Professional Documents

Culture Documents

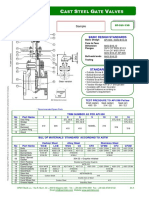

Gate Valve Class T Size 2 in

Uploaded by

Irfan Ismail0 ratings0% found this document useful (0 votes)

37 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

37 views2 pagesGate Valve Class T Size 2 in

Uploaded by

Irfan IsmailCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

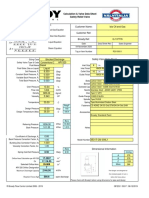

TYPE GATE VALVE

END CONNECTION RF FLANGED

FLUID SERVICE CONDENSATE, BRINE

PIPE CLASSES CLASS T

SIZE RANGE 2" and ABOVE

MAX. TEMP./PRESS. 475 °F / 500 psig

RATING ANSI CLASS 300

3 19-May-08 REVISED SB AJ AMS

2 31-Jan-07 REVISED SB AJ AMS

1 15-Jan-07 ADD REQUIREMENT SB AJ AMS

0 01-Dec-06 ISSUED FOR PURCHASE SB AJ AMS

No. DATE REVISIONS PREP'D CHK'D APP'D

DATA SHEET No.

GATE VALVE REV.3

GV04-NACE

VENDOR'S OFFER

CHARACTERISTICS DETAILS OF MATERIALS SPECS

PROPOSED

FOLLOWED -

MODIFICATION

Y/N

Flanged Gate Valve, flexible wedge disc, bolted

VALVE

bonnet, OS & Y, rising stem with backseating

Body Cast carbon steel to ASTM A 216 Gr. WCB

13 Cr Steel to ASTM A 182 Gr. F6a hardfaced

Seat

with Stellite 6

Cast carbon steel to ASTM A 216 Gr. WCB,

Disc

hardfaced with Stellite 6

Stem 13 Cr Stainless Steel to ASTM A276-410

Bonnet Cast carbon steel to ASTM A 216 Gr. WCB

ASTM A-193 Gr. B7 and A-194 Gr. 2H

Body to Bonnet

respectively with protective coating for sour

Bolts and Nuts

environment

Body to Bonnet SS-316 spiral wound gasket with graphite fibre

Gasket filler

Back seat Bushing 13 Cr Steel to ASTM A 182 Gr. F6a

Gland Follower 13 Cr Steel to ASTM A 182 Gr. F6a

Gland Flange Forged Carbon Steel to ASTM A 105

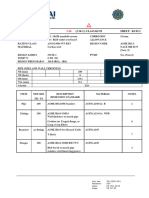

TYPE GATE VALVE

END CONNECTION RF FLANGED

FLUID SERVICE CONDENSATE, BRINE

PIPE CLASSES CLASS T

SIZE RANGE 2" and ABOVE

MAX. TEMP./PRESS. 475 °F / 500 psig

RATING ANSI CLASS 300

3 19-May-08 REVISED SB AJ AMS

2 31-Jan-07 REVISED SB AJ AMS

1 15-Jan-07 ADD REQUIREMENT SB AJ AMS

0 01-Dec-06 ISSUED FOR PURCHASE SB AJ AMS

No. DATE REVISIONS PREP'D CHK'D APP'D

DATA SHEET No.

GATE VALVE REV.3

GV04-NACE

Packing Interbraided Carbon Fibre lubricated with graphite

ASTM A-439 Gr. D2C with protective coating for

Stem nuts

sour environment

Carbon Steel, Malleable Iron, or Ductile Iron with

HANDWHEEL

protective coating for sour environment

NACE REQUIREMENT Follow NACE MR-01-75 latest edition

Valve design to API - 600, RF flanged ends to

OTHER DETAILS ANSI B 16.5, End to end dimension to B 16.10.

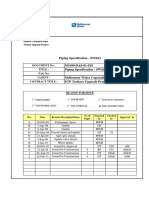

Copy of current certificate of authority to

OTHER use the American Petroleum Institute

1.

REQUIREMENTS monogram shall be submitted together with

the bid proposal.

Valve must be both hydrostatically shell

and seat tested without leakage to at least

2. the requirements set forth in API 598, copy

of hydrostatic certificate shall be submitted

together with the test valve delivery.

PREFERRED VENDOR'S

MODEL:

MANUFACTURER OFFER:

NOTES 'Detailed drawing of the valve indicating the parts, general valve dimesions, and material

specifications shall be submitted together with the bid proposal.

'In case of modification, use aditional sheet if necessary.

'Use preferred manufacturer associated with this bid

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Cryogenic Piping DesignDocument19 pagesCryogenic Piping Designsatishchemeng80% (10)

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- Piping Material Specification 1SA0S04Document5 pagesPiping Material Specification 1SA0S04Irfan IsmailNo ratings yet

- Technical Specification For Supply of Valves Table - 1: Manuf'S OfferDocument11 pagesTechnical Specification For Supply of Valves Table - 1: Manuf'S OfferRadhakrishnan SreerekhaNo ratings yet

- API 6A Gate ValvesDocument12 pagesAPI 6A Gate ValvesLee Sweningson100% (1)

- Data Sheet For Plug ValveDocument2 pagesData Sheet For Plug ValveTauqueerAhmadNo ratings yet

- Replace No.3 API Oil Separator Project: Daily Fitup ReportDocument20 pagesReplace No.3 API Oil Separator Project: Daily Fitup Reportsajay2010No ratings yet

- EIL - Specification Sheet123Document1 pageEIL - Specification Sheet123Dinesh ChouguleNo ratings yet

- Check ValveDocument1 pageCheck ValveRoshanKuckianNo ratings yet

- QM 07 - ValvesDocument6 pagesQM 07 - Valvesmohamed elmasryNo ratings yet

- DIN CatalogDocument60 pagesDIN CatalogAndor MolitoriszNo ratings yet

- D 1 1Document956 pagesD 1 1karthi82887No ratings yet

- Weir Oil Gas BrochureDocument33 pagesWeir Oil Gas BrochureRatnakar Patil100% (1)

- Equipment Data Sheet: Type: Doc No: Mds-Pv-01Document3 pagesEquipment Data Sheet: Type: Doc No: Mds-Pv-01Waqas WaqasNo ratings yet

- 12 Valves SpecificationsDocument19 pages12 Valves Specificationsshaliq28100% (1)

- 6.1 Data Sheet For Pipeline Ball ValveDocument3 pages6.1 Data Sheet For Pipeline Ball ValveDeepak PalNo ratings yet

- Demco Gate Valves BrochureDocument56 pagesDemco Gate Valves BrochureVictor100% (1)

- Uwp Model 2030 Os&y Gate Valve 2.5 In.-24 In. SizesDocument4 pagesUwp Model 2030 Os&y Gate Valve 2.5 In.-24 In. SizesHector Acaro RodriguezNo ratings yet

- Bellow Seal ValvesDocument36 pagesBellow Seal ValvesJake SparrowNo ratings yet

- MSS SP-151-2016Document10 pagesMSS SP-151-2016Денис Пекшуев0% (1)

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Request for Welding Procedure ApprovalDocument10 pagesRequest for Welding Procedure ApprovalAlam MD SazidNo ratings yet

- ALN FP ESA MEC SPC 2201 - 2B6B.1 Piping Materials SupplementDocument327 pagesALN FP ESA MEC SPC 2201 - 2B6B.1 Piping Materials Supplementahmed.njahNo ratings yet

- Piping and Valve Specifications Rev. A PDFDocument28 pagesPiping and Valve Specifications Rev. A PDFYessine RebaiNo ratings yet

- Wps Gt-9b-Cvn90 Rev 1Document6 pagesWps Gt-9b-Cvn90 Rev 1HAKANNo ratings yet

- WWS DSH 017 Butterfly ValveDocument2 pagesWWS DSH 017 Butterfly Valvekhairul ardyNo ratings yet

- Tdi 50000 Tpy, GNFCDocument6 pagesTdi 50000 Tpy, GNFCkrunal panchalNo ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- Provision of EPCC Services for Sufyan EPF Project Globe Valve Data SheetDocument4 pagesProvision of EPCC Services for Sufyan EPF Project Globe Valve Data SheetSandeepNBabuNo ratings yet

- GAIL Gas City Project Piping SpecificationDocument199 pagesGAIL Gas City Project Piping SpecificationankeshkatochNo ratings yet

- Mepl CPCLCBR Eil Qap&ds 001 2022 2023Document7 pagesMepl CPCLCBR Eil Qap&ds 001 2022 2023Mathi Vinoth PillaiNo ratings yet

- New 4. Sfe-Dst-Pip-1402-4104 DST For Check ValveDocument4 pagesNew 4. Sfe-Dst-Pip-1402-4104 DST For Check ValveSandeepNBabuNo ratings yet

- Valve Qap - IoclDocument96 pagesValve Qap - Ioclalokgoel_2006No ratings yet

- Project Data Sheet for Needle ValveDocument3 pagesProject Data Sheet for Needle ValveSandeepNBabuNo ratings yet

- DATA SHEET MTO # 1 (ITEM # 13) Data Sheet-8 Inch To 24 Inch Size-Reduced Port-Double Block Bleed-Gear OperatedDocument1 pageDATA SHEET MTO # 1 (ITEM # 13) Data Sheet-8 Inch To 24 Inch Size-Reduced Port-Double Block Bleed-Gear OperatedQualival EgyptNo ratings yet

- Revised Weld Map (23!07!2015)Document15 pagesRevised Weld Map (23!07!2015)Midhun K Chandrabose100% (1)

- Gate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDocument1 pageGate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDIPANKAR LALANo ratings yet

- Ss Globe Valve 150# - 1Document1 pageSs Globe Valve 150# - 1Vijay GaikwadNo ratings yet

- ADMA-OPCO Strainer Data SheetDocument7 pagesADMA-OPCO Strainer Data Sheetvinoj chandranNo ratings yet

- JIS B 0601-2001 Surface RoughnessDocument4 pagesJIS B 0601-2001 Surface RoughnessMatthew Johnston0% (1)

- Procurement of Butterfly Valves for Sea Water Supply LinesDocument1 pageProcurement of Butterfly Valves for Sea Water Supply Linesritoh8657No ratings yet

- Data Sheet Válvula de Seguridad y AlivioDocument4 pagesData Sheet Válvula de Seguridad y Aliviorenzo condeNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- VMS - 3Document1 pageVMS - 3ritoh8657No ratings yet

- Telescopic Valve Data Sheet (32003-Skws-Gn-Me-Ds-0025) Rev.aDocument6 pagesTelescopic Valve Data Sheet (32003-Skws-Gn-Me-Ds-0025) Rev.aSouvik DaluiNo ratings yet

- 3010-PS003 - 3 Valve ScheduleDocument61 pages3010-PS003 - 3 Valve ScheduleMichael adu-boahenNo ratings yet

- PURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Document4 pagesPURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- Hydrant PillarDocument1 pageHydrant PillarsobariNo ratings yet

- Agirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestDocument6 pagesAgirm Agn 4500210653 Itp 001 02 Kas3 Iso Seawater Strainer Forward Sea ChestRJS TUTORIALNo ratings yet

- AK2 - RevADocument13 pagesAK2 - RevAChirag ShahNo ratings yet

- Sizing PSV Broady Valvitalia-R4Document18 pagesSizing PSV Broady Valvitalia-R4Anggun RushNo ratings yet

- 1B. Vendor Offer KOSO-CV - Code2Document7 pages1B. Vendor Offer KOSO-CV - Code2vivekanandakuwaitNo ratings yet

- Material Requisition For Fuel Fittings-Rev0Document8 pagesMaterial Requisition For Fuel Fittings-Rev0altipatlarNo ratings yet

- 150# Globe Valve DatasheetDocument1 page150# Globe Valve DatasheetVijay GaikwadNo ratings yet

- Piping Class Specification - CNE-001-2006-E-08-M-L-10126Document20 pagesPiping Class Specification - CNE-001-2006-E-08-M-L-10126Mubashir fareedNo ratings yet

- 18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFDocument1 page18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFSantiago GarciaNo ratings yet

- Standard materials for CS900 piping systemDocument5 pagesStandard materials for CS900 piping systemCristobal Leal ArandaNo ratings yet

- Hojas de Cálcuo - PO-040 - ReviewedDocument86 pagesHojas de Cálcuo - PO-040 - Reviewedjuniuni18No ratings yet

- Valve Material Specification A1MDocument9 pagesValve Material Specification A1Mchintan100% (1)

- 167 - 26196-100-V288553-PS02-00163 (001) - Completed FormDocument98 pages167 - 26196-100-V288553-PS02-00163 (001) - Completed Formbaris121919No ratings yet

- Material - Specification Hyundai KC02Document3 pagesMaterial - Specification Hyundai KC02DilermandoNo ratings yet

- ASME Clad Steel Plate SpecDocument6 pagesASME Clad Steel Plate SpecDaison Paul100% (1)

- WAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1Document5 pagesWAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1tope odumboniNo ratings yet

- Cs Globe Valve 600#Document1 pageCs Globe Valve 600#Vijay GaikwadNo ratings yet

- Vtv-3281-Lit-9511-Pp-Drg-026 R2Document4 pagesVtv-3281-Lit-9511-Pp-Drg-026 R2VIVEK TIWARINo ratings yet

- VHM Lu01 Pi SP 001 - Piping Material SpecificationDocument7 pagesVHM Lu01 Pi SP 001 - Piping Material SpecificationchintanNo ratings yet

- VT4E-T-DMPPS-PMB-M-18-0089A VT4E-YR01-P3ZEN-080007 WPS and PQR For Vinh Tan 4 Extension Thermal Power Plant (Rev.B) PDFDocument55 pagesVT4E-T-DMPPS-PMB-M-18-0089A VT4E-YR01-P3ZEN-080007 WPS and PQR For Vinh Tan 4 Extension Thermal Power Plant (Rev.B) PDFHuu Dong HoNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Document3 pagesPURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- C2C Manual Valve Data SheetDocument13 pagesC2C Manual Valve Data Sheetpraveen kumar vengadasamyNo ratings yet

- RefBook Cashco ControlValvesDocument24 pagesRefBook Cashco ControlValvesAksheyNo ratings yet

- Tenses For SpeakingDocument2 pagesTenses For SpeakingIrfan IsmailNo ratings yet

- Adverb of FrequencyDocument1 pageAdverb of FrequencyIrfan IsmailNo ratings yet

- Energies: Stress Analysis of LNG Storage Tank Outlet Pipes and FlangesDocument19 pagesEnergies: Stress Analysis of LNG Storage Tank Outlet Pipes and FlangesrodrigoperezsimoneNo ratings yet

- Energies: Stress Analysis of LNG Storage Tank Outlet Pipes and FlangesDocument19 pagesEnergies: Stress Analysis of LNG Storage Tank Outlet Pipes and FlangesrodrigoperezsimoneNo ratings yet

- Vocab of NATUREDocument1 pageVocab of NATUREIrfan IsmailNo ratings yet

- Tenses For SpeakingDocument2 pagesTenses For SpeakingIrfan IsmailNo ratings yet

- Valve TestingDocument24 pagesValve TestingIrfan IsmailNo ratings yet

- Valve TestingDocument24 pagesValve TestingIrfan IsmailNo ratings yet

- Study CaseDocument11 pagesStudy CaseIrfan IsmailNo ratings yet

- Study CaseDocument11 pagesStudy CaseIrfan IsmailNo ratings yet

- EMKADE EDi Inventory-2016Document31 pagesEMKADE EDi Inventory-2016Renato BarbozaNo ratings yet

- Steam and Steam Condensate PDocument14 pagesSteam and Steam Condensate PDanny BoysieNo ratings yet

- Design and Fabrication of Wedge Milling FixtureDocument28 pagesDesign and Fabrication of Wedge Milling FixturedbzdivikNo ratings yet

- Est - New Pumpests - R5Document89 pagesEst - New Pumpests - R5rajsedasariNo ratings yet

- Avk Gate Valve, Flanged, Pn10/16 06/30-0035: EN 558-2 S.14/DIN F4, DN40-600Document3 pagesAvk Gate Valve, Flanged, Pn10/16 06/30-0035: EN 558-2 S.14/DIN F4, DN40-600Ali AafaaqNo ratings yet

- Liquid Process Piping - Part 5 Valves PDFDocument23 pagesLiquid Process Piping - Part 5 Valves PDFnitin guptaNo ratings yet

- Introduction To Gate Valves and Gate Valve TypesDocument14 pagesIntroduction To Gate Valves and Gate Valve Typesramyatan SinghNo ratings yet

- 45-5C AVK Gate Valve O&SY-Non-UL - ANSI FF - Blue Epoxy - Dated 28-07-2019Document2 pages45-5C AVK Gate Valve O&SY-Non-UL - ANSI FF - Blue Epoxy - Dated 28-07-2019Imtiyaz KhanNo ratings yet

- User Instructions: Installation Operation Maintenance Slab Gate Valve M34Document32 pagesUser Instructions: Installation Operation Maintenance Slab Gate Valve M34Riyan EsapermanaNo ratings yet

- Operation & Maintenance Manual Model Aph Hydraulic ActuatorDocument69 pagesOperation & Maintenance Manual Model Aph Hydraulic ActuatorSasan AbbasiNo ratings yet

- Corrigendum No.1 (Reply To Quieries) For C.A.NO.01-HETAWANEDocument4 pagesCorrigendum No.1 (Reply To Quieries) For C.A.NO.01-HETAWANEpratima jadhavNo ratings yet

- Cast Steel Gate ValvesDocument2 pagesCast Steel Gate ValvesMohamed SalehNo ratings yet

- Total Product CatalogueDocument37 pagesTotal Product CatalogueFARIDNo ratings yet

- CHOKE KILL MANIFOLD - 3.1-16-15k x 4.1-16-10 x 2.1-16-15KDocument2 pagesCHOKE KILL MANIFOLD - 3.1-16-15k x 4.1-16-10 x 2.1-16-15KOP GAMERNo ratings yet

- Resilient wedge gate valves testingDocument4 pagesResilient wedge gate valves testingroxxxNo ratings yet

- S & S ManualDocument75 pagesS & S ManualsambhajiNo ratings yet

- 10-DSRF-N 10K Ductile Cast Iron Gate Valve (Flange Type) TOYO VALVE 37700451 - MonotaRO PhilippinesDocument2 pages10-DSRF-N 10K Ductile Cast Iron Gate Valve (Flange Type) TOYO VALVE 37700451 - MonotaRO PhilippinesFredie LabradorNo ratings yet

- Gate ValvesDocument2 pagesGate ValvesCommunications ShipyardNo ratings yet

- Klinger Marine Bronze Valves: Globe & SDNR Valves - ThreadedDocument64 pagesKlinger Marine Bronze Valves: Globe & SDNR Valves - ThreadedPipolo PippoNo ratings yet

- Valvula Compuerta Una y MediaDocument1 pageValvula Compuerta Una y MediaRobertoNo ratings yet

- School of Maritime Studies Vels University ThalamburDocument5 pagesSchool of Maritime Studies Vels University ThalamburAayush AgrawalNo ratings yet