Professional Documents

Culture Documents

" Comparative Study of Different Formulation of Aceclonac

" Comparative Study of Different Formulation of Aceclonac

Uploaded by

safrinpujiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

" Comparative Study of Different Formulation of Aceclonac

" Comparative Study of Different Formulation of Aceclonac

Uploaded by

safrinpujiCopyright:

Available Formats

Patil et al., IJPSR, 2014; Vol. 5(8): 3401-3408.

E-ISSN: 0975-8232; P-ISSN: 2320-5148

IJPSR (2014), Vol. 5, Issue 8 (Research Article)

Received on 18 February, 2014; received in revised form, 07 April, 2014; accepted, 15 June, 2014; published 01 August, 2014

COMPARATIVE STUDY OF DIFFERENT FORMULATIONS OF ACECLOFENAC AS A

TOPICAL DRUG DELIVERY SYSTEM AND IT’S IN VITRO AND IN VIVO

CHARACTERIZATION

Akshata K. Patil*, Avinash B. Gangurde and Purnima D. Amin

Department of Pharmaceutical Sciences and Technology, Institute of Chemical Technology, N.P.Marg,

Matunga (E), Mumbai-400019, Maharashtra, India

Keywords: ABSTRACT: Aceclofenac is new NSAID which demonstrates its anti-

inflammatory and analgesic activity in a concentration of 1.5 %. Topical

Aceclofenac, silicone cream base, mode of administration help to avoid typical side effects associated with oral

Carbopol gel, Emulgel, In-Vitro

administration of NSAIDS such as irritation and ulceration to gastric

activity, In-Vivo activity

mucosa. Hence, an attempt has been made to prepare topical formulations

Correspondence to Author:

using various dermatological bases and to evaluate release properties and

Avinash Bhaskar Gangurde improved stability throughout its shelf life. Cream, gel and emulgel topical

(Ph. D. Tech. Senior research Fellow) formulations were formulated and characterized for its physicochemical

parameters such as pH, spread ability, rheological properties and occlusivity.

Current Mailing address: Department The in-vitro permeation potential of Aceclofenac was performed through

of Pharmaceutical Sciences and Dow Corning 7-4107 silicone elastomer membrane using Franz type

Technology, Institute of Chemical diffusion cell. The in-vitro permeation rate of drug from silicone cream base

Technology, N. P. Marg, Matunga was significantly higher compared to other vehicles. The in-vivo animal

(E), Mumbai 400019, Maharashtra, study was performed on croton oil induced ear edema model. Developed

India

Aceclofenac cream formulation showed 66.67% inhibition of ear edema

which was significantly higher than other formulation. The stability study of

E-mail:

gangurde.avinash8@gmail.com Aceclofenac formulations was performed at 25°C/60 % RH, 30°C/65 % RH

and at 40°C/75 % RH conditions. Stability study revealed that Aceclofenac

possessed higher stability in silicone cream formulation compared to gel and

emulgel formulation. Hence, silicone cream base is a stable and efficient

vehicle for delivery of Aceclofenac through dermal route.

INTRODUCTION: Topical drug delivery of non- The therapeutic efficacy of a topical formulation

steroidal anti-inflammatory drugs (NSAIDs) has depends on its composition of dermatological base

been recognized as an alternative to oral therapy. and the physicochemical properties of the base. The

The advantage of topical Delivery of NSAIDS is composition can affect drug release rate and

the direct accessibility of them to the affected permeability properties of drugs through skin.

tissues with minimal systemic side effects, such as Therefore, selection of appropriate dermatological

peptic ulcer disease and gastrointestinal base is most important parameter for increasing

haemorrhage 1. efficacy of topically applied formulation 2, 3.

QUICK RESPONSE CODE

DOI:

10.13040/IJPSR.0975-8232.5(8).3401-08

Aceclofenac (2-[(2, 6-dichlorophenyl) amine]

phenylacetoxyacetic acid) is a new NSAID of

Article can be accessed online on:

phenyl acetic acid group, demonstrated remarkable

www.ijpsr.com anti-inflammatory and analgesic properties.

DOI link: http://dx.doi.org/10.13040/IJPSR.0975-8232.5(8).3401-08

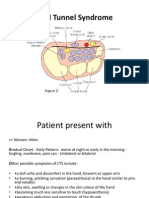

Structure of Aceclofenac is shown in (fig. 1).

International Journal of Pharmaceutical Sciences and Research 3401

Patil et al., IJPSR, 2014; Vol. 5(8): 3401-3408. E-ISSN: 0975-8232; P-ISSN: 2320-5148

determine the superior topical formulation for

Aceclofenac penetration.

MATERIALS AND METHODS: Aceclofenac

was obtained as a gift sample from Ajanta

pharmaceuticals Ltd. Methyl salicylate, menthol,

camphor and silicone cream base were procured

from Mascot Pvt. Ltd. Carbopol resin (Synthalen

FIG. 1: STRUCTURE OF ACECLOFENAC K) was procured from sigma 3V. Other chemicals

used were of analytical reagent grade.

Preliminary clinical studies have shown that

Aceclofenac 1.5% applied topically for 4 days is as Animals: Approval for the use of animals in the

well tolerated as placebo 4, 5. Aceclofenac is an study was obtained from the CPCSEA (Institute of

example of BCS class II compound, due to its chemical Technology, Regn. No:

lipophilic nature it will better absorbed by tissue 87/1999/CPCSEA dated 28th April, 1999) or

and will show better action 6. Pharmacologically Institutional Animal Ethics Committee (IAEC)

Aceclofenac stimulates glycosaminoglycan’s Mumbai, India.

(GAG) synthesis which results in enhancement of

skin permeation of NSAIDs. Stratum corneum is Preparation of semi-solid dosage forms: Semi

the principal barrier for cutaneous penetration solid formulations of Aceclofenac were prepared

allowing slow absorption of the drug 7. The according to the composition given below in Table

importance of Aceclofenac as a new generation 1 with various dermatological bases (Aqueous

NSAID has inspired development of topical drug silicone cream base, Carbopol gel base and

delivery. Topical formulation of Aceclofenac gives emulsified gel base) and applied standard

the opportunity to deliver the drug directly to the procedures. In each of the formulation Aceclofenac

diseased site 8, 9. incorporated into the formulation at 1.5%

concentration. To obtain homogenous mass all the

The objective of present investigation was to actives were triturated by using geometrical

compare the effect of different topical formulations dilution procedure. The three bases were chosen for

of Aceclofenac such as silicone cream base, their different hydrophilic, hydrophobic and

Carbopol gel base and Emulsified gel base and viscosity characteristics.

studied the in vitro release and in vivo animal study

with improved stability throughout its shelf life to

TABLE 1: COMPOSITION OF TOPICAL FORMULATIONS OF ACECLOFENAC FORMULATIONS

Quantity (%w/w)

Ingredients Batch No.

AC 1 AC 2 AC 3

Aceclofenac 1.5% 1.5% 1.5%

Methyl salicylate 10% --- 10%

Camphor 4% --- 4%

Menthol 5% --- 5%

PEG 400 --- 10% ---

Na-metabisulphite --- 0.1% ---

Na-methyl paraben --- 0.1% ---

Silicone aqueous cream base 24.65% --- ---

Glycerol Monostearate --- --- 3%

Span 85 --- --- 1%

Tween 20 --- --- 1%

Propyl paraben --- --- 0.05%

Methyl paraben --- --- 0.18%

Butylated hydroxytoluene --- --- 0.02%

Triethanolamine --- To adjust pH to 7 To adjust pH to 7

Synthalen K --- 1% 0.8 %

Purified water q.s for 100 gm. q.s. q.s.

International Journal of Pharmaceutical Sciences and Research 3402

Patil et al., IJPSR, 2014; Vol. 5(8): 3401-3408. E-ISSN: 0975-8232; P-ISSN: 2320-5148

Preparation of Aceclofenac cream (AC 1): pH: The pH of the Aceclofenac formulations was

Methyl salicylate, menthol and camphor were determined using a Eutech digital pH meter.

accurately weighed and heated in water bath to get

a clear solution. The solution was allowed to cool Texture profiles/Rheological studies: The

followed by addition of active to obtain clear formulations were evaluated for apparent viscosity

solution of Aceclofenac. and spread ability. Apparent viscosity was recorded

using Brookfield Viscometer RV model at 0.5, 1,

The clear solution of actives was added in small 2.5 and 5 rpm 10.

aliquots in silicone cream base with constant

agitation. The cream was stirred till desired The spreadability of obtained topical formulation

consistency and uniform cream was obtained. was analyzed using texture analyzer Brookfield

engineering labs which consist of a set of matched

Preparation of Aceclofenac Carbopol Gel (AC male and female Perspex cones. When the probe

2): Aceclofenac was added to PEG 400 and comes in contact with the sample, the instrument

sonicated until active drug was completely soluble. begins to measure the triggered force using test

Synthalen K was sprinkled into a mixture of speed. During this time, the force required to

measured amount of purified water containing penetrate the sample increases and at a specified

dissolved Na-metabisulphite and Na-methyl penetration distance the probe withdraws from the

paraben and agitated at high speed. This mixture sample at the post-test speed. The graph of Time

was soaked overnight to provide complete swelling (seconds) vs. Load (gm.) was plotted. The graph

of polymer. The clear solution of active was added indicates that maximum force value is a measure of

in small aliquots to gel base with constant agitation the firmness of sample at specified depth and area

followed by neutralization (pH 7) using under positive curve indicates the energy required

Triethanolamine. to deform the sample which is the hardness work

done. The firmness and energy required to deform

Preparation of Aceclofenac Emulgel (AC 3): An the sample are measures of the spread ability.

oily phase of the emulsion were prepared by adding Lower the firmness and hardness work done value

clear solution of Methyl Salicylate, Menthol, indicates a more spreadable sample. (Brookfield

Camphor and Aceclofenac to melted Glycerol Engineering laboratories)

Monostearate (GMS) followed by addition of

Butylated hydroxytoluene, Methyl Paraben and Stability under centrifugation: The cream was

Propyl paraben. An aqueous phase for emulsion evaluated for creaming i.e. aggregation of

comprised of Tween 20, Span 85 and purified emulsified oil particles at the top of the sample.

water. Two centrifugation tubes filled with 10 ml of cream

were centrifuged at 5000 rpm for 30 mins and

The emulsion was prepared by addition of aqueous evaluated for phase separation. It evaluates the

phase to oily phase to obtain a stable emulsion. stability of samples under high stress conditions

Soaking the Synthalen K in purified water for 24 and accelerated deterioration of the formulation 11,

12

hour to obtain the gel base. The emulgel was .

prepared by addition of o/w emulsion to gel base

with constant agitation followed by neutralization Stability under Thermal cycling: Wide mouth

(pH 7) with Triethanolamine (5%v/v) in water. plastic containers made up of Low Density

Polyethylene were filled with Aceclofenac cream

Characterization of semi-solid formulations: which was subjected to refrigerated temperature

(2°C -8°C) for 24 hrs. Followed by exposure to

Organoleptic properties: The physical appearance room temperature (30°C/60% relative humidity) for

of formulations was checked visually (Appearance, 24 hrs. And accelerated storage temperature

Color, odor and homogeneity) while greasiness was (40°C/75% relative humidity) for 24 hrs. This cycle

assessed by application into the skin surface. was repeated three times and any change in the

color, viscosity was recorded 13.

International Journal of Pharmaceutical Sciences and Research 3403

Patil et al., IJPSR, 2014; Vol. 5(8): 3401-3408. E-ISSN: 0975-8232; P-ISSN: 2320-5148

Determination of drug content by HPLC: In vitro drug release study: In vitro permeability

Sample solution was prepared by adding topical studies were carried out using Franz glass diffusion

formulation of Aceclofenac to acetonitrile and cell type apparatus containing six diffusion cells.

sonicated for 10 minutes to get complete solubility The diffusion apparatus have 0.785 cm2 diffusion

of drug. Reference solution was prepared by adding area and the volume of receptor chamber is 10 ml.

5mg of drug to 10 ml of acetonitrile and sonicated Dow Corning 7-4107 Silicone elastomer was used

for 10 minutes. These solutions were further diluted as semi-permeable membrane for 8 hrs permeation

and filtered through 0.2µm membrane and the studies, which is soaked in receiver medium before

resulting solution was estimated by HPLC at 275 mounting on Franz diffusion cells. Phosphate

nm 14. buffer pH 7.4 was used as receptor medium. A

weighed quantity of formulation were placed

evenly on the surface of the membrane and

immersed slightly on 10 ml receptor medium which

………………………………………………......(1) was continuously stirred with magnetic stirrer and

maintained at temperature 32±0.5°C. Aliquots of 2

Occlusion studies: 10 ml of water was added to ml were withdrawn at specified time interval up to

beaker which covered with cellulose nitrate filter 8 hrs. The withdrawal aliquots were diluted

paper and sealed. 200 mg of sample was spread suitably and Aceclofenac content was estimated by

evenly with a spatula on the filter surface. The spectrophotometrically at 275 nm.

Beaker covered with cellulose filter paper but

without applied sample served as reference sample. Kinetics of drug release study: The in-vitro

The samples were stored at 32°C (skin release data of all three semisolid formulations

temperature) and 50–55% RH for 24 hrs. The were subjected to kinetic analysis to establish the

samples were weighed after 24 hrs which gives the drug release mechanism. The release data were

water loss due to evaporation at each time (water fitted to the zero-order, first order and matrix

flux through the filter paper).The occlusion factor F (Higuchi model) equations 16.

was calculated according to the following equation;

In vivo anti-inflammatory activity: Anti-

inflammatory activities of topical formulations

…………………………(2) were evaluated using Female Wistar rats (150-200

by croton oil induced ear edema. For croton oil

Where, A is the water loss without sample induced ear edema rats were divided into three

(reference) and B is the water loss with sample. An groups as shown in Table 2.

occlusion factor of 0 means no occlusive effect

compared to the reference and 100 is the maximum

occlusion factor 15.

TABLE 2: GROUPS OF CROTON OIL INDUCED EAR EDEMA RATS FOR IN VIVO ANTI-INFLAMMATORY

ACTIVITY

Group 1:(Negative Control) Croton oil

Group 2 (Placebo Control) Croton oil + placebo

Group 3 (Test Group) Aceclofenac cream or Aceclofenac emulgel or Aceclofenac gel + Croton oil

The animals were housed at 22 ± 2 °C and relative followed by the application of formulation and the

humidity 60 ± 5 % with 12 hour light- dark cycle. left ear remains untreated.

Each group was fed with standard commercial

laboratory chow (solid) and supplied with purified The irritant was applied under halothane

water ad libitum. The irritant croton oil solution anaesthesia. The ear thickness was measured before

was prepared which consists of 4 parts croton oil, and after the induction of inflammation using a

10 parts ethanol, 20 parts pyridine and 66 parts digital Vernier caliper 17.

ethyl ether. 0.02 ml of this irritant croton oil

solution was applied on both sides of the right ear

International Journal of Pharmaceutical Sciences and Research 3404

Patil et al., IJPSR, 2014; Vol. 5(8): 3401-3408. E-ISSN: 0975-8232; P-ISSN: 2320-5148

formulated cream was evaluated for appearance,

pH and drug content by HPLC. All the parameters

for Aceclofenac formulations were evaluated for 3

months at interval of 1 month.

RESULTS AND DISCUSSION: All the

…………………………………………………(3) Aceclofenac topical formulations were white in

color. Carbopol gel base appeared to be translucent

and glossy while other formulations were opaque

and greasy on application. All the formulations

found to be smooth, free from grittiness on

…………………………………………………. (4) application and homogenous in nature.

Stability studies of formulations: The The drug concentration in dermatological bases

Aceclofenac formulations was packed in wide was found to be in the range of 100-110 % (Table

mouth plastic containers made up of low density 3). This reveals that the method used was suitable

polyethylene and was evaluated for stability at for preparation of topical dosage forms. As

room temperature, 25°C±2°C/ 60 % ± 5 % RH, indicated by the value of drug content there was no

30°C±2°C/ 65 % ± 5 % RH and at accelerated degradation of the active during the preparation

condition of 40°C±2°C/ 75 % ± 5 % RH. The process.

TABLE 3: PHYSICOCHEMICAL PROPERTIES OF TOPICAL FORMULATION CONTAINING ACECLOFENAC

Hardness work

Formulation Drug Content % pH Apparent Viscosity Occlusion Factor %

done (mJ)

AC 1 107.53±1.2 7.1-7.3 6.3 X 106 70 0.755±0.22

AC 2 109.06±1.6 7.4-7.6 5.2 X 106 5 0.868±0.12

AC 3 102.31±1.3 7.2-7.4 5.1 X 106 57.5 0.847±23

As indicated in table 3 the pH of the formulations It revealed that all the formulation is stable under

was in the range of 7.1– 7.6 that is suitable for skin stress conditions and varying temperature

pH, indicating compatibility of the formulations conditions.

with the skin.

In vitro drug release studies: The drug permeation

6

Apparent viscosity was ranged from 5.1 -6.3 X 10 patterns of all the formulations were presented in

centipoise at 5 rpm as indicated in Table 3. Fig.2 In vitro permeation and release were found to

Aceclofenac cream is less firm than other be better for silicone base cream as compared to the

formulations and had a lower hardness work done other dermatological bases. Cumulative % drug

which indicates that Aceclofenac cream was more permeated after 8 hrs was 7.02% in case of cream

spreadable than other formulations and occlusivity (AC 1) while the cumulative amount of drug

studies shows that Aceclofenac cream has higher diffused per unit area is 402.48 µg/cm2 within the

occlusion effect as compared to other formulation same time interval as shown in Fig. 2 (a) & (b).

which indicates a film was formed on the surface of

skin on application and hence prevents the loss of Enhancement of drug diffusion and permeation of

water which gives desirable occlusive effect as drug through silicone cream base was due to

shown in Table 3. All the Aceclofenac topical silicone polymers (polydimethylsiloxanes) used in

formulation were evaluated for their stability under Aceclofenac cream. They are highly permeable to

centrifugation and thermal cycling which indicates diffusion of various actives due to low

No creaming or phase separation was observed intermolecular interactions within silicone

under centrifugation while under thermal cycling molecule 18. Log P octanol/water of Aceclofenac is

there is no change in viscosity and color was 8 which indicates that the solubility of non-ionized

observed. form of the drug in octanol is much greater than

that of the aqueous solutions.

International Journal of Pharmaceutical Sciences and Research 3405

Patil et al., IJPSR, 2014; Vol. 5(8): 3401-3408. E-ISSN: 0975-8232; P-ISSN: 2320-5148

FIG. 2: A) CUMMULATIVE AMOUNT OF DRUG RELEASE OF ALL ACECLOFENAC FORMULATIONS B)

CUMULATIVE AMOUNT OF DRUG DIFFUSED PER UNIT AREA (µG/CM 2) OF ALL ACECLOFENAC

FORMULATIONS

In the cream formulations, oil phase contains drug and low amount of drug might be in desirable form

in non-ionized form and aqueous phase contains for penetration 20.

drug in ionized form. The drug in non-ionized form

has ability to penetrate into the skin. In such The amount of in vitro permeation of drug through

situation ionized drug in aqueous phase converts to the semipermeable membrane after 8 hrs was in the

non-ionized form to maintain the equilibrium range of 0.34-7.02% for Aceclofenac formulations

between two forms of the drug and causes a (Fig. 2a). The amount of drug permeation is not

significant increase in the drug concentration and sufficient to produce systemic action but it is

the thermodynamic activity of non-ionized form of sufficient enough to produce to local effect at the

the drug 19. site of application. This inadequate permeation of

the drug through semipermeable membrane was

Hence, the great enhancement in penetration of the due to the strong affinity of hydrophobic drug to

drug into the skin was observed in case of cream the lipophilic semipermeable membrane.

which contained 45% of oil phase. Emulgel showed

higher permeation due to presence of non-ionic The in vitro diffusion and in vitro permeation data

surfactants like tween 20 and span 85. The two of all the three formulation were subjected to

possible mechanisms involved in the enhancement kinetic analysis study. The selection criteria (R2)

of drug transport by non-ionic surfactants. Initially, and the equations best describing the kinetics of in

the surfactants may penetrate into the intercellular vitro drug release and in vitro permeation are given

regions of the stratum corneum, increase the in Table 4. The release of the drug from all

fluidity of lipids and eventually solubilize and formulations was found to follow the first-order

extract the lipid components. Secondly, penetration release kinetics. Higher correlation, as indicated by

of the surfactant into the intracellular matrix R2, was observed for the Higuchi matrix release

followed by interaction with and binding to keratin kinetics in all the selected formulations, suggesting

filaments may result in a disruption within the diffusion as a probable prominent mechanism of

corneocytes. Emulgel also contains Menthol as a drug release.

penetrating agent 19.

Anti-inflammatory activity: Edema can be

Gel formulation of Aceclofenac has very low indicative of inflammation; anti-dermatological

permeability due to absence of penetration activity was evaluated against croton-oil induced

enhancers and menthol. In aqueous gel of pH 7.2 dermatitis 6 h after its topical application to the

majority of drug might be present in ionized form skin of the ear.

International Journal of Pharmaceutical Sciences and Research 3406

Patil et al., IJPSR, 2014; Vol. 5(8): 3401-3408. E-ISSN: 0975-8232; P-ISSN: 2320-5148

TABLE 4: KINETIC RELEASE STUDY OF ACECLOFENAC FORMULATIONS

Zero order First order Higuchi

Formulation

R2 k 0% h-1 R2 k 1% h-1 R2 k H% h-1

AC 1 0.972±0.21 0.541±0.12 0.971±0.23 0.002 0.8344±0.21 2.160±1.12

AC 2 0.970±0.25 0.108±0.08 0.970±0.34 0.000 0.9970±0.23 0.286±0.11

AC 3 0.925±0.26 0.032±0.02 0.926±0.23 0.000 0.9623±0.34 0.106±0.02

As shown in (fig. 3), topical application of GEL BASE (AC 3) ON CROTON OIL INDUCED EAR-

EDEMA

Aceclofenac formulation caused a significant

inhibition of croton-oil-induced edema after Stability study: Stability study of formulations

application to right ear of female Wistar rats. The as shown in Table 5 indicated that Aceclofenac

anti-inflammatory activity of Aceclofenac silicone Cream AC 1 was stable at room temperature,

cream base (AC 1) was found 64% while other 25°C±2°C/ 60 % ± 5 % RH, 30°C±2°C/ 65 % ± 5

formulations have 52% for emulgel (AC 3) and % RH and at accelerated condition of 40°C±2°C/

12% for gel (AC 2) 21. 75 % ± 5 % RH as there was no significant

difference observed in drug content, pH of the

formulations was observed after 3 months as.

Also there was no evidence of phase separation,

development of disagreeable odor, change in color

and consistency of formulation during stability

study for three months.

Table 6 and Table 7 shows that formulation of AC

2 and AC 3 of emulgel and gel gives reduction in

the drug content and pH which indicate the

FIG. 3: EFFECT OF ACECLOFENAC SILICONE formulation was not stable after 3 months stability

CREAM BASE (AC 1), ACECLOFENAC EMULSIFIED studies.

GEL BASE (AC 2) AND ACECLOFENAC CARBOPOL

TABLE 5: STABILITY STUDY OF ACECLOFENAC SILICONE CREAM BASE (AC 1)

Drug content estimation (%)

Period pH

Room temperature 25°C/ 60 % RH 30°C/ 65 % RH 40°C/ 75% RH

0 month 7.12 107.53±1.2 - - -

1 month 7.09 102.18±0.96 99.96±0.92 95.35±0.93 92.19±0.92

2 months 7.11 102.43±1.3 99.95±0.85 95.08±0.91 81.33±0.84

3 months 6.89 94.13±0.89 94.69±0.83 93.78±0.93 86.65±0.89

TABLE 6: STABILITY STUDY OF ACECLOFENAC EMULSIFIED GEL BASE (AC 2)

Drug content estimation

Period pH

Room temperature 25°C/ 60 % RH 30°C/ 65 % RH 40°C/ 75% RH

0 month 7.2 102.31±1.4 - - -

1 month 7.1 91.89±1.2 90.90±0.71 86.02±0.64 84.78±0.89

2 months 6.8 88.34±0.91 88.39±0.93 83.99±0.78 81.40±0.87

3 months 7.0 69.42±0.73 75.15±0.89 67.83±0.72 57.51±0.65

TABLE 7: STABILITY STUDY OF ACECLOFENAC CARBOPOL GEL BASE (AC 3)

Drug content estimation

Period pH

Room temperature 25°C/ 60 % RH 30°C/ 65 % RH 40°C/ 75% RH

0 month 7.4 109.06±0.95 - - -

1 month 6.9 40.10±0.58 44.62±0.65 35.00±0.42 29.69±0.45

2 months 6.2 29.08±0.54 32.46±0.34 28.56±0.47 19.67±0.65

3 months 6.1 15.09±0.31 19.45± 0.21 17.69±0.43 11.29±0.68

International Journal of Pharmaceutical Sciences and Research 3407

Patil et al., IJPSR, 2014; Vol. 5(8): 3401-3408. E-ISSN: 0975-8232; P-ISSN: 2320-5148

CONCLUSION: Topical drug delivery shows a 6. Vivek Dave, Sarvesh Paliwal: A novel approach to

formulation factor of Aceclofenac eye drops efficiency

greater potential as an effective and safe way to evaluation based on physicochemical characteristics of in

administer Aceclofenac for local anti-inflammatory vitro and in vivo permeation. Saudi Pharmaceutical

Journal.2013; 1-6

and analgesic effect. Among all the semisolid 7. Md. Sahidullah Mondal, Mohamed Irshad Pasha, Vijay

formulations, aqueous silicone cream base was Pratap, Md. Shadab Ansari: In-Vitro Release Study of

found to be the most suitable dermatological base Aceclofenac from Different Topical Vehicles. IJPI’s Journal

of Pharmaceutics and Cosmetology.2012; 2(9): 33-38

for Aceclofenac semisolid formulation with 8. Jignesh d. Modi, jayvadan k. Patel: Nano emulsion Based Gel

maximum release of the drug and anti- Formulation

1. Aceclofenac for Topical Delivery International Journal of

inflammatory activity as compared to the other Pharmacy and Pharmaceutical Science Research 2011; 1: 6-12

formulation. Stability studies showed that 9. Kamal Dua, Kavita Pabreja Malipeddi Venkata Raman:

Aceclofenac cream formulation was stable Aceclofenac topical dosage forms: In vitro and in vivo

characterization. Acta Pharm. 2010; 60: 467–478

according to ICH guidelines while the emulgel and 10. Kamble S. R. Udapurkar, P. Nakhat, P. D. Yeole, P. G.

gel formulation was not stable after three months Biyani: Development and evaluation

2. of Sorbitan Monostearate Organogels as Topical Delivery

stability study. system for Aceclofenac. Indian Journal of Pharmaceutical

education and Research 2011; 45: 65-70.

ACKNOWLEDGEMENT: The authors are 11. Lubrizol corporation Centrifuge Stability: Lubrizol test

procedure.2002; 23

thankful to Ajanta Pharmaceuticals, India, for 12. Segall, A., Sosa, M., Alami, A., Enero C., Hormaechea, F.,

providing the gift sample of Aceclofenac, Mascot Pizzorno, M. T., Bregni, C., Serrao: Stability study of lipoic

acid in the presence of vitamins A and E in o/w emulsions for

Pvt. Ltd. Mumbai for the gift sample of excipients. cosmetic application. Journal of cosmetic science.2004; 55:

The author is also thankful to UGC for providing 449–461

the research fellowship and Institute of Chemical 13. Niazi, S: Handbook of Pharmaceutical manufacturing

formulation, Semisolid Products, CRS Press LLC, United

Technology, Mumbai, India, for providing all States of America. 2004; 4:54

facilities and guidance. The author is also thankful 14. The Indian Pharmacopoeia, The Indian Pharmacopoeia

Commision Ghaziabad: 2010

to Haffkine Institute, Parel, Mumbai, for providing 3. 15. Souto E. B., Wissing, S. A., Barbosa, C. M., & Müller,

animals required for in vivo anti-inflammatory RH: Development of a controlled release formulation based

on SLN and NLC for topical clotrimazole delivery.

activity studies. International Journal of Pharmaceutics 2004; 278:71–77.

15. T. Higuchi: Mechanism of sustained action medication,

CONFLICT OF INTEREST: Author declares theoretical analysis of rate of release of solid drugs dispersed

in solid matrices, J. Pharm. Sci. 1963; 52:1145–1149.

that we do not have any conflict of interest. 16. Bairy KL, Deepa Ayyappa, Chandrashekar BR, Avinash M

Holla, Pawan kumar A.V, Purnima Sirigiri, Avin D’Souza1,

REFERENCES: Satish Kumar MC: Effect of momentasone furoate and

betamethasone valerate on skin inflammatory model in wistar

1. Y Ozsoy, S Gungor, E Cevher: Vehicle effects on in vitro rats. J Biosci Tech. 2012; 1:446- 448.

release of tiaprofenic acid from different topical formulations. 17. Andriot, M., Degroot, J. V., Meeks, R., Gerlach, E., Jungk,

IL Famrmaco 2004; 59:563–566. M., Wolf, A. T., Cray, S., Easton,T., Mountey, A., Garaud, A.

2. Nahla S. Barakat: Evaluation of Glycofurol-based gel as a L., Gubbels, F., Lecomte, J. P., Lenoble, B., Stassen, S.,

new vehicle for topical application of naproxen AAPS Stevens, C.,Thomas, X., Shearer, G : Silicones in Industrial

Pharm Sci Tech, 2010; 11(3):1138-1146 Applications. Dow corning corporation :1–106

3. SC Pefile, EW Smith, C.F. Albrecht, P.B. Kruger: Release of 18. Shokri J. Azarmi S., Fasihi Z., Nokhodchi, A : Javadzadeh

rooperol tetra- acetate from topical bases: In vitro Effects of various penetration enhancers on percutaneous

studies using silicone membrane. Int. J. Pharm.1998; absorption of piroxicam from emulgels. Research in

161:237-243 Pharmaceutical Sciences. 2012;4: 225–234

4. Sougata Janaa, Abhimunya Sahaa, Amit Kumar Nayakb, 19. Marzouk M.. Kassem, A. E. A. Samy, A. M. Amer: In-vitro

Kalyan Kumar Sena, Sanat Kumar Basua: Aceclofenac-loaded release, Thermodynamics and Pharmacodynamic Studies of

chitosan-tamarind seed polysaccharide interpenetrating Aceclofenac Transdermal Eudragit Patches. 2009; 1:16–22.

polymeric network micro particles. Colloids and Surfaces Bio 20. John I D’Souza and Harinath N More: Topical Anti-

interfaces. 2013; 105:303- 309 Inflammatory Gels of Fluocinolone Acetonide Entrapped in

5. The British pharmacopoeia: Her Majesty Stationary Office. Eudragit Based Micro sponge Delivery System, Research J.

1998: 33-34 Pharm. and Tech. 2008;4.

How to cite this article:

Patil AK, Gangurde AB and Amin PD: Comparative study of different formulations of Aceclofenac as a topical drug

delivery system and it’s in vitro and in vivo characterization. Int J Pharm Sci Res 2014; 5(8): 3401-08.doi:

10.13040/IJPSR.0975-8232.5(8).3401-08

All © 2014 are reserved by International Journal of Pharmaceutical Sciences and Research. This Journal licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 3.0 Unported License.

This article can be downloaded to ANDROID OS based mobile. Scan QR Code using Code/Bar Scanner from your mobile. (Scanners are

available on Google Playstore)

International Journal of Pharmaceutical Sciences and Research 3408

You might also like

- Manual For The Dyadic Parent-Child Interaction CodDocument244 pagesManual For The Dyadic Parent-Child Interaction CodLyz LunaNo ratings yet

- Cardiac Electrophysiology, From Cell To Bedside, 6th EditionDocument1,319 pagesCardiac Electrophysiology, From Cell To Bedside, 6th EditionGabriel CruzNo ratings yet

- Fetal Echocardiogram ProtocolDocument4 pagesFetal Echocardiogram Protocolapi-349402240No ratings yet

- Formulation, Development and Evaluation of Injectable Formulation of AspirinDocument7 pagesFormulation, Development and Evaluation of Injectable Formulation of AspirinDrugs & Therapy StudiesNo ratings yet

- European Journal of Biomedical AND Pharmaceutical SciencesDocument14 pagesEuropean Journal of Biomedical AND Pharmaceutical SciencesSACHIN BHASKAR NARKHEDENo ratings yet

- TRT Targets and Side Effect Management TablesDocument5 pagesTRT Targets and Side Effect Management TablesLucas Ely100% (1)

- DRUG STUDY OXYTOCIN, METHERGINE EtcDocument9 pagesDRUG STUDY OXYTOCIN, METHERGINE EtcPatricia Reese YutiamcoNo ratings yet

- Cushing's SyndromeDocument8 pagesCushing's SyndromeNader Smadi100% (3)

- Animal Pharm Top20 - ReportsDocument294 pagesAnimal Pharm Top20 - ReportsnghuuducNo ratings yet

- Manipura MeditationDocument3 pagesManipura Meditationprashant_dc_in100% (1)

- Formulation and Evaluation of Ocular Inserts of Acyclovir PDFDocument8 pagesFormulation and Evaluation of Ocular Inserts of Acyclovir PDFcilamananta100% (1)

- HIPAA Patient Authorization For ROI FormDocument1 pageHIPAA Patient Authorization For ROI FormDawn M. Rapoport, Rapoport Law GroupNo ratings yet

- AD-210052-01-CT - B-MDR Comparison Table STERRAD Vs VPRO Max2 - TM - 2022Document1 pageAD-210052-01-CT - B-MDR Comparison Table STERRAD Vs VPRO Max2 - TM - 2022Abdessamad ZaherNo ratings yet

- Preparation and Evaluation of Azelaic Acid TopicalDocument8 pagesPreparation and Evaluation of Azelaic Acid TopicalGourav SainNo ratings yet

- Ethosome For Enhanced Transdermal Drug Delivery of AceclofenacDocument12 pagesEthosome For Enhanced Transdermal Drug Delivery of Aceclofenacmeme itsNo ratings yet

- Formulation and Evaluation of Transdermal Patch of AceclofenacDocument11 pagesFormulation and Evaluation of Transdermal Patch of AceclofenacMuhammad ArmandsyahgzNo ratings yet

- Hz78x6 PDFDocument9 pagesHz78x6 PDFreskyNo ratings yet

- Preparation and Evaluation of Wound Healing Activity of Ursolic Acid Nanoemulgel Formulations in RatsDocument11 pagesPreparation and Evaluation of Wound Healing Activity of Ursolic Acid Nanoemulgel Formulations in RatsRAPPORTS DE PHARMACIENo ratings yet

- Comparative Pharmacokinetic Profile of Aceclofenac From Oral and Transdermal ApplicationDocument6 pagesComparative Pharmacokinetic Profile of Aceclofenac From Oral and Transdermal ApplicationSai HS BodduNo ratings yet

- Aceclofenac ArticleDocument5 pagesAceclofenac ArticleHaroon RahimNo ratings yet

- 10 1088@1757-899X@523@1@012011Document7 pages10 1088@1757-899X@523@1@012011Monyet...No ratings yet

- Formulation and Evaluation of Itraconazole Opthalmic in Situ GelsDocument8 pagesFormulation and Evaluation of Itraconazole Opthalmic in Situ GelsiajpsNo ratings yet

- 3661 PDFDocument9 pages3661 PDFMahe JabeenNo ratings yet

- Development of Curcumin Based Ophthalmic FormulationDocument9 pagesDevelopment of Curcumin Based Ophthalmic FormulationBagus Prasetya WirawanNo ratings yet

- 10.1007@s40005 020 00477 WDocument16 pages10.1007@s40005 020 00477 WVj McNo ratings yet

- 109-Article Text-182-1-10-20181220Document5 pages109-Article Text-182-1-10-20181220SadishkumarNo ratings yet

- Available Online Through: ISSN: 0975-766XDocument20 pagesAvailable Online Through: ISSN: 0975-766XnurulNo ratings yet

- Nanoemulsi PDFDocument7 pagesNanoemulsi PDFAkhmad NgafifNo ratings yet

- 25 Iajps25102017 PDFDocument7 pages25 Iajps25102017 PDFBaru Chandrasekhar RaoNo ratings yet

- Kelompok 1 Nanogel (Jurnal)Document12 pagesKelompok 1 Nanogel (Jurnal)apoteker inkesdelihusadaNo ratings yet

- Original Article Bioadhesive and Mechanical Properties of Triamcinolone Acetonide Buccal GelsDocument11 pagesOriginal Article Bioadhesive and Mechanical Properties of Triamcinolone Acetonide Buccal GelsJulia BottiniNo ratings yet

- Sajp2 (4) 315 318Document4 pagesSajp2 (4) 315 318Habibur RahmanNo ratings yet

- Pharmaceutics 10 00227Document16 pagesPharmaceutics 10 00227Raul NicoaraNo ratings yet

- 7.formulation and Evaluation of Lycopene EmulgelDocument4 pages7.formulation and Evaluation of Lycopene EmulgelYuppie RajNo ratings yet

- Dissolution Rate Enhancement of Aceclofenac by Solid Dispersion TechniqueDocument5 pagesDissolution Rate Enhancement of Aceclofenac by Solid Dispersion TechniqueMuthia ZhafiRaNo ratings yet

- Research Paper WJPPS - 1Document10 pagesResearch Paper WJPPS - 1Farahat AliNo ratings yet

- Gel FormulationDocument11 pagesGel FormulationKhuncoro AdiNo ratings yet

- European Journal of Pharmaceutical Sciences: Development of Shellac-Coated Sustained Release Pellet FormulationsDocument6 pagesEuropean Journal of Pharmaceutical Sciences: Development of Shellac-Coated Sustained Release Pellet FormulationsThuy Khanh LeNo ratings yet

- Aprepitant Chinese Disso ArticleDocument12 pagesAprepitant Chinese Disso ArticleSpectre SpectreNo ratings yet

- Oamjms 10a 585Document5 pagesOamjms 10a 585krystelmae009No ratings yet

- Hz78x6 PDFDocument9 pagesHz78x6 PDFAhmed ZakariaNo ratings yet

- 67939-Article Text-140062-1-10-20110714 PDFDocument8 pages67939-Article Text-140062-1-10-20110714 PDFNourhan AbdalkaderNo ratings yet

- Alhamdany, A. T.10 (6), 119. Doi10.22159ijap.2018v10i6.28687Document9 pagesAlhamdany, A. T.10 (6), 119. Doi10.22159ijap.2018v10i6.28687Maria CamiloNo ratings yet

- Vol 2 - Cont. J. Pharm SciDocument48 pagesVol 2 - Cont. J. Pharm Sciwilolud9822No ratings yet

- 1 s2.0 S0378517307005960 Main PDFDocument9 pages1 s2.0 S0378517307005960 Main PDFPrasun PatraNo ratings yet

- Formulation and Evaluation of Topical Dosage Form Containing Microspheres For Model Anti Inflammatory DrugDocument15 pagesFormulation and Evaluation of Topical Dosage Form Containing Microspheres For Model Anti Inflammatory DrugCandriya LaelNo ratings yet

- Influence of Excipients On The Structural and Mechanical Properties of Semisolid Dosage FormsDocument4 pagesInfluence of Excipients On The Structural and Mechanical Properties of Semisolid Dosage FormsyaimeNo ratings yet

- Insitu: Formulation and Evaluation of Ocular Hydrogels of AcyclovirDocument9 pagesInsitu: Formulation and Evaluation of Ocular Hydrogels of Acyclovirazita nezamiNo ratings yet

- Vi SibelDocument8 pagesVi SibelMaulidia RizqianaNo ratings yet

- Arelocoline PatchesDocument7 pagesArelocoline PatchesIrene CayaNo ratings yet

- Abdellatif2019 Article HydrogelContainingPEG-CoatedFlDocument11 pagesAbdellatif2019 Article HydrogelContainingPEG-CoatedFlWassini BensNo ratings yet

- 10textural and Sensory M. MartinovicDocument12 pages10textural and Sensory M. MartinovicbabithyNo ratings yet

- A Validated Stability Indicating Method For The Estimation of Diclofenac Acid in Bulk and Dosage Forms Using Lc-PdaDocument14 pagesA Validated Stability Indicating Method For The Estimation of Diclofenac Acid in Bulk and Dosage Forms Using Lc-PdaSaravanan RamNo ratings yet

- Formulation and Evaluation of New Long Acting Metoprolol Tartrate Ophthalmic GelsDocument9 pagesFormulation and Evaluation of New Long Acting Metoprolol Tartrate Ophthalmic GelsmelyNo ratings yet

- Jurnal KLP 11Document11 pagesJurnal KLP 11Niluh Komang Tri AndyaniNo ratings yet

- Formulation and Evaluation of Microemulsion Based Gel of KetoconazoleDocument19 pagesFormulation and Evaluation of Microemulsion Based Gel of KetoconazoleAndre HopfnerNo ratings yet

- Nanoemulsion For Improved Permeability of Centella Asiatica Extract: Formulation, Ex-Vivo and In-Vivo EvaluationDocument8 pagesNanoemulsion For Improved Permeability of Centella Asiatica Extract: Formulation, Ex-Vivo and In-Vivo EvaluationhabibieNo ratings yet

- Treatment of Superfacial Mycoses Research-Ebercanozole /ebernetDocument10 pagesTreatment of Superfacial Mycoses Research-Ebercanozole /ebernetHajrah MirandaNo ratings yet

- Development and In-Vitro Evaluation of Catechin Loaded Ethosomal Gel For Topical DeliveryDocument6 pagesDevelopment and In-Vitro Evaluation of Catechin Loaded Ethosomal Gel For Topical DeliveryRAPPORTS DE PHARMACIENo ratings yet

- Design and Evaluation of Spherical Agglomerated Crystals Loaded Fast Disolving Tablets For Enhancing The Solubilityof Mefenamic AcidDocument7 pagesDesign and Evaluation of Spherical Agglomerated Crystals Loaded Fast Disolving Tablets For Enhancing The Solubilityof Mefenamic AcidBaru Chandrasekhar RaoNo ratings yet

- Combination of HPMC and Peg 400 As A Taste Masking Agent of Film-CoatedDocument5 pagesCombination of HPMC and Peg 400 As A Taste Masking Agent of Film-CoatedAdi permadiNo ratings yet

- Analytical Method Validation On Simultaneous EstimDocument8 pagesAnalytical Method Validation On Simultaneous EstimОксанаNo ratings yet

- Formulation and Characterization of Drug in Adhesive Transdermal Patches - Kunal N Patel, DKKDocument4 pagesFormulation and Characterization of Drug in Adhesive Transdermal Patches - Kunal N Patel, DKKAdityaWijayaNo ratings yet

- Jurnal Transdermal PatchDocument4 pagesJurnal Transdermal PatchTazkiyatul Asma'iNo ratings yet

- 16363797731583832601formulation and Evaluation of Ophthalmic Antibacterial Gels and Comparison of Different Polymers Using Factorial DesignDocument7 pages16363797731583832601formulation and Evaluation of Ophthalmic Antibacterial Gels and Comparison of Different Polymers Using Factorial Designazita nezamiNo ratings yet

- J Ultsonch 2017 09 042Document38 pagesJ Ultsonch 2017 09 042lmNo ratings yet

- Journal PDFDocument5 pagesJournal PDFNura AnisariNo ratings yet

- Jojoba 1Document10 pagesJojoba 1Nadia Namira Devita SinagaNo ratings yet

- Oral Formulation Roadmap from Early Drug Discovery to DevelopmentFrom EverandOral Formulation Roadmap from Early Drug Discovery to DevelopmentElizabeth KwongNo ratings yet

- Carpal Tunnel Syndrome Power Point PresentationDocument6 pagesCarpal Tunnel Syndrome Power Point Presentationapi-237061134No ratings yet

- BMJ 334 7593 CR 00579Document10 pagesBMJ 334 7593 CR 00579RonaMaulidiaBakhitaNo ratings yet

- Sicknessandfitnesscertificates PDFDocument6 pagesSicknessandfitnesscertificates PDFniraj_sdNo ratings yet

- Nejmoa2215145 ProtocolDocument151 pagesNejmoa2215145 ProtocolGonçalo TorrinhaNo ratings yet

- 8 CPSDocument2 pages8 CPSpharmacist2000No ratings yet

- STFR Control Set.12178206001.V6.EnDocument2 pagesSTFR Control Set.12178206001.V6.EnARIF AHAMMED PNo ratings yet

- PMR Poster TBI Takotsubo AAP 2010 PosterDocument1 pagePMR Poster TBI Takotsubo AAP 2010 PosterjuanvelasquezNo ratings yet

- AnalysisDocument20 pagesAnalysisajaysomNo ratings yet

- Easypep-A New Simplified and Optimized Workflow For Ms Sample PreparationDocument1 pageEasypep-A New Simplified and Optimized Workflow For Ms Sample PreparationkarthikNo ratings yet

- Logical Fallacies EssayDocument3 pagesLogical Fallacies Essayfz75nk7v100% (2)

- Autopsy: Bocoboc, Castillo, Miguel, Nalupta, RoldanDocument28 pagesAutopsy: Bocoboc, Castillo, Miguel, Nalupta, RoldanAya CstlNo ratings yet

- Emergency ProtocolsDocument5 pagesEmergency Protocolsapi-360747004No ratings yet

- Wellness CenterDocument6 pagesWellness CenterMuntasir SizanNo ratings yet

- Unit 6 Biomedical Waste ManagementDocument14 pagesUnit 6 Biomedical Waste ManagementjyothiNo ratings yet

- Cholesterol Tri FoldDocument2 pagesCholesterol Tri FoldJake PetrykowskiNo ratings yet

- The Development of Polycarbophil As A Bioadhesive MaterialDocument10 pagesThe Development of Polycarbophil As A Bioadhesive MaterialCesar Rodolfo Angulo DelgadoNo ratings yet

- Sifaat Al Huroof Lesson 1 (4th Dec)Document24 pagesSifaat Al Huroof Lesson 1 (4th Dec)ShahnazNo ratings yet

- NCP Risk For InfectionDocument6 pagesNCP Risk For InfectionCazze SunioNo ratings yet

- Kothala HimbutuDocument2 pagesKothala HimbutuHashan ErandaNo ratings yet

- OtDocument10 pagesOtsantosh_usa_indNo ratings yet