at the consistency

between people.

Reproducibility is the variation in the average of measurements made by different

operators using the same measurement process when measuring identical

characteristics of the same parts or items.

Possible causes of poor reproducibility include: measurement process is not clear,

operator not properly trained in using the measurement system, and operational

definitions are not clear nor well established.

All Rights Reserved, Juran Institute, Inc. 6 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Attribute Measurement Systems Study

Discrete qualitative data

Go/no-go basis; or limited data categories

Compares parts to specific criteria for accept/not accept or

to be placed in category

Must screen for effectiveness to discern good parts from

bad

At least two appraisers and two trials each

If available, have Quality Master rate parts first

MSA for Continuous Processes 7 .PPT All Rights Reserved, Juran Institute, Inc.

Listed here are the key highlights of conducting an MSA for attribute or categorical

data. The “parts” can be invoices, parts or reason codes for customer returns, for

example.

All Rights Reserved, Juran Institute, Inc. 7 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Attribute MSA Study

Attribute MSA Example

Appraiser A Appraiser B

Master 1 2 1 2

1 G G G G G

2 G G G G G

3 G NG G G G

4 NG NG NG NG NG

5 G G G G G G = Good

6 G G G NG G

NG = Not Good

7 NG NG NG G NG

8 NG NG NG G G

9 G G G G G

10 G G G G G

11 G G G G G

12 G G G G G

13 G G NG G G

14 G G G G G

15 NG G G G G

16 G G G G G

17 G G G G G

18 G G G G G

19 G G G G G

20 NG G G G G

MSA for Continuous Processes 8 .PPT All Rights Reserved, Juran Institute, Inc.

This shows the results of 2 rounds using 2 appraisers, assessing the same 20

items.

All Rights Reserved, Juran Institute, Inc. 8 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Challenges of Continuous Process MSA

MSA study is an experiment

Requires two or more trials for calculating Repeatability

Needs a way to present the inspection units to the appraiser

multiple times

Is not possible within the continuous process

MSA for Continuous Processes 9 .PPT All Rights Reserved, Juran Institute, Inc.

When conducting an MSA for a continuously running process, parts should be

taken off-line to conduct the MSA study.

All Rights Reserved, Juran Institute, Inc. 9 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Case Example: Visual Inspection of Glass

Packers

Catwalk

Cutter

Inspector

Glass

MSA for Continuous Processes 10 .PPT All Rights Reserved, Juran Institute, Inc.

The example given here is that of visual inspection of glass.

All Rights Reserved, Juran Institute, Inc. 10 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Case Example: Challenges to Overcome

Bias to the standard could be evaluated on-line.

Repeatability and Reproducibility (R & R) could not be

evaluated on-line.

A method had to be devised to allow the inspectors to view

the same pieces of glass repeatedly.

The solution was an off-line conveyor which simulated the

on-line condition as closely as possible.

MSA for Continuous Processes 11 .PPT All Rights Reserved, Juran Institute, Inc.

All Rights Reserved, Juran Institute, Inc. 11 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Case Example: Attribute MSA Method Employed

20 pieces of glass from the process that included both good

and bad samples were selected.

A team of people well versed in the quality standard

classified each piece of glass as either “pass” or “fail.”

All regular inspectors independently evaluated each piece

twice (in random order).

The inspectors used a log sheet to record the data.

Minitab® was used to analyze the data.

MSA for Continuous Processes 12 .PPT All Rights Reserved, Juran Institute, Inc.

There were two outcomes in this inspection or measurement process: pass or fail.

Twenty pieces, a team of inspectors, and two rounds (or trials) were used in the

MSA.

All Rights Reserved, Juran Institute, Inc. 12 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Case Example: Attribute MSA Study Data

Excerpt of

full data

for 20

inspectors

MSA for Continuous Processes 13 .PPT All Rights Reserved, Juran Institute, Inc.

This slide shows the data in MINITAB®. The “Standard” column documents the

correct or expert answer for each piece of glass.

All Rights Reserved, Juran Institute, Inc. 13 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Case Example: Attribute MSA Study Results

Date of study : 9/13 and 9/19/07

Assessment Agreement

Reported by : Bill Sunderland and Bob Panatieri

Name of product: Solar

Misc: Mainline Mark ing

Within Appraisers Appraiser vs Standard

100 95.0% C I 100 95.0% C I

P ercent P ercent

90 90

80 80

Percent

Percent

70 70

60 60

50 50

40 40

l t l t

n y o lly Tim E a r e v e ni e oh n n ie lin rry n y o lly T im E a r e v e ni e oh n n ie lin rry

To M n

S t J ea J Ro C L

n a To M n

S t J ea J Ro C L

n a

Appraiser Appraiser

MSA for Continuous Processes 14 .PPT All Rights Reserved, Juran Institute, Inc.

The graph on the left shows the agreement (or repeatability) of each appraiser

between Trial 1 and Trial 2.

The graph on the right shows the agreement of each appraiser with the Standard.

As shown on both graphs, the blue dots show the percent agreement and the

redlines are the 95% confidence intervals.

All Rights Reserved, Juran Institute, Inc. 14 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Case Example: Attribute MSA Study Results (continued)

MSA for Continuous Processes 15 .PPT All Rights Reserved, Juran Institute, Inc.

This slide shows the Within Appraiser agreement.

For example, Larry scored 100% - Trial 1 and Trial 2 are in full agreement.

On the other hand, Allen scored only 50% agreement – there is only a 50%

agreement between his Trial 1 and Trial 2 measurements. Or he disagrees with

himself half the time!

All Rights Reserved, Juran Institute, Inc. 15 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Case Example: Attribute MSA Study Results (continued)

MSA for Continuous Processes 16 .PPT All Rights Reserved, Juran Institute, Inc.

This slide shows the agreement of each Appraiser (across both trials) with the

Standard.

For example, Larry has 89% agreement with the Standard but, Allen only has 39%

agreement with the Standard.

All Rights Reserved, Juran Institute, Inc. 16 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Case Example: Attribute MSA Study Results (continued)

MSA for Continuous Processes 17 .PPT All Rights Reserved, Juran Institute, Inc.

This shows the level of agreement across all Appraisers. In this case, only 5.56%

agreement!

All Rights Reserved, Juran Institute, Inc. 17 #### XXXX.#### vx

MSA for Attribute or Categorical Data

Case Example: Attribute MSA Study Conclusions

What could have caused the poor agreement?

What was done to improve consistency?

MSA for Continuous Processes 18 .PPT All Rights Reserved, Juran Institute, Inc.

Given the results of the MSA study, what could have caused the poor agreement?

And what should be done to improve the measurement system?

The measurement system must be improved and tested again (with another MSA

study) to reach at least 90% agreement before the data can be used for baselining

process performance or further analysis.

All Rights Reserved, Juran Institute, Inc. 18 #### XXXX.#### vx

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Perfect Rigor - A Genius and The Mathematical Breakthrough of The CenturyDocument217 pagesPerfect Rigor - A Genius and The Mathematical Breakthrough of The CenturyChin Mun LoyNo ratings yet

- MechatronicsDocument12 pagesMechatronicsgkarthikeyanNo ratings yet

- B.Tech. Mecb Anical Engineering (Btmevi)Document2 pagesB.Tech. Mecb Anical Engineering (Btmevi)itzvenkataramananNo ratings yet

- BIME-020 B.Tech. Mechanical Engineering (Btmevi) Term-End Examination June, 2013 Bime-020: Industrial EngineeringDocument2 pagesBIME-020 B.Tech. Mechanical Engineering (Btmevi) Term-End Examination June, 2013 Bime-020: Industrial EngineeringitzvenkataramananNo ratings yet

- B.Tech. Mechanical Engineering (Btmevi) Term-End Examination June, 2013 O Bimee-019: Total Quality Management (TQM)Document2 pagesB.Tech. Mechanical Engineering (Btmevi) Term-End Examination June, 2013 O Bimee-019: Total Quality Management (TQM)itzvenkataramananNo ratings yet

- Daftar Pustaka: Regina Lorinda, 2014Document6 pagesDaftar Pustaka: Regina Lorinda, 2014seprieNo ratings yet

- The Science of PersuasionDocument5 pagesThe Science of PersuasionMala RahmanNo ratings yet

- Watson's Theory of Caring ScienceDocument44 pagesWatson's Theory of Caring ScienceAyyu SandhiNo ratings yet

- Roots of Adam Smith Division of Labor in Medieval PersiaDocument29 pagesRoots of Adam Smith Division of Labor in Medieval PersiaMELİHNo ratings yet

- JournalElectrobotz PDFDocument56 pagesJournalElectrobotz PDFLilibeth Allosada LapathaNo ratings yet

- Principles of Auditing I Group Assignment - PDF - Principles of Auditing I Group Assignment 1.the National Auditing Framework in - College SidekickDocument18 pagesPrinciples of Auditing I Group Assignment - PDF - Principles of Auditing I Group Assignment 1.the National Auditing Framework in - College Sidekicknatnaelpom0No ratings yet

- Business StudiesDocument41 pagesBusiness StudiesArun DalalNo ratings yet

- ID Pengaruh Strategi Diferensiasi TerhadapDocument13 pagesID Pengaruh Strategi Diferensiasi TerhadapIka IgaNo ratings yet

- Bahasa Inggris Erika Viona RoslinaDocument3 pagesBahasa Inggris Erika Viona RoslinaerikaNo ratings yet

- BSCS Curriculum 2004Document1 pageBSCS Curriculum 2004John Gabriel CanoyNo ratings yet

- Fore Word: PerformanceDocument1 pageFore Word: PerformanceDesai NileshNo ratings yet

- 1.1 Introduction To The Particulate Nature of Matter and Chemical ChangeDocument19 pages1.1 Introduction To The Particulate Nature of Matter and Chemical ChangeJuan Fernando Velasco ForeroNo ratings yet

- Motion: Immobile, Stationary, or To Have A Constant or TimeDocument9 pagesMotion: Immobile, Stationary, or To Have A Constant or TimeJohn HenryNo ratings yet

- AP 8 3rd Quarter TOSDocument1 pageAP 8 3rd Quarter TOSGejel MondragonNo ratings yet

- Newtons Law of Universal GravitationDocument10 pagesNewtons Law of Universal Gravitationdheerajr97No ratings yet

- Name: Menahel Nosheen Section: 6 B Evening Roll No: IFE18873 Submitted To: Sir AltafDocument11 pagesName: Menahel Nosheen Section: 6 B Evening Roll No: IFE18873 Submitted To: Sir Altafsafder aliNo ratings yet

- Lilis SusantiDocument14 pagesLilis Susantiihsan alutfi3No ratings yet

- CONTEXTUALIZED-IPAT-FOR-GRADE-6 LatestDocument8 pagesCONTEXTUALIZED-IPAT-FOR-GRADE-6 LatestMary Rose JalipaNo ratings yet

- Meaning and Relevance of History: Readings in Philippine HistoryDocument27 pagesMeaning and Relevance of History: Readings in Philippine HistoryAlthea Faye RabanalNo ratings yet

- Sample Discussion Section in Research PaperDocument4 pagesSample Discussion Section in Research Paperc9qb8gy7100% (1)

- 1B1 de Brigard HistoryDocument46 pages1B1 de Brigard HistoryDookcaseNo ratings yet

- Literature Searching TechniquesDocument28 pagesLiterature Searching Techniquessivman.selNo ratings yet

- Technology As A Way of RevealingDocument29 pagesTechnology As A Way of RevealingGillian Joy Landicho II100% (4)

- O Level Pakistan Studies 2059/01: Unit 13Document2 pagesO Level Pakistan Studies 2059/01: Unit 13mstudy123456No ratings yet

- Experiment 1 Planck'sconstantDocument6 pagesExperiment 1 Planck'sconstantsurajNo ratings yet

- Researcher Positionality: Angel LinDocument20 pagesResearcher Positionality: Angel Lin1000018207No ratings yet

- The SAT Writing and Language Test: Contact UsDocument20 pagesThe SAT Writing and Language Test: Contact UscadyNo ratings yet

- Business Research Methods: © Oxford Fajar Sdn. Bhd. (008974-T), 2012 1 - 1Document18 pagesBusiness Research Methods: © Oxford Fajar Sdn. Bhd. (008974-T), 2012 1 - 1Parcelhub Bandar Saujana PutraNo ratings yet

- State Average Individual Income in 2020Document7 pagesState Average Individual Income in 2020Onyx CoffeeLabNo ratings yet