Professional Documents

Culture Documents

IJAERS 1220194 APick

IJAERS 1220194 APick

Uploaded by

AHMED ghribiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IJAERS 1220194 APick

IJAERS 1220194 APick

Uploaded by

AHMED ghribiCopyright:

Available Formats

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-6, Issue-12, Dec- 2019]

https://dx.doi.org/10.22161/ijaers.612.43 ISSN: 2349-6495(P) | 2456-1908(O)

A Pick and Place Task with an KUKA Industrial

Robot, Aided by an Arduino Board

Rodrigo Barbosa Tudeschini1, Raphael Barbosa Carneiro de Lima1, Luiz

Flavio Martins Pereira1, Álvaro Manoel de Souza Soares1,2

1Mechanical Engineering Department, University of Taubate, Brazil

alvaro@unitau.br

2São Paulo University (Unesp), School of Engineering, Guaratinguetá, Brazil

alvaro.soares@unesp.br

Abstract— Work with industrial robots is a very challenge task. Those kinds of robots, usually, have an

architecture very difficult to interact with and their programming language is not quite friendly. In the Robotics

Laboratory of the Taubaté’s University, we have an industrial robot KUKA KR 6 R900 Sixx. In order to develop

some research with focus in the robotics field and the applications of robotics in the industry we propose the

development of these work, which has the idea to interact an industrial robot with a low-cost board (Arduino) to

perform a pick and place task. To do so, we assembled an experimental setup, where a two-finger shape claw

mounted on the end effector of the robot and controlled by an Arduino board, was used to pick an object and

place it in a known position. The robot and the Arduino board are linked by the Kuka control unit, using digital

ports in the PWM mode. After few tests and analyzing the results, we consider the performance of the system

quite good.

Keywords— KUKA, industrial manipulator, Arduino, robotics, pick and place,

I. INTRODUCTION system is continuously learning, the behavior of the robot

The pick and place task are very common, considering can always be adapted by the human interacting with it.

industrial robots. In Saut, J. et all (2010), the authors The idea of moving a robot in an environment, with

propose a planning framework to deal with the problem sensors, can allow the manipulator to develop tasks in

of computing the motion of a robot with dual arm/hand, closed loop, avoiding obstacles and changing its path at

during an object pick-and-place task. They considered the any time. Connecting a camera to a Kuka robot, for

situation where the start and goal configurations of the example, enables the robot to observe the environment

object constrain the robot to grasp the object with one and react responsively. The low-level information

hand, to give it to the other hand, before placing it in its captured by the camera, namely the pixels, can be

final configuration. transformed into a certain meaningful signal that

In H. Işıl Bozma, M.E. Kalalıoğlu, (2012), the authors constantly informs the robot’s motion. In Sanfilippo, F. et

consider the problem of multirobot coordination in pick- all (2015) the authors discuss a Java open-source cross-

and-place tasks on a conveyor band. The robot team was platform communication interface, JOpenShowVar, to

composed of identical robots with mutually exclusive, but Kuka industrial robots. The novel interface developed,

neighboring workspaces. The products were fed in at one allows to read and write, using the controlled

end of the band, move through each workspace manipulator, variables and data structures.

sequentially until being picked up and were collected at JOpenShowVar, which is compatible with all the Kuka

the other end—if not picked up interim. industrial robots that use KUKA Robot Controller version

In Rengerve, A. et all (2011), the authors present a 4 (KR C4) and KUKA Robot Controller version 2 (KR

bio-inspired neural network used in a robot to learn arm C2), runs as a client on a remote computer connected with

gestures demonstrated through passive manipulation. The the Kuka controller via TCP/IP. Even though only soft

neural network allowed the robot to plan arm movements real-time applications can be implemented,

according to activated goals. The model was applied to JOpenShowVar opens up to a variety of possible

learning a pick-and-place task. The robot learned how-to applications, making the use of various input devices and

pick-up objects at a specific location and dropped them in sensors as well as the development of alternative control

two different boxes depending on their color. As the methods possible.

www.ijaers.com Page | 398

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-6, Issue-12, Dec- 2019]

https://dx.doi.org/10.22161/ijaers.612.43 ISSN: 2349-6495(P) | 2456-1908(O)

In Safeea, M. and Neto, P. (2019), the authors present III. THE EXPERIMENTAL SETUP

a tutorial of the KUKA Sunrise Toolbox (KST), a To perform the pick and place task, we attach at the

MATLAB toolbox that interfaces with KUKA robot end effector a two-finger shape claw (Figure 3)

Sunrise.OS. KST contains functionalities for networking, which is controlled by an Arduino UNO R3 board. The

soft control in real time, point-to-point motion, parameter claw has a servomotor which is wiring to an Arduino’s

setters/getters, general purpose, and physical interaction. PWM port.

The toolbox includes approximately 100 functions and

runs on a remote computer connected with the KUKA

Sunrise controller via Transmission Control

Protocol/Internet Protocol (TCP/IP). The potentialities of

the KST are demonstrated, by the authors, in nine

application examples.

In this work, we propose a very simple way to control

a pick and place task, performed by an industrial Kuka

robot KR 6 R900 Sixx, aided by a low-cost board, in an

attempt of to simplify the communication between

industrial robots and its environment allowing the Figure 3 - Claw attached at the robot end effector

simplification of robot’s operations. The Arduino board is programed to open and close

que claw, depending on a command received by the

II. THE ROBOT KUKA KR 6 R900 SIXX Arduino, sending by the robot, through its KR C4

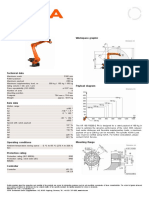

The robot KUKA KR6 R900 SIXX AGILUS controller device. The KR C4 controller has about sixteen

(Fig.1(a)) is a small industrial robot that features high digital available ports, which can be accessed via the KSS

work speed, with high precision in the activities (Kuka System Software).

performed. Can be used handling, loading and unloading

activities, and many others. At the Robotics Laboratory of IV. DEVELOPMENT OF A SIMPLE

the University of Taubaté, this robot is being used in COMMUNICATION PROTOCOL

postgraduate research activities focused on robotic The KSS (KUKA System Software) includes basic

control. Table 1 summarizes the robot information and functions such as trajectory planning or input/output

figure 1 presents the robot model referred to in this management. In addition, advanced features are already

article. integrated in KSS. These features offer many possibilities

Table 1 – Robot information in robot programming, including access to the controller

KRC4 digital ports.

The Arduino board works with voltages from 0 to 5V,

making it incompatible to use the direct signal from the

robot's digital ports - which are from 0 to 24V with 0.5A

of current. Thus, a conditioning and protection board was

designed to receive the 24V signal from the robot and

The robot working envelope is shown in Figure 1 (b) convert it to 5V, using an LM7805 IC, which is a tension

and clarifies the reach of the robot, during its operations. regulator, that will be connected to one of the Arduino's

The dimensions are in mm. digital input ports protected by a 4N35 opto-coupler (Fig.

4).

Fig.4 – Input signal conditioner

The figure 5, shows the scheme of the hardware used

in this work. The robot, initially, moves to a known point

Fig.1 - KUKA robot in its work space, and stop in this point for a few seconds.

www.ijaers.com Page | 399

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-6, Issue-12, Dec- 2019]

https://dx.doi.org/10.22161/ijaers.612.43 ISSN: 2349-6495(P) | 2456-1908(O)

After it stops, it sends a 24V signal to a digital port on the mounted, on the robot’s end-effector, we performed the

KR C4 controller. This port will be wired at the pin 1 of robot calibration to include the end-effector in the robot

the voltage regulator, LM7805. kinematics. After that the industrial robot was able to

interact quite fine with its work space. The robot was able

to execute several pick and place tasks and the

communication protocol shown no problems in exchange

signals with the Arduino Uno board.

With this improvement, we can program the robot to

execute more complicated tasks, obeying a control

The voltage regulator, coupled to the opto-coupler strategy executed by the Arduino board.

4N35, sends to the Arduino board, port 3, a 5V signal.

When the Arduino board reads this signal, it will close the REFERENCES

claw, acting in Arduino’s PWM port 3. After that, the [1] J. Saut, M. Gharbi, J. Cortés, D. Sidobre and T. Siméon,

robot moves to another known position in its work space, "Planning pick-and-place tasks with two-hand regrasping,"

stops for a few seconds, and sends a 0V signal to a digital 2010 IEEE/RSJ International Conference on Intelligent

Robots and Systems, Taipei, 2010, pp. 4528-4533.

port on the KR C4 controller. When the Arduino board

[2] H. Işıl Bozma, M.E. Kalalıoğlu, Multirobot coordination in

reads this signal, it will open the claw, acting in pick-and-place tasks on a moving conveyor, Robotics and

Arduino’s PWM port 3. Those steps will be repeatedly Computer-Integrated Manufacturing, Volume 28, Issue 4,

executed, putting the robot in a pick and place task. 2012, Pages 530-538, ISSN 0736-5845,

Once the setup was assembled, we developed a simple https://doi.org/10.1016/j.rcim.2011.12.001.

program, off-line, which is shown in figure 6. [3] Antoine de Rengervé, Julien Hirel, Mathias Quoy, Pierre

Andry, Philippe Gaussier. On-Line Learning and Planning

in a Pick-and-Place Task Demonstrated Through Body

Manipulation. IEEE International Conference on

Development and Learning (ICDL) and Epigenetic

Robotics (Epirob), Aug 2011, Frankfurt am Main,

Germany. pp.1-6, ff10.1109/DEVLRN.2011.6037336ff.

ffhal-00631114f.

[4] F. Sanfilippo, L. I. Hatledal, H. Zhang, M. Fago and K. Y.

Pettersen, "Controlling Kuka Industrial Robots: Flexible

Communication Interface JOpenShowVar," in IEEE

Robotics & Automation Magazine, vol. 22, no. 4, pp. 96-

109, Dec. 2015. doi: 10.1109/MRA.2015.2482839

[5] M. Safeea and P. Neto, "KUKA Sunrise Toolbox:

Interfacing Collaborative Robots With MATLAB," in

IEEE Robotics & Automation Magazine, vol. 26, no. 1, pp.

91-96, March 2019. doi: 10.1109/MRA.2018.2877776

Fig.6 – Program developed to perform the pick and

place task

V. CONCLUSIONS AND FURTHER WORK

The integration proposed in this work, worked very

well. After the installation of the two-finger shape claw

www.ijaers.com Page | 400

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- KR210-R2700 Extra enDocument383 pagesKR210-R2700 Extra encabecavilNo ratings yet

- Kuka Sunriseos IIWADocument557 pagesKuka Sunriseos IIWAAgus Perales CuestaNo ratings yet

- BA VKR C4 TVW enDocument237 pagesBA VKR C4 TVW enemersonNo ratings yet

- Enhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionDocument6 pagesEnhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionIJAERS JOURNALNo ratings yet

- Climatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninDocument8 pagesClimatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninIJAERS JOURNALNo ratings yet

- Beef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaDocument7 pagesBeef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaIJAERS JOURNALNo ratings yet

- Impacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicDocument7 pagesImpacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicIJAERS JOURNALNo ratings yet

- Analysis Damage To The Inpres Elementary School Building Village Asilulu Central Maluku RegencyDocument5 pagesAnalysis Damage To The Inpres Elementary School Building Village Asilulu Central Maluku RegencyIJAERS JOURNALNo ratings yet

- Analysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingDocument11 pagesAnalysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingIJAERS JOURNALNo ratings yet

- Breastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewDocument16 pagesBreastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewIJAERS JOURNALNo ratings yet

- Playfulness in Early Childhood EducationDocument7 pagesPlayfulness in Early Childhood EducationIJAERS JOURNALNo ratings yet

- Associativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMDocument9 pagesAssociativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMIJAERS JOURNALNo ratings yet

- Komla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)Document9 pagesKomla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)IJAERS JOURNALNo ratings yet

- Business Logistics and The Relationship With Organizational SuccessDocument4 pagesBusiness Logistics and The Relationship With Organizational SuccessIJAERS JOURNALNo ratings yet

- The Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaDocument4 pagesThe Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaIJAERS JOURNALNo ratings yet

- Study of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractDocument8 pagesStudy of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractIJAERS JOURNALNo ratings yet

- Childhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationDocument12 pagesChildhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationIJAERS JOURNALNo ratings yet

- Constructed Wetlands: Technology For Removing Drug Concentration From WaterDocument12 pagesConstructed Wetlands: Technology For Removing Drug Concentration From WaterIJAERS JOURNALNo ratings yet

- VCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodDocument6 pagesVCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodIJAERS JOURNAL100% (1)

- Water Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaDocument11 pagesWater Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaIJAERS JOURNALNo ratings yet

- Sociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilDocument9 pagesSociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilIJAERS JOURNALNo ratings yet

- Morphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaDocument9 pagesMorphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaIJAERS JOURNALNo ratings yet

- Design and Building of Servo Motor Portable Coconut Peller MachineDocument5 pagesDesign and Building of Servo Motor Portable Coconut Peller MachineIJAERS JOURNALNo ratings yet

- Process Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47Document5 pagesProcess Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47IJAERS JOURNALNo ratings yet

- Multiprofessional Care For A Patient With Gestational DiabetesDocument12 pagesMultiprofessional Care For A Patient With Gestational DiabetesIJAERS JOURNALNo ratings yet

- Does Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyDocument12 pagesDoes Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyIJAERS JOURNALNo ratings yet

- Mining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaDocument7 pagesMining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaIJAERS JOURNALNo ratings yet

- Association of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixDocument15 pagesAssociation of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixIJAERS JOURNALNo ratings yet

- Modeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilDocument5 pagesModeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilIJAERS JOURNALNo ratings yet

- Humanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveDocument12 pagesHumanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveIJAERS JOURNALNo ratings yet

- Assessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsDocument13 pagesAssessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsIJAERS JOURNALNo ratings yet

- The Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsDocument8 pagesThe Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsIJAERS JOURNALNo ratings yet

- Detection and Control of Bacterial BiofilmsDocument15 pagesDetection and Control of Bacterial BiofilmsIJAERS JOURNALNo ratings yet

- Model-Based Hardware in The Loop Control of CollabDocument7 pagesModel-Based Hardware in The Loop Control of CollabquNo ratings yet

- Cobots 20190403Document76 pagesCobots 20190403Colin DanielNo ratings yet

- User Manual For The Kuka Krc4 Hex Sensor Kit E9 enDocument31 pagesUser Manual For The Kuka Krc4 Hex Sensor Kit E9 enMuntean VladNo ratings yet

- KST ForceTorqueControl 30 en PDFDocument75 pagesKST ForceTorqueControl 30 en PDFRoger MorescoNo ratings yet

- KRC4 Device Net ConfigurationDocument41 pagesKRC4 Device Net ConfigurationPatrykNo ratings yet

- KUKASystemSoftware ENDocument3 pagesKUKASystemSoftware ENdommegekke1No ratings yet

- Sriram 3Document3 pagesSriram 3avinash14 neereNo ratings yet

- Kuka Control PanelDocument6 pagesKuka Control PanelGiuliano Martelli100% (1)

- Teach PendantDocument1 pageTeach PendantTuấn TúNo ratings yet

- Ba KR 16 Arc HW enDocument207 pagesBa KR 16 Arc HW enBerkanBağNo ratings yet

- Series 2000: The All-Rounders in The High Payload RangeDocument4 pagesSeries 2000: The All-Rounders in The High Payload RangeNahuel Rm100% (1)

- PurchoreDocument3 pagesPurchoreMohamed abd elraoufNo ratings yet

- Katalog 2015 CNC GB PDFDocument124 pagesKatalog 2015 CNC GB PDFregeniusNo ratings yet

- KR180R3200-2PA SpecDocument1 pageKR180R3200-2PA SpecNgoctien BuiNo ratings yet

- Tc3 Robotics Mxautomation: ManualDocument132 pagesTc3 Robotics Mxautomation: ManualArūnas TalvaševičiusNo ratings yet

- KUKA SunriseFRI 116 enDocument62 pagesKUKA SunriseFRI 116 enMatyas TakacsNo ratings yet

- PF0060 KR QUANTEC Pro en PDFDocument2 pagesPF0060 KR QUANTEC Pro en PDFdanipopa_scribdNo ratings yet

- KUKA Datenblatt FlexFELLOW enDocument2 pagesKUKA Datenblatt FlexFELLOW enMarincean MihaiNo ratings yet

- KST CNC 20 enDocument61 pagesKST CNC 20 enJose Ortiz MerinoNo ratings yet

- Kuka PB Palettierer enDocument13 pagesKuka PB Palettierer ensoniaNo ratings yet

- Quanser Robotics Platforms BrochureDocument8 pagesQuanser Robotics Platforms BrochureAdriano Nogueira DrumondNo ratings yet

- KST CRArcTech Digital 32 enDocument65 pagesKST CRArcTech Digital 32 enRodrigo CaldeiraNo ratings yet

- 1165 Kuka KR 30 3 Robot Adatlap PDFDocument4 pages1165 Kuka KR 30 3 Robot Adatlap PDFRafael González ChacónNo ratings yet

- Kuka Robotics Low PayloadsDocument25 pagesKuka Robotics Low PayloadsManuel Alejandro AVNo ratings yet

- Kuka Catalogue of Ideas2010Document79 pagesKuka Catalogue of Ideas2010Vignesh DeepNo ratings yet

- Kuka Case Study Report PagesDocument32 pagesKuka Case Study Report Pagespruma.ruNo ratings yet

- Cararacteristicas Kuka Agilus KR3Document1 pageCararacteristicas Kuka Agilus KR3flavioscrNo ratings yet