Professional Documents

Culture Documents

Mercury 115 Manual 1b

Uploaded by

Momed MdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mercury 115 Manual 1b

Uploaded by

Momed MdCopyright:

Available Formats

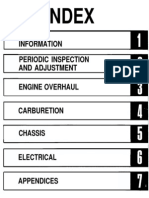

MAINTENANCE

IMPORTANT INFORMATION 1

Section 1B - Maintenance B

Table of Contents

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B-1 Checking Power Trim Fluid . . . . . . . . . . . . . . . . . 1B-8

Inspection And Maintenance Schedule . . . . . . . 1B-2 Changing Engine Oil . . . . . . . . . . . . . . . . . . . . . . . 1B-9

Before Each Use . . . . . . . . . . . . . . . . . . . . . . . 1B-2 Oil Changing Procedure . . . . . . . . . . . . . . . . . 1B-9

After Each Use . . . . . . . . . . . . . . . . . . . . . . . . . 1B-2 Changing Oil Filter . . . . . . . . . . . . . . . . . . . . . 1B-10

Every 100 Hours of Use or Once yearly, Checking and Adding Engine Oil . . . . . . . . 1B-10

Whichever occurs first . . . . . . . . . . . . . . . . . . 1B-3 4-1/4 In. (108mm) Diameter Gear Case . . 1B-11

Every 300 Hours of Use or Three Years . . . 1B-3 Storage Preparation . . . . . . . . . . . . . . . . . . . . . . 1B-12

Every 400 Hours of Use or Four Years . . . . 1B-3 Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . 1B-13

Before Periods of Storage . . . . . . . . . . . . . . . 1B-3 Protecting External Outboard

Corrosion Control Anode . . . . . . . . . . . . . . . . . . . 1B-4 Components . . . . . . . . . . . . . . . . . . . . . . . . . . 1B-13

Spark Plug Inspection . . . . . . . . . . . . . . . . . . . . . . 1B-5 Protecting Internal Engine Components . . 1B-13

Battery Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 1B-5 Gear Case . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B-13

Fuse Replacement – Electric Start Models . . . . 1B-6 Positioning Outboard for Storage . . . . . . . . 1B-13

Timing Belt Inspection . . . . . . . . . . . . . . . . . . . . . 1B-6 Battery Storage . . . . . . . . . . . . . . . . . . . . . . . 1B-13

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . 1B-7

Special Tools

1. Flushing Attachment P/N 44357A2

2. Crankcase Oil Pump P/N 90265A5

3. Oil Filter Wrench P/N 91-802653Q1

90-881980R1 NOVEMBER 2001 Page 1B-1

MAINTENANCE

Inspection And Maintenance Schedule

To keep your outboard in the best operating condition, it is important that your outboard re-

ceive the periodic inspections and maintenance listed in the Inspection and Maintenance

Schedule. We urge you to keep it maintained properly to ensure the safety of you and your

passengers and retain its dependability.

WARNING

Neglected inspection and maintenance service of your outboard or attempting to

perform maintenance or repair on your outboard if you are not familiar with the cor-

rect service and safety procedures could cause personal injury, death, or product

failure.

Before Each Use

1. Check engine oil level.

2. Check that lanyard stop switch stops the engine.

3. Visually inspect the fuel system for deterioration or leaks.

4. Check outboard for tightness on transom.

5. Check steering system for binding or loose components.

6. Visually check steering link rod fasteners for proper tightness.

7. Check propeller blades for damage.

After Each Use

1. Flush out the outboard cooling system if operating in salt or polluted water.

2. If operating in salt water, wash off all salt deposits and flush out the exhaust outlet of the

propeller and gear case with fresh water.

Page 1B-2 90-881980R1 NOVEMBER 2001

MAINTENANCE

Every 100 Hours of Use or Once yearly, Whichever occurs first

1. Lubricate all lubrication points. Lubricate more frequently when used in salt water.

2. Change engine oil and replace the oil filter. The oil should be changed more often when

the engine is operated under adverse conditions such as extended trolling.

3. Inspect thermostat visually for corrosion, broken spring, and to determine that the valve

is completely closed at room temperature. If questionable, inspect thermostat as out-

lined in Section 4B “Thermostat”.

4. Inspect and clean spark plugs.

5. Check engine fuel filter for contaminants.

6. Check engine timing setup.

7. Check corrosion control anodes. Check more frequently when used in salt water.

8. Drain and replace gear case lubricant.

9. Lubricate splines on the drive shaft.

10. Check power trim fluid.

11. Inspect battery.

12. Check control cable adjustments.

13. Inspect timing belt.

14. Remove engine deposits with Power Tune Engine Cleaner.

15. Check tightness of screws, nuts, and other fasteners.

Every 300 Hours of Use or Three Years

1. Replace water pump impeller (more often if overheating occurs or reduced water pres-

sure is noted).

Every 400 Hours of Use or Four Years

1. Check and adjust valve clearance if necessary.

Before Periods of Storage

1. Refer to Storage procedure (this section).

90-881980R1 NOVEMBER 2001 Page 1B-3

MAINTENANCE

Corrosion Control Anode

Each anode requires periodic inspection especially in salt water which will accelerate the

erosion. To maintain this corrosion protection, always replace the anode before it is com-

pletely eroded. Never paint or apply a protective coating on the anode as this will reduce

effectiveness of the anode.

1. The gear case has two corrosion control anodes. Another anode is installed on the bot-

tom of the transom bracket assembly.

c

a

a - Bottom Anode c - Side Anodes

b - Trim Tab

2. Three anodes are installed in the engine block. Remove anodes at locations shown.

Install each anode with rubber seal and cover. Tighten screws to specified torque.

NOTE: Do not remove center screw (b) until cover had been removed from engine.

e

c d

a

b

Do Not Remove

a - Anode d - Anode

b - Screw e - Rubber Seal

c - Cover

Anode Screw Torque

70 lb-in. (8 Nm)

Page 1B-4 90-881980R1 NOVEMBER 2001

MAINTENANCE

Spark Plug Inspection

Inspect spark plugs at the recommended intervals.

1. Remove the spark plug leads by twisting the rubber boots slightly and pull off.

2. Remove the spark plugs to inspect and clean. Replace spark plug if electrode is worn

or the insulator is rough, cracked, broken, blistered or fouled.

3. Set the spark plug gap. See Specification Chart.

4. Before reinstalling spark plugs, clean away dirt on the spark plug seats. Install plugs fin-

ger tight, and tighten 1/4 turn or torque to 20 lb-ft (27 Nm).

Battery Inspection

The battery should be inspected at periodic intervals to ensure proper engine starting capa-

bility.

IMPORTANT: Read the safety and maintenance instructions which accompany your

battery.

1. Turn off the engine before servicing the battery.

2. Add water as necessary to keep the battery full.

3. Make sure the battery is secure against movement.

4. Battery cable terminals should be clean, tight, and correctly installed. Positive to positive

and negative to negative.

5. Make sure the battery is equipped with a nonconductive shield to prevent accidental

shorting of battery terminals.

90-881980R1 NOVEMBER 2001 Page 1B-5

MAINTENANCE

Fuse Replacement – Electric Start Models

The electric starting circuit is protected by overload fuses. If the fuse is blown, the electric

starter motor will not operate. Try to locate and correct the cause of the overload. If the cause

is not found, the fuse may blow again. Replace the fuse with a fuse of the same amperage

rating.

1. Open the electrical cover and pull fuse with fuse puller. Look at the silver colored band

inside the fuse. If band is broken replace the fuse. Replace fuse with a new fuse of the

same amperage rating.

e

b

a

a - Fuse Puller

b - Electrical Cover

c - Fuses - 20 Amp.

d - Fuses - 30 Amp.

e - Blown Fuse

Timing Belt Inspection

1. Inspect the timing belt and replace if any of the following conditions are found.

a. Cracks in the back of the belt or in the base of the belt teeth.

b. Excessive wear at the roots of the cogs.

c. Rubber portion swollen by oil.

d. Belt surfaces roughened.

e. Signs of wear on edges or outer surfaces of belt.

a - Timing Belt

Page 1B-6 90-881980R1 NOVEMBER 2001

MAINTENANCE

Lubrication Points

Lubricate Point 1 with Anti-Corrosion Grease or 2-4-C Marine Lubricant with Teflon

1. Propeller Shaft – Refer to Propeller Replacement for removal and installation of the pro-

peller. Coat the entire propeller shaft with lubricant to prevent the propeller hub from cor-

roding and seizing to the shaft.

Lubricate Points 2 thru 4 with 2-4-C Marine Lubricant with Teflon or Special Lubricant

101.

2. Swivel Bracket – Lubricate through fitting.

3. Tilt Support Lever – Lubricate through fitting.

4. Tilt Tube-Lubricate through fitting.

90-881980R1 NOVEMBER 2001 Page 1B-7

MAINTENANCE

5. Steering Cable Grease Fitting (If equipped) – Rotate steering wheel to fully retract the

steering cable end into the outboard tilt tube. Lubricate through fitting.

Lubricate Point 5 with light weight oil.

a

b

5

a - Steering Cable End

b - Fitting

WARNING

The end of the steering cable must be fully retracted into the outboard tilt tube be-

fore adding lubricant. Adding lubricant to steering cable when fully extended could

cause steering cable to become hydraulically locked. An hydraulically locked steer-

ing cable will cause loss of steering control, possibly resulting in serious injury or

death.

Checking Power Trim Fluid

1. Tilt outboard to the full up position and engage the tilt support lock.

a - Tilt Support Lock

2. Remove fill cap and check fluid level. The fluid level should be even with the bottom of

the fill hole. Add Power Trim & Steering Fluid. If not available, use automotive (ATF) au-

tomatic transmission fluid.

a - Fill Cap

Page 1B-8 90-881980R1 NOVEMBER 2001

MAINTENANCE

Changing Engine Oil

Oil Changing Procedure

Pump Method

1. Place the outboard in an vertical upright position.

2. Remove dipstick and slide adaptor tube/pump down dipstick tube. Pump out the engine

oil into an appropriate container.

a

90265A5

a - Crankcase Oil Pump

Drain Plug Method

1. Tilt the outboard up to the trailer position.

2. Turn the steering on the outboard so that the drain hole is facing downward. Remove

drain plug and drain engine oil into an appropriate container. Lubricate the seal on the

drain plug with oil and reinstall.

a - Drain Hole

90-881980R1 NOVEMBER 2001 Page 1B-9

MAINTENANCE

Changing Oil Filter

1. Place a rag or towel below the oil filter to absorb any spilled oil.

2. Unscrew old filter by turning the filter counterclockwise.

3. Clean the mounting base. Apply film of clean oil to filter gasket. Do not use grease.

Screw new filter on until gasket contacts base, then tighten 3/4 to 1 turn.

91-802653Q1

a - Oil Filter

Checking and Adding Engine Oil

IMPORTANT: Do not overfill. Be sure that the outboard is upright (not tilted) when

checking oil.

1. Remove the oil fill cap and add oil to to proper operating level.

2. Idle engine for five minutes and check for leaks. Stop engine and check oil level on dip-

stick. Oil must be between full mark and add mark. Add oil if necessary.

58653 58655

a - Dipstick c - Full Mark

b - Oil Fill Cap d - Add Mark

Engine Oil Capacity

5 U.S. Quarts or (5.0 Liters)

Page 1B-10 90-881980R1 NOVEMBER 2001

MAINTENANCE

4-1/4 In. (108mm) Diameter Gear Case

When adding or changing gear case lubricant, visually check for the presence of water in

the lubricant. If water is present, it may have settled to the bottom and will drain out prior

to the lubricant, or it may be mixed with the lubricant, giving it a milky colored appearance.

If water is noticed, have the gear case checked by your dealer. Water in the lubricant may

result in premature bearing failure, or in freezing temperatures, will turn to ice and damage

the gear case.

Whenever you remove the fill/drain plug, examine the magnetic end for metal particles. A

small amount of metal filings or fine metal particles indicates normal gear wear. An exces-

sive amount of metal filings or larger particles (chips) may indicate abnormal gear wear and

should be checked by an authorized dealer.

DRAINING GEAR CASE

1. Place outboard in a vertical operating position.

2. Place a drain pan below outboard.

3. Remove vent plugs and fill/drain plug and drain lubricant.

c

b

a - Fill/drain Plug

b - Rear Vent Plug

c - Front Vent Plug

Gear Case Lubricant Capacity

24 fl oz (710 ml)

90-881980R1 NOVEMBER 2001 Page 1B-11

MAINTENANCE

CHECKING LUBRICANT LEVEL AND FILLING GEAR CASE

1. Place outboard in a vertical operating position.

2. Remove the front vent plug and rear vent plug.

3. Place lubricant tube into the fill hole and add lubricant until it appears at the front vent

hole. At this time install the front vent plug and sealing washer.

4. Continue adding lubricant until it appears at the rear vent hole.

5. Stop adding lubricant. Install the rear vent plug and sealing washer before removing lu-

bricant tube.

6. Remove lubricant tube and reinstall cleaned fill/drain plug and sealing washer.

c b

a - Front Vent Plug

b - Rear Vent Plug

c - Front Vent Hole

d - Rear Vent Hole

e - Fill/Drain Plug and Sealing Washer

Storage Preparation

The major consideration in preparing your outboard for storage is to protect it from rust, cor-

rosion, and damage caused by freezing of trapped water.

The following storage procedures should be followed to prepare your outboard for out-of-

season storage or prolonged storage (two months or longer).

CAUTION

Never start or run your outboard (even momentarily) without water circulating

through the cooling water intake in the gear case to prevent damage to the water

pump (running dry) or overheating of the engine.

Page 1B-12 90-881980R1 NOVEMBER 2001

MAINTENANCE

Fuel System

IMPORTANT: Gasoline containing alcohol (ethanol or methanol) can cause a forma-

tion of acid during storage and can damage the fuel system. If the gasoline being

used contains alcohol, it is advisable to drain as much of the remaining gasoline as

possible from the fuel tank, remote fuel line, and engine fuel system.

Fill the fuel system (tank, hoses, fuel pump, and carburetor) with treated (stabilized) fuel to

help prevent formation of varnish and gum. Proceed with following instructions.

1. Portable Fuel Tank – Pour the required amount of Fuel System Treatment & Stabilizer

(follow instructions on container) into fuel tank. Tip fuel tank back and forth to mix stabi-

lizer with the fuel.

2. Permanently Installed Fuel Tank – Pour the required amount of Fuel System Treatment

& Stabilizer (follow instructions on container) into a separate container and mix with

approximately one quart (one liter) of gasoline. Pour this mixture into fuel tank.

3. Place the outboard in water or connect flushing attachment for circulating cooling water.

Run the engine for ten minutes to allow treated fuel to fill the engine fuel system.

Protecting External Outboard Components

1. Lubricate all outboard components listed in the Inspection and Maintenance Schedule.

2. Touch up any paint nicks.

3. Spray Corrosion Guard on external metal surfaces (except corrosion control anodes).

Protecting Internal Engine Components

1. Remove the spark plugs and inject a small amount of engine oil inside of each cylinder.

2. Rotate the flywheel manually several times to distribute the oil in the cylinders. Reinstall

spark plugs.

3. Change the engine oil.

Gear Case

1. Drain and refill the gear case lubricant (refer to maintenance procedure).

Positioning Outboard for Storage

Store outboard in an upright (vertical) position to allow water to drain out of outboard.

CAUTION

If outboard is stored tilted up in freezing temperature, trapped cooling water or rain

water that may have entered the propeller exhaust outlet in the gear case could

freeze and cause damage to the outboard.

Battery Storage

1. Follow the battery manufacturer’s instructions for storage and recharging.

2. Remove the battery from the boat and check water level. Recharge if necessary.

3. Store the battery in a cool, dry place.

4. Periodically check the water level and recharge the battery during storage.

90-881980R1 NOVEMBER 2001 Page 1B-13

You might also like

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Important Information: Section 1B - MaintenanceDocument17 pagesImportant Information: Section 1B - MaintenanceDr. Centelha Mecânica NaúticaNo ratings yet

- 1b PARTE MERCURY V6Document9 pages1b PARTE MERCURY V6Antonio VillafuerteNo ratings yet

- Maintain Outboard Engine EasilyDocument14 pagesMaintain Outboard Engine EasilyJoswyn LopesNo ratings yet

- Ajuste Inyector UnitarioDocument190 pagesAjuste Inyector UnitarioHamilton MirandaNo ratings yet

- Maintenance: Outboard CareDocument18 pagesMaintenance: Outboard Careshygal1981100% (1)

- MaintenanceInformation 6CylVeradoDocument25 pagesMaintenanceInformation 6CylVeradocombaheeNo ratings yet

- ALISSON HT 700 Hydr Service ManualDocument328 pagesALISSON HT 700 Hydr Service ManualAnonymous eExWojLxNo ratings yet

- Maintenance BFPDocument28 pagesMaintenance BFPYulianto Kartono100% (1)

- MaintenanceInformation 4CylVeradoDocument27 pagesMaintenanceInformation 4CylVeradocombaheeNo ratings yet

- Hyundai Exel 89 1.5l.mantenimientoDocument18 pagesHyundai Exel 89 1.5l.mantenimientoAlexander cesar neyra sotoNo ratings yet

- December 2009 Edition AnglaiseDocument247 pagesDecember 2009 Edition Anglaisedfry wsertstsxNo ratings yet

- Doosan d12 p126 Op Maintenence ManualDocument140 pagesDoosan d12 p126 Op Maintenence Manualmaher100% (1)

- MaintenanceInformation OptiMaxDocument20 pagesMaintenanceInformation OptiMaxcombaheeNo ratings yet

- M34b Master Cylinder PDFDocument9 pagesM34b Master Cylinder PDFLuis MarquezNo ratings yet

- Yamaha XS650 XS 650 Service Repair ManualDocument213 pagesYamaha XS650 XS 650 Service Repair Manualandy miller100% (4)

- Royal Enfield Bullet Workshop Manual PDFDocument110 pagesRoyal Enfield Bullet Workshop Manual PDFdyna1450hotmail.frNo ratings yet

- NoticeDocument14 pagesNoticeColin SmithNo ratings yet

- Mercury Maintenance ManualDocument27 pagesMercury Maintenance ManualJens Adam Hedegaard HansenNo ratings yet

- Caterpillar Engine Service Manual Eng d379Document18 pagesCaterpillar Engine Service Manual Eng d379Bonggo pribadiNo ratings yet

- Outboard Manual 70 75 80 90 100 115 PDFDocument391 pagesOutboard Manual 70 75 80 90 100 115 PDFTudorel Iancu0% (1)

- Service Manual #06Document566 pagesService Manual #06Bull White100% (2)

- #6 R, MR, Alpha I Outdrives 1983 To 1990Document566 pages#6 R, MR, Alpha I Outdrives 1983 To 1990hormiganegra431100% (1)

- Maintenance enDocument23 pagesMaintenance enAline BritoNo ratings yet

- 01 08 01 - Ing M 4.1HR10 (1) 002 eDocument48 pages01 08 01 - Ing M 4.1HR10 (1) 002 eTheULTRANo ratings yet

- Sebu6617-04 MDocument38 pagesSebu6617-04 MCDDPPJNo ratings yet

- 1a3 Двигатель. Общая ИнформацияDocument15 pages1a3 Двигатель. Общая ИнформацияLuis Alberto BernalNo ratings yet

- Beta RR 250 400 450 525 Service Repair Manual 2005-2007 PDFDocument215 pagesBeta RR 250 400 450 525 Service Repair Manual 2005-2007 PDFvadim vadimNo ratings yet

- Tech-Ss80v Manual 01 GeneralDocument18 pagesTech-Ss80v Manual 01 GeneralMaximiliano RiosecoNo ratings yet

- Turbo InspectDocument4 pagesTurbo Inspectzawmoe aungNo ratings yet

- Vento SrevemanualDocument146 pagesVento SrevemanualDaniel HernandezNo ratings yet

- Mercruiser Service Manual - 31 2001 - Newer GM Small Block V8Document636 pagesMercruiser Service Manual - 31 2001 - Newer GM Small Block V8Des Stirling100% (6)

- Beta - BETA RR 4t 250-400-450-525 - Workshop - Manual PDFDocument139 pagesBeta - BETA RR 4t 250-400-450-525 - Workshop - Manual PDFLeandro MoyanoNo ratings yet

- Royal Enfield Bullet 1995 Owners ManualDocument109 pagesRoyal Enfield Bullet 1995 Owners ManualAndrea De SantisNo ratings yet

- Outside Vehicle: General MaintenanceDocument8 pagesOutside Vehicle: General MaintenanceTung NguyenNo ratings yet

- Alexander Dennis PDFDocument5 pagesAlexander Dennis PDFAgustin BerriosNo ratings yet

- AC 43.13-1B Chapter 08Document42 pagesAC 43.13-1B Chapter 08Vorrataa KulkeitpravatNo ratings yet

- Workshop ManualDocument34 pagesWorkshop ManualRobert JamnikNo ratings yet

- Rboat Davit MAINTENANCE MANUAL PDFDocument14 pagesRboat Davit MAINTENANCE MANUAL PDFAnoop AnupNo ratings yet

- MT 600 Service Manual SM1317 199907Document277 pagesMT 600 Service Manual SM1317 199907Ruben Antonio Huaranca Cruz100% (2)

- Doosan Diesel Engine DL06 PDFDocument211 pagesDoosan Diesel Engine DL06 PDFHANSELL MIRANDA ALVA100% (2)

- Chapter Three: Pumps and Their MaintenanceDocument6 pagesChapter Three: Pumps and Their MaintenanceAhmed RezkNo ratings yet

- 1988-1989 Yamaha Enticer 340 400 Snowmobile Service Manual RepairDocument199 pages1988-1989 Yamaha Enticer 340 400 Snowmobile Service Manual Repairtimmckenna100% (1)

- Instruction Manual: ADONY Series AHDocument47 pagesInstruction Manual: ADONY Series AHHong Trung DuongNo ratings yet

- Turbocharger - Inspect: Shutdown SIS Previous ScreenDocument4 pagesTurbocharger - Inspect: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- Mercruiser Service Manual - 25 GM V6 1998 - 2001Document225 pagesMercruiser Service Manual - 25 GM V6 1998 - 2001an82mustang100% (3)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- XT-LITE - brochureDocument6 pagesXT-LITE - brochureMomed MdNo ratings yet

- UM-Tron-40AIS_rev_GDocument56 pagesUM-Tron-40AIS_rev_GMomed MdNo ratings yet

- 161-Gyro AM AlphaMiniCourse MK2 InstOper Manual 24-1-2022Document75 pages161-Gyro AM AlphaMiniCourse MK2 InstOper Manual 24-1-2022Ivo CastroNo ratings yet

- XTLITEManualAllRev121909201Document136 pagesXTLITEManualAllRev121909201Momed MdNo ratings yet

- User-Manual-Tron-TR30_vBDocument72 pagesUser-Manual-Tron-TR30_vBMomed MdNo ratings yet

- User-Manual-Tron-TR30-AIR_vBDocument44 pagesUser-Manual-Tron-TR30-AIR_vBMomed MdNo ratings yet

- ManualDocument52 pagesManualMomed MdNo ratings yet

- User Guide: Interactive Fire Alarm SystemDocument30 pagesUser Guide: Interactive Fire Alarm SystemFrank1No ratings yet

- Obsolete Products List V2.2Document15 pagesObsolete Products List V2.2Momed MdNo ratings yet

- NSO-evo3S IM EN 988-12478-001 WDocument48 pagesNSO-evo3S IM EN 988-12478-001 WMomed MdNo ratings yet

- Tron AIS TR 8000 MkII v2Document2 pagesTron AIS TR 8000 MkII v2Momed MdNo ratings yet

- NSS-evo3 IM EN 988-11364-001 WDocument56 pagesNSS-evo3 IM EN 988-11364-001 WMomed MdNo ratings yet

- 225-225 EFI - 50 EFI-3.0 Litre Marathon-3.0 Litre SeaPro United States-With Serial Numbers 0D280813 and AboveDocument639 pages225-225 EFI - 50 EFI-3.0 Litre Marathon-3.0 Litre SeaPro United States-With Serial Numbers 0D280813 and AboveMomed MdNo ratings yet

- AIS Saab R5 Supreme AIS InstallOper Manual 8-6-2021Document145 pagesAIS Saab R5 Supreme AIS InstallOper Manual 8-6-2021jm colladoNo ratings yet

- Manual Usuario Alarma Incendio DECKMA, 815.8-6Document12 pagesManual Usuario Alarma Incendio DECKMA, 815.8-6pevalpevalNo ratings yet

- Xpack DsDocument74 pagesXpack DsKoitoheNo ratings yet

- Water Mist Test Report PDFDocument5 pagesWater Mist Test Report PDFMomed MdNo ratings yet

- Gyro Compass Standard 22 NX Operator Manual: Type: 110-244.NG001Document38 pagesGyro Compass Standard 22 NX Operator Manual: Type: 110-244.NG001Aung Myo ThantNo ratings yet

- Portable Multi-Gas Detector User Manual: Ver BSA20150424001Document16 pagesPortable Multi-Gas Detector User Manual: Ver BSA20150424001Momed MdNo ratings yet

- Manual Usuario Alarma Incendio DECKMA, 815.8-6Document12 pagesManual Usuario Alarma Incendio DECKMA, 815.8-6pevalpevalNo ratings yet

- STD22 NG002 Operator ManualDocument50 pagesSTD22 NG002 Operator ManualnikolaytelenkovNo ratings yet

- Xpack DsDocument74 pagesXpack DsKoitoheNo ratings yet

- Electrical: Section 2A - IgnitionDocument47 pagesElectrical: Section 2A - IgnitionMomed MdNo ratings yet

- Mercury 115 Manual 1dDocument15 pagesMercury 115 Manual 1dMomed MdNo ratings yet

- Mercury 115 Manual 1cDocument24 pagesMercury 115 Manual 1cMomed MdNo ratings yet

- Mercury 115 Manual 2bDocument33 pagesMercury 115 Manual 2bMomed MdNo ratings yet

- Mercury 115 Manual d1Document15 pagesMercury 115 Manual d1Momed MdNo ratings yet

- Types of Vehicle LayoutDocument7 pagesTypes of Vehicle LayoutAnk VaaiNo ratings yet

- Homepage Provides VIN Help for Holden OwnersDocument933 pagesHomepage Provides VIN Help for Holden OwnersSanket KareNo ratings yet

- STIHL TS410, TS420 Spare PartsDocument11 pagesSTIHL TS410, TS420 Spare PartsMarinko PetrovićNo ratings yet

- Understanding Scale and Proportion in Maps and DrawingsDocument14 pagesUnderstanding Scale and Proportion in Maps and DrawingsZeke Isaiah Wijaya 2052028No ratings yet

- Hitachi excavator technical manual overviewDocument6 pagesHitachi excavator technical manual overviewyasirNo ratings yet

- Vehicle To Diagnostic Tool Reference Chart-HighltDocument9 pagesVehicle To Diagnostic Tool Reference Chart-HighltblzfmyNo ratings yet

- Engine Control HR12DEDocument843 pagesEngine Control HR12DEKongkiat TanamitNo ratings yet

- Champion Rescue SuperBeastDocument2 pagesChampion Rescue SuperBeastForum PompieriiNo ratings yet

- Bobkat 435 6902330 enUSDocument182 pagesBobkat 435 6902330 enUSviktor0% (1)

- Capital GoodsDocument5 pagesCapital GoodsByamugisha ImerioNo ratings yet

- Engine 4JJ1Document254 pagesEngine 4JJ1kidskung100% (22)

- 3.4 Burner Lance ManualDocument3 pages3.4 Burner Lance ManualANTONIO MEDINA RIOSNo ratings yet

- Speed Control of 3ph IMDocument4 pagesSpeed Control of 3ph IMKrushna PisalNo ratings yet

- Fault Code 0169 Kone ElevatorDocument7 pagesFault Code 0169 Kone ElevatorSaleh El Daly25% (4)

- Proxima Z 6421-8441 GBDocument222 pagesProxima Z 6421-8441 GBLicínio DâmasoNo ratings yet

- SM2059 (Apr-67)Document310 pagesSM2059 (Apr-67)EdU RECTIFICANo ratings yet

- Service Manual-C5, B5, GT-Engine - Euro IVDocument152 pagesService Manual-C5, B5, GT-Engine - Euro IVEdgar PinedaNo ratings yet

- RWF Operacion y MantenimientoDocument52 pagesRWF Operacion y MantenimientodfmolinaNo ratings yet

- 8) O & M Manual PristineDocument2 pages8) O & M Manual PristineWan HaikalNo ratings yet

- Electro Magnetic Braking System Review 1Document18 pagesElectro Magnetic Braking System Review 1sandeep Thangellapalli100% (1)

- Catalogo Centaflex Serie ADocument15 pagesCatalogo Centaflex Serie ACarlos Gallardo LagosNo ratings yet

- Tc21 - 305 - 4 Training Program For Driving HMMWVDocument134 pagesTc21 - 305 - 4 Training Program For Driving HMMWVaveryNo ratings yet

- Ahu SpecificationDocument8 pagesAhu SpecificationUzair QuraishiNo ratings yet

- Pajero 4WD Flashing Light Fix and TroubleshootingDocument13 pagesPajero 4WD Flashing Light Fix and TroubleshootingAren MendozaNo ratings yet

- Development of A Cone CVT by SDPD and Topology Optimization: April 2019Document11 pagesDevelopment of A Cone CVT by SDPD and Topology Optimization: April 2019Humayu RehmanNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentsKevin TtitoNo ratings yet

- Access - Catalog.805b.color - DP&Casing Tools-50Document1 pageAccess - Catalog.805b.color - DP&Casing Tools-50RICHARDNo ratings yet

- BATS-S, BATS-D, BBOX-L, BBOX-EF, 2BATT170, 2BATT225, 2BAT210B, UBAMAFRE, BAMAFREE, MSWI-B, MSWI-C, MSWI-R, MSWI-A - Eng - 01 - 307895105Document8 pagesBATS-S, BATS-D, BBOX-L, BBOX-EF, 2BATT170, 2BATT225, 2BAT210B, UBAMAFRE, BAMAFREE, MSWI-B, MSWI-C, MSWI-R, MSWI-A - Eng - 01 - 307895105Gary GuzmánNo ratings yet

- Gearbox Clutch Driveshaft Steering PDFDocument190 pagesGearbox Clutch Driveshaft Steering PDFluisxxx1100% (1)

- CH024Document34 pagesCH024Selva RamNo ratings yet

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)