Professional Documents

Culture Documents

SNR LM Ball Screws

SNR LM Ball Screws

Uploaded by

Volodymyr0 ratings0% found this document useful (0 votes)

16 views44 pagesSNR LM Ball Screws

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSNR LM Ball Screws

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views44 pagesSNR LM Ball Screws

SNR LM Ball Screws

Uploaded by

VolodymyrSNR LM Ball Screws

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 44

ST Tete Clete

Ball screws

Soe |

ike

For almost a century, SNR has designed, developed

‘and manufactured bearings to mest the most deman-

ding of applications. In April 2008, SNR and the

Japanese Group NTN joined forces.

‘As one the 3 largest companies in the manufacture

of bearings, our group offers its customers added

value in terms of service, quality and products.

‘The NTN-SNR Group is distinguished by its global

presence and by its company-wide quality assuran-

ce system.

We have been active in linear ball ral systems since

1985 and our complete range, based on innovative,

high-quality products, has developed significantly.

‘Today, we can offer a solution for a vast range of appl-

cations that need linear motion systems.

Tris catalogue aims to help you discover our new

standard range of ball screw products in rolled and

‘ground versions,

er of bearings.

‘The large range of nuts, options for custom mach

ning and our extensive technical knowledge enable

Us to design and propose custom-made solutions for

our customers.

Ball rail systems find applications ina diverse range

of industries such as machine tools for metal, wood,

plastic, specialist machinery, aeronautics, automa-

ted assembly lines and semi-conductor industries.

ur technical department draws on many years of

experience in all these areas and is available to help

you develop solutions suited to your needs.

With that in mind, this technical documentation was

designed as a basis for dialogue. Our technical and.

sales engineers will provide you with any technical

information you may require.

‘SNR cannot be held responsible for consequences arising from any errors or omissions that may be

contained in this documentation, although every care has been taken in its preparation. As part of our

programme of continuous research and development, we reserve the right to make comprehensive or

partial modifications to products and data appearing in this technical catalogue without prior notice.

‘SNR Copyright International 2011

Contents Page

Ball screws overview 2

Standard programme, Rolled, Tolerance G98 7, .seesusseueseissieseutenienresnte 2

Special programme wnileg or round 3

Standard programme Ball screws .......0..00+ 4

Rolled models tolerance class 7) forthe compact DIN Nut (ype SC/DC) 4

Rolled models tolerance class 7 tor nut (ype SK, Cl, SUIDU, SE) 5

‘Standard programme Ball nut 6

Type Sk single miniature flange nut for rolled screws 6

Type Cl single eylingrical nut or rolled sorews 7

Type SC single compact flange nut to DIN 6906), for oled screws, 8

Type DC double compact lange nut to DIN 69051, for rolled screws 3

Type SU single lange nut to DIN 69051, for rolled sores 10

"

12

3

‘Type DU double flange nut to DIN 69051, for rolled screws

‘Type SE single wide pitch nut for rolled screws

‘Type SH single threaded nose nuts for rolled screws

Bearing units 14

Fixed bearing unt PBUF with ang eI sacs

Eloatngbearne unit PEUL win grooved bell bearng DINGS weno cc eceecencts TAT

Fixed bearing unit BK ves. DINNIIIIIEED 8

Fixed bearing unt EK 19

Floating bearing unt BF 20

vee 24

F, Machining for fixed bearings 2

, Machining for supported housing 2

Travel variation and travel deviation

Running and bearing test according to ISO 3408-3 . 25

Functional tests according to ISO 3408-3 ........ ++ 28

Axial clearance and preloading .......-+++++e+0+ +» 30

Critical speed of ball screws .. 31

Permissible axial load for the screw (buckling) .... 1. 32

Calculation basis ..

Mounting the nut on the screw.

Operating and maintenance information

for the ball screws .

Typ designation code

Ball screw coding

Your enquiry form

Other Catalogue Documentation ..

wv

‘Standard programme. Rolled. Tolerance class 7.

Materials: Spindles k55

Nuts 18CrMo5

Balls 1000r6

Sealing system for ball screws: Smooth running sealing

oeqr?

ut ype

Sze

‘807

0825

‘1008

‘O1204

205.

1402

‘T1605

7

T1616

‘02004

mt

(02020

(02505

iT

(02525

ESGESEERESEG

03210

(03232

04070

(04040

‘=| |ele|

05020

6310

lolele| [al

‘08070

BEEEEEEEEEEEREE

Rolled, right-hand thread

Rolled, left-hand thread

‘Available from stock

Available from ex stock

Not a standard programme, request through project

.

‘Special programme whirled or polished

Whirled Tolerance classes 17, 15

Ground: ‘Tolerance classes TS, 1, T1

Models: Metric and inch

Diameter: From 6 mm to 125 mm

Pitch: From 1 mm to 50 mm,

Nut variants: With flange according to DINASO

Cylindrical

With thread socket

Miniature

Special models

Proload: Max 5% of dynamic load rating (single nut)

Max 10% of dynamic load rating (double nut)

Materials: Spindles C153, X80CrMoVS (rust-proof e.g. for application

in medical technology)

Nuts 16MnCr5, rust-free models are possible

Balls 1000r6, X45Cr13 (rust-esistant) ceramic balls

Wiper: PTFE wipers, brush wipers, felt wipers ete

ATC coating e.g. for use in corrosive media, food industry,

‘The ATC coating consists of more than 98% pure chromium. Its an extremely hard, crack-iree, dome-shaped,

precise, very thin and highly pure chromium coating,

Las

4 Reference diameter [mm]

dy Nominal ciameter (ren)

4, Outside diameter mm]

4, Diameter atthe thread root [men]

P Pitch fmm)

Lae Maximum length of screw [men]

Rolled models (tolerance class 7) for the compact DIN Nut (Type SC/DC)

Dimensions Imm [Moment of inertial Wass

References | d | a | P | oe Tee | kgemaim | kgim

asHoizes | 12 [i230 | 5 [12 | 980 1000 | 7.6410 [0.6

BsHoI210 | 12 [12,30 [10] 12 [9.80 71000" 1,42x105 | 0.85)

BsHo16s | 16 | 15.67 | 5 | 16 | 12.80 3000 3,i7x105 | 1.24

BSHO'610, 16 [15,67 [10_| 18 [12.89 3000 [354x105

BSHOI616, 16 [15.67 | 16 | 18 | 12,80 2900 | 345x105

[BSHO1620, 16 [15,67 [20 | 15 [12,89 '3000_[3,64x105

psHo2005 | 20 [21,08 | 5 | 20 | 17.90 3000 | 1,04x107

[BsHo2010 | 20 [21,08 | 10] 20 | 17,90 '3000_[ 1, 14x107

[BsHo2020 | 20 [20.75 | 20 | 20 | 17.60 3000 1,12x107 | 2.94

[BsHo2505 | 25 [26,08 | 5 | 25 | 22,90 5800 | _2,62x107

[sHo2510 | 25 | 26,08 | 10 | 25 | 22,90 5800 | 2,82x107

[psHo2525 | 25 [26,08 | 25 | 25 | 22,90 5500 | 262x107

[psHoa205 | 32 [93,08 [5 | 32 | 29,90 6000 | 7,24x107

[psHo3210__| 2 [92,35 [10 [31 [28.38 '5600_ | 6,54x107

jpsHo3220_| 32 [92,35 | 20 | 31 | 28,38 5500 | 6,54x107

jpsHos232_|32_[92,35 | 32 | 31 | 28.38 5000 | 6,76x107

jpsHoso0s | 40 [41,08 | 5 | 40 | 97,90 6000 | 1,80x107 | 9.44

BsHoso10 | 40_[ 99.52 [10 | 38 | 93.17 6000_|1,28x102 | 7,93,

psHoso20 | 40 [39.52 | 20 | 38 | 33.17 5000 _1,29x102 | 7.93,

[psHoaoao | 40 [3952 | 40 | 38 | 93.17 5000 | 1.454103 | 6.42,

BsHoso0s | 50 [51,08 | 5 | 50 | 47.92 6000_| 449x102 114,88

[BsHoso10 | 50 [0,16 [| 10 | 48 | 43.81 6000 | 354x109 [13.18

jpsHo5020_| 50 [80.16 | 20 | 4a | 43.81 6000_|3,54x107 113.18

[psHos050 | 50 [80.16 | 50] 48 43.81 6000 3,87x109 113.80

jpsHoesi0_|63_[ 63.16 | 10 | 61 | 56,81 7o00_| 922x107 |21,64

jpsHo6s20_| 63 [63.43 [20 | 61 | 56,29 | 7000 | 951x103 [21.29

psHoso10 | 80 _| vate | 10 | 77 | 72.80 7000_| 247x102 134,92

[psHos020 | 80 [80.24 [20 [7770.71 7000" 2.45x102 134,72

Rolled models (tolerance class 7) for nut (type SK, Cl, SU/DU, SE)

Dimensions [nm] [Moment of inertia] Wass

References [| G [| P| & oe Trax | kgema/m [kg/m

[BSHO0601 6 | ea] 1 [6 SAT 900 | 0.834107 0,20

[BSHOO8O1 8 | 820] 1 [8 7.40 [1200] 2.67x10% [0.36

[BSHOOBO2 3 | ea] 2] 8 721 | 1000_|_2,71x10% | 0.36

BsHooso25 | 8 | e4tas | 10 | 7.21 | 1000 | 280x107 [0.37

BsHoioo2 | 10 | to4t{ 2 | 10 | 921 | 1200 | S.tixi0 | 058

[BsHOI004 | 10 | 1068[ 4 | 12 [868 | 1200 [653x107 [0.57

BsHoiz02 | 12_| 12.41] 2 | 12 | 14,21 | 1200 | _1,07x10= 0,62

BSHO1204 12 [12,304 [12- | 9.80 | 1000 4.5txt0= | 0.86

[BSHO1205 12 [12,90[ 5 | 12 | 9,80 | 1000_| 7.64x10" | 0,78

BsHoI402 | 14_[ 14,412 | 14 | 10,21 | 1200_| 2.01x102|_0.85,

BsHoreo4 | 16 | 1682{ 4 | 16 | 14.40 | 3000 | 435x102 1.46.

BsHoTe05 | 16 | 17,08[ 5 | 16 | 13.90 | 3000 | 4,45x10= 141

BsHoIe10 | 16 | 17,08| 10 | 16 | 12,90 | 3000 | _4,36x10= 1.46

BsHoIe16 | 16 | 15.67 | 16 | 16 | 12,90 | 3000 |_3,34x10= 1.27

BsHoz004 | 20 | 20,82| 4 | 20 | 18.40 | 000_| 1,09x10 2.32

jpsHo2005 | 20 [21,085 | 20 | 17,90 | 3000_[ 1, 12x10 [2.35

psHo2010 | 20 | 21,08{ 10 | 20 | 17,90 | 3000_| _1,18x10~ 241

[psHo2020 | 20 | 20,76| 20 | 20 [17.60 | 3000 | 1,00x10 [2.24

BsHozso4 | 25 | 25.82{ 4 | 25 | 23,40 | 6000 | 2.73x10 3,65

[psHozs0s | 25 | 26.08[ 5 | 25 | 22.00 | 5800 | 262x104 | 3.50

psHosi0_| 25 | 27.15{ 10 | 25 | 20,80 | 5800 | 2,94x107 3.81

psHo2525 | 25 | 26.09 | 25 | 25 [22,90 | 5000 | 2,60x10 3,64

BsHoszoa | 32 | 32.82{ 4 | 32 | 30.40 | 6000 | 7,48x10" 6,08

psHosz05 | s2_|33.08[ 5 | 32 | 29.90 | 6000 | 7,25x10% 5.98

psHoszi0_|~s2_|34.15{ 70 | 32 | 27.80 | 5900_[7,69x10" 6.16.

[psHos220 | 32 | 33,a5{ 20 | 32 | 29,98 | 6000 | _7,76x10" 637

psHoszs2_| 32 | 92.95[ 32 | 32 | 28.0 | 5000_[6,69x107 5.81

[BsHo4o0s | 40 | a1,08[ 5 | 40 | 37,90 | 6000 | 1,81x107 | 9.40

BsHoao10 | _40_| 42,15{ 10 | 40 | 26,80 | 6000 | _1,66x109 9,02

[BsHo4o40 | 40 [-a9.52[ 40] 38 [93,20 | 5500 | 1,43x109 8.29

BsHos010 | 60 | 62,15{ 10 | 50 | 45.80 | 6000 | 4,19x1 14.35.

[BsHo5020 | 60_[ 63.58{ 20 | 50 | 44,05 | 6000 | 445x107 | 14,82,

[BsH05050_| 60 | 52,25[ 50 | 50 | 44,31 | 6000 | 4,33x10: 14,59

[BsHO6s10 | 63| 65.15| 10 | 63 | 58,80 | 7000 | 1,09x107 | 23.12

[psHoes20 | 63_| 66.24[ 20 | 63 | 56,72 | 7000 | 1,15x107 | 23.83,

[BsHo8010 | 80_| 82,15{ 10 | 80 | 75,80 | 7000 | 28x10" | 37,76

jpsHoso20 [a0 [93.25 | 20 | 80 [73,72 | 7000 | 2,87x102 [37,56

oO

gramme

‘Type SK single miniature flange nut for rolled screws:

Form 01004

Dimensions frm) Toad rating EN Tstiiness

Size [Thread D H ayn. | stat | K

'o| bert

4] Baal og] AVE) E |W} 20,10]* | ¥ | 2 12 Cy | Cao | itu)

coor] a [el [oso [2 [e[salis[ral ve sa[-[-[-| 5 | 109 | 20 | a

coor! A | [1 foso [afer] 4 frelar[ te sal-[-[-| 4 | 158 | 395 | 197

ooeo2| A] [2 fizolialer[afielar[ ve _foat-[-[-| 3 [air | aaa [ar

fooe2s| A [26] 1,20|16|29| « [e6|2a| 20 fuel |-[-[ 3 | air | 4ao | 127

oro0a| A | >| 2 [120 [elas s [aalar| op fest |---| 3 [298 | ss8_[ tar

or0o4 |_| a [2,00 |26|46|10|94|96[ 28 |a5[e [a5|ve] 3 [450 | eee | 67

orao2| a |ra[ 2 [120 |aolar|s faslea] 2a es[-|-|-| 4 | 328 | aes | 216

ovaoa| A [14[ 2 [120 [a1 |40[6 [ale 26 Is8[-[-[-| 4 | 348 | 103 | 236

Ball nut sizes shown in bold are available ex stock.

+ Number of circuits

P-Pitch

‘Type Cl single cylindrical nut for rolled screws

bo ek

PETER

seo fread | Jeate) 2 [a [ur] ue

por}, Preamp ae ees s

presss[n| [eforra| oo pas po [aos

pmor|—F pe feamf an posts

pamssatri|° rferrel-ar pape poops

pmoeF-| pr femr pepo ef ref

passa HI os [fove|-apas Po [os

pastoa[ | oferae-m-per potas

ser “RO] [a faset [ae [woo [ss bs

pros] orfesso| er Pas Poa aos as|a0 eae a

pamesRp Ps [ass @ [aos foes 20| | ao =

panosrr| ° [rote pars a8 7

pros fax-sofeasa teparps aS 3

psnos[-r— fer rope rertar pe fowstas {apes oz

panos[-r—fsssofea reparte forctests [rest To

Balu sn show bl ar bo sto

5

easing

rele

&

vp to 05282 ‘rom 93008005

Form 8 Form 8

Dimensions Imma Nam [Leacratna ANT | StTness

See faye porsAleye mH) # [x] @ [ter | 2 |S | ah

oraos-za| ara] 5 [Bs00 oa ao] os [oa|sOpzO To] as Zax -eao [1290] 105

oreos-sa| a] [5 |2779|ea) as} i0| o5 fo] sofs0.16] 55 [Weim [aoxt | 10,50" 2asa [200

orero-28] a] [10 |2r7efoo)ashiol ar fofsofs0.15] 55 [Maxim [acer | 020 | 17.56 [206

orere-18] A ]:5) 16 [2779foo) cafiolas fof ofs06] 55 [Maxim oer 62 [115 [97

orere-28| a] [6 [2r7afoo) cahof or foo olios|s5 [vexiP|aser 7.92 [1791 [26

oread-is| a] [20 ]2relealasliolsrfoeolioe] 55 [Maxim eet | 6a [thar [ar

azo0s-s8| a] [a.75|as)saf0| «0 frfaali0.15] 6 [ext [aoe | 16.55 [0.10 [260

ozor0-38| A ,,.| 10 |a75}o6) 58] solo raalsoas| 66 [MexiP aot | va67 [o7s0 [02

ozoe0-18| a |°° 0 farafao)safvol sr farfaaluoas] a6 [oxi oer [7.96 1724 [06

azaeo-28| a] [20 a:ro}ao)sefsolr7rlaals0,6] 66 [MexiP|aoet | 1000 [ost | ee

azs08-38| A] [5 [a75|a0)oo[ rol <0 ora [-05] 66 [oxi [aot | 16,16 [a8 | 20

azs10-38| A, | 10 |a:7o| a0) oa} aL fr a0. 16] 46 [MexiP [aber [Tene | a5.as [ear

a2ses-18 | |°°| 25 fa.s7s|eo|o2| 2] ro [sr fas)s0.76| 09 [WoiP| ext | 0.20 [arr | 2166

e2ses28| A] [25 .i75|ao|o2| 2] 5 srlaa|s0.16| 66 |[WociP [Zant | 1208 [355 | a3

aseos-s8| A [52] 5 [a.75|s0) sofa] fosfoo|s0.15] 40 [oxiP [seer | ra03 [69.10 [00

aser0-38| A] [10 |969{s0) s0|ra[ 2 fs|ao{s0.15] 40 [MaxiP seer | 2413 | ri.16 [00

asez0-2.8| A, [20 |s960{s0) sofa 6 fosfa{s0.15] 40 [MaxiP|2eer | vero .76 [22

| [32 fa.0 [so] 80 ro oe fos|e2[z0-r[ 90 [wexiP| tax | 12.99 [as 60 | 20s

|_| 32 fa.co [so] 20 rales|ee[s0.16[ 90 [wexiP| 2 | 1902 [5250 | ara

A [A0|-5 [a.175 [oa] 29 15] 45 [rel 70fs0.6[ 90 | wed] 90 | 19.90 [rae | soe

A] [10.0 |sa]29 a] ea rel 70ls0.6[ 90 [wexiP| 9.0 | «o.97 [198 73] 657

FT| 420 [8.250 [6a] 29 [1a] 2 7a 0fs0.6[ 90 | wee | 200 | 99.02" [105 08 sao

B_|°° [40 [6250/63] 03 [15 [105]7a] 70]:0,15] 9.0 [Maxi | 1.8x1 | 25,35 [65,19 | 330)

27] [20.5060] a9 [ro}s|78|0ls0,6[ 90 [wade | 200 | 707 Fotar| S10

a [50] 5 [a.s75 75} 06146 fosfas|s0.6[1%.0] wexiP| oc | 21,65 [ons | 067

A] gq 10 [6.50|75}10lv9[ 68 oafes|s0-6[17.0| Maxie] 3x | 5.29 [17507| 776

&|"°[ 0 fos [75h o|ralionloale5|s0.19[r.0 [Made [ aoe [36.99 [161.27] —e53

Bal nut sizes shown in bold are available ex stock.

* Number of circuits

Pitch

‘Type DC double compact flange nut to DIN 69051, for rolled screws

Greasing

hole @ '

ae ae

upto 03232 from size 04005 : :

Form B Form B

Dimensions inl Sines

Sze [Tread D Number" K

a] par efalefe|w] x |x]a Nia

(or605-38| A [2,774| 28 | 48 [10]73 | 3840] IaxiP| ae 402

(or610-28| A [2,776] 28 [48 [1097 [8] 40 0,16] 5.5 [MexIP| _2.8x1 304,

joao0s-s,6]—R_[--[s o.17s] 9658 10] 75]47[aaf.0.1 6.6 MoxiF|_3.8x 490)

fo2010-3,8 B_ |*° [103,176] 36 | 58 10 [120] 47 [44|:0. 19] 6.6 MExt|_3.8x1 520,

[o2505-5.8| “R_[-[5 [3.175] 2062 [10 480.15) 6.6 [MexiP|_9,xi 579)

jo2s10-3,8|_R_ | |10 [3,175] 40 [62 [12 122] |48|+0, 15] 6.6 MExtP| 598)

(o3208-3,8] A [32/8 [3,178]50] 80] 12 | 82 [65]62|:0,15] 9.0 MexiP]_3.8x1 606.

loszt0-3.8| “A _| ., [10)3.969] 50/80] 1322] 65]62|.0.16] 90 [MoxiP|_3.8x1 735

(oaa20-28 _&_|° 50 [@0 [72 160 0,75] 8.0 MxiP|_2.8x0 568

(04005-3,8| A [20] 5 [s.175]03] 93] 15] 85 |76|70/:0.75] 9.0 MaxiP|_ Ser Ey

[oxoi0-5.8| A _|., [10fsg50f 6a] a3] 14 IMaxiP|_3.6x1 92

(oa020-2,8| | °° [206.350] 63] 93] 14 162] 78|70):0.75] 0.0 MaxiP|_2aet 718

fos00s-3,8] —R_|50| 5 [3.175] 75110] 15 IMaxiP|_3.8x1 at

losoro-sa[—R_, [10|e.350) 75] tole IMexi|_S.8et 1068

3.8] _F_|"* [20)6,.350]75 110] 18 216) 99) 85):0, tot .O[MaxtP| 3.8 1138

Bal nut sizes shown in bold are available ex stock.

opgramme

‘Type SU single flange nut to DIN 69051, for rolled screws.

_|—--_ aa

~ prodx0 vomate otos

Fo Form

aT CaS SRNL Ss

see [Tens aT fear] S| afelelw] # [xfef me] S| 8 | ay

el

vs] Aas [26 aso] 20820 soso] a [vase [on ate

eros] a | ols [>on so sr[an|20 [sores [we] —2 [vo Lonss [ose

ose] “Ro [ a [6580 | ar [ar sos|es| we] a sas [aoe [are

aoa] | sr |aefea | s0|er[ar|er[sorefos|ws] 1 [va Pano [ar

OS

cm a

astoa|—a | fofa7ao|aof a9] es]r [as |sorelan|we] a oar [rst [a

eos] a] [fz [sooo [9] |ee[sorefao|we] afar barat [eo

Osama] rc 7s |s0| so [79s] |e [sore|a0| we] a [vans [ea [ae

swea|—er—|ofesso|s0| so 9 |so[ ese [sorelao|we| a [arse [rare [sar

rouse] ere. [s [sana [vee] mao |sone|an|wal a sone ra [arr

sores] —rvc—|“ffofassofsn |e [sx] 7a|70|aoselao|wal —¢— spor-[reaoo [ris

soa] rve— [fro sso|7e v0 aes | aaa [sonehrchwal a saa roo [mer

lsorea|—= file ssofa0 fas 9 [es|oalse[sosehtaiwal —¢—[esav-[oanas [oro

foes20-4[ A |°° 2a]9,s25 [95 [135] 20 [14/1 15[100|0.18[a.5[Me[ a 112,23 | 359,44 | 1098,

sro] — 1c elas ooo ia solani ve| —1—[ var [ovase | roan

foaoz0-4] A | fpofo.sa5 [i2slte5|25 [reahtas|ia0)sozohiaaivel 4 426,61 [468,24 [1352

Bal nut sizes shown in bold are available ex stock.

* Number of circuits

P-Pitch

‘Type DU double flange nut to DIN 69051, for rolled screws

ag aa

up to 08210 from size 04008, -

Form 8 Form B

Dimensions In] [kead rating TKN Stiiness

Sze | tweed FeToyeara] [4 fale fw] [x [o[m Paes ae

a 6 me] 4 | ose [250 | 421

[or605-4] Ac 48 4 [1383 [2999 [431

loret0-3 A 48, 3 [roge [23.55 | 3s

fo2004-4[ A 5B. 410.45 [29:29 | 500.

[o2005-4| ar 58 Me] 4 28,00 | 519)

[o2504-4[ A 2 Me] 4 588

[0205-4] ar holior] 51 mel 4 608

jozst0-4| ot Mel 4 657

os20-4[ 8 & Mela e

[oa205-4] AL 80 [12] 102 65; 4 725

fosai0-4| AL a0 [ra[r62] 65 4 504

[o4008-4] Av 33 |14|105 | 78 4 55;

foaoro-a] A 96 [i4[165] 75 4 970

[os0t0-4] hiojie)171 [es [es |20.15 [11.0] Me] 4 1147

losst0-4] A 20 [125 ra] 182 olme| 4 1362

[oes20-4] A 95 [135 20]200/115 [100] +0.15 [13.5] Ma] 4 1490)

josoto-4| | fro} 6.260 105/145 20) 182 i35|Mel 4 1529)

[oaozo-4[ A 1° polo.s0s [125|r65 [as|205) 145 ]190|20.20 [13.5] M—| 4 1838

Ball nut sizes shown in bold are available ex stock.

* Number of creuts

P-Pitch

‘Type SE single wide pitch nut for rolled screws

opgramme

Greasing

ae

Fom 8

Danaea Ta [came ate RAT Siow

ssze_ fred o un: an] sat] K

afepard efafeeefw] a |x [ao | ber | Se | vim

fwereal aT, ferral so won| so ao [a [oalaara| as [we [ine romr [ase | 2be

orer6-6[ "| “frre so [6 ft] 10 [oe [a2 [oe 076] 45 [Me [1a 18 te [4726 | 56a

ocooal_rf .rel sol [2 [ol r [so [ai fanis| ss [we [ina reas | 925 | a0

oz020°6| 17586 [62 [12 [70 [47 [so at [0.76] 5 [Me [17a | east [6.12 | 6s

ososal_rffoooal ar [a [1237 [eo [0.5/6 [we [ine too soe | a!

025056) 5 seo] ar [ra [ra [12 [67 [60 [40]20-76[ 66 [We [174 [65.14 [103.76 [1S

cooanalr [foal sal 2 7 [2] [7 feols.i5| a0 [ve [ine [anzt | aoa | so

joszaz-e| ||": reel 58 | oo [a7 [12 [rere foo] 0.18] 90 [Me [1a] 6.88 [160.06 | 099

owao-o| aL, fasol 3 |rralioal 16] oo raf v0.6] 0] we [rz a0. | ra02e [ear

joao4o-6[ (6.350[ 73 [114/19.5[ 15 | @9 [93 |75[20,15[11,0| m6 | 7,7x4 | 81,87 [260,08 [1254

osae0-9|a [201 oo [tase 0 [07] alaa[ao.s6| 20] we [1792 [90 [rose [ran

osaso-6[a |) sal oo [rosa el.o0 Hor[a2lse]ao5Ls<0Lve [a malice [ence] 761

Ball nut sizes shown in bold are available ex stock.

+ Number of circuits

{Ground on request

Type SH single threaded nose nuts for rolled screws,

dde14 Extemal recirculation)

216 (Internal

Dimensions [rl

See teat T5Jearojo] a jel ec fu

loos2.s| [8 [2a 7.| misxiP |7.5|23,5]+0.15| 10

jorooz| A] [2 | a2 [sal miner [75] o2 |o0.5| 3

joroos| A |'°fa [2 | 25 | MaoxiP [10] a 3

jorzo4| “Rf [a 25 Ps.al 20x [10 13

jora0s[ A |'* [S25 [25.5] MaoxiP [10] 3 SE

foraoe| A [fa] 4 [2.98% 92,7] va5 SP] 10, 13

foreos| “| [4 [acer | 29 [Means S| 6 4.

foros | A |'° [5 [a.17s [a2.5| Moe 5|12 fa.25|

fozo0s| [20] 5 [3.175 | 3 [Missi Se |15 205 204

jozs0s| A [25] 5 [3.175 [43 |Mzox1 50] 19] 69 [20.15 [92.17 363

Ball nut sizes shown in bold are available ex stock.

* Number of

Ground on request

ats

G@

&

Fixed bearing unit PBUF with angular contact ball bearing

The fixed bearing units consist of

* Pillow block housing made of stee! with stop edges on both sides, direct drive adaption and lubrica-

tion option

Double row angular contact ball bearing with a contact angle of 58°

Slotted nut with radial clamping

Thread ring

Suitable for standard spindle ends type F3, Fé (see page 21)

= ; "

Unit [Nerina] Pitch fad 0 18] Beaing CIN) | CO[NI] Sioted nut [en I .oco SHH)

[PBUETO| 16 _| 475 — [70] 34 [OBSCN Tose APS] TST] TE7OO PSL Tox | 6 | 2 [S| G2 [aa]

Jpaur rf 28 ft t6 Tio] 2a aslasin 1242 -2ns| 12000] 21300 Pas| 12x | @ | 2 [oa] a4 J2a| 5]

[PBUETS| 20 | 7020 [75] a5 [SBSIN 1545 -2F| 16600] 24700 [PAS| oat [10 | 3 [eal Ge ala]

[PSUEr?| 25 | Br 10725 [17] 47 [s|BSUN 1747 -2ns| 20800 | 27e00 PAS| xt [15 | 3 [7a] 35 [75 |]

[peur20| se [10 [20] 52 [s)BSiN 2052 -2n|24500| s4000 PAS|zoxt [48 | 5 [77 42 [er] 2 fl

[PaUF25| se [6757 2072|20| b7 [25|BSIN 2567 -2AS|27000| 41000 PRS] 25x1 [25 [5 [rr 42 [27] 3

[PBUESO|—40_[ 5/10/40 [sO] 62 [25/BSLN S082 -2AS| 25300] 49750 PRSBOxI S| S2| 5 [=o] 50 [aa] 2 [a1

[Paurs5| “0 10/20 _Jas[ 72 aJ@SIN 3572 -2R| 37000 | 64200 PRS xts] 405 5

[PeuFa0| 50 | 50 [40] 90 /46)BSLN 4090 -2rs| usrer |r2asod)PRSKOxT |] 55 [5 I

|paursol 82 | 19120 eo} 10]54[asun sor 0 -2Rs|10560¢]17a70q]pAsfsox1.9 85] 5

Ma Tightening torque slotted nut

MG - Tightening torque threaded pin

asfar}as|M}v [St] 2 |se) or bdoz}e | or] cr | w

Leloo|r7 is afeofos|asfas|or fos] ar | 47] © fas |violz.r) esis fo] «o]s.5] so | ms|-0 foals for] .2]s0

(cleo rr [am [ee eles [es ar es | oar] @ em Ole [Me Bro we Pe [a fo a

sles as] a [eoleofros|es |x fos] 20 [5« [10 froshwre| a7 | Msox 5 2 [ro [we [2 [45 |e

Flo |ae [eo [eoleafos] 10 Pashroseas| oe [10 [aa)w2|a. [Moats 2 [rows [o fas a

lz} 7092 56 [eo|20f:05] 10 pa shosfess| sx-[ 10 fros}wre| a7 | Moox.s 2 [75 [we [20 [a5 [a

fsfoo frel eo [rofaslenshias|ss issleos) ra [12 frae|wrala] wre lool so|2.5[r00|wiol 20 [as [4 [ofa

lof fes10 -ens| 50] 110 | 27 | s2000 | a8000 | sox | 165] 20

a ry ka ls]

[woah onty

u]si Weight

Ho] Ha | Hs fut Jus |u| us Jer] a2) | 8) | s2 |v foods) wa | MEER | housing

Zs | S| || | 2 [eal 7s | S| Be [MOS] [se] 08

22| 5 | 15 | 24 | 60] 77] a8 | 26] 8 | 47 | a4 mola] s2 | se] o8 07

Zs |S |e |e] 7 | x |e | 75 | a | Be [MO a] [3S

27] 8 | 18 | 108 | 66 | | 47 [2a] 6 | 84 [TOS |MIa|TO| 40 37

ar [6 [te [2 [70 | a2 | 40 [3a] 10 | 56 [105 |mi2| 10] a7 | ae

ar|6 | 18 [12] 70] 2 | 40 [34] a5 | 56 [105 |MI2| TO] 32 | 48

az] 55 | 21 | 126 | 80 [105 | 2 [se] 11 | 3 [126 |Mte|r2| ez | 45

3] 75 | 22 [144 |e [re] 4 [at | 2 | 72 [2s |Mra[i2| 72 | 6

50 2 [190 [140 [160] 76 | 46] 18 | os [125 [Mra] te] 20 | 5

50 96 | 205 |145] 175] 91 | 50 | 14 f102,5] 17,9 |m20] 16] +10 | 6

wo

Fixed bearing unit BK

‘The fixed bearing unit consists of

Pillow block housing made of black oxided stee!

‘Two angular contact ball bearings

Two seals with contact rings

Slotted nut

Suitable for standard spindle ends type F1, F2 (see page 21)

Unt

Eerat|

‘oni

Dia-

axxo]

i

1

lax:2|

16

20,

IBK5|

20)

IBKI7|

IBK20|

3

iBx25|

a

IBKa9|

40

[BKa5|

50

IBKa0|

0

SSS RSS

28/2] slalz/a] &

Fixed bearing unit EK

The fixed bearing unit consists of:

* Pillow block housing made of black oxided steel

+ Two angular contact ball bearings

+ Two seals with contact rings

* Slotted nut

Suitable for standard spindle ends type F1, F2 (see page 21)

(L2) 3

Ni

i} x

: -

t

zl-| + = r

E. il

LU exos

tat

x Lo

Wihx Lol a

pia M

8

2 bl Weight

unt | Sena] pin fn} L fus]u2 fs] | etalon] © x] vz || | Mes

a

EKOS| [ares w | wo ss] ze [asl ae|es [zr [Ts | Te [20] oo [ss] aS|TT [wale | ore

Toa

exos FS fa] 20] 7 | 20 | « 50] 22 20] 17 ]25]20|20 foo] 1] 12ual 14] oar

Floating bearing unit BF

‘The floating bearing unit consists of

++ Bearing housing made of black oxided steel

‘+ Deep grooved ball bearing

“© Retaining ring

Suitable for standard spindle ends type St (see page 22)

2 x counter bore - Bt ~

sin bts +00

, \. /

:

Sy a

rer

=z fw

«| “| :

fia erat ae [sees im

> i

Pp L

B

Sena aa

hema bn Weight

uni rs] nich le} |i | foal adn| as |r| © | [ath] sonra | ra | a

aa

ie a7

riof S275 Tichofoofao| 20 | 22 ]2« foxs] 15 [ae fos) o| eoezz | ox | oa

arral = {OIE tale cofea| oo | a [ox |aza| ve | oe || eomzz | 100 | om

EIS -20| “To ro0 ape To ae Ge | Be Paw | Se Te Loe Bp | oma | Teo

Bri7| 25 Br Tore rales ea] ao] So [so [55 [ 26 [ee fess | eeasez [rat [Ors

BreO| se] 10 pope aa eal ae | st sz | 50[ ee | ro feel @| wooaeZ [Foxe | OT

FOS] ao [57SoO7sapspcoa| so] SO] aw Yee | TO Se | BS. |w HO] BrOEAZ [ETD | TS

FIO] —aO_| S07 a pepeza| way oe | st re | Te | se [Toe [Tra] eroeeZ [Toes [TS

FIS| 50 _| Toe) —fefeao| wero se ww | rw [os [ra [are] weareZ_ [ors | as

FAO] 50 ~| 50 —fcbsrreohiop wo | wo roo) 90 [ar [rao |ralse| ezowez [aor 75| 3

| Standard spindle ends

Machining for fixed bearings

| —

Typ F2/F4 SI +

Typ Firs

Wesel 2

am TR pea

Unit | Nomina | pion |2°|28) & | & M eae - p | mended

Diameter B |h7 bearing unit

xs ste ss

oe

of-o te Te fef« fo] mon | ol -|- | - | ee

wo a ns ; 7

2} -8 te Thole [is] won | |e ftw |

ea ie apes es

ete ans pete test tt oo Ss

SS ae ies oe

Shreve tote tet es tee a

Se

Se Stott hime Pst ra

Mocel FF

cord ieFA Ron] poco

Unit | Nominal Pitch (ele M e|s]r mended

Diameter he) hz G Pp TJ bearing unit

oe | as oh ae a ae

2 6 1016 fo] 40] mraxt 2 | 25 3 1.8 PRUFI2

ofa s[ 3

S$ see re er to

Sof arose Hs ante ae

St be et St

So [asin fos os pasos repo 3

ore alee ett et

ne

St a

2a :

co Ff fo] ao| moons [ise] 2 70] 2 | co 20

Form $1/S2

Mode! $1

Nomad

Recommended

Model | ameter | Pitch A E 8 6 F

ofthe since bearing unit

10 a 2 10 " os | ts | ons BrI0

76 475 : :

16 T076

12 # oe 12 " es | 1s | ons BFI2

5 20 Tore0_[ 15 | s_|_48_|_ Tors BFE

17 | stores [17 Te [162 [4.18 | 18,15 | BF, PBULTT

20 32 70 20 76 73} 435_|_13.35 BF2O

25 ‘32_ [ATS 7207S2| 25 20 [258 | 135 | 16.35 | BFS5, PBULAS

30) @__| sf0740 [30 2i__| 286 |_175 | 17,75 | BFS0, PBULSO

35) 50 10720 [35 2 33 [175 | 18,75 BFS

a0 50) Ey a0 2 [195 [19.95 BFAD

Model S2

Recon

Model Pitch | Ais 8 E F | Gis | mended

ofthe spinel feearing un

0 16 478 [38 | Ao |_| Wt [47 _| PBULTO

16 TOT

12 o os 2 | 14s | om | a3 | tt ] 21 | Pune

1S 20 70720 | 15_| 143 [an |__| 121 | 11 _| PBULTS

17 25 __ [5/70/25 S105) PBULIT

20 2 10 a [pan | @ | 3 | 13 _| Paulo

ra S2_ [ATS 72D S105) PBULZ5

30 40 | 5710740 St (use) PBULSO

3% 30 7070 | 35 as Ae | | 188 [76 | PBULSS:

40 30 50 40 [375 [hie | 28 | 24,85 | 1,85 | PBULAO

3 0720

50 4 sso] 50 | 47 | m2 | 27 | 2918 | 215 | pBuLs0

®&

| Travel variation and travel deviation

The tolerance classes of the SNR ball screws are defined in accordance with ISO 3408, The tolerance

classes TO-T5 are determined according to the mean travel variation and the tolerance of the travel

deviations over the entire usable travel |, For tolerances T7-T10 the mean deviation over the length 300 mm

is defined at anywhere over the length of thread.

5

3

&

‘The usable travel is the stroke plus length of the ball nut.

‘The overrun is the axial travel beyond the usable travel serving the safety purpose.

‘The narrowed travel and hardness tolerances for the usable travel are not used.

‘The nominal travel is the axial travel that results from the nominal pitch mutilied

with the number of turns with the rotation of the ball nut relative to the ball screw spindle.

‘Travel compensation over the usable travel. Difference between target and actual travel

is defined by the user. (Standard c=0)

Upper and lower limit of the target travel form the tolerance fields for the mean travel.

Tolerance of the travel variation above the usable travel |,

Tolerance of the travel deviation for a travel of 300 mm, anywhere over the length of

thread.

Tolerance of the travel deviation within one revolution,

Permissible variances of the intermediate travel variation and the travel fluctuation

“oleae cass

Screw length ly, mm 7 nl Re 18 7 To

w oe | ]% | [~|%]w |] w & We

0 ae [se 6 6 |e] pe]

35 woo Sse 7 pe |e |e |e | ee

400 so 8 pa ep |) |r| ee

500 CO

650 5

500 | 100 |e ee pa | ao] oe

ooo | 1250 | ef | 13 | 0 |e | 8 | ar | se

5

600 | 2000 [= [fre [as as | 2s | es | at

000 [2500 [= 2 pts | at 28 | ee

2500_| 3160 | | | 26 [7 | 50 34 _| 06 | oo

3150} 4000 [= = spar | ee fats | ae

40005000 | =| - | - 76 | 49] 140 | 99

30006300 = == == es

Tolerance of the travel variation within an interval of 300 mm and a turn

Tolerance class To 13 | 15 | 17 | to

DIN, ISO 38 12 | 23 | 2 | 210

vis B 1192 38 8 | 18 | 50 | 210

DIN, ISO 3 efsa|-|-

.

R]

(international standards).

Running and bearing test according

to ISO 3408-3

for determining the straightness relative to AA‘ -

i Nona dante] — [Sonne renal

— dg in mm 15 |__ per tolerance class

(aoe] TSS [ro

© |e [a

8 apse

3 2577375} 16 20] 252 | 0 ]e0

roa 50] 00 [90

: 100 200 [7250]

4 Nominal dameterli/ag [Smaxp num por 4x

* Roo Te fos [3 [37 [0

r 7 =a [3220] 505069

J a0 a3 [60 75 [96 [702

soa [80 [0025] 020070

30 [roo fzafeoeooseroa

Measurement ofthe concent vation fg ofthe bearing seat relative to AA‘over the length

< [).Forlength J, > / must be applicable f,., <1,

(Lenath Kh,

er

Nominal 16.1 in yim per

lciameter dy] jn |__ee nome’ _|

roa srl in | risus Sa

b nl RS

A 20 | 50 | 125] 12 | 16 | 25 | 50 | 80

2. 125 | 200[ 315] - | 25 | 40 | ao [125

Measurement ofthe concentrcity variation /, , of the shatt-diameter relative to the bearing seat (C),

L

by subtraction for the length, / / must be applicable f, St>,,, 7

Nominal

ee an Wipinum pert

inmm | yin [__ per tolerance class

Above] to t13]5|]7)9

e|a|als|els|a2|e

20 | 50 [725] 6 | 8 | 10 | 18 | 20

125 [200 | 8 | 10 | 12 | 20 |

125 | 200 | 515 | - | 12 | 18 | 28 |

Measurement of the axial runout variation fof the contact surface for bearing relative to AA’

sare {B.p in um pertoernce class

£5)

s[e[s[4|s 10

e|m[«ps|e[e)@

p vs fo] - ps fs |).

a ‘tetas tp Lal

Measurement of the axial runout variation {4 of the contact surface of the ball nut relative to AA‘ (only for

preloading ball nuts)

e Flange

diameter | {9p in yum per tolerance class

Da inmm

oe] to | O] 1] S [5] 7] 0

= F [ae [se [8 [10 | 12 | 16 | 20

| 32 | 6 [10 [12 | te | 20 |

— os [15 [12 [16 | 0 | S| | -

oe ee 725 | 250 | 16 | 20 | 25 | 32 | 40

2h, 250 | soo | - | - | a2 | 40 | 80

Measurement of the concentriity variation f,

preloading ball nuts)

1 0f the outer diameter of the ball nut relative to AA (only for

DASE

jameter D1] _ 100 num per tolerance class

(ZEEE fx inmm

“! Woe] to DO] TP SS 7 Lo

a 73 1 wefefe fol] | -

—_— — [R= >ole pele

es [v5 | 12 [6 | 20 | 25 | a2 | -

725 [250 16 | 20 | 25 | 32 | 40 | -

A a zo [soo] - [| - [2] [50] -

24, 28,

Parllelty variance f; ofa rectangular ball nut eative to AA’ (only for pre-oaded ball nuts)

TS

| 2 Flip num per 100 mm (cumulative)

| fixed per tolerance class

_ = 0 1 3 5 7 10

“3 [we [2 [ae fe | -

K

240 _ 20,

.

®

Measurement of the drag torque at preloading ATo

Staring Towe vation value

oraue! //- Torque variations ()

= a Actual torque

em scu|_ wean | average tome

5 | Aes nat noverent

go

i ‘eta na EEE T

3 rian tah

.

Torque vations i)

eae ee —

a Ln so

Drag torque through preloading Tp,

The torque at the ball screw that is required to turn the ball nut against ball screw (or vice versa) without

external load. Possible friction torques due to the sealing elements are not considered.

Total drag torque T,

‘The torque that is required to turn the ball nut against ball screw (or vice versa) without external load, inclu-

sive of the friction torques.

Torque variation

Fluctuation value of the predefined drag torque under preload. A positive or negative value relative to the

‘mean torque.

Measuring method

Preloading generates a dynamic friction torque between the nut and the thread. This is measured by moving

the threaded spindle at a constant speed, whilst the nut is held with a special lacking device. The force F (Ft)

‘measured by the force transducer is used to calculate the friction torque of the threaded spindle.

Fealet

st ,

‘| Load cell

Total ength fr)

TpTe 5,000 From a 00076 T0000

Average 7 imeaceaeng Traaaea Teng

sera 40< —Screw dameter— “© | —Serew aiameter— “4° :

IN

c ‘pp fn %6 up Tyo) ‘pp (in %6 up ioTpa) | ATpp (n % upto Tyo)

Tolerance class Tolerance class Tolerance class

wpe loti, s[s,7po[t{[s{sy7| 3s 7

02 | 04 [2096] =35% | =40%% [50% | -_[aa0%6 -aosefesom|z00% — | —- |

DA [ 0,8 [2596] 8096 | 238% [40M | |oS8He BB AOA] —— ||

TS _| 1,0 [2096] =759% | 230% [ 95% [409% | 5096] 30D6|= 950.40 ASH 3AOW | ABTS | BOT

TO [2B [1596] =209% | 22596 | 550M [9896 [2596 | = 7596]=90%| 35% AOR 35H | e409 | ABN

Z5_| 63_|a 1096] 21596 | 220% [125% [290% [2209 [270% 259] 30%6 23595 | 240%

63 [ 0] = |= _ataem [20m [sa0% | — | — |e20vfazene frase «2% [90% [059%

ice and preloading

‘Through the preloading the axial clearance of the ball screw is removed and the stiffness is increased. In ad-

dition the positional accuracy is also improved.

‘The preloading of the single nut is achieved by instaling balls of selected dimensions.

‘The preloading of the double nut is created by tensioning two nuts against each other

‘Combination of axial clearance and preloading

Symbor o T z a

‘Axial clearance yes 76) 10 16

Pretoading 70. 70) Tight Tigh

% of dynanve Toad rang = =r

‘Combination of axial clearance 0

‘Spinale Gameter mT Toled bal screw axial clearance [nm]

CEU) O05,

15-40. 0,08

50-100 2

Critical speed of ball screws

Critical length In (om)

2 48 8 we 2 48 8 i

poise aa to tae

mee Le

Petey ea z tea z

critical speed (rp.m.)

'As with any rotating shaft, a ball scrow has a crtical speed,

\whichis a harmonic vibration, Running the balscrew inthe or

‘ical speed area consistently wll shorten its operational te,

and could affect the performance of a machine asthe vibra-

‘ton passes through the machine chass's. For examgle: On a

‘machine toolt could cause flaws inthe surtace fish as ball

sero reaches its citcal speed, as the vibration is ransmitied

to other parts ofthe machine. The crticl speedis a function

ofthe diameter and length of tne bal screw shaft, and the

‘mounting coniguration. The axial clearance ofthe nut has no

Inuenee onthe erteal S900

‘The operating speed should be kept ator below 80% of the

citical se Tho formula below, fr calculating the admiss~

ble speed nay takes account of ths 0.8 safety actor.

co. fe de aor

Page OG ES arte 10

(min)

™

Pay

k

r

critical speed (p.m)

permissible operating speed (p.m)

safety factor (0.8)

elasticity modulus (E=2.06x105 N/mm?)

‘geometric moment of inertia (mm?)

diameter at the ball screw root (mm)

specific material density (7,6x10 N/mm?)

‘earth's gravitational constant (8,8x10° mirvsi)

cross section of the ball screw (mm?)

Unsupported length between the two housings

‘correction factor due to mounting

‘supported-supported 14

fixed-supported d=3,927 1154

fixed-fixed 730 1,9

fixed-floating

1,875

“The maximum permissible speed of the ball screw is ited by the DN value in adton tothe rtcl speed

+ Mt $ 120.000

5 Phay S 90.000

For the nuts SC/DC.

For the nuts Cl, Sk, SU/DU, SE

dy Contre diameter of the spindle, mm

Please contact our application engineers if the required speed exceeds the DN value, or the ball screw is used for

higher speeds.

®

Similar to ary shatt, ball screws can only withstand a limited axial load. Any stress greater than the maximum

defined values can lead to fallure ofthe screw. The permissible axial compression is @ function ofthe length,

diameter and the type of mounting of the screw. The maximum axial compression load should be 50% orless

ofthe theoretical permissible load. The calculation made using the formula below takes ths safety factor into

account,

1

4

Unsupported threaded length (mm)

"i

ae eo a oe 8 bee

‘Axial load Fk (N)

F, theoretical maximum permissible axial load (N)

Fixy maximum permissible working axial load (N)

a safety factor (0,5)

E modulus of elasticity

2,08 + 108 Nim?)

2 0%) | geometric moment of inertia

ik b= Zea

d: diameter at the ball screw root (mm)

Ik. _ unsupported length between the two housings (men)

m,N factor linked to the

supported-supported

fixed-suoported

fixed-fixed

{ixed-floating

.

2

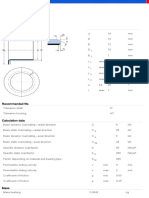

| Calculation basis

In the event of variable operating conditions (speed and toad),

Average speed ‘the working life calculations will rely on the average values Fm

and average load: and Py

For the average speed nm, in the case of variable speed, apply

ne Gy nt Hy m2 + Bis te avrage speed tom

For the average load Fm, in the case of a variable load, apply

va de aes Pa Fry= average load “

Foe VF gay + Ferd t = * Forty q" = movernent or time at

constant speed )

For the average load Fm, in the case of both variable load and speed, apply

re ee ‘average load wy

LGA ena time 6)

average speed (pm)

Nominal working life

Working lie L, expressed in revolutions

° L =working lite (nro)

La (Ee) 10° Cyn = Fa AV ae Fy = average load GN}

™ , = dynamic load capacity (KN)

Working life, expressed in hours Ly y= working life 0

L U working life (in revolutions)

be BOE n= average speed (p.m)

ED= operating time 0)

Motor torque and output power

Output torque May pp

forthe transformation of Mu= oe (Nm)

rotational moverrent into linger movement (wm)

()

Resistive torque Mig (ram)

_ Pay

fortho transformation of Mjq= £3P-1 (approx. 0.9)

linear movement into rotational movemight (approx. 0.8)

For preloaded double nuts, take no-load torque into account.

‘Output power P, uiput power Kw)

put torque (Nm)

n= speed of rotation (vimin)

In case of separate delivery of ball screws and ball

ruts, qualified personnel must carry out the assem-

bly of the ball screws. Ball nuts should be mounted.

only with the help ofa fitting sleeve, The fiting sleeve.

delivered with the ut unit can be used. The start of

the thread of the spindle must be aligned, so that the

wiper and the internal single parts of the nut unit are

not damaged

‘As standard SNR ball screws are delivered with an

installed nut unit, The nut unit and spindle should not

bbe dismantled (especially applicable for a preloaded.

ul). If this is unavoidable, please contact our appli-

cation engineers,

Proceed with the mounting as follows

Remove the rubber washer from one side of the

sleeve. Push on the nut withthe sleeve on the end of,

the screw. Press the sleeve against the start of the

screw thread

Sorew the nut on to the thread, using a slight axial

pressure. Then screw the nut on for its entire length.

Remove the mounting sleeve only when the nut is

completely threaded on to the screw. Lock the nut to

prevent any unscrewing (using @ rubber washer or fi-

xing the sleeve axially)

What do I do when.

Balls escape while threading on the nut?

1. Pick up the balls (the nut is only compatible with the

original balls). The load capacity is then ensured,

even if two or three balls are missing,

2. Carefully clean all the components.

3. Use the sleeve as a mounting jig.

4, Replace the balls

6. Start with the lowest circuit. Insert the balls into the

‘ut circut, the sleeve prevents the balls from falling

insige.

nut on the screw

Note:

Ground ball screws, with a single or double nut

are always delivered with the nut assembly moun-

ted, similarly to rolled double nut screws,

Please contact us if you absolutely must dis-

mantle a nut assembly.

Nut Screw

Mounting sleeve

Rubber washer

Important:

Use only the original balls!

Important:

Do not place the balls inthe empty circuit located

between the two deflectors!

.

@

Operating and maintenance

information for the ball screws

Operating conditions

Inadcition to the load rating, the maximum speed, critical bending speed and the permissible buckling force

should also be considered. Ball screws are conceptualised as a drive element for creating axial feed force,

Radial forces and torques that have an impact on the nut, lead to the reduction of durability. When using a

ball sorew the ambient temperature shall not exceed 80°C.

Assembly

During assembly, parallel alignment of the guiding elements should be ensured. Special care must be taken

to achieve a concentric assembly of the nut on the spindle. Here attention should be paid to the tolerance re-

lationship between the guiding elements and layout as well as the bearing units and nut housings. By provie

ding alignment options to the nut or to the bearing, good accuracy with lower cost can be realised

Lubrication

For maintaining the performance of a ball screw, it must be lubricated adequately. Similar lubricants that are

used for rolling bearings should be used. Lubricants containing MoS, or graphite should not be used. The

selection of the lubricant and the type of supply can be adjusted to match the lubrication of the other cor

ponents of the machine. A one off lifetime lubrication of the ball screw is not adequate based on experience,

4s the spindle constantly discharges small amounts of lubricant from the nut.

‘SNR — ball screws are supplied with the conserving oil "Contraktor Fluid H1”, "“Contraktor Fluid H1” is

‘compatible with the SNR standard lubricant “SNR LUB Heavy Duty”

‘The lubrication period is dependent on many factors such as:

» Load

erature

‘The following factors reduce the lubrication interval

* Greater load

* High speed

+ Short stroke (stroke is smaller than three times the length of the nut)

* Lower ageing resistance of the lubricant

Grease lubrication

For operation under normal conditions, grease SNR Heavy Duty is used. Specific requirements under certain

environmental conditions require the use of a suitable grease. In the food industry and clean room there are

‘special requitement for the lubricant with regard to emission and compatibility. Basically the compatibility of

the lubricants against each other should be checked. In case of special ambient conditions we will gladly

assist you, Depending on the area of application the following lubricants can be used:

Ta

Gand al

ct |Pereraton| sy fperey| meee

me | ote, | ss RED, Joost | me ce | Fels

Nar consistency | DIN | 2157. | PEE: od oa application

siete|_250

[0,1 mm} | Immes) | kg/ma) ro

Pain nr

halle thm ca cto [Lowerticton, ——[oenerat

Foyt, | gine | 2 | 20s | car | soo | oo. Leet [eghorra

‘Synthetic KW |very good achesion,

ownuuson |e] 2 |os.2a5] 2 | soo | ..t20 fongansna” gn ses

= psocncs

[grinpeae

‘Synthetic KW Jresistance, good — | High

SMASUB HICH Tot jmneralol/| 2 | 266...205] 180 | 900 | -40...160. foorasion protection, |iempeature

ome fio” [or

fossane

[x crea

lamin [Pastime Proctor gud

yeu [Sivan | 2 | 295.205] ca.240 | 20 | 2o..110 fismeningt: [ord rt

Soe fessor

fog!

Jos en er

hacen) Mowat [ex claps [sng nan

wea incre | + fic.ow | 280 | ao | 20.10 fontircoacane [octane

specu Scap [eanate (rete

reser erates

Parc sara

srwtc cw fear footer

zen can-oon

gat’ | 2 | 28.206] cao | eo | 50,000) the quality K1K or KP1K should be selected. Speed para-

meters under 2,000 require a grease of the consistency class 8 (K3K or KPSK DIN 51825). The required

lubrication period is based on the ambient conditions. In general re-lubrication should be carried out every

200-600 operating hours. The following is applicable as a reference value for the lubricant quantity: Per cm

spindle diameter > 1 cr grease for each nut. Only greases of same soap base should be used for lubrication.

Oil lubrication

‘As.arrule, cil lubrication is used in conjunction with centralised lubrication equipment. The advantage of cen-

tralised automatic oil lubrication is a continuous lubricant supply to all the lubrication points. Lubricant cils

ensure a very good dissipation of friction heat. In contrast there are higher design and assembly requirements

{or the lubrication lines. Depending on the area of application the following lubricant oils can be used:

Kiomate

viscosty Temperature

a vyoeot | onsisee | Pesty | Tange sotto! appteation

Na woreane | "wrave Provertes | Fels of applica

imme [ior [rer

eprom

Food rcs

prctacton "

Kaaoerot uni-8en | Poyapnacisin | 680 60 | 25....120 fm =

NSE gsr |e

* This grease is registered as H1 product: it has been developed for occasional, technically unavoidable

contact with foodstuff. Experiences have shown that the grease can also be used for the corresponding

applications in the pharmaceutical and cosmetic industry, on the conditions listed in the product information.

However, there are no specific test results, for instance, on the biocompatibility, as may be required under

certain circumstances in the pharmaceutical area. Therefore, before it is used in this area by equioment

‘manufacturers and distributors, corresponding risk analyses must be performed. If necessary, measures to

avoid health hazard and injuries must be taken. Source: Kidber Lubrication)

‘At higher speeds (speed parameter DN > 50,000) oils ofthe viscosity class ISO VG 46-22 should be used. For

‘speed parameters under 2,000 the viscosity ISO VG 150-460 should be used. If the load is above 10%

Of the dynamic load rating, an oll with additives is recommended for increasing the load capacity (class CLP,

DIN 51517 Part 3). With oil bath lubrication the spindle must be 0.5 to 1 mm above the oil level. The cil supply

with re-citculation lubrication should be 3 cm? for each ball circulation.

ee:

ation code

(1) Product

BSC" Screw + Nut assembly

BSH Ball screw

BRU Nutalone

2) Nominal diameter (mm)

(9) Pitch (mm)

Direction of pitch

(0 Rect 1 of pitc!

(9) Type of nut

'Single cylindrical nut (Page 7)

SK Sate langed mature rut (Page 6)

SE Single tangod nut (wide pitch) Page 12)

Single Nanged comoact hut to DIN 69021 (Page 8,

BG Double flanged compact nut to DIN 69051 (Page 8)

ged put io DIN 68051 (Page 10)

SU Sin

BU Bauble flanged nut to DIN 69051 (Page 11)

SH Single threaded nut (Page 13)

For the coding of screws alone:

‘Sorew for compact series DIN nut

00 Screw for special nut types

(6) Number of circuits

‘Type of flange

ye

DIN 68051 section § form A (round)

B DIN 68051 section form B

© DIN 69051 section § form C

Z Cylindrical nut

Precision class (Page 2:

eee Ta tee TP tn sock, T10

Mode!

©) Mose ound

Rn Shed

(10) Preload

(10) Prolog Nard ened clerance

1 Noaxial clearance

2 Light preload

3 Medium preload

4 High prefoac

(11) Total length (mm)

ete Ss 50 ga, sri

Cll rears

(19) Left side screw end, see right side screw end

(14) Lubrication

0 Standard nut greasing

1 Ant-corrosion greasi

2 Greasing to customer instructions

(15) Special

‘0 None:

1. Taking account of drive torque measurement

2 Taking account of pitch error,

.

®

Sorew + NutassemblyBSC 020 05 A

Nut

Screw

a

2)

6)

@)

6)

©

a

@)

®

(10)

(11)

(12)

(13)

(14)

(18)

(

(2)

8)

@)

6)

©

a

®

(14)

a)

@)

cc)

4)

(6)

@)

(9)

1)

(12)

(13)

(14)

BNU 020 05

E

BSH 020 05

—_T

LL

a2

R ol

R 00

Zz

2

7

&

wR

Z R-o

R-1000-F115-S115- 0

0- 1000-F115-S115- 0 -

Q

Company

Address Contact

Position Telephone Fax

Description of the application

solatedneed No. of pieces ‘New construction

Production need Required delivery Weeks [~] Technical improvement

Pieces per year Cost reduction / Current price €

Davey of pieces requiedin Weeks

Application parameters:

‘Type of mounting: [7] Horizontal Nerical Usable stroke:

Maximum usable load: kg Additional axial load:

Maximum movement speed: m/s Maximum acceleration:

Positioning accuracy: mm Reproducibty: mm

Maximum inversion clearance: mm Cycle time: sec

Required working ite strokes or hours

‘Ambient conditions of use: ‘Special circumstances:

Dimensions and features, if existing application

Flange nut Maximum dimensions of the nut:

(Cylindrical nut Nominal serew diameter: mm

DIN nut Pitch: mm

Total length: mm

Housings

(re supgetedipgoesthatea With machining of the ends to drawing no,

|Machining of the ends for use with SNR

housings

INo end machining

The consultation of SNR WALZLAGER GMBH is exclusive for the function of the ball screws. As a supplier

of a component SNR accepts no liability for the function, operation or performance for the machine, system

‘or assembly to which the ball sctew is mounted. This responsibility ies with the machine designer, manu-

facturer, operator or other relevant parties.

~

we

some at SNR:

Let us guide you!

Our latest general catalogue with our complete product range

‘As a PDF File on our website:

‘Also available as a printed versi

linear@snde

Use also our Productconfigurator for 20/30 at:

‘Shoo acl: NIVEL ROULEVENTS st Ues-7E500 anya rn Ba -ahA Cae CE NR)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mechanical Seals Mechanical Seals For Pumps Pusher Seals M7NDocument6 pagesMechanical Seals Mechanical Seals For Pumps Pusher Seals M7NVolodymyrNo ratings yet

- SKF Product RangeDocument315 pagesSKF Product RangeVolodymyrNo ratings yet

- Maximizing Bearing Performance: Radial Shaft Seals HMS5 and HMSA10Document12 pagesMaximizing Bearing Performance: Radial Shaft Seals HMS5 and HMSA10VolodymyrNo ratings yet

- SKF Speedi-SleeveDocument24 pagesSKF Speedi-SleeveVolodymyrNo ratings yet

- Catalogue of Spherical Roller and Special BearingsDocument67 pagesCatalogue of Spherical Roller and Special BearingsVolodymyrNo ratings yet

- SKF Concentra Ball Bearing Units: True Concentric Locking, For Fast and Reliable MountingDocument28 pagesSKF Concentra Ball Bearing Units: True Concentric Locking, For Fast and Reliable MountingVolodymyrNo ratings yet

- Catalog ZKL-ZRL PLC InfoDocument32 pagesCatalog ZKL-ZRL PLC InfoVolodymyrNo ratings yet

- Large Size and Special BearingsDocument16 pagesLarge Size and Special BearingsVolodymyrNo ratings yet

- Heavy Duty V-Belt Drive Design Manual PDFDocument324 pagesHeavy Duty V-Belt Drive Design Manual PDFAnonymous jW9BkgbQmENo ratings yet

- Pages From Chains - With - Attachments-Rexnord PDFDocument1 pagePages From Chains - With - Attachments-Rexnord PDFVolodymyrNo ratings yet

- Ethylene V-Belt Technology: Your Best Defense Against Belt FailureDocument2 pagesEthylene V-Belt Technology: Your Best Defense Against Belt FailureVolodymyrNo ratings yet

- Grounds Maintenance Equipment 4312061 PDFDocument750 pagesGrounds Maintenance Equipment 4312061 PDFVolodymyrNo ratings yet

- Powergrip GT3: Expands The Limits of Your Power Transmission SolutionsDocument8 pagesPowergrip GT3: Expands The Limits of Your Power Transmission SolutionsVolodymyrNo ratings yet

- High Perf PT Products Brochure Ausnz April 2017Document12 pagesHigh Perf PT Products Brochure Ausnz April 2017VolodymyrNo ratings yet

- Optibelt ALPHA TORQUE Length RangeDocument12 pagesOptibelt ALPHA TORQUE Length RangeVolodymyrNo ratings yet

- Eagle NRG Brochure, EUDocument4 pagesEagle NRG Brochure, EUVolodymyrNo ratings yet

- ZKL Bearings For The Mining IndustryDocument31 pagesZKL Bearings For The Mining IndustryVolodymyrNo ratings yet

- Bushings-PCMF 101212 EDocument2 pagesBushings-PCMF 101212 EVolodymyrNo ratings yet