Professional Documents

Culture Documents

Egbert CPUC DR4 - Attachment3 - MotorGrader Specs

Egbert CPUC DR4 - Attachment3 - MotorGrader Specs

Uploaded by

agusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Egbert CPUC DR4 - Attachment3 - MotorGrader Specs

Egbert CPUC DR4 - Attachment3 - MotorGrader Specs

Uploaded by

agusCopyright:

Available Formats

24

Motor Grader

The Cat ® 24 Motor Grader continues the Caterpillar tradition of being the industry leader in enabling you to build and maintain your

haul roads to maximize your mine-site productivity and lower your owning and operating costs. The 24 motor grader is designed

to help you get more work done in less time while keeping you safe and comfortable.

Serviceability Safety

The improved power train rebuild life, new modular design Fifteen tie-off points located around engine enclosure and cab

and new machine protection features can save you up to provide secure tie off hooks protecting you and your technicians

2,400 servicing hours over the life of the machine.* when performing service operations.

Cat C27 ACERT™ engine, 533 mm (21 in) transmission and Optional Working at Heights package adds an extra layer of

lower power train provide 33 percent additional machine life safety by providing handrails and hand holds to improve access

before needing to be rebuilt.** and safety.

New, innovative main component modular design means they The 24 is a Fire Suppression-Ready machine which means you

can be removed and installed quicker and easier. Transmission can easily install a fire suppression system to further protect

and cooling package can be removed up to 70 percent faster your investment.

than the 24M.

Standard rearview camera provides better visibility from the

Fluid Service Center provides single location at ground level cab to behind the machine while optional front-facing cameras

for access to engine, transmission, hydraulic oil and coolant. provide enhanced forward and side visibility.

This feature, along with clustered filters and extended service

Standard seat belt indicator provides visual/audible alerts when

intervals, saves you maintenance time and operating costs.

the seat belt is not in use. The 24 is pre-wired so you can easily

Hoses and electrical harnesses are split at easily accessible install a beacon on top of the cab to indicate seat belt usage.

bulkhead locations allowing your service technicians to work

with smaller sections easier and faster.

Technology

Ok-to-Start and Critically Low Fluid monitoring systems protect The 24 features asset protection and performance-improving

your machine by providing electronic verification of fluid levels technologies including: engine overspeed/underspeed, second

and alerting you when low fluid levels are detected, protecting generation steering system, articulation eStop, ripper auto stow,

your machine. implements lock out and circle angle limits, to name a few.

Standard Cat GRADE with Cross Slope improves operator

Performance productivity and haul road quality and durability by helping

Cat C27 ACERT engine provides enhanced altitude capabilities maintain desired cross slope for appropriate water drainage

with no derate up to 3048 m (10,000 ft) for U.S. EPA Tier 4/ by automatically controlling one side of the blade.

EU Stage IV emission standards and 4572 m (15,000 ft) for

engines equivalent to Tier 2/Stage II. The Cat 24 is MineStar™ ready and includes Cat Product Link™

Elite and VIMS™ to help optimize equipment management,

An 11 percent weight increase helps provide more traction and remote monitoring capabilities, machine availability and

blade down pressure than the 24M. component life while reducing both repair cost and the risk

Consistent Power-to-the-Ground changes real-time engine power of a catastrophic failure.

levels to offset cooling fan losses resulting in best performance

at all times independent of ambient conditions.

**Life assumed is 64,000 hours.

**24 power train rebuild life target is 16,000 hours.

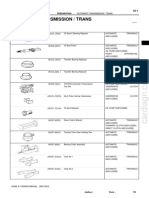

24 Motor Grader Specifications

Engine Power Train

Engine Model Cat C27 ACERT Forward/Reverse Gears 6 forward/3 reverse

Emissions Tier 4 Final/Stage IV Transmission Automatic, electronic,

Equivalent to Tier 2/Stage II Power Shift

Base Power (1st gear) – Net 399 kW 535 hp Brakes

Base Power (1st gear) – Net (Metric) 543 hp Service Oil-actuated, oil-disc

Displacement 27.0 L 1,649.5 in3 Dynamic Brake Torque Per Wheel 75 383 N∙m 55,600 lbf-ft

Bore 137.2 mm 5.4 in Parking Spring applied,

Stroke 152.4 mm 6 hydraulically released

Torque Rise ISO 9249 19%

Secondary Oil-actuated, oil-disc

Maximum Torque ISO 9249 3277 N∙m 2,417 lbf-ft

Hydraulic System

Speed @ Rated Power 1,800 rpm

Number of Cylinders 12 Circuit Type Electro-hydraulic load

sensing, closed center

Derating Altitude

Pump Type Variable piston

Tier 4 Final/Stage IV 3048 m 10,000 ft

Pump Output 504 L/min 133 gal/min

Equivalent Tier 2/Stage II 4572 m 15,000 ft

Maximum System Pressure 24 150 kPa 3,500 psi

Standard – Fan Speed

Standby Pressure 5800 kPa 841.2 psi

Maximum 1,330 rpm

Minimum 50 rpm • Pump output measured at 1,800 rpm.

Standard Capability 50° C 122° F

Operating Specifications

• The 24 is offered with two variations of the C27 Engine with

ACERT Technology. One meets U.S. EPA Tier 4 Final/EU Stage IV Top Speed

emission standards and is required for higher regulated countries. Forward 41.9 km/h 26 mph

The other option emits equivalent to Tier 2/Stage II and is Reverse 41.2 km/h 25.6 mph

available for lesser regulated countries.

• On Tier 4/Stage IV machines, Ultra Low Sulfur Diesel (ULSD) Turning Radius, Outside Front Tires 12.5 m 41 ft

and lower ash oil are required. Steering Range – Left/Right 47.5 degrees

Articulation Angle – Left/Right 25 degrees

Net Power Forward

Net Net Metric 1st 4.8 km/h 3.0 mph

Gear kW HP HP 2nd 6.9 km/h 4.3 mph

Forward 3rd 10.3 km/h 6.4 mph

1st 399 535 543 4th 14.9 km/h 9.3 mph

2nd 399 535 543 5th 28.9 km/h 18.0 mph

3rd 407 546 554 6th 41.9 km/h 26.0 mph

4th 424 569 577 Reverse

5th 463 621 630 1st 6.8 km/h 4.2 mph

6th 518 694 704 2nd 14.7 km/h 9.1 mph

Reverse 3rd 41.2 km/h 25.6 mph

1st 399 535 543 • Machine speed measured @ 1,800 rpm with 29.5R29 radial tires,

2nd 399 535 543 no slip.

3rd 463 621 630

• Net power is tested per ISO 9249 at rated speed of 1,800 rpm

and includes an engine equipped with fan, air cleaner, muffler/after

treatment and alternator.

24 Motor Grader Specifications

Ser vice Refill Moldboard

Fuel Capacity 908 L 240 gal Width 7.3 m 24 ft

Cooling System 191 L 50.5 gal Height 1025 mm 42.4 in

Hydraulic System Thickness 50 mm 2 in

Total 270 L 71.3 gal Arc Radius 550 mm 21.7 in

Tank 130 L 34.3 gal Throat Clearance 162 mm 6.4 in

Engine Oil 99 L 26. 2 gal Cutting Edge

Transmission 122 L 32.2 gal Width 406 mm 16 in

Differential and Final Drives 190 L 50.2 gal Thickness 60 mm 2.4 in

Tandem Housing (each) 322 L 85.1 gal End Bit

Front Wheel Spindle Bearing 4L 1.1 gal Width 203 mm 8 in

Housing (each) Thickness 25 mm 1 in

Circle Drive Housing (each) 8L 2.1 gal Blade Pull*

Base GVW 46 502 kg 102,519 lb

Frame

Maximum GVW 49 263 kg 108,607 lb

Circle Down Force

Diameter 2631 mm 103.6 in Base GVW 32 597 kg 71,863 lb

Blade Beam Thickness 160 mm 6.3 in Maximum GVW 34 020 kg 75,001 lb

Drawbar *Blade pull calculated at 0.9 traction coefficient, which is equal

Height 215 mm 8.5 in to ideal no-slip conditions, and Gross Machine Weight.

Thickness 16 mm 0.6 in

Width 225 mm 8.9 in Blade Range

Front-Top/Bottom Plate Circle Centershift

Width 514 mm 20.2 in Right 437 mm 17.2 in

Thickness 50 mm 2 in Left 804 mm 31.7 in

Front Side Plates Moldboard Sideshift

Width 415 mm 16.3 in Right 1150 mm 45.3 in

Thickness 25 mm 1 in Left 970 mm 38.2 in

Front Axle Maximum Blade Position Angle 55 degrees

Height to Center 882 mm 34.7 in Blade Tip Range

Wheel Lean, Left/Right 18 degrees Forward 40 degrees

Total Oscillation Per Side 32 degrees Backward 0 degrees

Maximum Shoulder Reach Outside of Tires

Tandems Right 3175 mm 125 in

Height 1040 mm 41 in Left 3175 mm 125 in

Width 353 mm 13.9 in Maximum Lift Above Ground 410 mm 16.1 in

Sidewall Thickness Maximum Depth of Cut 550 mm 21.7 in

Inner 25 mm 1 in • Maximum lift above ground and depth of cut with

Outer 30 mm 1.2 in 406 mm × 60 mm (16 in × 2.4 in) cutting edges.

Drive Chain Pitch 76 mm 3 in

Wheel Axle Spacing 2285 mm 90 in

Tandem Oscillation

Front Up 20 degrees

Front Down 20 degrees

24 Motor Grader Specifications

Ripper

Standards

Ripping Depth – Maximum 454 mm 17.9 in ROPS/FOPS ISO 3471,

Ripper Shank Holders 7 ISO 3499

Shank Holder Spacing Steering ISO 5010:2007

Minimum 593 mm 23.3 in Brakes ISO 3450

Maximum 604 mm 23.8 in Sound ISO 6394,

ISO 6395,

Penetration Force 142 kN 31,922.9 lbf

ISO 6396

Pryout Force 182 kN 40,915.2 lbf

• The dynamic spectator sound power level is 112 dB(A) for Tier 4/

Stage IV certified configurations and 113 dB(A) for equivalent

Weights – Tier 4/Stage IV Tier 2/Stage II configurations when measured according to the

Gross Vehicle Weight – Typically Equipped dynamic test procedures that are specified in ISO 6395:2008.

The measurement was conducted at 70 percent of the maximum

Total 73 344 kg 161,695 lb

engine cooling fan speed. The machine was equipped with a sound

Front Axle 20 170 kg 44,467 lb suppression system.

Rear Axle 53 174 kg 117,228 lb • The dynamic operator sound pressure level is 77 dB(A) for Tier 4/

Gross Vehicle Weight – Base* Stage IV certified configurations and 73 dB(A) for equivalent

Total 71 563 kg 157,769 lb Tier 2/Stage II configurations when measured according to the

dynamic test procedures that are specified in ISO 6396:2008.

Front Axle 19 894 kg 43,858 lb The measurement was conducted at 70 percent of the maximum

Rear Axle 51 669 kg 113,910 lb engine cooling fan speed, with the cab doors and the cab

Gross Vehicle Weight – Maximum Tested windows closed. The cab was properly installed and maintained.

Total 75 500 kg 166,449 lb The machine was equipped with a sound suppression system.

Front Axle 20 763 kg 45,775 lb

Rear Axle 54 737 kg 120,674 lb

*For machines not equipped with Tier 4 Final emission engine,

subtract 40 kg (88.2 lb) from the rear axle weight and total

weight. Base operating weight calculated on standard machine

configuration with 29.5 R29 tires, full fuel tank operator

and ROPS cab.

24 Motor Grader Specifications

Dimensions

1 10

9

2

8

3 4

11 5

13 6

12 7

24

mm in

1 Height – Top of Cab 4380 172.4

2 Height – Front Axle Center 914 36

3 Length – Between Tandem Axles 2285 90

4 Length – Front Axle to Moldboard 4048 159.4

5 Length – Front Axle to Mid Tandem 10 388 409

6 Length – Front Tire to Rear of Machine (includes tow hitch) 14 880 585.8

7 Length – Counterweight to Ripper 16 707 657.8

8 Ground Clearance at Rear Axle 404 15.9

9 Height to Top of Cylinders 3800 149.6

10 Height to Exhaust Stack 4373 172.2

11 Width – Tire Center Lines 3664 144.3

12 Width – Outside Rear Tires 4433 174.5

13 Width – Outside Front Tires 4280 168.5

All dimensions are approximate, based on standard machine configuration with 29.5R29 tires.

Optional Tire Arrangements

Common tire options for the 24.

Wheel Group Tires

29.5 × 29 29.5R29 Michelin XLDD2A ★ L5

29.5 × 29 29.5R29 Bridgestone VSTD D2A ★ L5

Factory options may vary based on availability.

24 Motor Grader Standard Equipment

Standard Equipment

Standard equipment may vary. Consult your Cat dealer for details.

POWER TRAIN TECHNOLOGY PRODUCTS

• Engine: C27 with ACERT technology • VIMS – 3G

• 24-volt electric start • Grade control X slope

• Air filters, dual with precleaner • Overspeed/underspeed protection

• Automatic dust ejector • Second generation steering system

• Aftercoolers, air-to-air • Ripper auto stow

• Ether starting aid • Circle angle limits

• Automatic fan, suction with hydraulic demand

• Drive, near zero fan speed SAFETY AND SECURITY

• Torque divider, lock-up • Fire suppression ready

• Transmission, 533 mm (21 in) planetary powershift with • Circle drive slip clutch

6F/3R, ECPC • Locking doors

• Enhanced auto-shift, APECS • Ground level engine shutdown

• Directional shift management • Secondary steering

• Differential, lock/unlock (auto/manual) • Working at heights tie-off anchors

• Parking brake, multi-disc, sealed and oil cooled • Rear tandem access platforms

• Fast fill (fuel, hydraulic, transmission, coolant) • Seat belt indicator

• Fuel priming pump, electric

• Electronic prescreener water/fuel GROUND ENGAGING TOOLS

• Prescreener separator, water/fuel • Moldboard, 7315 mm × 1067 mm × 50 mm (24 ft × 42 in × 2 in)

• Thermal shields • Rear ripper with seven shank capacity, three shanks/tips provided

• Fluid monitoring (engine, transmission, hydraulic, differential)

OTHER STANDARD EQUIPMENT

ELECTRICAL • Blade lift accumulators

• Alarm, back-up • Lincoln Centro-Matic Autolube System

• Alternator, 150 ampere, sealed, filtered air intake • Drawbar, eight shoe with replaceable wear strips

• Maintenance free batteries, 12V (4), 200 amp-hour • Fuel tank, 908 L (240 gal) fast fill

• Heavy duty starter (two) • Ground level fueling

• Electrical hydraulic valves, base 8 • Push plate-counterweight

• Electrical system, 24 volt • S∙O∙SSM ports, engine, hydraulic, transmission, coolant, fuel

• Lights, reversing, stop, tail, turn • Hydraulic and electric bulkheads

• Starter receptacle plug-in • Fluid service center: engine, transmission, hydraulic oil,

and coolant ports

OPERATOR ENVIRONMENT

• Air conditioner and heater sound suppressed,

pressurized cab 73 dB(A) ISO 6394 at 70 percent fan speed.

• Rollover protective structure (ROPS/FOPS)

• Adjustable armrest

• Electro-hydraulic controls

• Electronic throttle control

• Automatic return to center articulation

• 10 inch digital touch screen information display

• Rear vision camera

• Coat hook

• Comfort suspension seat, cloth-covered

• Front fixed laminated window glass with intermittent wiper,

sides (two), rear with wiper/washer

• Retractable seat belt, 76 mm (3 in)

• Hydraulic implement lockout for roading and servicing

24 Motor Grader Optional Equipment

Optional Equipment

Optional equipment may vary. Consult your Cat dealer for details.

OPER ATOR ENVIRONMENT SAFE T Y

• Heated seat • Dual Access CAB platform

• Heated and ventilated seat • Front facing cameras (two)

• Air horn • Fire suppression system

• Radio Bluetooth® • Wheel chocks with mounting bracket

• Radio Satellite Sirius

• Outside mounted mirrors OTHER AT TACHMENTS

• Heated outside mounted mirrors 24V • VIMS and Satellite Product Link

• Rear view camera additional dedicated monitor • VIMS and Dual (Cell/Satellite) Product Link

• Auto articulation • Rims Only option , 25" × 29" MP

POWER TR AIN WORK TOOL S/G.E.T.

• Bar and plate dual core radiator • Flat 406 mm × 60 mm (16 in × 2.36 in) cutting edge

• Precleaner Sy-klone • Serrated 406 mm × 75 mm (16 in × 2.95 in) cutting edge

• Control bade variable float • Miningbit™ 355.6 mm × 75 mm (14 in × 2.13 in) cutting

edge system

GUARDS • Tooth, ripper

• Guard Package including mud guard (two) bottom,

eng. compartment and front axle (two) FLUIDS

• Tandem fenders with mounted guardrails • Cold Weather Package – Arctic hydraulic oil, engine, hydraulic,

• Sound suppression guard package transmission and coolant heater (240V/30A)

ELECTRICAL

• Halogen operator access lighting package

• LED operator access lighting package

• Working halogen lighting package

• Working LED lighting package

• LED warning strobe light

24 Motor Grader

For more complete information on Cat products, dealer services, and industry solutions, visit us on the web AEHQ8102-01 (12-2017)

at www.cat.com Replaces AEHQ8102

Build Number: 24-14A

© 2017 Caterpillar

All rights reserved

Materials and specifications are subject to change without notice. Featured machines in photos may include

additional equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow” and the “Power Edge”

trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may

not be used without permission.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Fuse Box Diagram Peugeot 406, 1995 - 2004Document8 pagesFuse Box Diagram Peugeot 406, 1995 - 2004MARGOTTONo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2006 Nissan X Trail 38615Document50 pages2006 Nissan X Trail 38615Alonso IbarraNo ratings yet

- Dimension 650Document8 pagesDimension 650juanNo ratings yet

- The Improvement of Flaw Detection by The Configuration of Uniform Eddy Current ProbesDocument15 pagesThe Improvement of Flaw Detection by The Configuration of Uniform Eddy Current ProbesjuanNo ratings yet

- 02 Día 16-12-2020 PDFDocument1 page02 Día 16-12-2020 PDFjuanNo ratings yet

- Img 20201219 0001Document1 pageImg 20201219 0001juanNo ratings yet

- Literatura Tecnica 2Document53 pagesLiteratura Tecnica 2Dennis Rogers Hewstone MandujanoNo ratings yet

- 09 2016 PDFDocument60 pages09 2016 PDFbyungchul kimNo ratings yet

- Diagnosis by SymptomDocument3 pagesDiagnosis by SymptomMaster XeotoNo ratings yet

- Gp125150180efi20181215 Maintenance Manual 1Document167 pagesGp125150180efi20181215 Maintenance Manual 1darren walkerNo ratings yet

- 2022 NC750X BrochureDocument3 pages2022 NC750X Brochureaa100% (1)

- Maintenance Information: 1991 Mitsubishi MonteroDocument16 pagesMaintenance Information: 1991 Mitsubishi MonteroAnimemanuel MuñozNo ratings yet

- Tesmec Catalogue TmeDocument208 pagesTesmec Catalogue TmeDidier solanoNo ratings yet

- Drive Pinion Shaft: Automatic TransmissionDocument7 pagesDrive Pinion Shaft: Automatic TransmissionAnton FortovNo ratings yet

- Jeep AW-4 ASTG Automatic Transmission Service ManualDocument115 pagesJeep AW-4 ASTG Automatic Transmission Service Manualdan themanNo ratings yet

- Hitachi zw250 GBDocument20 pagesHitachi zw250 GBKhaleel100% (1)

- Technical Service Information: Daimler/Chrysler 40te, 41te, 42le, 42rle, 45RFE & 545RFEDocument2 pagesTechnical Service Information: Daimler/Chrysler 40te, 41te, 42le, 42rle, 45RFE & 545RFEJose garcua vargas 2006401321No ratings yet

- Gr-300ex S G PDFDocument12 pagesGr-300ex S G PDFnorsallim syamsuddinNo ratings yet

- Filter InfoDocument4 pagesFilter InfoCarlos Ediver Arias RestrepoNo ratings yet

- Automatic Transmission: SectionDocument326 pagesAutomatic Transmission: Sectionswasty1No ratings yet

- Technical Service Information: FORD 4R100Document3 pagesTechnical Service Information: FORD 4R100Jose garcua vargas 2006401321No ratings yet

- Changan 2014 Cx20 1 4l Amt Sunroof: General DetailsDocument6 pagesChangan 2014 Cx20 1 4l Amt Sunroof: General Detailsrstec pyNo ratings yet

- Design and Analysis of Gear BoxDocument5 pagesDesign and Analysis of Gear BoxTemesgen ErenaNo ratings yet

- 2012 Peugeot 3008 101609Document328 pages2012 Peugeot 3008 101609Predrag VajagićNo ratings yet

- A07 024Document2 pagesA07 024r3388No ratings yet

- Bom A4VG - REXROTHDocument44 pagesBom A4VG - REXROTHnamduong368100% (4)

- Automatic Transmission / Trans: PreparationDocument2 pagesAutomatic Transmission / Trans: PreparationDang Tien PhucNo ratings yet

- 19MY F PACE Spec Sheet 1 - tcm635 642181Document2 pages19MY F PACE Spec Sheet 1 - tcm635 642181Yogesh Wadhwa100% (1)

- Beekeeping Cranes Catalogue: Aj Is The Perfect Solution For Handle Your HivesDocument17 pagesBeekeeping Cranes Catalogue: Aj Is The Perfect Solution For Handle Your Hiveschira AurelNo ratings yet

- LEON Conduccion 11 22 ENDocument30 pagesLEON Conduccion 11 22 ENttrtNo ratings yet

- 2022 ARP CatalogDocument180 pages2022 ARP Catalogdonny rebornNo ratings yet

- Continuous Variable: TransmissionDocument17 pagesContinuous Variable: TransmissionSanthosh GoudNo ratings yet

- ZG Starting Systems 8B - 1Document14 pagesZG Starting Systems 8B - 1ensmartisNo ratings yet

- HX220ALDocument636 pagesHX220ALГригорий Григорян100% (5)