Professional Documents

Culture Documents

Fluidized Bed

Uploaded by

Noreen Guiyab TannaganCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fluidized Bed

Uploaded by

Noreen Guiyab TannaganCopyright:

Available Formats

Differentiate fluidized bed from fixed bed.

Ø

A fluidized bed is widely used in many modern technologies for efficient

implementation of various physical and chemical processes. It is a physical

phenomenon occurring when a quantity of a solid particulate substance is placed

under appropriate conditions to cause a solid/fluid mixture to behave as a fluid.

Fluidized bed reactors are heterogeneous catalytic reactors in which the mass of catalyst is fluidized.

This allows for extensive mixing in all directions. A result of the mixing is excellent temperature stability

and increased mass-transfer and reaction rates. Furthermore, fluidized bed reactors are capable of

handling large amounts of feed and catalyst.

It is also used as a technical process which has the ability to

promote high levels of contact between gases and solids.

Fixed bed reactors are often used for catalytic processes and are the simplest type

pf reactor to design, and consist of solid catalyst particles being loaded

and packed into the bed. Fixed bed reactors consist of a cylindrical shell with

convex heads. Most are vertical, and allow reactants to flow by gravity. Inside the

reactor is an immobilized, or fixed, bed of catalyst. The basic operation of a packed

bed reactor are as follows; The reactants enter the reactor on the top, then flow

through. Upon entering the reactor, the reactants flow through the packed bed of

catalyst. By contacting with the catalyst pellets, the reactants react to form

products, which then exit the reactor on the bottom.

Ø

2. Discuss the pros and cons of fluidized bed and fixed bed.

Pros of Fluidized Bed

Ø Excellent bed-to-surface heat transfer coefficients (typically 1 order of magnitude better than in fixed

beds and 2 orders of magnitude better than in empty columns.)

Ø Offer a much higher efficiency in heat exchange

Ø Ability to add and remove particles continuously, facilitating catalyst regeneration

and continuous operation.

Ø Good turndown capability: The gas flow rate can be varied over a wide range, typically by at least a

factor of 2–3

Ø The rapid mixing of solids leads to nearly isothermal conditions throughout the reactor, hence the

operation can be controlled simply and reliably.

Ø It is suited to large-scale operations.

Ø The circulation of solids between two fluidized beds makes it possible to transport

the vast quantities of heat produced or needed in large reactors.

Ø Wide particle size distributions

Ø Heat and mass transfer rates between gas and particles are high when compared with other modes of

contacting.

Ø Relatively low pressure drops (essentially only enough to support the bed weight per unit cross-

sectional area.)

Ø The rate of heat transfer between a fluidized bed and an immersed object is high, hence heat

exchangers within fluidized beds require relatively small surface areas.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Milk and Rennin PracDocument7 pagesMilk and Rennin PracTherese Nguyen50% (2)

- Iron Removal From Industrial Waters by Water HyaciDocument7 pagesIron Removal From Industrial Waters by Water HyaciNoreen Guiyab TannaganNo ratings yet

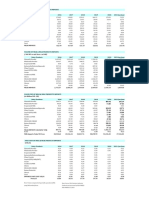

- Using TMS Method/factor Gathered and Processed by NDA-PMSED NDA-PMSD9/17/2021 Basic Source: Phil. Statistics AuthorityDocument1 pageUsing TMS Method/factor Gathered and Processed by NDA-PMSED NDA-PMSD9/17/2021 Basic Source: Phil. Statistics AuthorityNoreen Guiyab TannaganNo ratings yet

- Molar Mass From Boiling Point Elevation or Freezing Point DepressionDocument1 pageMolar Mass From Boiling Point Elevation or Freezing Point DepressionNoreen Guiyab TannaganNo ratings yet

- in Liquid Form, Including Condensed Form Net KG 720 SingaporeDocument29 pagesin Liquid Form, Including Condensed Form Net KG 720 SingaporeNoreen Guiyab TannaganNo ratings yet

- Value and Volume of Philippine Imports: January To December 2010Document36 pagesValue and Volume of Philippine Imports: January To December 2010Noreen Guiyab TannaganNo ratings yet

- Aqueous Solution On Nitric Acid Modified Activated Carbon Prepared From Water Hyacinth. ABCDocument14 pagesAqueous Solution On Nitric Acid Modified Activated Carbon Prepared From Water Hyacinth. ABCNoreen Guiyab TannaganNo ratings yet

- Slader: Advanced Engineering Mathematics, 7th EditionDocument1 pageSlader: Advanced Engineering Mathematics, 7th EditionNoreen Guiyab TannaganNo ratings yet

- Description of Populations of ParticlesDocument1 pageDescription of Populations of ParticlesNoreen Guiyab TannaganNo ratings yet

- Engineering Economy Simple InterestDocument1 pageEngineering Economy Simple InterestNoreen Guiyab TannaganNo ratings yet

- Laboratory 12.1 Determine The Effect of Temperature On Reaction Rate Make DIY Projects and Ideas For MakersDocument1 pageLaboratory 12.1 Determine The Effect of Temperature On Reaction Rate Make DIY Projects and Ideas For MakersNoreen Guiyab TannaganNo ratings yet

- Describing The Population by A Single NumberDocument1 pageDescribing The Population by A Single NumberNoreen Guiyab TannaganNo ratings yet

- Setting Goals For Success 1111Document47 pagesSetting Goals For Success 1111Noreen Guiyab TannaganNo ratings yet

- Steel Production: PicklingDocument2 pagesSteel Production: PicklingNoreen Guiyab TannaganNo ratings yet

- Adya Filtration SysDocument3 pagesAdya Filtration SyscolostgrpNo ratings yet

- 0610 s14 Ms 32 PDFDocument8 pages0610 s14 Ms 32 PDFCorinSaputraNo ratings yet

- Apa Structurata PDFDocument101 pagesApa Structurata PDFromeocostiNo ratings yet

- AHU Instalation Manual YorkDocument36 pagesAHU Instalation Manual YorkBangto Yibsip50% (2)

- Answers To End-Of-Chapter Questions: Chapter 11 Petrochemicals and PolymersDocument2 pagesAnswers To End-Of-Chapter Questions: Chapter 11 Petrochemicals and PolymersMP3 MusicNo ratings yet

- PS5000 1Document2 pagesPS5000 1swarupkumarnayakNo ratings yet

- Synthesis of Methylamine - OrgSynDocument5 pagesSynthesis of Methylamine - OrgSynzodd01No ratings yet

- Injection Blow Moulded Products Book PDFDocument13 pagesInjection Blow Moulded Products Book PDFShafeeq AhmedNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocument9 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingMuhammad UsmanNo ratings yet

- EmulsionsDocument17 pagesEmulsionsthereseNo ratings yet

- Determination and Correlation of Heat Transfer Coefficients in A Falling Film EvaporatorDocument7 pagesDetermination and Correlation of Heat Transfer Coefficients in A Falling Film EvaporatorSeyit AvcuNo ratings yet

- Density Meter For The DMA 4200 M Petroleum IndustryDocument8 pagesDensity Meter For The DMA 4200 M Petroleum IndustrymodsimcaNo ratings yet

- F 2129 - 04 - RjixmjkDocument8 pagesF 2129 - 04 - RjixmjkPrakash MakadiaNo ratings yet

- Products - Shree Surya CoatingsDocument4 pagesProducts - Shree Surya CoatingsRahul JadhavNo ratings yet

- Somethinc-Jakartaxbeauty2023 (Booth XL) (21.12)Document16 pagesSomethinc-Jakartaxbeauty2023 (Booth XL) (21.12)ARIF WIDIANTORO 211212138No ratings yet

- Normosol-M and Dextrose DescriptionDocument1 pageNormosol-M and Dextrose Descriptioned120888No ratings yet

- Quality Assurance OF Pharmaceutical Herbal PreparationsDocument20 pagesQuality Assurance OF Pharmaceutical Herbal PreparationsHazrati UmmiNo ratings yet

- Aits 1819 Jeea FT Xi Paper 2 SolDocument11 pagesAits 1819 Jeea FT Xi Paper 2 SolPollardNo ratings yet

- Preferred Features Advanced Technology Proven Design: Bulletin 4000Document12 pagesPreferred Features Advanced Technology Proven Design: Bulletin 4000saulomonNo ratings yet

- Concept Paper: Vulcanizing ShopDocument4 pagesConcept Paper: Vulcanizing ShopMaria Jean Niña PiroteNo ratings yet

- Crop Prod'n 2 Midterm and Final ExamDocument3 pagesCrop Prod'n 2 Midterm and Final ExamAlleija 09No ratings yet

- Price List Kitoderm 19 Juli 2016Document4 pagesPrice List Kitoderm 19 Juli 2016RSIA RESTU BUNDANo ratings yet

- Self Etching Adhesive On Intact Enamel: Devarasa GM, Subba Reddy VV, Chaitra NLDocument6 pagesSelf Etching Adhesive On Intact Enamel: Devarasa GM, Subba Reddy VV, Chaitra NLNiNis Khoirun NisaNo ratings yet

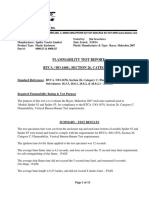

- Spider 3 - 4 - 5 - DO-160 Sec 26Document13 pagesSpider 3 - 4 - 5 - DO-160 Sec 26Jacob MillerNo ratings yet

- Nasa - Workmanship Standard For Surface Mount Technology - Nasa Technical Standard - Nasa-Std-8739.2 - ManualDocument84 pagesNasa - Workmanship Standard For Surface Mount Technology - Nasa Technical Standard - Nasa-Std-8739.2 - Manualhbpr9999100% (1)

- Chemical Engineering For Non-Chemical Engineers - Vol. 02 - DHARMSINH DESAI UNIVERSITYDocument150 pagesChemical Engineering For Non-Chemical Engineers - Vol. 02 - DHARMSINH DESAI UNIVERSITYGustavo Gonzalez ServaNo ratings yet

- DOWSIL™ 982-H Curing Agent Black SDSDocument21 pagesDOWSIL™ 982-H Curing Agent Black SDSAquatic studentNo ratings yet

- A Review On Anthraquinones Isolated From Cassia Species and Their ApplicationsDocument29 pagesA Review On Anthraquinones Isolated From Cassia Species and Their ApplicationsAnne Calyx100% (1)

- Corrugated Single Wall PCPP BrochureDocument1 pageCorrugated Single Wall PCPP BrochurebcsmurthyNo ratings yet