Professional Documents

Culture Documents

SA-765/SA-765M SA-350/SA-350M: Melting Process Melting Process

Uploaded by

Hobinca MarianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SA-765/SA-765M SA-350/SA-350M: Melting Process Melting Process

Uploaded by

Hobinca MarianCopyright:

Available Formats

SA-765/SA-765M SA-350/SA-350M

This specification covers heat-treated carbon steel This specification covers several grades of carbon

and alloy steel forgings with mandatory toughness and low-alloy steel forged or ring-rolled flanges,

requirements. Forgings are intended for pressure forged fittings and valves intended primarily for

vessels, feedwater heaters, and similar uses, such as low-temperature service and requiring notch

tube sheets, covers, channel barrels, integral forged toughness testing

channels, rings, nozzles, flanges, and similar parts.

Melting Process – Cross Referred in SA -788- Melting Process -- The steel shall be produced

The steel shall be produced by any of the following by any of the following primary processes: open-

primary processes: electric-furnace, basic oxygen, hearth, basic oxygen, electric-furnace, or vacuum-

vacuum induction (VIM), or open-hearth. The induction melting (VIM). The primary melting may

primary melting may incorporate separate incorporate separate degassing or refining, and may

degassing or refining and may be followed be followed by secondary melting using electroslag

by secondary melting, using electro slag remelting remelting (ESR), or vacuum-arc remelting (VAR).

(ESR) or vacuum arc remelting (VAR).

Heat treatment:- shall consist of normalizing and Heat treatment:- shall consist of normalizing and

tempering, double normalizing and tempering, or tempering, double normalizing and tempering, or

quenching and tempering at the manufacturer’s quenching and tempering at the manufacturer’s

option. option.

Grain Size Grain Size:- Fine grain size.

The forgings, subsequent to the final heat

treatment, shall have prior austenitic grain size of 5

or finer.

CHEMICAL REQUIREMENTS

CHEMICAL REQUIREMENTS

Carbon, max-- 0.30

Carbon, max--0.30 Manganese- 0.60–1.35

Manganese- 0.60 to 1.35 Nickel- 0.40 max

Nickel-- 0.50 max Chromium- 0.30 max

Vanadium, max-0.05 Molybdenum- 0.12 max

Aluminum, max-0.05 Copper- 0.40 max

Chromium, max- 0.40 Columbium -0.02 max

Molybdenum, max-0.10 Vanadium- 0.08 max

Copper, max- 0.35

Tensile strength, ksi [MPa]-- 70 to 95 [485 to 655] Tensile strength, ksi [MPa]-- 70 to 95 [485 to 655]

Yield strength,min, ksi[MPa]- 37.5 [260] Yield strength,min, ksi[MPa]- 37.5 [260]

Elongation in 2 in. [50 mm],min, %- 22 Elongation in 2 in. [50 mm],min, %- 22

CHARPY V-NOTCH IMPACT CHARPY V-NOTCH ENERGY

REQUIREMENTS REQUIREMENTS:-

Minimum average value of set, of three Minimum Impact Energy Required for

specimens, ft-lbf (J)-- 15 [20] Average of Each Set of Three Specimens,

Test temperature of, °F [°C]- −50 [−46] ft-lbf [J]

LF2, Class 1-- 15 [20]

Mandatory conformance to the values Test temperature of, °F [°C]- −50 [−46]

listed is a matter of agreement between the

purchaser and the manufacturer. The

energy values above are shown for

information as to guarantees that are

generally available.

SUMMARY:-

SA-350 LF2 has a long and successful history in both the petrochemical and power industries in

similar thickness and thicker tube sheet applications.

SA-765 is more recent , specifically developed for forgings.

Some comparisons of both specs, probably would tell that both the specs are equally matching.

But since SA-765 is specially designed for heavy forgings probably clients/users would prefer to

stick to this specification.

You might also like

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

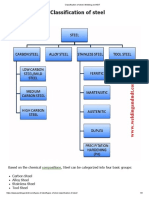

- Classification of Steel - Welding and NDTDocument3 pagesClassification of Steel - Welding and NDTAshif Iqubal100% (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Bomba de EspumaDocument16 pagesBomba de EspumaArmandoAndreNo ratings yet

- ASTM Piping CodesDocument6 pagesASTM Piping CodesMohd ZaieriNo ratings yet

- Gold AlloysDocument15 pagesGold AlloysJennifer Dotado MaderazoNo ratings yet

- ASTM A335 Pipe Specification1 PDFDocument8 pagesASTM A335 Pipe Specification1 PDFRoberto EliasNo ratings yet

- ASTER Processing For Mineral ExplorationDocument8 pagesASTER Processing For Mineral ExplorationwerewaroNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Alloy 310 Spec Sheet: Multi-Purpose Austenitic Heat Resistant Stainless SteelDocument2 pagesAlloy 310 Spec Sheet: Multi-Purpose Austenitic Heat Resistant Stainless SteelManoj PaneriNo ratings yet

- Aluminium AlloyDocument14 pagesAluminium AlloyPenka VasilevaNo ratings yet

- Heat Treatment Processes for Different MaterialsDocument31 pagesHeat Treatment Processes for Different MaterialsvinayakNo ratings yet

- Piping FabricationDocument36 pagesPiping FabricationMouchartStéphanieNo ratings yet

- Specification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Document2 pagesSpecification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Felipe A. Gutiérrez M.No ratings yet

- Concrete Masonry Solid Units 140mmDocument40 pagesConcrete Masonry Solid Units 140mmwearplayNo ratings yet

- Non-Ferrous Alloys: Dr. Indika de Silva Senior Lecturer Dept. of Materials Science & Engineering University of MoratuwaDocument68 pagesNon-Ferrous Alloys: Dr. Indika de Silva Senior Lecturer Dept. of Materials Science & Engineering University of MoratuwaChandima K Priyamal100% (1)

- Science 8 Quarter 3 Module 7Document20 pagesScience 8 Quarter 3 Module 7marlonjabadanNo ratings yet

- Userguide For SSDocument26 pagesUserguide For SSehsan4uNo ratings yet

- Sa765 - VS-350LF2Document2 pagesSa765 - VS-350LF2rtrajan_mech5408No ratings yet

- ASTM A335 Pipe Specification1Document8 pagesASTM A335 Pipe Specification1Rupam BaruahNo ratings yet

- WB5525E MMA Welding Electrode Spec SheetDocument1 pageWB5525E MMA Welding Electrode Spec SheetcwiksjNo ratings yet

- M.tech FinalDocument43 pagesM.tech FinalRaghav AcharyaNo ratings yet

- Nitronic 50 SheetDocument3 pagesNitronic 50 SheetSam PeñaNo ratings yet

- Aletas de Aluminio-United Aluminum Technical ManualDocument19 pagesAletas de Aluminio-United Aluminum Technical ManualDaniel Herrera100% (1)

- Invar 36Document3 pagesInvar 36TrentStewartLaCourNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- EN19 Alloy Steel Properties GuideDocument5 pagesEN19 Alloy Steel Properties GuideNaiduNo ratings yet

- Nichrome Alloys For HeatingDocument10 pagesNichrome Alloys For HeatingRajaram GanesanNo ratings yet

- WB35S welding electrodeDocument1 pageWB35S welding electrodelathasri78No ratings yet

- Abrasion Steel Plate PropertiesDocument4 pagesAbrasion Steel Plate PropertiesPond KampeeraNo ratings yet

- EN24 and EN24T SteelDocument3 pagesEN24 and EN24T Steelpatrik710No ratings yet

- CR Mo Temper EmbrittlementDocument26 pagesCR Mo Temper EmbrittlementAsad Bin Ala QatariNo ratings yet

- LM25 Aluminium Casting Alloy (Al Ð Si7Mg) : Chemical CompositionDocument3 pagesLM25 Aluminium Casting Alloy (Al Ð Si7Mg) : Chemical Compositionsankar4582No ratings yet

- A 808 - A 808M - 00 Qtgwoc9boda4ts1sruqDocument3 pagesA 808 - A 808M - 00 Qtgwoc9boda4ts1sruqdelta lab sangliNo ratings yet

- Tooling Materials&Heat TreatmentDocument13 pagesTooling Materials&Heat TreatmentVinod MadireddyNo ratings yet

- A234WPB Material InformationDocument1 pageA234WPB Material InformationM Kumar KumarNo ratings yet

- A234WPB Material InformationDocument1 pageA234WPB Material InformationM Kumar KumarNo ratings yet

- A234WPB Material Information PDFDocument1 pageA234WPB Material Information PDFAllwynNo ratings yet

- Steel UserguideDocument50 pagesSteel UserguideBhanu Pratap ChoudhuryNo ratings yet

- E8018-B6 Data SheetDocument2 pagesE8018-B6 Data SheetMurad AlmoudiNo ratings yet

- Material SpecificationDocument50 pagesMaterial SpecificationSangyt Karna0% (2)

- Gresham Boiler Manufacturing CompanyDocument5 pagesGresham Boiler Manufacturing CompanymuddassirNo ratings yet

- Alloy 625 Spec Sheet PDFDocument3 pagesAlloy 625 Spec Sheet PDFRaghNo ratings yet

- Welding Techniques and Guidelines for Power Sector ComponentsDocument50 pagesWelding Techniques and Guidelines for Power Sector ComponentsaadmaadmNo ratings yet

- Fundamentals of Fabrication WeldingDocument22 pagesFundamentals of Fabrication WeldingKevinNo ratings yet

- CPM Magnacut - Technical Data: Your in Specialty MetalsDocument2 pagesCPM Magnacut - Technical Data: Your in Specialty MetalscpNo ratings yet

- Technical Datasheet: High Purity Solder AlloyDocument6 pagesTechnical Datasheet: High Purity Solder Alloyاوس محمد رؤوف لؤيNo ratings yet

- Plate Asme Sa516 Grade 70Document10 pagesPlate Asme Sa516 Grade 70Deaz AmbrsNo ratings yet

- Alloy904L SpecSheet PDFDocument2 pagesAlloy904L SpecSheet PDFPieter BrodeouxNo ratings yet

- Amardeep Steel - Corten Steel Products Corten Steel Tube IntroductionDocument3 pagesAmardeep Steel - Corten Steel Products Corten Steel Tube IntroductionAmardeep Steel SalesNo ratings yet

- All-position stainless steel electrode for difficult weldsDocument1 pageAll-position stainless steel electrode for difficult weldscwiksjNo ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- En 10132-A-C75s - Astm A 684 Grade 1074 - 1075Document1 pageEn 10132-A-C75s - Astm A 684 Grade 1074 - 1075Emmanuel Jiménez EcheverríaNo ratings yet

- Astm A560Document5 pagesAstm A560MAX ALBERTO JUAREZ AVALOSNo ratings yet

- Hollow Bar Ovako 280Document3 pagesHollow Bar Ovako 280fernandojNo ratings yet

- Chemical Composition of Studs and BoltsDocument1 pageChemical Composition of Studs and BoltsRajuNo ratings yet

- P355NL1 structural steel for pressure vesselsDocument2 pagesP355NL1 structural steel for pressure vesselsbramantiya100% (1)

- Master Alloys - HPNbMasteralloysDocument8 pagesMaster Alloys - HPNbMasteralloysdei_sandeep7994No ratings yet

- P91 MaterialDocument15 pagesP91 MaterialelrajilNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- TOR Refractory For LD Converter, Ladle, Stirrer and Metal Runner Rev1Document3 pagesTOR Refractory For LD Converter, Ladle, Stirrer and Metal Runner Rev1Aqilah MazayaNo ratings yet

- WB4303EDocument1 pageWB4303EcwiksjNo ratings yet

- Ni base flux cored wireDocument1 pageNi base flux cored wireBBalopesabbNo ratings yet

- Kalinga Nagar - Part3Document10 pagesKalinga Nagar - Part3cet.ranchi7024No ratings yet

- Characteristics of High-Sulfidation Epithermal Deposits, and Their Relation To Magmatic FluidDocument36 pagesCharacteristics of High-Sulfidation Epithermal Deposits, and Their Relation To Magmatic FluidTzontonelNo ratings yet

- November 2021 (v2) QP - Paper 4 CAIE Chemistry IGCSEDocument16 pagesNovember 2021 (v2) QP - Paper 4 CAIE Chemistry IGCSENam KhanhNo ratings yet

- Water Solubility ChartDocument3 pagesWater Solubility ChartLuzarro BNo ratings yet

- RP - 60.11 Crating, Shipping, and Handling For Control CentersDocument40 pagesRP - 60.11 Crating, Shipping, and Handling For Control CentersmilecsaNo ratings yet

- Edu 2140 Google Earth Utah Mineral Hunt and Answer KeyDocument4 pagesEdu 2140 Google Earth Utah Mineral Hunt and Answer Keyapi-253449144No ratings yet

- 22 Petrucci10e CSMDocument41 pages22 Petrucci10e CSMAlexNo ratings yet

- Full Download Solutions Manual To Accompany Fundamentals of Statistics 3rd Edition 0321641876 PDF Full ChapterDocument36 pagesFull Download Solutions Manual To Accompany Fundamentals of Statistics 3rd Edition 0321641876 PDF Full Chapterfound.raven.og16yi100% (19)

- SuppEx Solution 2B EDocument133 pagesSuppEx Solution 2B EElva liNo ratings yet

- Metal Solid Nickel PDFDocument18 pagesMetal Solid Nickel PDFNur Indah KartikasariNo ratings yet

- DeepCryogenicTreatment LibreDocument11 pagesDeepCryogenicTreatment LibreFernando Carvalho100% (1)

- Ashcroft OH1 Pressure GaugesDocument108 pagesAshcroft OH1 Pressure GaugesAdolfo Esteban Borromé CabelloNo ratings yet

- Vetas Tech ReportDocument135 pagesVetas Tech ReportDiego URibeNo ratings yet

- Phase-1 Chemistry Day-1 In-Class AssignmentDocument3 pagesPhase-1 Chemistry Day-1 In-Class AssignmentArnab DasNo ratings yet

- Elements (Perodic Table)Document7 pagesElements (Perodic Table)Ritobrata NathNo ratings yet

- Deformation and Textures Grain SizeDocument64 pagesDeformation and Textures Grain Sizefalso bosNo ratings yet

- Cutting of Soft Gummy MetalsDocument26 pagesCutting of Soft Gummy MetalsManoj Dhage100% (1)

- Jorc 2004Document21 pagesJorc 2004M Nur WahidanNo ratings yet

- 5070 s05 QP 1Document20 pages5070 s05 QP 1Faraz AlamNo ratings yet

- Chapter 17 - CorrosionDocument11 pagesChapter 17 - CorrosionmuthuhcuNo ratings yet

- Weldbrite MSDSDocument3 pagesWeldbrite MSDSTan Chee Ming50% (2)

- Apendice EntalpiaDocument6 pagesApendice EntalpiaCamila Garcia CruzNo ratings yet

- 085200fl PellaDocument21 pages085200fl PellaabobeedoNo ratings yet

- Various Welding ProcessesDocument24 pagesVarious Welding ProcessesLalit YadavNo ratings yet