Professional Documents

Culture Documents

Uctcf-5000 TDS

Uploaded by

jude tallyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uctcf-5000 TDS

Uploaded by

jude tallyCopyright:

Available Formats

UCTCF-5000

Description

UCTCF-5000 polyurea crack filler is two parts, high penetration, fast setting, hybrid polyurea

for repairing and re-building, damaged concrete. The product is a 1:1 ratio, easy to mix system that is

98% solids and VOC compliant. The UCTCF-5000 can be used to set anchor bolts, repair damaged control joints,

fill spalling, and rebuild vertical curbing and steps. Sand or gravel can be added to extend the volume of the

material and acts as filler for repairing large spalls, holes and cracks.

Primary applications

ü Aircraft hangar floors

ü Commercial freezer repairs

ü Aircraft hangar floors

ü Low temperature equipment

ü Maintenance facility floors

ü Industrial shop floors

ü Car washes or wash bays

ü Forming/ rebuilding stairs and steps

ü Leveling and grade matching

ü Bridge/ street repairs

ü Concrete polishing and other coating applications

Advantages

ü Application temperature between -5 C to 38 C

ü Product cures in 10 minutes @ 22 C with excellent adhesion

ü Self-leveling and self-priming

ü Ready to service in 10 to 20 minutes

ü Easy to mix 1:1 ratio by volume

ü Highly chemical resistant

ü Excellent for industrial floor repairs subject to forklift traffic and harsh conditions

XTREME POLISHING SYSTEMS

2200 NW 32nd Street #700, Pompano Beach, FL 33069

Tel: 800.255.3924 www.shopxps.com

UCTCF-5000

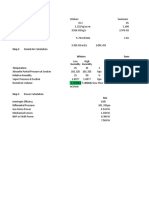

TECHNICAL DATA

Packaging litres / gal us Color

7.56 / 2 Part A Part B Mixture

Mix Ratio by volume Black Amber Black / Grey

A:B=1:1 Shelf Life

Mix Ratio by weight 12 months in original unopened factory sealed containers. Keep away

from extreme cold, heat, or moisture. Keep out of direct sunlight and away

A : B = 100 : 118 from fire hazards.

Pot Life (40 g) Cure Time Density (kg/litre)

2 – 3 minutes 10 – 15 minutes Part A Part B Mixture

VOC (g/litre) Recommended Thinner 0.94 1.12 1.11

397 DO NOT DILUTE! Solids by weight %

Viscosity @ 25⁰C (cps) Part A Part B Part A Part B Mixture

15 -30 15 - 30 100 100 100

Foot Traffic 10 minutes

Light Traffic 30 minutes

*Note: Times and data mentioned are based on laboratory conditions. Field results may vary and will be affected by

changing ambient conditions, especially changes in temperature and relative humidity.

PROPERTIES @ 23°C (73°F) 50% R.H.

Adhesion (concrete-primer) Water Absorption (%) ASTM D570

ASTM D4541

- -

Hardness (Shore D) ASTM D2240 Tensile Strength (psi) ASTM D638

68-72 4500 - 4800

Compressive Strength ASTM D695 Elongation at break (%) ASTM D638

5600 psi 6-8

XTREME POLISHING SYSTEMS

2200 NW 32nd Street #700, Pompano Beach, FL 33069

Tel: 800.255.3924 www.shopxps.com

UCTCF-5000

SURFACE PREPARATION

The surface to be coated must be well primed. Remove dust, laitance, grease, oils, dirt,

impregnating agents, foreign matter, any previous coatings, and disintegrated substances by mechanical

means such as shot-blasting (BLASTRAC) or any other approved method to obtain an ICRI-CSP 3-4 profile. The

compressive strength of the concrete must be at least 25 MPa (3625 lbs/in2) after 28 days and the tensile strength

at least 1.5 MPa (218 lbs/in2).

MIXING

Mix each component separately. Pour component B into component A using the proper mixing ratio. Mix together

both components for not more than 30 seconds. Only prepare quantity that may be applied during pot life.

APPLICATION

Pour the UCTCF-5000 into the cracks and allow material to overflow slightly. Once hardened, grind the surplus

with a grinder equipped with a diamond wheel.

CLEANING

Clean all application equipment with the recommended cleaner (SCT-0001). Once the product has hardened, it

can only be removed by mechanical means. In case of skin contact, wash thoroughly with warm soapy water.

XTREME POLISHING SYSTEMS

2200 NW 32nd Street #700, Pompano Beach, FL 33069

Tel: 800.255.3924 www.shopxps.com

UCTCF-5000

RESTRICTIONS

ü Do not apply at temperatures below 10 ° C / 50 ° F or above 30 ° C / 86 ° F

ü The relative humidity of the surrounding work environment during the application of the coating and

throughout the curing process should not exceed 85%

ü Substrate temperature must be 3 °C (5.5 °F) above dew point measured

ü Humidity content of substrate must be <4% when coating is applied

ü Do not apply on porous surfaces where a transfer of humidity may occur during the application

ü The application of this coating on an interior or exterior substrate without a moisture barrier is at risk of

detachment (by hydrostatic pressure).

ü Protect the coating from all sources of moisture for a period of 48 hours

HEALTH AND SAFETY

In case of skin contact, wash with water and soap. In case of eye contact, immediately rinse with water for at least

15 minutes. Consult with a doctor. For respiratory problems, transport victim to fresh air. Remove contaminated

clothes and clean before reuse. Components A and B contain toxic ingredients. Prolonged contact of this product

with the skin is susceptible to provoke an irritation. Avoid eye contact. Contact with may cause serious burns.

Avoid breathing vapors release from this product. This product is a strong sensitizer. Wear safety glasses and

chemical resistant gloves. A breathing apparatus filtering organic vapors approved by the NIOSH/MSHA is

recommended. Predict suitable ventilation. Consult the material safety data sheet for further information.

IMPORTANT NOTICE

The information and recommendations contained in this document are based on reliable test results according to

Xtreme Polishing Systems. The data mentioned are specific to the material indicated. If used in combination with

other materials, the results may be different. It is the responsibility of the user to validate the information therein

and to test the product before using it. Xtreme Polishing Systems assumes no legal responsibility for the results

obtained in such cases. Xtreme Polishing Systems assumes no legal responsibility for any direct, indirect,

consequential, economic or any other damages except to replace the product or to reimbursement the purchase

price, as set out in the purchase contract.

XTREME POLISHING SYSTEMS

2200 NW 32nd Street #700, Pompano Beach, FL 33069

Tel: 800.255.3924 www.shopxps.com

You might also like

- TD Epg 233 2K Ext WB PDFDocument3 pagesTD Epg 233 2K Ext WB PDFLevina VaniaNo ratings yet

- TD Puas-620-2k WBDocument3 pagesTD Puas-620-2k WBRizki PutriNo ratings yet

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- TD PFT-253-2K SBDocument3 pagesTD PFT-253-2K SBGo Joko AriefNo ratings yet

- PFT-213-2K SF: Polyfloor Epoxy Top Coat Solvent FreeDocument3 pagesPFT-213-2K SF: Polyfloor Epoxy Top Coat Solvent FreeDodi Tri WibowoNo ratings yet

- Ceramic-Polymer 232 Spray Version - Ds - PDSDocument3 pagesCeramic-Polymer 232 Spray Version - Ds - PDSANIBALLOPEZVEGANo ratings yet

- Technical Data DeflakesDocument3 pagesTechnical Data DeflakesMeliany SariNo ratings yet

- TD Puep 216 2K SBDocument3 pagesTD Puep 216 2K SBMeliany SariNo ratings yet

- TD Polyfloor EpoxyDocument6 pagesTD Polyfloor Epoxyepoxycenter.idNo ratings yet

- TDS - Propan PFT-253 SBDocument2 pagesTDS - Propan PFT-253 SBDodi Tri WibowoNo ratings yet

- Sikagard 63n Pds enDocument3 pagesSikagard 63n Pds enariorasalahNo ratings yet

- Silane HybirdDocument6 pagesSilane HybirdMeliany SariNo ratings yet

- MX-94-2K SB: Epoxy Floor Thin CoatingDocument3 pagesMX-94-2K SB: Epoxy Floor Thin Coatingilham tri oktaNo ratings yet

- Deckpro 800: High Hardness Chemical Resistant Seamless FlooringDocument2 pagesDeckpro 800: High Hardness Chemical Resistant Seamless FlooringMyraNo ratings yet

- UV FloorDocument6 pagesUV FloorMeliany SariNo ratings yet

- Proguard CN 100 Iso TDSDocument3 pagesProguard CN 100 Iso TDSm_f_deathNo ratings yet

- HYSOL® FP4323 (ES4323) : Technical Data SheetDocument2 pagesHYSOL® FP4323 (ES4323) : Technical Data SheetAsad NaeemNo ratings yet

- TDS 25740 Jotafloor EP SL Euk GBDocument5 pagesTDS 25740 Jotafloor EP SL Euk GBDavid TumboimbelaNo ratings yet

- Securea SCDocument2 pagesSecurea SCAutumn HernandezNo ratings yet

- Sikagard - 62Document4 pagesSikagard - 62dineshNo ratings yet

- Sikagard®-62: Product Data SheetDocument4 pagesSikagard®-62: Product Data Sheetantonsugiarto20_7049No ratings yet

- Chemstat ESDDocument3 pagesChemstat ESDpadmanabh alatNo ratings yet

- Sikagrout Cable PTDocument3 pagesSikagrout Cable PTYASHICA VAITTIANATHANNo ratings yet

- Triblock Finish GBDocument4 pagesTriblock Finish GBdraganugNo ratings yet

- Sikagard 62 PDSDocument3 pagesSikagard 62 PDSMattNo ratings yet

- Mea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaDocument2 pagesMea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaMuhammad hussainNo ratings yet

- TD Polyfloor-SealerDocument12 pagesTD Polyfloor-SealerDhani RamadhanNo ratings yet

- Superseal P 110Document3 pagesSuperseal P 110rohan100% (1)

- Intersleek 1100SR: Advanced Fluoropolymer Foul Release CoatingDocument4 pagesIntersleek 1100SR: Advanced Fluoropolymer Foul Release CoatingYanyan2009No ratings yet

- DR - Fixit Cipoxy 16DDocument3 pagesDR - Fixit Cipoxy 16DKiran KumarNo ratings yet

- Technical Data Polyfloor CementDocument2 pagesTechnical Data Polyfloor CementMeliany SariNo ratings yet

- Tefcote N4000Hrx: Product FunctionDocument2 pagesTefcote N4000Hrx: Product Functionphoebe chanNo ratings yet

- Product Description: Epoxy Coating System, 100% SolidsDocument4 pagesProduct Description: Epoxy Coating System, 100% SolidsKatherine GonzalesNo ratings yet

- Sikagard 63 N PDS enDocument3 pagesSikagard 63 N PDS ennoto.sugiartoNo ratings yet

- Attachment-4 Sikagard 63 N PDSDocument3 pagesAttachment-4 Sikagard 63 N PDSnoto.sugiartoNo ratings yet

- Adhesive PDS & MSDS PDFDocument25 pagesAdhesive PDS & MSDS PDFsmartayaz1987No ratings yet

- Mea Polybit Tds Polybit Polythane PR en MeaDocument2 pagesMea Polybit Tds Polybit Polythane PR en MeaShahsoor Shah MajeedNo ratings yet

- Tennokote 1000 Wa 2023Document3 pagesTennokote 1000 Wa 2023suryaNo ratings yet

- ShaliProtek PuR 40Document3 pagesShaliProtek PuR 40Rana MahatoNo ratings yet

- Product Data: Hempadur Multi-Strength 35530Document2 pagesProduct Data: Hempadur Multi-Strength 35530Vijayaraj KumarNo ratings yet

- Jotafloor TC EDocument6 pagesJotafloor TC ERidwanSalminNo ratings yet

- UHT (Spray Grade) : Product Summary Typical Chemical Resistance (Full Immersion)Document2 pagesUHT (Spray Grade) : Product Summary Typical Chemical Resistance (Full Immersion)rezaeifNo ratings yet

- HEMPADUR MULTI-STRENGTH 35530 BlackDocument2 pagesHEMPADUR MULTI-STRENGTH 35530 BlackRuby Faith EspinosaNo ratings yet

- Weberep 331 TXDocument2 pagesWeberep 331 TXmoizm53No ratings yet

- KCC - DATASHEET - Korethan Topcoat UT6581 (Two-Component) - EngDocument2 pagesKCC - DATASHEET - Korethan Topcoat UT6581 (Two-Component) - EngIsabelo AbaoNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake SpecialBiju_PottayilNo ratings yet

- PDS Hempadur Multi-Strength 35842 en-GBDocument2 pagesPDS Hempadur Multi-Strength 35842 en-GBIfrahimNo ratings yet

- TDS ADINO PUF 1K 311 v10Document4 pagesTDS ADINO PUF 1K 311 v10Ravi CRTNo ratings yet

- Hempadur Multi-Strength GF 35870 PDFDocument3 pagesHempadur Multi-Strength GF 35870 PDFAnuar SalehNo ratings yet

- Cds TM 9910 Pouring-Concrete-Uw en 2015-09Document2 pagesCds TM 9910 Pouring-Concrete-Uw en 2015-09mihabubu80No ratings yet

- Sikagard®-63 N: Product Data SheetDocument3 pagesSikagard®-63 N: Product Data SheetAMIT HALDERNo ratings yet

- PDS STRATA EPOXY HT 35590 en-GB PDFDocument3 pagesPDS STRATA EPOXY HT 35590 en-GB PDFMohamed Nouzer0% (1)

- Weberdry 130 PR Grey-White PDFDocument2 pagesWeberdry 130 PR Grey-White PDFabbNo ratings yet

- Flexane HP PuttyDocument2 pagesFlexane HP PuttyDivyanshu GuptaNo ratings yet

- Chemflake Special: Technical Data SheetDocument5 pagesChemflake Special: Technical Data SheetSalmanNo ratings yet

- Sigacoat 111: Technical Data SheetDocument2 pagesSigacoat 111: Technical Data SheetAmirhossein LotfiNo ratings yet

- Technical Data Polyfloor Anti StatisDocument3 pagesTechnical Data Polyfloor Anti Statismujahidinandri3No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionFrom EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNo ratings yet

- Cat K Series Tooth System Model Guide: Conversion ChartDocument4 pagesCat K Series Tooth System Model Guide: Conversion ChartJOSE FRANCO CRUZNo ratings yet

- Aashto CatalogDocument40 pagesAashto CatalogRudy SetiawanNo ratings yet

- Astm D 3515 PDFDocument5 pagesAstm D 3515 PDFJulio Cesar Rojas Apaza100% (1)

- AASHTO Standard Specifications For Highway Bridges 17th - TOCDocument84 pagesAASHTO Standard Specifications For Highway Bridges 17th - TOCGeorge Christodoulidis71% (7)

- ASTM D2995-99 (R04) Estimating Application Rate of Bituminous Distributors PDFDocument4 pagesASTM D2995-99 (R04) Estimating Application Rate of Bituminous Distributors PDFPatagon Eduardo50% (2)

- Cat K Series Tooth System Model Guide: Conversion ChartDocument4 pagesCat K Series Tooth System Model Guide: Conversion ChartJOSE FRANCO CRUZNo ratings yet

- The Asphalt Compaction Technology Guide: Best Practices For Using Technology To Increase Pavement Durability & SmoothnessDocument17 pagesThe Asphalt Compaction Technology Guide: Best Practices For Using Technology To Increase Pavement Durability & Smoothnessjude tally100% (1)

- AASHTO Guide Specifications For Highway ConstructionDocument561 pagesAASHTO Guide Specifications For Highway ConstructionAbdissa Bekele92% (59)

- A675/A675MDocument5 pagesA675/A675Mpavan_joshi_5100% (1)

- Flexseal PS660Document4 pagesFlexseal PS660jude tallyNo ratings yet

- DM45/50 Blasthole Drills: Multi-Pass Rotary and DTH DrillingDocument7 pagesDM45/50 Blasthole Drills: Multi-Pass Rotary and DTH DrillingEdwin Antonio Flores MoralesNo ratings yet

- Material Safety Data Sheet Cellrod: 1: Product and Company IdentificationDocument3 pagesMaterial Safety Data Sheet Cellrod: 1: Product and Company Identificationjude tallyNo ratings yet

- Flexseal PS660 Method Statement (High Performance Two Component Polysulphide Civil Sealant)Document2 pagesFlexseal PS660 Method Statement (High Performance Two Component Polysulphide Civil Sealant)jude tallyNo ratings yet

- CellrodDocument2 pagesCellrodjude tallyNo ratings yet

- Material Safety Data Sheet Flexseal PS660 - Curing Agent: 1: Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet Flexseal PS660 - Curing Agent: 1: Product and Company Identificationjude tallyNo ratings yet

- Material Safety Data Sheet Flexseal PS660 - Curing Agent: 1: Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet Flexseal PS660 - Curing Agent: 1: Product and Company Identificationjude tallyNo ratings yet

- Material Safety Data Sheet Keyfix E - Base: 1: Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet Keyfix E - Base: 1: Product and Company Identificationjude tallyNo ratings yet

- Keyfix E - Hardener - MSDSDocument5 pagesKeyfix E - Hardener - MSDSjude tallyNo ratings yet

- MotoniveladorasDocument22 pagesMotoniveladorasperulocaNo ratings yet

- Cellrod Method Statement (Closed Cell Polyethylene Backing Rod)Document1 pageCellrod Method Statement (Closed Cell Polyethylene Backing Rod)jude tallyNo ratings yet

- Material Safety Data Sheet Flexseal PS660 - Base: 1: Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet Flexseal PS660 - Base: 1: Product and Company Identificationjude tallyNo ratings yet

- CellrodDocument2 pagesCellrodjude tallyNo ratings yet

- Keyfix E Method Statement (High Strength Epoxy Resin For Anchoring and Fixing)Document2 pagesKeyfix E Method Statement (High Strength Epoxy Resin For Anchoring and Fixing)jude tallyNo ratings yet

- Spraying Tank-Hot Oil Heating (Massenza)Document2 pagesSpraying Tank-Hot Oil Heating (Massenza)jude tallyNo ratings yet

- Terex TA30 Articulated Dumptruck Maintenance ManualDocument371 pagesTerex TA30 Articulated Dumptruck Maintenance Manualrcval88% (8)

- Detailed Specification For: 230 Gallon Crack Sealing Trailer / Melter Applicator 1.0 PurposeDocument6 pagesDetailed Specification For: 230 Gallon Crack Sealing Trailer / Melter Applicator 1.0 Purposejude tallyNo ratings yet

- Diesel Generator Set: Output RatingsDocument9 pagesDiesel Generator Set: Output Ratingsjude tallyNo ratings yet

- AF 3000 Material Submittal FormDocument2 pagesAF 3000 Material Submittal Formjude tallyNo ratings yet

- S D V S C: SpecificationsDocument2 pagesS D V S C: Specificationsjude tallyNo ratings yet

- Chapter 1 - Main Hydrological ConceptsDocument16 pagesChapter 1 - Main Hydrological ConceptsWhy Merah0% (1)

- Thermik-Artikel-V3.3-aleman ENDocument45 pagesThermik-Artikel-V3.3-aleman ENLeo BeeNo ratings yet

- Significance of Air Movement For Thermal Comfort in Warm ClimatesIndragantiDocument15 pagesSignificance of Air Movement For Thermal Comfort in Warm ClimatesIndragantiAmit MendirattaNo ratings yet

- Aerody Quizlet 489Document62 pagesAerody Quizlet 489Jecah Angelu S. SaquianNo ratings yet

- Kardos1986 - Void Growth and Resin Transport During Processing of Thermosetting Matrix Composites PDFDocument23 pagesKardos1986 - Void Growth and Resin Transport During Processing of Thermosetting Matrix Composites PDFDaniel Maldonado ForinNo ratings yet

- Artigo Monitoramento Colméia Jiang2016Document15 pagesArtigo Monitoramento Colméia Jiang2016Washington BrazilNo ratings yet

- Moisture Related Problems and Their Solution Through DehumidificationDocument38 pagesMoisture Related Problems and Their Solution Through DehumidificationoooZNo ratings yet

- Field VisitDocument4 pagesField VisitGimhan JayasiriNo ratings yet

- Price List Environ Analysis ENG 2019Document72 pagesPrice List Environ Analysis ENG 2019Angelo Leonardo Ameri PerezNo ratings yet

- Cryogel Z: Thicknesses Required To Prevent Surface CondensationDocument2 pagesCryogel Z: Thicknesses Required To Prevent Surface CondensationdidapopescuNo ratings yet

- m2588-Hvm-11-h01-001!20!1, Painting Procedure Rev 1, Sent Code-BDocument13 pagesm2588-Hvm-11-h01-001!20!1, Painting Procedure Rev 1, Sent Code-Brajesh100% (1)

- Verification Procedure For Accuracy and PrecisionDocument24 pagesVerification Procedure For Accuracy and PrecisionhunggaumanhNo ratings yet

- Blower Power CalculationsDocument7 pagesBlower Power CalculationsMuzzamilNo ratings yet

- Boat Painting GuideDocument36 pagesBoat Painting Guidedjakarona100% (1)

- Hygrowin: Humidity and Temperature Probe For Direct Connection To Your PCDocument2 pagesHygrowin: Humidity and Temperature Probe For Direct Connection To Your PCMiguel Angel Pacahuala CristobalNo ratings yet

- LampSite 3.0 Datasheet - en - 20170523 PDFDocument9 pagesLampSite 3.0 Datasheet - en - 20170523 PDF123 mlmbNo ratings yet

- 4095 - Stulz MRD 552 PDFDocument114 pages4095 - Stulz MRD 552 PDFxuyen tranNo ratings yet

- Composite Insulator Core Material Test Report PDFDocument33 pagesComposite Insulator Core Material Test Report PDFDaniel MargineanNo ratings yet

- Intro To Kiln Drying GuideDocument24 pagesIntro To Kiln Drying GuideWisam Ankah100% (1)

- A Guide To The Measurement of HumidityDocument71 pagesA Guide To The Measurement of HumidityCyriaque KagororaNo ratings yet

- Sikafloor 155 WNDocument4 pagesSikafloor 155 WNLuis BarriosNo ratings yet

- 109 JadDocument24 pages109 JadLim ChsNo ratings yet

- Met Question BankDocument168 pagesMet Question BankasthNo ratings yet

- Met Q OxfordDocument158 pagesMet Q OxfordEagle NavNo ratings yet

- Manual Phalaenopsis Pot Plants ENGDocument12 pagesManual Phalaenopsis Pot Plants ENGhlfmNo ratings yet

- Basic PneumaticsDocument120 pagesBasic PneumaticsVinot Nathan100% (4)

- Lenovo System x3650 M5 Installation and Service Guide: Machine Type: 5462Document1,192 pagesLenovo System x3650 M5 Installation and Service Guide: Machine Type: 5462rexNo ratings yet

- 1042 Legacy Humidifier Installation & Owners Manual RDocument8 pages1042 Legacy Humidifier Installation & Owners Manual Rsphinx360No ratings yet

- Environmental Guidelines For Museums - Temperature and Relative Humidity (RH)Document12 pagesEnvironmental Guidelines For Museums - Temperature and Relative Humidity (RH)jdcr77No ratings yet

- Insulation CalcDocument4 pagesInsulation Calcjacok22No ratings yet