Professional Documents

Culture Documents

DoR News Letter Vol 25 - Department of Roads

Uploaded by

trilokbist040 ratings0% found this document useful (0 votes)

72 views17 pagesnews

Original Title

DoR News Letter Vol 25 __ Department of Roads

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentnews

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

72 views17 pagesDoR News Letter Vol 25 - Department of Roads

Uploaded by

trilokbist04news

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 17

\._ Progress in Fiscal Year (F-Y) 2076/07

SN] Det as | Tage [Prue |S

1 [Blacktop Read | Km [ 1200 [729 | 60.75

2 [GrwvetRoad | Km [1200 | 757 | x08

3 [Earthen Road | Km | 300 | 368 | 7300

Reconstruction

and

3 |Retubitiation | Km | 200 | 270 | 100

of blackion|

Road

Periods km | =

+ |isitenance | Km | S24 | 360] 687

5 eee ion | Nos} 300 | 210 | 70.00

Financial Progress 36

4. Progress in current FY.

Poush)

[Annual Prosress

N

SN] Devils | Units | 00 | Prowress | PES

[Blacktop Road | Km | 1800 | 96

2 [Gravel Road | Km | 1000 | 330

3 [Earthen Road [Km [soo [152

Reconstruction

and

4 [Renabtiation | xm | 331 | 167 | sooo

of blacktop

roads

«5 |Petiodie .

Ferodie [Km | 729 | tse | tao

Bridge "

6 | ere ion [Nos | 300] 77 | 2567

Financial Progress

Ongoing National Pride Projects under DoR.

‘oval | Physical | Financiat

‘Length | Progress | Progress

km | eo | 06)

SN] Name of Projets

Pashpaal (Mighil)

1 fares ww | 7325 | 7246

2. [PawtHigiway 1792 [| 7oas | 3826

3, | Nowt-South Highway

a) [Katigandaki Corde | 44 [sist [ stot

1) [ Koshi Condor aes [tht 7559

©) [Karna Coridor oa2 [3283 | 7489

Galei-tvshali-

4, [Maitunesyatabes- | 55 | 359 | 3200

Rashuwagadhi Road

Project

6. Falling Weight Deflectometer (FWD)

6.1 Introduction

Millenium Challenge Account Nepal (MCA-Nepal) has

recently provided the Falling Weight Deflectometer (FWD)

equipments to DoR (Fig). FWD is designed to impart a load

pulse Wo the pavement surfae simulating the load produced

byanlling vehicle

wheel. The load

is produced by

dropping large

‘weightontoasctof

rubber buffers on

bracket eannocted

1o 8 eieular lood

plate. Toad cell

‘mounted on tp of

the plate measures

Figl: Falling Weight Defectomeer(PWD) the imparted load

Deflection sensors (geophones) mounted radially ffom the

center of the load plate measures the deformation of the

pavement in response (0 the loa. The pavement response is

‘analyzed with Dynatest'sELMOD (Evaluation of Layer Modul

and Overlay Design) software to determine the elastic moduli,

stresses and strains of each modeled layer based on the impact

Tod and surface delstions basin, ELMOD reports the weakest

layer of filure, residual life and determines the optimum

rehabilitation alematives. The results can effectively be used

for the evaluation of pavement structural condition and overlay

«esign based on empirical or mechanistic ~empirieal pavement

design guides

62. Fewures ofthe Dynatest Felling Weight Deflectometer

= Nondestructive structural testing device operated by

single person

= Automated and rapid structural pavement testing machine

applicable to pavements all over the word

+ Determines the layer” of flue, rather than simply

determining the bearing capacity.

+ Quality assurance and qualiy control of newly built

pavements.

= Compares a range of rehabilitation options, includ

plane off and recycling rather than just applying overlays

= The we of the FWD provides accurate, reproducible and

repeatable strctural dat

= Uses mechanstc-empi

pavement structures.

= The FWD is used worldwide from the hottest ad driest

deserts, tothe humid topics and te cooler Polar Regions

~ Wide leading range (4-120 KN), suitable for testing a

\arioty of paved and unpaved roadways, parking lots and

tril surfaees,

= Accommodating upto 15 deflection sensors (Geophoncs)

+ Upto 60 test points per hour

al analysis applicable to most of

63 Parts ofthe FWD System

FWD System consists of folowing thre parts

a) Trailer Control and Data Collection Electonics

by Field program

©). Software Analysis (ELMOD progrem)

(2), Trailer Control and Data Collection Eketronies

In this stage of FWD system, iis assured that all the pars of

the equipment are fited propery. A single-mass falling weight

buffer subassembly system i famished which directly tansfors

the fall energy of the single falling mass to the loading plate

through the proper configuration of buffers to achieve along

time 0f25 10 30 msec, foranyflling muss and drop height This

loading system is hydraulically operate! and designed so, that,

at lest, four different configurations of mass and rubber buts

may be employed. All mass configurations produce a transient

Toad pulse approximately half sine wave formed and 25 to 30

rmsccin duration, with arise time of 10t0 15 msec forany aling

height for all loads. All measured load and deflection data can

be displayed for comparison purposes (e4., repeatability), and

no “averaging” or semi-frequent data anomalies oceurs. The

esuipment allows up to 15 defletion sensors (geophones) be

‘sed simultancousy

() Field Program

‘With the help of Software DDC (Dynatest Data Colleton) the

required das re colleted i he fed. The Sollware is designed

to operate asa native program in the Windows 10 environment

‘on the system compte. The System Software is GUI (Graphical

Usor Interface) based and allow exible layout and resizable

‘windows. The optional Geographic Position Data (GPS or

DGPS) canbe viewed ina numeric format or the postion viewed

transposed on a map to allow easy identification of postion,

‘One man can bands the field program fitting equipment with

suitable vehicle, The software allows to

Graphical and numerial displays forthe air, mid asphalt

and surface temperature

Plots the lod snd defections time history

Calculates and graphically plots the surface modulus and

Elastic values along a section as the data is collected, 10

allow the operator to assess the dats

Displays the video from an optional camera, mounted to

etermineexoet location while testing on jointed concrete

ravements, removing the requirement to have two display

Sercens within the vehicle eabin

Both voice and text feedback for enor and warning

messages is present in the sofware

(6) Analysis software

After colleting dat, the analysis software, ELMOD, is able to

analyze the FWD data bythe following modules

| A Finite Element Module, FEM, which makes use of an

axial symmetric finite element program

2A Linear Blast Theory (LET) option makes use ofthe

‘Waterways Experiment Staon’s program, (WESLA)

3. The Method of Equivalent Ticknesses (MET)

6.4 Observations and Conctusion:

MCA Nepal have conducted three weeks trining program of

Dynatest Falling Weight Deflectometer with participants from

DOR and Pulchowk Engineering College. The frst week was

dedicated tokaow the equipment adits ats propedly, Partiipants

themselves calibrated equipment withthe help of trainer from

Denmark (Mr. Jan. Winterskoy, Senior Technical Specials)

‘Trainer also aught about the DDC software for collecting the dita

in fild_In sooond week, there was a fed workin Dhankhola

Lamahi-Shivakhola (76 km) section of East West Highway (plot,

projec). Participants took data of lft lane whecl path and right

lane whes! path at every 400m chainage. Afr collecting all

required dat, it was imported in analyzing software ELMOD to

evaluate the road section. AIL the measured raw data imported

fiom DDC sofware tothe ELMOD were overviewed and changed

1 per roquiroment of ELMOD. Pavement layer thickness,

measured temperature, trafic data and thet distributions were

depted according to site condition, Some design parameters are

adopted fom the ASTM and European standard. ELMOD showed

Aitferont responses in different road sections and chainages under

the same design parameter setup. From the results obtained from

this software with proper engineering judgment it was found that

the rad section is inbomiogeneous. In some section, the particular

road bas got severe flue fom sub grade level and in some

section, theres failure in top layer only. Also it shoved that some

Potion ofoad is stifenough to bear the assumed trafic for design

Tie of 20 years

Since it was til atempt for truinces and dere was limite time

to go through the proces, the data measured isonly suitable for

network evel planning. For detail design and recommendation,

further detail investigation and testsin the intervals as suggested

by ASTM, 10 m to 100 m distance is required. But ftom the

‘overview of analysis itcan be said tat the road setion needs

{0 for maintenance and rehabilitation as soon as possible, From

this taining, puneipant gained in depth knowledge of use of

FWD and they have got confident that they ean conduct FWD

test themselves in fate

7. Quality Research and Development Centre

(QRDC)

QRDC has been establishment in DoR in 2019 A.D that

consist of Innovation (Tunnel and Altemative. Transport)

Unit, Research & Development (R & D) Uni, Road Sector

Skill Development Unit (RSSDU}, Central Road Laboratory,

Administration Section al Finance Seetion. On its leadership,

the Consulting Norms for Detail Feasibility Stady of Tunnel

Works and Spesficationsand Norms for construction of Tunnels

in Enginccring, Procurement and Construction (EPC) modality

has been developed and later approved by cabinet. QRDC is

preparing bid document for constuction of Sidababa road

‘tunnel. Similarly feasibility study of Dharan Leu, Khutiya-B.P

Nagar-Dipayal tunne! and Godaworikunda-Kabhre-Mancchour

Tunnel is undergoing. QRDLC has been conducting detail design

of grade separated intersection along ring road, st Gwarko,

Satdbato &¢ Ekunte Kuna Chk

8. Dudhkoshi Motorable Suspension Bridge

£7 tabodacion Dr Bite ish Director, RDC

The bridge ste

is located in

Jayaramghat,

Okhaldhunea-

Khotang border.

The goosle

covondinale of

bridge site is

27°10°36.4"

apaore Fig.1 Google map of bridge site

“The Google image of bridge site is shown in Fig.1. Before

construction of this bridge, there used to be a temporary bailey

bridge in winter season for tafe operation and during summer

season there had been no connectivity. With the completion

of the bridge in 2074 Kartik, the Khotang district has been

linked tothe national rood network. The comtract was awarded

jn 2066(03/23 as a design and build contract. The contactor

was Kalika’ Hulas JV, Mahargjgsnj, Kathmandu, After some

years of coniract award, the highway was declared as Mid-

Hill highway. This is the fist matorable suspention bridge

designed by Nepalese as per IRC loading and constructed by

Nepalese Contractor. Suspension bridge bas unique advantage

in Nepalese topography since the construction does not demand

construction of pier inthe middle of deep channel and work can

be carried ou inal seasons

8.2 Salien features

The elevation and plan of bridge is shown in Fig.2. The salient

feature of bridge is presented below:

Span (L)=122.5 m

Torwer height from road level =14.706 m

Diameter of cable =24 mm

Number of cable each side “19

Diameter of suspender = 40mm

“Truss camber =0.5 m

‘Height of road surface from center line of top chord = 0.5 mn

Width of tower at its bse, along the bridge axis =

Tris length ignoring camer =120:m

CIC spacing of hangars = 6.0

Total number of Hangers = 20

COC Height of truss = 2.50 m

Carriageway:4 25m

Contract amount: NRs, 99,619,000.00

Fia.2 Elevation and plan ofbridae

£3 Design

The bridge is designed a per IRC design code and specification,

Tho main loads considered in design are (i) Dead load ii)

Moving loo (il) Braking load (ivy Wind load (v) Earthquake

Toad. The main design steps are:

(a) Design ofsab

(0) Desian of stringer

(6) Design ofeoss girder

(a) Designo cormecin between stinger and cro gine

(e) Design of main cable

(1) Design of suspender

(2) Design oF eonnection between suspend and tp chord of

(2) Design of pin conection between suspender and main

cable

(i) Design of tfening uss

(i). Design of eonnection of stiffening truss

(&) Design of tower and comeeting beam

(0). Design of anchorage chamber

(om) Design of tower footing (combined footing)

The finite element model is developed in SAP2000 (Fie3)

to find out the internal stresses in different elements. Cables,

towers are modeled with frame elements, deck is modeled with

sholleloment,susponder is modeled with strut clement and

trusses ae modeled with frame element with end release, Linear

static analysis, non-linear sate analysis and response speeitum

analysis as been carried out. The main design features ae:

‘Type of suspension bridge-Stifening suspension bridge

Maximum sag due to sef-weight “11.762 m

Cable hoisting sag-I128m

Design loads: IRC-, live lad: IRC Class A

‘Unimate tensile strength of Main cables, hanger

Factor of safety of eable=3

Grade of reinforcement: 415 Ninn

Grade ofsirvetural sect: 250 Nimam2

1570 Ninn

Fig Finite clment model of ridge

84 Conspuction Sequence

The construction sequence adopted are presented below. The

construction of superstructure portion of bride had been aided

by three Chinese Engincerstechnicians. They spent about 3

months in site assisting forthe following activities.

G) Tower constuction

() Anchorage block construction

(6) Catwalk ope constuction

(@)Sadile placement

(e) Cable hoisting

(1) Hanger placement

(a) Stilfening truss bearing construction

(h)Saifening truss constuction

0) Concrete dock eonstruetion

The constnction sequences and completed bridge are

demonstrated in Fig. There are fer important observations that

sre Ieamt

stilfening truss, the pylon’s movement should be carefully

monitored since it leans towards river while lad increases

‘As soon as it reaches some value as per calculation, the pylon

should be pulled back in position by some moans (b) the sag

should be measured in night in hot places and temperature less

than 25, prefeably between 12 PM

AM.

a sninitn| satan

fuga

Fig Big Consrcton Sequeae

5

85 Conclusion

‘Although ridge construction took long time, succesful

Construction ofthis bridge i the milestone for construction of

‘motorable suspension bridge in Nepal The Nepalese Engincers

has gained a lot of knowledge and confidence alter constructing

this bridge. Ihe replication of construction of such type of

Tide in othe locations is highly commended.

9._Web-based Applications in DOR

1 [Web Server

> [MIS (Financial Management Information System)

[3_[ CMS (Contract Monitoring System)

4 [Progress Monitoring Information System (PMIS)

[5__[ BMIS (Bridge Management Information System)

6

7

o

3

RMIS (Road Inventory Management System)

"ARMP (Ansual Road Maintenance Project)

SSRN (Statistics of Static Road Network)

‘GRMS (Grievance Redress Management Syem)

IS (Emergency Information System)

Distance Calculator

12 [Store Inventory System

Document Management Sytem

‘Central Authentication System

10. Strategic Road Connectivity & Trade

Improvement Project (SRCTIP)

The Goverment of Nepal as reeeived financing from the

‘World Bank toward the cos of Strategic Road Connectivity &

‘Trade Improvement Project (SRCTIP). This project will help

to improve roads of regional importance and set the course

for post COVID-19 economic exovery through greater eros

border trade, more jobs, and better road safety. The Project

will enbance regional road connectivity by improving the

Nagdhungs-Naubise-Mugling and upgrading the Kamala-

Dhulkchar-Pathlaiya road section along East West Highway.

Both are enucial 1 Nepal's connectivity and trade with India

and other countries. The projet will also enkance infiastrucure,

facilities, and sanitation at border erossing points to ease wade

‘onstrints and spur agricultural exports.

The projct wil strengthen the National Road Safety Council

and the Department of Roads and support peri maintenance

of high-tatfic ronds within the Swategic Road Network. It

also includes a contingency emergency response component

to reallocate project finds to support emerpency response and

recovery

The project will reduce the time and cost of moving goods and

boost Nepa's trae, which accounts for about 40 percent ofthe

country’s economic output. The project includes best practices

in safety, climate resilience, rood asset management, gender

equality, socal inclusion and citizen engagement, which the

federal, provincial and local governments can take on.

The project is well-alimed with the past and ongoing efforts

‘of Nepal and is regional partners to achieve the fll potential

fr trade in the eastem sub-region of South Asia. It a part

‘of the World Bank's Eastem Corridor Connectivity Program,

Which since 2013, has Hanced «continually evolving regional

Program to improve connectivity and trade in Bangladesh,

Bhutan, Inia, and Nepal

Projast Development Objestives (PDO) statement ofthe Project

is t0 improve the efficiency and safety of select transport

inffastructure, improve the eliceney of eros-bonder trade, and

strengthen capacity for strategic ad network management in

Nepal

Project Components

The project will hve four components as detuiled below:

Component 1: Trade Facilitation. The objective of this

component is to: (0) reduce the time taken for goods transit

at selecied border crossing points; (i) improve capacity and

eficioney for sanitary and pHyto-sanitary (SPS) management at

selected locations and for targeted products; and (i) enhance

capacity for managing trade.

Component 2: Regional Road Conneetvity. The objective of

this component i to improve efficiency, climate resilience and

salety of movement of goods and people aeross two roads within

‘wo transport corridos tht are key for Nepal's connectivity and

teude with India und ober countries. The component comprises

three sub-componets

(@) Improvement ofthe existing Nagdhunga-Naubise-Mugling

road to t40 lanes, with one-mieter paved shoulders

Upgrading of the Kamale-Dbalkebar Pathliya road from

two lanes to four lanes

A safe corridor demonstration program (SCDP), with

support for toad safety improvement initiatives including

enforcement and pos-crash respomse, covering a length oF

shout 250 km,

‘Support fo implementation, coordination, monitoring and

supervision ofthis Component 2 ofthe Project.

©

cc)

@

Component 3: Institutional Strengthening. The ohjctive of

this component isto improve the capacity for management of

the strategic road networkin Nepal, with afoeus on rad safer,

roall asset management, training and periodic maintenance, 2

well as support for trining of Teal women in finding skilled

employment snd livelihoods, This component comprises tree

sub-components:

(4) Suppoct for the National Read Safety Council through,

ster ale

establishment of an interim seorctarat with seed

funding in the form of sang and equipment; and

support for prioritized activites trom the National

Roid Salty Action Plan (RSAP), including

coordinating, monitoring. and evaluating: measures

lunder the SCDP; monitoring the working of

Management Information Systems and equipment

service provider; supporting nation-wide roll-

ut of the webbased Roed Accident Infomation

Management System (RAIMS); and supporting

traning and poor exchange programs.

Capacity enbiancement of DoR for improved management

of SRN through

(i) development and mainstreaming of the road asset

‘management system:

‘support for taining facilities and traning in selected

priority areas, including network-level safety

assossments, quality, procurement, design of advanced

structures, and management of environmental and

social rsks and impos and

i support for training of local women to find skilled

‘ensployient and livelibood opportunites

Support for periodic maintenance of the Core Road

@

©

w

©

6

Nowrork (CRN).

(4) Support for implementation, coordination, monitoring and

‘supervision of this Component 3 ofthe Project,

(e) ‘Training and placement support for local women i aimed

at supporting the training of 00 women fram the project,

areas, with a target of Facilitation suitable employment or

livelihoods opportunities for $0 participants. The Periodic

maintenance activity is designed to strengthen the capacity

‘of Dok to plan snd undertake works to cover te significant

backlog in periodic maintenance of the SRN, focusing

‘on “high traffic" roads. The project will support periodic

‘maintenance of about 3400 Lane-km of high-traffic roads

‘within the SRN, that would be notified by the Department

‘of Reads as the Core Road Network (CRN)

Component 4: Contingeney Emergeney Response. This

component will provide immediate response 10 an etigible

crisis or emergency s needed, Inthe event of an eligible crisis

or emergency, the World Bank to re-llcate projest fds 10

support emergency response and recover.

(@) Climate related measures. In view of the critical

vulnensbility context, the project will be implementing

4 comprehensive approach ~ fom resilient constuction

‘and maintenance, to improved planning and contingency

planning ~ to increase the efficiency of targeted corridors

‘and reduce negative economic impacts due to climate

‘elated incidents. Other components and activities too will

‘support specific climate related measures

Component-wise Project Costs and Funding from GoN and,

IDAGinS mn)

“oak | IDA | Percent

Comp. [Sub-component | 698] 8) | rrcne

1 [Trade Factitaton | 20 [ 294 | 70%

3 Facies arbordes | a5 Pana | am

points seo | ea |

8 Santayana Phyo =| &

Sanitary Mam ao | 56 | am

= [Keowlege Spon [20 [1a [70

2 | Regional Road 7

ee ine 639.0 | ss0a | 53%

3] Nagthunga-Naatise- |, i

pane | 1740 | rans | to

| Kamal: Dhaba ;

Pathlaya Road | 400 | 2024 | 4%

© Supervision Cons | 200-[ 203 | 70%

a) Land aequsiion,

Resetlment,Utiity | 80 } 00

Shutting

© | Sate Corridor 5

Demonstration Pils | 8° | 8% | 7%

3 [Institutional i

Strengthening pc a

| Suppor for NRSC | 40 | 28 | Tom

wb] Capacity >

enhancement of bor | © | 42 [7%

i Bacio 00 | s60 | 70%

Maintenance

Incremental

Operation Cost jor | 7

4 [eominsaney

Emergency Response

3 _ [Front-end Fest*)

TOTAL,

oo | oo | x

037s | om

won | 450.0

Tos

50%

() Project Financing, IDA credit financing for the project

will be through @ combination of Nepal IDA (USS100

million), Regional IDA (US$200 million, and Seale Up

Faciliy (SUF, USS1S0 million). GoN will nance its

share directly, and ifthe Modified Annuity Model (MAND

Hybrid Annuity (HAM) model is adopted, aso through

deferred payment obligations towards financing from the

private seotor.

IL, Nagdhunga tunnel construction project

11 Project dents

The Goverment of Nepal, Ministy of Physical nfustructure

and Transport, DoR has initiated the study of Nogdhunga

turmel consniction project since Febavary 2013 on the basis of

various phases ofthe survey. The main objective of this project,

is wo improve the ond by constructing a tunel at Nagdhunga

Bhanjyang (Chanragiri Municipality on the east, Kathmandu

Distt and Dhunibost Municipality, Dhading Distt on the

\west) in Narayunghat Muglin Naubise section of the main

road entering the Kathmanda Valley. After the construction of

the proposed tunnel, the condition of the road in Nagdhunga

Bhanjyang will bo improved, 252 result of which the tansport

‘connectivity with other places andmajorcitiesof the country Will

beveliable, efficent, coanomic safe. The main companentsof

the proposed Naguhunga tunnel project are;

) Roads and tunnels

1. Tunnel» Length 2.68 km, 2 lames each with 3.5 m width

1.5 m wide in the middle (Rumble Sti), 0.5 m on both

sides drainage facility. The typical tunnel cross section is

shown in Fig

Approach Road, East - Length 2.32 km, Approach Road

‘West - Length 0.568 km

East Portal/West Portal

Bridges -3 Nos.

Undepass ~2 Nos.

Overpass No.

Flyover ~ No.

Toll structures on both sides.

24 Fes Ventilation (Jet Fan) and Lighting System

10, Drainage Structures

1 Emergency rescue system

12. Telephone Facilites, Fire Hydrants

'b) Control room and operations office

Control roan and operations office are located on both the east

and wos sidos, from where every activity inside and outside the

‘une will be monitored by CCTV and a reseue team will be

‘immediately deployed in case of any emergency.

©) Others

Road Side service center, restrooms, restaurants, parking Its,

shops IIKV Transmission Lin, 4.14 Kim long,

11.2 Financial resources

Aoft oan agreement has ben signed between the Government

‘of Nepal and the Government of Japan on December 22, 2016

for the cansruction ofthe proposed Nagdhunga Tunnel. Oat of

the toil cost of the prjoct oF about Rs. 20.6 billion, the donor

JICA as contributed about Rs. 5.8 billion tha il be provided

through loan with interest ae of 0.01 percent and the remaining

thout Rs 4 billion is tobe borne by the Govemment of Nepal

11.3 Contact details

Name of Consukant: IV of NK-EJEC-NCC in Assocation with

GEOCE & ITECO Nepal

Contractor Name: HAZAMA Ando Corporation, Jann

Contract Agroument Date: September 23, 2019

‘Commencement date: November 14,2019

Construction tobe completed: pei 26,2023

Contract amount: NRS: 5,500.213,019.29

Physical progress 8%

11-4 Ongoing construction work:

1

Excivation of evaeuation tunnel, drilling and blasting

method in West Portal. So far, 138 meters of excavation

work has been done and shotercte and steel ribs support

system has been installed in the excavated tunnels.

Soil cutting, retaining wall constuction, read widening

and embankment filing and diversion canal works are

underway in Dhading section,

Hoth main and evacuation tunnel are being excavated in

to shifts, day ad ght. Sofi, 43 meters of main tunnel

and 36 meters of evacuation tunnel in the cast are being,

excavated where shoterete and steel ribs support system

has also boon installed

Crib walls being constueted for slope protection in East

portal

‘Approach rosd works are constructing on bath East and

‘Wost sides

Overpass, Undespass, and Culvertsare under consivetion.

Water supply related constuction works are underway.

event tunnel photographs and 3D computer model of

portals are shown in Fig. 2

Fig: Typical Cress sesion of Main Tunnel al mensions arin mn)

1S Problems and issues in the construction work

1. Dificulty in approach road construction as locals have not

demolished houses in the Fast (Portal) area even after

compensation. Although discussions with the concemed

locals have yielled positive results, some structures are

yet tobe demolished,

2 A-sub-commines has been formed to sequite land for

consiruction of Balambu Flyover and the process of

fixation ofthe rates inte final stage. Duet the unnatural

‘ate ofthe locals, the sub-committee could not reach a

agreement for a long tim (about 6 month).

(On the eastside (Chandragiti) as in Dhading, there is a

demand foe equal treatment of half of the Guth land

‘compensation to publi.

‘Road Construction materials could not be storod et the

Road Side Service Staton inthe West (Portal area due to

‘theresa ofthe locals to remove houses and tents which

‘were constructed illegally and under investigation by the

authorities,

(2) Cab Walk ast

(vo parle Tunels at East Pore

(6) Mosel of East Port (f) Model of To parle! Tunnels at Eat Petal

Fig2: Receat tunel photowaphs and 3D computse model of portals

9

12, Recent Road Safety Activities

Road Safety and Trafic unit (RSTU) is established in Do to carry out road safety related activities. In Road safety sector, DOR is

responsible for Pillar 2 of Road Safity Action Plan 2013-220. Dedicated budget head i allocated for rad safety works in DoR

and about 300 million rupees is allocated forthe curent fiscal yeu. The major activities tobe performed on Road Safety area sre

construction of Crash Burver, use of Road Markings installation of Trae Signals, contruction of Delineator posts and Railing,

Intersection Improvement, Traffic Studies, Road safety AvdivlInspection etc The wad sofa works cared ou in dilrent highways are

shown in Figs 6.

1 een

Fig6: Bhaaka-Singhdarba Roads

Fig: BaluwatarRoad Fig5: Nats Jetngon Kerbston Else hae

Some activities performed on Road Safety sector inthis EY. O7T/78 are:

(@) ‘Trafic Signal Light maintenance, Installation and operation at 14 Inersections and Installation werk running at ational $

Interscctions with & Pedestrian crossings in Kathmandu Valley.

(©) 6047 Sqm Road Marking works within Road Division Kathmandu, Road Marking and Kerb Stone marking 9.5 km along,

Kalank-Satdobato Koteswor Ring Road om Road Division Lalitpur, about 5.5 km Railing Works installed in Kathmandu

‘alley and About $700 m, W-Bearn Crash Barter along Ghurmi-Okhaldhunga-Sailesi Rood Section from RSTU.

(6) Preparation of Revised Road Safety Action Plan 2021-2030 is in process from MoPIT and procurement of consultant isin

process for Design Review of intelligent Trafic Signal Light System prepared from KSUTP at about 44 locations in Kathmandu

Valley fiom RSTU.

13. The list of National Highways that are approved by the Government of Nepal, Cabinet of Mi

‘on BS. 2076-02-06 are:

Highway Tength

a aie "Name of Roads &

1 [Nol [East-West Matendra) Highway 1028

HG? | Keebn-Chandragadhi-Charaal-lan-Fidia, Gancshohowk-Teplgjung Olamgehungola | 352

(Mech Highway)

3 | Nr103 | Pusipala (wid HID Highway Te

| xrtor | Birtamod-Chandrayadhi-Bhadrepur Mechi bridge 5

5 [Nios [Postal Highway 7016

© _|_NH05 | Chatara-Mulghar-Majhiar-Ararapardands Ganoshchawk (Famor Conder) Bs

7_|_NHO7__[ Pabli:New Koshipul-Rupnagar, Pali Nadaba-Koshipal-Chawa a

S| NHos | Rani-Birtmagar-ttahar- Dharan-Diankua-Hile, Loghuwaghat-TunlinglarKhandwar | 320

Nam-Kimathanka (Koshi Highway)

10

SN fen ‘Name of Roads =

9 | NH09 | Bahundangi-Shantinsgar Dharan-Chatras-Gaighat Katari Sindhulimadi-Hetauda,| — 1200

Gaindakot-Rampur-Ramdi-Ridi-Balkot-Sandhikharka-Bijuwar-Sitalpati-Surkhet

Backichaur-Sanspur-Budar-Jogbodha-Rupal (Madan Bhandari Highway)

TO_[ NAO | Dour udhe-Chainpur- Boba a

T_| NH | Fikal-Shriant-Chabise am o

1_[ N12 | Ghurmi-Chatera-Udaipur 163

13 | _NHI3 | Bandibas-Sindhuli-Khuekot Dhulihel (BP Highway) 160)

14 | _NH14 | Gaighat-Maahuli Khola-Rupani-Kunaul-Rajiry-Chhinnamasta Nivt, Kunaul 100)

Rajbira) Kanchanpur Barrer Fatehchaur-Basaha Udaypur

1S [NHS | Govarko-Lubhu-Lakuribanjyang-Kushadevi-Panawi-Dahaltar

TS_[__NI16 | Thand- Bhapwanpur-Lahan, Kadmahchok-Gaighat- Mahure-Khavpa Sola

17_[_NHI7__| Naubise-Mugin-Pakhara (Prithvi Highway)

TS [_NHIS | BalajucTrishulDhunche-Syaphnubesti

19 _[__Nui9 _[Ridi-Balkor-Hanspur Pyuthan, Pyutban-Surkne road

20 | _NH20__ | Madar-Chaurabawa, Golbuzar Siraba Sanghure Udaipur, Michaija-Katan-Ghurm,

Hilepani-Okhaldhungs Salles

2 [Nit _[Stapail-dtarke 2

22_|__NH22__| Dhatkewar-anakpur Tata, Ghorghans-NimetiurThalhighaAKaraharghat i

23__[_NH23__| Diktel-Solu-Junbensi-Khshone-iri Bazar-Tomakoshi-Charikot-Khadichaue 231

24 [_Nv24 [Talend Ranieas (RT. O. Read) -Bishmat-Bahunmara-B.P. Highyay 29

25_[_N#25 | Durre-Reshiahar-Chame m7

26_[_NH26 [Hamnuninas-Bateshavar Saipar Kurta Fanalpar @.

27_[_NH27 | Stalpat Sayan Kubhinds Raluwa Sanath a0

28 | _NH2S _ | Bhitemod-aleshwar-Bandivas, Khurkot ManthaliTunakoshi-Singit Lamabagar- at

Lapohegaun

2 | NiD9 | Kanchanban-Jenaki Medical College-Mithileshovar SabailaSiraba- Nakai 0

Ramlaxmanchowk-Healthpost Mahendra Highway

30 | NH30__ | Janakpur (Mujelia)-Dhanushedham-Dharapani Ramayana Cicult, TarapaivPalhara 36

MRM Pustpalpur

3 [NAST [Dotaghar Chaar

32_ | Ni52_[Nawalpur-Malasgwa Shona

3 [NIB [Nijgadh-Kethmand

34 [NHB | Kathmanv- Dhulikel-DolalghatKhadichaur Koda (Araniko Highway)

35_[_NH35__| Piluhavva-Mamamat-KalaiyaeMartih

36 [N36 | Chandranigahpur Gaur

37_[_NH37__ | Hetuds-BagmatiTikabhairav-Bhaisepat-Ekantakana (Kaaii Rajpath)

38 [NH | Roundabout outside Kathmanda o

30 | _NH39 | Kathmandu Ring Road 2

40 [NFO | Somakhshi- Toa. Gur Bidar 26

41_|_Niat — [Sisiya-Pathiya, Hetanda-BhaisePalang-Naobise Kathmandu (Tibhuvan Mighway) [155

4 | _NH@2 | Thov-sshandara-Malokha, GalehicTrishul-Bevawati Mailung Syaphrubes wT

Rasuwagndht

8 _[_Nias [Malek Dhading Salvantar 7

4 [Nisa] Thov-Bharstput-Mogling, Aabikiniren-Gorkin-Ghyampesl, AnighatSindiwas Rola | 300

Bhhanjyane

S_[_ Nis [ Khairanitr Bhirmnd Kawasont 106,

46 [Nias rumti-paras °

a7_[_NHA7__| Bolahiva-Bhairahawa Butwal-bhatang- Rama Syangja Pokus (Siduhanha Highway)

as | _NHAS | Tansen-Rigi-Korla

29 [Niro [Bartung Tansen Reid Varialsar Kbarvang

30_[_NHS0__[Fitpur-Toulibava-Khunuwa

n

=| ar a

14, Pile Integrity Testing

14d Introduction

Some information on the frequency of defective bored piles,

identified through NDT inspection, can be taken from the

results of surveys published in the technical Iiterature, Davis

and Dunn (1974) [1] report 9.7% defective out af a ttal 717

piles tested on five projects; Pleming ctl (1985)2] found 15%

000 ples ested and 1.9% detective out

ofa father 4,550 piles tested, Ellway (19873) reports 4.2

detective of total 4,400 piles tested: Thasnanipan etal (1988)

[A}state 3.3% defetive of a total 8,689 piles tsted: Lew et al

(2002) [s]report 7% defective within» population of S80 piles

tested and 15% defective of a total S000 piles tested. Press and

‘Shapiro (1981)[6] sugges that approximately 5% to 10% of the

piles projet could be defective

Obwicusly, there are numerous factors influencing the quality of

the pling work in each case, some of which may be noted re

+ The variability of ground conditions across the ste and

with depth

+ Knowledge of the specific ground conditions gained trom

detailed site investigation

+ Contactor skill and experience with a given pile type

under similar operating conditions

+ Supply ofmateril of eomect quality

+ Appropristeness of consiuction procedures for the

Particular soil and groundwater conditions

+ Level of workmanship and site supervision during

constuction

+ Intensity of programme pressure on the piling work

+ ffets of ground movements and site tific dur

conerete hardening

+ Approprite method and cae in trimming pile head to

cto level

According t0 the ASTM DSS82, pile integrity refers to

‘qualitative evaluation of the physical dimensions, continuity

12

of a pill, and consistency ofthe ple material. ASTM DS882

inyoduees & standard method for integnty testing of ples

and deep foundations using low strain impact. This method

includes generating acoustic waves using a hammer impulse

tnd transmission of acoustic probe waves through the test area

(ie, piles or deep foundations). The transmitted waves are

reflected off boundaries (e. pile toe) and interal anomalies,

reconled by 2 transducer (¢., accelerometer, geophone) on

the tip of pile. The recorded signal is further analyzed using

diferent signal analysis features (e.2., FFT, Low-Pass Filter and

thas become an inherent feature of quality assurance system,

‘Such rapid tests are extied out over and above the traditional

system of load testing (also called routine pile load tess). PIT

is known to analyze acoustic anomalies wih respect to pile toe

level, shaft restraints, over-break,

and zones of poor-quality conrete.

142 PIT Apparatus requirement (ASTM D5882.

‘Accelerometers shall be linear o a least 50g, For DC Device,

device with faqueney response upto5 KHz with less than 348

redvetion of content

ibeate the transducer to an securacy of

High-Pass Filler, et.) to ind out possible anomalies, and pile $% throughout the applicable measurement range

toe for pile length testing. Use of Pile Inegety Testi

300 mm

Fig. 1 Conducting PIT Tet

‘The tess shall be conbvced at $6 places (in no case less than 3 hammer blows; masimum distance hetween hammer snd sensor

should not exceed 300mm to cover the entire section ofthe pile. The typical pile load testing is shown in Fig.

14.3 Theoretical background and application

The time (T) between the str of the hammer blow and the time ofarival of the reletion from the pile toe i measure. The pile

length (L) is caleulated with: L=e-12, where the stress wave velocity (¢ )isknown, where “ea function ofthe pile density “p”

tnd pile mateialmodulus of elasticity “E” €~ Sqrt (Ep). Selection of Wave velocity for tet is shown in Table | and traveling of

stress wave is shown in Fig, 2.

‘Wavelet Representation option 2

To present the mossurng results the time avs (tis scaled to length (depth) (1) axis with L= V2. Due to shaft ction the toe

reflction might be of small magnitude. To make the reflestion visible, the measured signal is amplified. To remave noise fom the

signals filter value ean be applied, The rest of three hanwner blows is shown in Fig. 3

‘Table | Selection of Wave Velocity foe test

Pile Concrete Sirengih, Mpa 20 25 30 =

Modis of Elasticiy,KNimd DAE? 2ENO7 RET TET

Density vin’ 24 2a 24 2A

[Wave Velociy, Ome aes 3476 3868 305

Adopted Wave Velosiy, Cus 3100) 3500 3000) 3700

3

Rew | Tass Ll | |)

eae

vave [ro | | | tet | — hicaton pie

or 7

ta a

Wave

velonty Filer valve

Leng }— | Aretiaton

as || 139 | | 424

= ee

corecen

ae Ta ‘re

20 cy

vr.

Program

Version

Fig. 3 Reslt of tee hammer blows

sity testing analysis is based on the one dimensional stress wave they, Ref

(discontinuities) travel to the pile top and are recorded and analyzed, The impedance Z is defined as

Z=AV(E-p) or EAC, In which, A= cross sectional area of pile

Any change in A, E,orp ora combination of them will enerte a reflection rom an impedance change (discontinuity). Te intensity

ofthe defect is quantifid in terms ofthe paranicter defined as Z1/22. Classification of defects could be made based on the vale

‘of B (Rausche & Goble, 1979) [7h shown in Toble 2 and typical refletograns are shown in Fig. 4, The suggested valve to input

dhring PIT tests are shown in Table 3

‘Table 2 Defex classification

pane Damage assesment

10 Uniform

O80 Sight

06-08 Dani

06 Pie witha major discomtinuiyy

PILE PROFILE, DESCRIPTION REFLECTOGRAM

ee

a otto ete renee |

Co eet ree

retainer

So

Fo | reed tpn soe

a recreate |

— evens | were eee ey

ee Ni

sane +t

Tie {Type Reaogr

“4

‘Table 3 The suggested value to input during PIT

Wavelet Im

MD 20% oF Pile Length

MA Pile Length

Ti Pass Filter 0

Tse of LO Pass filter i discouraged, Soild

144 Conclusion

Integrity testing is based on the stress wave propagation concept

and reflection theory. A stress wave gonerated by a hammer

impact ina uniform rod is reflected if the wave encounters an

impedance change ora strong soil effect. A strcturally sound

tnd generally uniform diameter shaft is indicated by election

fom the ile toe with only minor variations in the velocity record

amplitudes between the times of impact and toe reflection. A.

sound shat also indicated by negative velocity elections

‘which are often caused by so-called bulges where softer soils

or auger wobble allow for an enlargement ofthe pile diameter.

An impedance reduction is indicated by a positive velocity

reflection before the pile toe, This can indicate a reduction in

shut cross section such as from u void, soil inclusion, neck

in, or eack,Itcan also indicate reduction in elastic modulus

hich conld be de to poor concrete quality, ot sol or ground

water mixing during installation

‘Slape Sailization work t BP highway

References

1

5. Photographs of some major works in recent years

Davis AG and Dunn CS (1974) From theory to feld

experience with the non-destrctve vibration testing of

piles, Procoedings of the Institution of Civil Engineers,

Vol. $7, Par 2, ps71-893

Fleming WGK, Weliman AJ, Randolph MP and Elson WK

(1585) Piling engincering, Sumey University Press

Ellway K (1987) Practical guidance on the use of integrity

ty control of cast inst piles, Proceeding

of the fist imernational conference on foundations and

tuonels.London, p228-234.

Thasnanipan N, Maung AW and Baskaran G (1988) Sonic

integrity test om piles foundedin Bangkok subsoil signal

characterises and their inerpretations, Proceedings of

the Fourth Interational Conference on Case Histories in

Gootcchnical Engineering, StLouis, Missouri, 9-12 March,

086-1092,

Lew M, Zaoorin C3 and Carpenter LD (2002) Integrity

testing of drilled piles for tall buildings, Structure

Magazine, National Council of Structural Engineers and

the ASCE, Ostobor 2002

Preiss K and Shapiro J (1979) Staisical estimation

of the umber of ples to be tested ona project, RILEM

Commission on Non-Destructive Testing, Stockolm,

Rausche, F, and GobleGG, 1979. Determination of

pile damage by top messurements. Beluvior of Deep

Foundations ASTM,SPT 670,American Society for Testing

and Materals:500-506

Dhobitola Newark Ach Beda Kathmatd (50m span)

Chief Advisor :Asjun Tung Thape, DG

Advisors: Shiva Prasad Nepal, DDG

Dipak Shrestha, DDG

Bhimayjun Adhikar, DDG

Ram Har Pokharel, DDG

BBhuvwan Adhikari, DDG

Editorial Board

Chet Bator : De. Bijaya ashi, Director

ators: Krishna Neth Ojha, SDE

Laxmi Dutt Bhatia, SDE

‘ibendra Mishra, SDE

+ Saurabh Bujacharya, SDE

Jigesh Prasad Chaudhary, Er.

h DoR Newsletter Vol 26

16

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 1425 5374 1 PBDocument9 pages1425 5374 1 PBtrilokbist04No ratings yet

- Assessment of Surface Friction Characteristics For EgyptianDocument15 pagesAssessment of Surface Friction Characteristics For Egyptiantrilokbist04No ratings yet

- ESAL and Axle LoadingDocument4 pagesESAL and Axle Loadingtrilokbist04No ratings yet

- Air Transportation and Its Impact Upon The Tourism Industry of NepalDocument43 pagesAir Transportation and Its Impact Upon The Tourism Industry of Nepaltrilokbist04No ratings yet

- Air Passenger Demand Model (APDM) : Econometric Model For Forecasting Demand in Passenger Air Transports in NepalDocument6 pagesAir Passenger Demand Model (APDM) : Econometric Model For Forecasting Demand in Passenger Air Transports in Nepaltrilokbist04No ratings yet

- Planning Lessons Why Planning and Preparing Are ImportantDocument35 pagesPlanning Lessons Why Planning and Preparing Are Importanttrilokbist04No ratings yet

- Bioengineering in India-ID - Mizoram - Final - For - PrintDocument12 pagesBioengineering in India-ID - Mizoram - Final - For - Printtrilokbist04No ratings yet

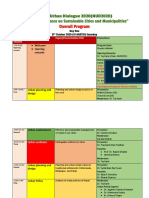

- (FINAL) NUD2020 Schedule 31st Oct-1st NovDocument9 pages(FINAL) NUD2020 Schedule 31st Oct-1st Novtrilokbist04No ratings yet

- Paper Title: Authors Name/s Per 1st, Authors Name/s Per 2ndDocument6 pagesPaper Title: Authors Name/s Per 1st, Authors Name/s Per 2ndtrilokbist04No ratings yet

- TF - CSE Referencing GuideDocument15 pagesTF - CSE Referencing Guidetrilokbist04No ratings yet

- Stone Masonry For StructuresDocument8 pagesStone Masonry For Structurestrilokbist04No ratings yet

- Bituminous CoursesDocument16 pagesBituminous Coursestrilokbist04No ratings yet

- Impact of Covid-19 On Budget Implementation at Gaindakot Municipality, NepalDocument8 pagesImpact of Covid-19 On Budget Implementation at Gaindakot Municipality, Nepaltrilokbist04No ratings yet

- Earthwork and Drain ConstructionDocument34 pagesEarthwork and Drain Constructiontrilokbist04No ratings yet

- Sub-Base, Base and ShouldersDocument10 pagesSub-Base, Base and Shoulderstrilokbist04No ratings yet

- Specif 1Document8 pagesSpecif 1trilokbist04No ratings yet

- Gales Traverse TableDocument1 pageGales Traverse Tabletrilokbist04No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)