Professional Documents

Culture Documents

System Integration

Uploaded by

HabibOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

System Integration

Uploaded by

HabibCopyright:

Available Formats

4

Control System Integration

Contents

Objective...............................................................................................................................................1

Commission All Control Blocks............................................................................................................2

Complete Process Using Blocks............................................................................................................4

Process Control Block Diagram............................................................................................................5

Integrating Project.................................................................................................................................6

Stage 1: Configure Tank Level Sensor................................................................................................6

Stage 2: Configure Valve 1 (Raw Water Supply)................................................................................8

Stage 3: Configure Valve 1 (Raw Water Supply)................................................................................8

Stage 4: Configure Valve 2 (Water Supply Control Valve)..................................................................8

Stage 5: Configure Valve 2 (Water Supply Control Valve)..................................................................8

Extra Information..................................................................................................................................8

SCADA Representation.......................................................................................................................11

Graphics..........................................................................................................................................11

Alarm...............................................................................................................................................11

Trend...............................................................................................................................................11

No of Starts......................................................................................................................................11

Objective

BASIC PLC TRAINING | TECHNICAL – MOTOR CONTROL BLOCK

4

The Objective is to integrate all process to complete the project

Full understanding of blocks

Integrate all blocks to complete the process

Demonstrate a working project

Troubleshooting & Fault finding

Exams

Commission All Control Blocks

For this project, we have designed two standard blocks.

BASIC PLC TRAINING | TECHNICAL – MOTOR CONTROL BLOCK

4

1. Valve control blocks

2. Motor control blocks

Objective 1:

Commission Motor control block using simulator

Complete simulation.

Create DB tag to replace it

Objective 2:

Commission Valve block using simulator

Complete simulation.

Create DB tag to replace it

BASIC PLC TRAINING | TECHNICAL – MOTOR CONTROL BLOCK

4

Complete Process Using Blocks

Objective 1:

Simulate 4-20 mA Signal in PLC SIM

Define a DB for analogue signal

Add in VAT file

Objective 2:

Link all Blocks as per process flow diagram

Objective 3:

Commission the project

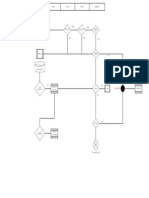

Process Control Block Diagram

BASIC PLC TRAINING | TECHNICAL – MOTOR CONTROL BLOCK

4

Integrating Project

BASIC PLC TRAINING | TECHNICAL – MOTOR CONTROL BLOCK

4

Stage 1: Configure Tank Level Sensor

Setup Potentiometer to generate 4-20 mA Signal (using ohms law V=IR).

Understand about 4-20 mA signal generation

V = 24 Vdc, I mA = 4, R =? (6Kohm)

V = 24 Vdc, I mA = 20, R=? (1.2Kohm)

Wiring to PLC analogue card terminal

BASIC PLC TRAINING | TECHNICAL – MOTOR CONTROL BLOCK

4

Define analogue reading block in PLC

Process DATA

Save it in DB

Use the DB variable for process.

Stage 2: Configure Valve 1 (Raw Water Supply)

BASIC PLC TRAINING | TECHNICAL – MOTOR CONTROL BLOCK

4

Install moisture sensor

In this case install a push button

Stage 3: Configure Valve 1 (Raw Water Supply)

Stage 4: Configure Valve 2 (Water Supply Control Valve)

Stage 5: Configure Valve 2 (Water Supply Control Valve)

Extra Information

Motor control Block

BASIC PLC TRAINING | TECHNICAL – MOTOR CONTROL BLOCK

4

BASIC PLC TRAINING | TECHNICAL – MOTOR CONTROL BLOCK

4

BASIC PLC TRAINING | TECHNICAL – MOTOR CONTROL BLOCK

4

SCADA Representation

Graphics

Alarm

Trend

No of Starts

BASIC PLC TRAINING | TECHNICAL – MOTOR CONTROL BLOCK

You might also like

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- I M C T P L C C: Ntegration OF Otion Ontrol Echnologies Into A Rogrammable Ogic Ontrols OurseDocument5 pagesI M C T P L C C: Ntegration OF Otion Ontrol Echnologies Into A Rogrammable Ogic Ontrols OurseGoran MiljkovicNo ratings yet

- Prem Project Report PLC Final Traffic - 1Document50 pagesPrem Project Report PLC Final Traffic - 1Mohammed FazalNo ratings yet

- Project Timeline - Training Simulator, SCADA & Project ManagementDocument8 pagesProject Timeline - Training Simulator, SCADA & Project ManagementHabibNo ratings yet

- Project Report On Bottle Filling PlantDocument24 pagesProject Report On Bottle Filling PlantVishal Saini100% (3)

- GBC_PLC_PLCII_materialDocument25 pagesGBC_PLC_PLCII_materialroberto obiangNo ratings yet

- Programmable Logic Controller (PLC) - Industrial Wiki - ODESIE® by Technology TransferDocument41 pagesProgrammable Logic Controller (PLC) - Industrial Wiki - ODESIE® by Technology TransferAbhishek SinghNo ratings yet

- Docslide - Us - 41 Ovation Dcs 2007 PDFDocument52 pagesDocslide - Us - 41 Ovation Dcs 2007 PDFtriplbingazi100% (1)

- PLC Programming FileDocument33 pagesPLC Programming FileRahul kumarNo ratings yet

- LAB 1: TO Fpga Hardware, Control Design and Simulation: ObjectivesDocument13 pagesLAB 1: TO Fpga Hardware, Control Design and Simulation: ObjectivesAidil AzharNo ratings yet

- Student Design Projects in A Programmable Logic Controller PLC CourseDocument10 pagesStudent Design Projects in A Programmable Logic Controller PLC CourseMarees KannanNo ratings yet

- Getting Started With Processlogix R400.0: Quick StartDocument24 pagesGetting Started With Processlogix R400.0: Quick StartfitasmounirNo ratings yet

- Lab 3 - Conveyor System ControlDocument10 pagesLab 3 - Conveyor System ControlAaron BachtiarNo ratings yet

- Final Year Project Report FainalllllDocument45 pagesFinal Year Project Report Fainalllllanon_76743611No ratings yet

- PLC Programming MPS 152Document25 pagesPLC Programming MPS 152ivan garciaNo ratings yet

- Microsoft Word - INTRODUCTION TO PLC CONTROLLERSDocument115 pagesMicrosoft Word - INTRODUCTION TO PLC CONTROLLERSMilan RakshitNo ratings yet

- FAT Procedure For PLC Panel - PLC (Programmable Logic Controllers) - Industrial Automation, PLC Programming, Scada & Pid Control SystemDocument7 pagesFAT Procedure For PLC Panel - PLC (Programmable Logic Controllers) - Industrial Automation, PLC Programming, Scada & Pid Control Systemnzar HasanNo ratings yet

- "Plc-Scada": Bachelor of Technology in Electronics & Communication EngineeringDocument50 pages"Plc-Scada": Bachelor of Technology in Electronics & Communication EngineeringluvnshaadiNo ratings yet

- B&R Automation Studio Target For SimulinkDocument76 pagesB&R Automation Studio Target For SimulinkAdrian MeleroNo ratings yet

- Embedded System & Microcontroller Application Course Code: 4351102Document8 pagesEmbedded System & Microcontroller Application Course Code: 4351102Raggy TannaNo ratings yet

- Boiler Automation PDFDocument5 pagesBoiler Automation PDFHarshada DeokateNo ratings yet

- PLC Lab ExeercisesDocument73 pagesPLC Lab Exeercisesmanicks369601No ratings yet

- Conveyor System ControlDocument11 pagesConveyor System ControlNurul FatasyaNo ratings yet

- Bottling Machije 2Document47 pagesBottling Machije 2Umar Farouq Mohammed GalibNo ratings yet

- LAB 4 Aaron ConveyerDocument12 pagesLAB 4 Aaron ConveyerAaron BachtiarNo ratings yet

- Mechatronics WS CĹëÇŐ AlexDocument246 pagesMechatronics WS CĹëÇŐ Alexethanhunt85No ratings yet

- Technical Description Mechatronics 2014Document5 pagesTechnical Description Mechatronics 2014JavierRuizThorrensNo ratings yet

- Vehicle Control UnitDocument20 pagesVehicle Control Unit시드세흐리아르알리나크비No ratings yet

- PLCDocument56 pagesPLCFelix Lee Kah NgieNo ratings yet

- PLC Scada Training ReportDocument31 pagesPLC Scada Training ReportÄkshãy SaçhånNo ratings yet

- Automation of Water Tube Boiler Electrical ThesisDocument53 pagesAutomation of Water Tube Boiler Electrical ThesisMuhammadIrfanNo ratings yet

- TwinCAT Basic TrainingDocument21 pagesTwinCAT Basic TrainingPrengga100% (1)

- INDCERT - mMS4.0 v1.0Document4 pagesINDCERT - mMS4.0 v1.0Luis Alberto Zapata OjedaNo ratings yet

- Control Boiler Operation PLC-SCADADocument26 pagesControl Boiler Operation PLC-SCADAKannan S100% (2)

- Programmable Logic Control Trainer IT-1200SDocument34 pagesProgrammable Logic Control Trainer IT-1200SImran ShaukatNo ratings yet

- 09 20R300 1 Data Acquisition Control ModuleDocument82 pages09 20R300 1 Data Acquisition Control Moduleavandetq15100% (1)

- Factory Acceptance Test ProceduresDocument14 pagesFactory Acceptance Test ProceduresPrashant Mohokar100% (1)

- Microprocessor Interfacing & Programming - Lab-Manual - September - 2021Document40 pagesMicroprocessor Interfacing & Programming - Lab-Manual - September - 2021Muiz MalikNo ratings yet

- Introduction To Manufacturing: Automation and RoboticsDocument202 pagesIntroduction To Manufacturing: Automation and RoboticsCesar GeronimoNo ratings yet

- Testing Hydro Power Plant Governors with Hardware-in-the-Loop SimulationsDocument4 pagesTesting Hydro Power Plant Governors with Hardware-in-the-Loop Simulationsemilzaev01No ratings yet

- MATLAB HardwareDocument1 pageMATLAB HardwareImran KhanNo ratings yet

- Volume6 2003 PDFDocument31 pagesVolume6 2003 PDFZeljkoSipcicNo ratings yet

- Blaise Kevine Matlab-PlcDocument13 pagesBlaise Kevine Matlab-PlcMP INTERNATIONAL EXPORT PVT. LTD.No ratings yet

- National Institute of Technology, Kurukshetra Haryana: Submitted To Submitted byDocument31 pagesNational Institute of Technology, Kurukshetra Haryana: Submitted To Submitted byÄkshãy SaçhånNo ratings yet

- Dyna DCMC Curriculam ManualDocument203 pagesDyna DCMC Curriculam ManualDevSinghNo ratings yet

- CAN Lab Exercise: Controller Area NetworkDocument21 pagesCAN Lab Exercise: Controller Area NetworkCotfas PetruNo ratings yet

- Guide Utilisateur MCSDocument41 pagesGuide Utilisateur MCSken TIZEN DJONGUENo ratings yet

- Part Q Multiple Production: TeciamDocument22 pagesPart Q Multiple Production: TeciamAyoubNo ratings yet

- Sorting Conveyor SystemDocument11 pagesSorting Conveyor SystemNurul FatasyaNo ratings yet

- PLCDocument34 pagesPLCManisha Sudeep Kaintura100% (2)

- Syeda HusnaDocument31 pagesSyeda HusnaSyeda HusnaNo ratings yet

- Analog & Digital Motor Control ManualDocument204 pagesAnalog & Digital Motor Control ManualRafath Mohammed100% (2)

- Costomer TrainingDocument51 pagesCostomer TrainingAhmad NilNo ratings yet

- J450 Power Electronics: AC 800PEC Matlab/SimulinkDocument1 pageJ450 Power Electronics: AC 800PEC Matlab/SimulinkNikolaBuljaNo ratings yet

- Introduction to IEC 61131-3 programming languagesDocument29 pagesIntroduction to IEC 61131-3 programming languagesRasim UmurNo ratings yet

- Programmable Logic Controller (PLC)Document57 pagesProgrammable Logic Controller (PLC)Sumanta Gupta100% (1)

- PLC Elevator DocumentationDocument35 pagesPLC Elevator DocumentationvamshivarunNo ratings yet

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- Binary Operation & Data BlockDocument11 pagesBinary Operation & Data BlockHabibNo ratings yet

- Process DrawingDocument1 pageProcess DrawingHabibNo ratings yet

- Holding File - To Be ReplacedDocument1 pageHolding File - To Be ReplacedHabibNo ratings yet

- BOMDocument7 pagesBOMHabibNo ratings yet

- Basic PLC Course - Payment Date UpdatedDocument1 pageBasic PLC Course - Payment Date UpdatedHabibNo ratings yet

- ExportDocument11 pagesExportHabibNo ratings yet

- Weekly Report ProcedureDocument3 pagesWeekly Report ProcedureHabibNo ratings yet

- Analysis - June - 2021Document1 pageAnalysis - June - 2021HabibNo ratings yet

- Basic PLC Course - Payment Date UpdatedDocument1 pageBasic PLC Course - Payment Date UpdatedHabibNo ratings yet

- s7300 Module Data Manual en-US en-US PDFDocument648 pagess7300 Module Data Manual en-US en-US PDFPauloHackNo ratings yet

- Process DrawingDocument1 pageProcess DrawingHabibNo ratings yet

- s7300 Cpu 31xc Technological Functions Operating Instructions en-US en-USDocument404 pagess7300 Cpu 31xc Technological Functions Operating Instructions en-US en-USRaul BertoncelloNo ratings yet

- Data Sheet 6ES7331-7NF10-0AB0: Supply VoltageDocument3 pagesData Sheet 6ES7331-7NF10-0AB0: Supply VoltageHabibNo ratings yet

- BOMDocument7 pagesBOMHabibNo ratings yet

- Bs 5467 Copper Conductor Multi Core Swa PVC 1 9 3 3kv CableDocument2 pagesBs 5467 Copper Conductor Multi Core Swa PVC 1 9 3 3kv CableSaqib JavedNo ratings yet

- 4 Special Fire Hazards and PreventionDocument22 pages4 Special Fire Hazards and Preventiondroffilcz27100% (1)

- Menu utama komponen KRDocument33 pagesMenu utama komponen KRRizkye Arvia Nantha100% (1)

- Arduino Nano Propeller LEDAnalog Clock 20190403 ADocument4 pagesArduino Nano Propeller LEDAnalog Clock 20190403 AJeng RaffaNo ratings yet

- MongoDB MonitoringDocument6 pagesMongoDB Monitoringsnet solutionsNo ratings yet

- MEITRACK - MVT600-User-Guide-V2.0 Sensor de Combustible ResistenciaDocument22 pagesMEITRACK - MVT600-User-Guide-V2.0 Sensor de Combustible ResistenciaManuel Flores CorderoNo ratings yet

- Circular XIDocument2 pagesCircular XIRavi Teja RTNo ratings yet

- T19PC Type Temperature Controls With NEMA 4X Raintight EnclosuresDocument3 pagesT19PC Type Temperature Controls With NEMA 4X Raintight EnclosuresEnrique GomezNo ratings yet

- Assignment 2 SMN3043 A211Document4 pagesAssignment 2 SMN3043 A211ChimChim UrkNo ratings yet

- Mathematical Modeling Performance Evaluation of Electro Hydraulic Servo ActuatorsDocument24 pagesMathematical Modeling Performance Evaluation of Electro Hydraulic Servo ActuatorsZyad KaramNo ratings yet

- Properties of Recurisve and Recursively Enumerable Languages PDFDocument2 pagesProperties of Recurisve and Recursively Enumerable Languages PDFBelex ManNo ratings yet

- AVIC-Z150BH, X950BH, X850BT Firmware Update InstructionsDocument4 pagesAVIC-Z150BH, X950BH, X850BT Firmware Update InstructionsEnlight Lab AlbaniaNo ratings yet

- EmpgDocument10 pagesEmpgShravanNo ratings yet

- Isolation AmplifierDocument11 pagesIsolation AmplifierSadikielNo ratings yet

- History of Computer: Basic Computing Periods: Week 3 Living in The IT Era Maria Michelle VinegasDocument41 pagesHistory of Computer: Basic Computing Periods: Week 3 Living in The IT Era Maria Michelle VinegasMary Ianne Therese GumabongNo ratings yet

- Release Mode Bundle ErrorDocument11 pagesRelease Mode Bundle ErrorRaman deepNo ratings yet

- 1.1 Huntleigh Doppler Models FD1 and FD3Document4 pages1.1 Huntleigh Doppler Models FD1 and FD3user 01No ratings yet

- Challenges and Prospects of Digital SwitchoverDocument26 pagesChallenges and Prospects of Digital SwitchoverPst W C PetersNo ratings yet

- Python Notes - 1Document364 pagesPython Notes - 1hopefulantonelliNo ratings yet

- Digital Products Decommissioning Checklist: The Purpose of This Document Is ToDocument7 pagesDigital Products Decommissioning Checklist: The Purpose of This Document Is ToadiNo ratings yet

- 11-Programming Concepts-Flowcharts 2Document10 pages11-Programming Concepts-Flowcharts 2nebiat nerayoNo ratings yet

- Surface Vehicle Recommended PracticeDocument12 pagesSurface Vehicle Recommended Practiceferhat aydoganNo ratings yet

- Safety Logic For Machines and Systems - Easysafety ES4P - Safety Relay ESR5Document16 pagesSafety Logic For Machines and Systems - Easysafety ES4P - Safety Relay ESR5geocaustasNo ratings yet

- SSV 2019 - Wiring Diagram - 219100978 - WD91Y019S10 - enDocument9 pagesSSV 2019 - Wiring Diagram - 219100978 - WD91Y019S10 - enAlex CachuNo ratings yet

- Superconductivity (Physics Ch.4 Group 2)Document19 pagesSuperconductivity (Physics Ch.4 Group 2)mnvsptlNo ratings yet

- DPWH DupaDocument274 pagesDPWH DupaCelsoRapi80% (5)

- Allison Transmission ECUDocument1 pageAllison Transmission ECULouis Hardy50% (2)

- CSP Networking 5g EbookDocument14 pagesCSP Networking 5g EbookLeopoldo Lopez QuinteroNo ratings yet

- Decision Support Systems: Mcgraw-Hill/IrwinDocument67 pagesDecision Support Systems: Mcgraw-Hill/IrwinAlexNo ratings yet

- S7 Communication Between SIMATIC S7-1500 and SIMATIC S7-300: Step 7 V16 / Bsend / BRCVDocument45 pagesS7 Communication Between SIMATIC S7-1500 and SIMATIC S7-300: Step 7 V16 / Bsend / BRCV9226355166No ratings yet