Professional Documents

Culture Documents

Upgrade Biogas

Uploaded by

Harsh GutgutiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Upgrade Biogas

Uploaded by

Harsh GutgutiaCopyright:

Available Formats

[Katare* et al.

, 5(7): July, 2016] ISSN: 2277-9655

IC™ Value: 3.00 Impact Factor: 4.116

IJESRT

INTERNATIONAL JOURNAL OF ENGINEERING SCIENCES & RESEARCH

TECHNOLOGY

BIOGAS PURIFICATION & ENRICHMENT THROUGH STEPPED SCRUBBING

Suryansh Katare*, Prof. Dal Chand Rahi

* M.E. Environmental Engineering, Civil Engineering Department, Jabalpur Engineering College,

Jabalpur R. G. P. V. University, Bhopal, India

Asst. professor, Civil Department, Jabalpur Engineering College, Jabalpur R. G. P. V. University, Bhopal,

India

DOI: 10.5281/zenodo.57872

ABSTRACT

Biogas is produced by anaerobic digestion of degradable wastes such as cattle dung, poultry droppings, municipal

solid waste, sewage water, etc. This anaerobic decomposition causes evolution of Biogas contain Methane, Carbon

Dioxide, Hydrogen sulphide, and water vapor, Since the raw biogas have low calorific value and low intensity for

ignition due to the presence CO2 , H2S and water vapor. Hence it is needed to enrich biogas by removing these

undesirable gases to save compression energy and space in bottle and corroding effect, which can be done by stepped

scrubbing. The scrubbing system is found to enrich methane about 95 % or more depending upon biogas inlet and

water injection pressure. Biogas can be used for all applications designed for natural gas, assuming sufficient

purification.ie: by extraction and separation of these impurities by scrubbing process, we can purify and enrich the

percentage of CH4 in raw biogas make its compression and bottling enable. Biogas can be converted in bio CNG

after enrichment and bottling LBG, it becomes just like CNG.

KEYWORDS: Liquefied Biogas (LBG), BV- ball valve. NRV- non return valve, PG -pressure gauge, MB - manifold

block.

INTRODUCTION

Upgraded biogas is a renewable energy source which can help both in waste management and in building a clean and

sustainable environment. This technology is an economically viable option for biogas produced at medium to large

scales. The purity of biogas can be achieved up to 90% Methane and this objective can corroborated through the

stepped scrubbing process. The purified biogas is equivalent /similar to CNG. The purified biogas is filled in CNG

cylinder and supplied for various purposes such as cooking & heating etc. Calorific value of purified biogas is

equivalent / similar to CNG. As a matter of fact, the biogas bottling plants are one of the most potent tools for

mitigating climatic change by preventing black carbon emission from biomass chulha since biogas is used as a cooking

fuel and methane emissions from untreated cattle dung and biomass wastes are also avoided. The purified biogas can

be bottled in CNG cylinders and wherever CNG is currently used, biogas bottling can be used as an alternative.

The slurry which comes out of the biogas plant is directly or after drying used as bio/organic manure for improving

soil-fertility and reducing use of chemical fertilizers. It is also non-pollutant because it is free from weed-seeds, foul

smell and pathogens. The slurry is rich in main nutrients such as Nitrogen, Potassium and Sodium (NPK) along with

micronutrients - Iron & Zinc etc. As such there is no pollution from biogas plant. The slurry/manure of biogas plant

is being sold to the farmers and used in liquid/solid form by them in agricultural crops. The field trials have indicated

the excellent growth in agro-production and substantial improvements in the quality.

Biogas is non-toxic, color less and flammable gas. It has an ignition temperature of 650 - 7500C. Its density is 1.214kg/

m3 (assuming about 60% Methane and 40% CO2). Its calorific value is 20 MJ/m3 (or 4700 kcal.). It is almost 20%

lighter than air. Biogas, like Liquefied Petroleum Gas (LPG) cannot be converted into liquid state under normal

temperature and pressure. It liquefies at a pressure of about 47.4 Kg/cm2 at a critical temperature of -82.10c. Removing

http: // www.ijesrt.com © International Journal of Engineering Sciences & Research Technology

[795]

[Katare* et al., 5(7): July, 2016] ISSN: 2277-9655

IC™ Value: 3.00 Impact Factor: 4.116

carbon dioxide, Hydrogen Sulfide, moisture and compressing it into cylinders makes it easily usable for transport

applications & also for stationary applications. Already CNG technology has become easily available and therefore,

bio-methane (purified biogas) which is nearly same as CNG, can be used for all applications for which CNG are used.

Purified biogas (bio-methane) has a high calorific value in comparison to raw biogas.

GENERAL BIOGAS PROPERTIES GENERAL BIOGAS COMPOSITION

PARAMETERS VALUE S. No. BIOGAS COMPONENT %

3

Calorific value 1 CH 50-60

20MJ/m 4

3

Density 2 CO 30-40

1.214 kg/m 2

It liquefies at pressure 200 bar 3 H 5 - 10

2

0

Critical temperature 4 Moisture 0.5-1.0

82 C

5 HS 0.3

2

METHODOLOGY

The biogas scrubbing system consists of three units: Carbon dioxide (CO2) removing unit, Hydrogen sulphide (H2S)

removing unit, and moisture trapping unit. The three units are interconnected with plastic hoses. In the purification

process of biogas which was conducted; pure water, steel wool, and an adsorbent material (silica gel) were used. The

water is to reduce the percentage of carbon dioxide, steel wool is to react with the hydrogen sulphide and the silica

gel is to reduce the presence of water vapor in the purified biogas. The experiment was done by taking the raw biogas

with pressure builds up in the digester head and passes into the water scrubbing unit for CO separation, further the

2

raw biogas forced through the steel wool on its way to the biogas scrubber unit to remove H2S.

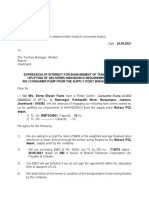

Fig 1: Typical arrangement of biogas enrichment plant.

BV- Ball Valve, NRV- Non Return Valve, PG – Pressure Gauge, MB – Manifold Block

The Scrubbing unit consists of the following sub units;

http: // www.ijesrt.com © International Journal of Engineering Sciences & Research Technology

[796]

[Katare* et al., 5(7): July, 2016] ISSN: 2277-9655

IC™ Value: 3.00 Impact Factor: 4.116

1. CO separation unit. 2. H S separation unit. 3. Moisture separation unit.

2 2

The function of each unit is as follows:

CO Separation Unit.

2

When carbon dioxide dissolved in water carbonic acid (H 2CO3) is formed. It is a weak acid.

H2O + CO2= H2CO3

The liquid leaving the scrubbing unit will thus contain increased concentration of carbon dioxide, while the gas leaving

the scrubbing unit will have an increased concentration of methane. The purified biogas that was collected at the top

of the scrubber unit has some water vapors. Water vapor is the leading corrosion risk factor. To reach water contents

as low as in the purified biogas, silica gel was used in this experimental set up. Silica gel is a material that has a

capability of absorbing moisture.

CO Scrubber also consist limestone bedding since limestone crystals are used to remove carbon dioxide. Carbon

2

dioxide reacts with Limestone to form calcium carbonate.

CaO + CO = CaCO

2 3

Fig 2: Schematic view of the CO Wash

2

H S Separation Unit:

2

Hydrogen sulphide is removed by using catalyst iron oxide in the form of oxidized steel wool or iron turning from any

workshop. Once biogas comes in contact with this wool, iron oxide is converted into elemental Sulphur.

2Fe O + 6H S = 2Fe S + 6H O

2 3 2 2 3 2

2Fe S + 3O = 2Fe O + 6S

2 3 2 2 3

http: // www.ijesrt.com © International Journal of Engineering Sciences & Research Technology

[797]

[Katare* et al., 5(7): July, 2016] ISSN: 2277-9655

IC™ Value: 3.00 Impact Factor: 4.116

Fig 3: Hydrogen Sulphide Remover

a) Steel wool before scrubbing b) Steel wool after scrubbing

Fig 4: Steel wool before and after scrubbing

Moisture separation Unit:

Finally the biogas is passed through a moisture separation unit. Here silica gel crystals are proposed to separate

moisture. Silica gel crystals should be replaced after a specific time according to the rate of purification. The capacities

of the scrubbing units are decided according to the size of the biogas plant. Now the out coming biogas from the

scrubbing unit is 98% pure.

a) Ready to use silica gel b) Silica gel turns pink once it has soaked up moisture.

Fig 5: Moisture Absorber

http: // www.ijesrt.com © International Journal of Engineering Sciences & Research Technology

[798]

[Katare* et al., 5(7): July, 2016] ISSN: 2277-9655

IC™ Value: 3.00 Impact Factor: 4.116

EFFECTS OF BIOGAS ENRICHMENT

Comparison between raw and enriched biogas:

Raw Biogas

A low Grade fuel (CH4 55-65 % & CO2 35-45 %) with lower percentage of methane.

On site or nearby, Cooking

The presence of CO2 besides being noncombustible, restrains its compressibility there by making biogas

difficult to be stored in containers

Upgraded Biogas (BIS-16087:2013)

A high grade fuel CH4> 90 % and < 10 % other gases) with high percentage of methane.

Remote applications.

Methane burns faster hence yields a higher specific output and thermal efficiency compared to raw biogas

when used as engine fuel.

Upgrading , compression and bottling facilitates easy storage and transportation as a vehicle fuel, as a cooking

fuel, for electricity production

CONCLUSION

1. It is proved that the concentration of methane available in the purified biogas was higher than that of raw

biogas. The approximate methane concentration for purified and raw biogas was 68 ± 2.52 % and 90 ± 1.53

% respectively.

2. Biogas enrichment tends to utilization of biomass in four verticals: 1. Low Carbon fuel generation. 2.Manure

formation as a byproduct from digester. 3. Excellent solid waste management & 4. Sustainable development

REFRENCES

[1] Upgraded Biogas (BIS-16087:2013)

[2] BIS - 8749: 1988

[3] S.S Kapdi, V.K. Vijay, S.K. Rajesh, Rajendra Prasad “Biogas scrubbing, compression and storage:

perspective and prospectus in Indian context”. Centre for rural development and technology, Indian Institute

of Technology, New Delhi 110 016, India.

[4] “Design of Biogas Scrubbing, Compression & Storage System”VinayakR.Gaikwad, Dr. P. K.

Katti,(Electrical Engineering Department/ Dr. BabasahebAmbedkar Technological University Raigad, India)

[5] “Biogas purification, compression and Bottling”Ramesh Babu Nallamothu, ( Research Scholar, Marine

Engineering Department, College of Engineering, Andhra University, Visakhapatnam, India. (Associate

Professor, SOE, ASTU, Adama), AbyotTeferra, (MSc student, SOE, ASTU, Adama) & Prof B.V.Appa Rao

(Professor, Marine Engineering Department, College of Engineering, Andhra University, Visakhapatnam,

India).

[6] “Water Scrubbing: A Better Option for Biogas Purification for Effective Storage”C. Ofori-Boateng and E.M.

Kwofie (Department of Energy Systems Engineering, School of Engineering, Koforidua Polytechnic,

Ghana).

[7] Purification Technologies for Biogas Generated by Anaerobic Digestion,Q. Zhao, E. Leonhardt, C.

MacConnell, C. Frear and S. Chen

http: // www.ijesrt.com © International Journal of Engineering Sciences & Research Technology

[799]

You might also like

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationFrom EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationNo ratings yet

- Biogas purification, compression and bottling process optimizedDocument5 pagesBiogas purification, compression and bottling process optimizedAYOMIDENo ratings yet

- Adsoprtion EA13Document11 pagesAdsoprtion EA13sharemwNo ratings yet

- International Journal of Greenhouse Gas Control: Liyuan Deng, May-Britt Ha GGDocument9 pagesInternational Journal of Greenhouse Gas Control: Liyuan Deng, May-Britt Ha GGMiguel RibeiroNo ratings yet

- JETIR1607020Document3 pagesJETIR1607020Suraj Kumar SamalNo ratings yet

- Iarjset 2022 9440Document10 pagesIarjset 2022 9440RaviNo ratings yet

- TEST BKC4543 Sem 1 20192020Document5 pagesTEST BKC4543 Sem 1 20192020mustaf mohamedNo ratings yet

- Biogas Supply To Diesel EngineDocument7 pagesBiogas Supply To Diesel EngineZubair Shaikh100% (1)

- 5 0114936Document7 pages5 0114936yusuf rosadiNo ratings yet

- Steam gasificationofbiomasswithCaOascatalystforhydrogen RichsyngasproductionDocument7 pagesSteam gasificationofbiomasswithCaOascatalystforhydrogen Richsyngasproductionrizkyfahmisaputra27No ratings yet

- Removal of CO From Biogas Plant Using Chemical Absorption ColumnDocument7 pagesRemoval of CO From Biogas Plant Using Chemical Absorption ColumnanirudhNo ratings yet

- Design of Biogas Purification To Reduce Carbon Dioxide (CO2) and Hydrogen Sulfide (H2S)Document7 pagesDesign of Biogas Purification To Reduce Carbon Dioxide (CO2) and Hydrogen Sulfide (H2S)Karen Joy BabidaNo ratings yet

- Development of A Low-Cost Biogas Filtration System To Achieve Higher-Power Efficient AC GeneratorDocument8 pagesDevelopment of A Low-Cost Biogas Filtration System To Achieve Higher-Power Efficient AC GeneratorKaren Joy BabidaNo ratings yet

- Development of A Low-Cost Biogas Filtration System To Achieve Higher-Power Efficient AC GeneratorDocument8 pagesDevelopment of A Low-Cost Biogas Filtration System To Achieve Higher-Power Efficient AC Generatordhineshbabu rNo ratings yet

- Techniques of Tar Removal From Producer Gas - A ReviewDocument9 pagesTechniques of Tar Removal From Producer Gas - A ReviewHotib PerwiraNo ratings yet

- Accepted ManuscriptDocument29 pagesAccepted ManuscriptAlek KrótkiNo ratings yet

- Dynamic Simulation and Process Design Analysis of Syngas Purification and The Utilization of Gas PermeationDocument8 pagesDynamic Simulation and Process Design Analysis of Syngas Purification and The Utilization of Gas PermeationIJRASETPublicationsNo ratings yet

- Carbon Particule Reduction From The Flue Gas of Brick IndustryDocument5 pagesCarbon Particule Reduction From The Flue Gas of Brick IndustryCristhyan Willy Raa TorresNo ratings yet

- Purification of Biogas at Domestic LevelDocument2 pagesPurification of Biogas at Domestic LevelIJAMTESNo ratings yet

- Performance Characterization of Gas-Solid Cyclone PDFDocument14 pagesPerformance Characterization of Gas-Solid Cyclone PDFJhonatan Román RománNo ratings yet

- Catalysts: An Overview On Catalytic Hydrodeoxygenation of Pyrolysis Oil and Its Model CompoundsDocument22 pagesCatalysts: An Overview On Catalytic Hydrodeoxygenation of Pyrolysis Oil and Its Model CompoundsTusharNo ratings yet

- Effluent Treatment in LPG Bottling Plants A Study On Mysore LPG Bottling PlantDocument5 pagesEffluent Treatment in LPG Bottling Plants A Study On Mysore LPG Bottling PlantInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Artikel 1Document6 pagesArtikel 1iimcaemdwNo ratings yet

- Journal of Analytical and Applied PyrolysisDocument10 pagesJournal of Analytical and Applied PyrolysisPranav PrajapatiNo ratings yet

- Biogas PurificationDocument5 pagesBiogas PurificationHarsh GutgutiaNo ratings yet

- 2014 - CO2 Capture Using Biochar Produced From Sugarcane Bagasse and Hickory WoodDocument27 pages2014 - CO2 Capture Using Biochar Produced From Sugarcane Bagasse and Hickory WoodpreemeeNo ratings yet

- Pure BiogasDocument8 pagesPure Biogasapi-3706974100% (1)

- Investigation of The Long-Term Performance of An Industrial-Scale Biogas Upgrading Plant With Grid Supply Applying Gas Permeation MembranesDocument6 pagesInvestigation of The Long-Term Performance of An Industrial-Scale Biogas Upgrading Plant With Grid Supply Applying Gas Permeation MembranesBenjamin F ZavalaNo ratings yet

- Removal of Hydrogen Sulfide From Biogas Using Dry Desulfurization Systems PDFDocument4 pagesRemoval of Hydrogen Sulfide From Biogas Using Dry Desulfurization Systems PDFLương Hữu BắcNo ratings yet

- Use of Biomass Gas in Running Internal Combustion Engine To Generate Electricity-A ReviewDocument7 pagesUse of Biomass Gas in Running Internal Combustion Engine To Generate Electricity-A Reviewkashipuranataraj69No ratings yet

- A Simple Mass Balance Model For Biological Sequencing Batch Reactors Used For Carbon and Nitrogen Removal D.Mazouni, M. Ignatova, J. HarmandDocument6 pagesA Simple Mass Balance Model For Biological Sequencing Batch Reactors Used For Carbon and Nitrogen Removal D.Mazouni, M. Ignatova, J. Harmandsharan kommiNo ratings yet

- Press MUd To Bio GasDocument5 pagesPress MUd To Bio GasAyush AgrawalNo ratings yet

- Tyre Pyrolysis by Using Nano Catalyst ToDocument6 pagesTyre Pyrolysis by Using Nano Catalyst ToSaif Khan MubinNo ratings yet

- Kobya 20061Document11 pagesKobya 20061Violeta GarciaNo ratings yet

- Thermodynamics-Ii Lab Oel: Submitted ToDocument13 pagesThermodynamics-Ii Lab Oel: Submitted Toharis khalilNo ratings yet

- IPA SE 476 Revision FinalDocument7 pagesIPA SE 476 Revision FinalDzaky hilalNo ratings yet

- 1 s2.0 S0168165620301383 MainDocument7 pages1 s2.0 S0168165620301383 MainMichael WangNo ratings yet

- Biogas Cleaning and Upgrading Technologies - OhiolineDocument6 pagesBiogas Cleaning and Upgrading Technologies - Ohiolinebhuneshwar paswanNo ratings yet

- 1 s2.0 S0961953413001177 MainDocument31 pages1 s2.0 S0961953413001177 MainPtrr TrpperNo ratings yet

- Bader - 2018 - JPorousMater-How The Activation Process Modifies The Hydrogen Storage Behavior of Biomass-Derived ACDocument14 pagesBader - 2018 - JPorousMater-How The Activation Process Modifies The Hydrogen Storage Behavior of Biomass-Derived ACvituruchNo ratings yet

- Pyrolysis of Municipal Sewage Sludge For Bio Oil Production and Characterization of Bio-OilDocument6 pagesPyrolysis of Municipal Sewage Sludge For Bio Oil Production and Characterization of Bio-OilSMIT CHRISTIANNo ratings yet

- Detailed Project Report of Biogas Project For Thermal ApplicationsDocument22 pagesDetailed Project Report of Biogas Project For Thermal ApplicationsLoveroop SinghNo ratings yet

- Comparative Process Study of Biomass Gas PDFDocument6 pagesComparative Process Study of Biomass Gas PDFhmpackingNo ratings yet

- Experiment Evolution For Downdraft Gasifier: With Using Various Biomass Wood, Bagasse and Coconut ShellDocument5 pagesExperiment Evolution For Downdraft Gasifier: With Using Various Biomass Wood, Bagasse and Coconut ShellMounicaRasagyaPallaNo ratings yet

- A Review of Biogas Utilisation, Purification and Upgrading TechnologiesDocument17 pagesA Review of Biogas Utilisation, Purification and Upgrading TechnologiesXavier OrtizNo ratings yet

- Methods to Capture Carbon from Combustion EmissionsDocument30 pagesMethods to Capture Carbon from Combustion EmissionsRamana Kumar SkvNo ratings yet

- Co2 and H2S Removal From Biogas by Using Four Membran of InterestDocument7 pagesCo2 and H2S Removal From Biogas by Using Four Membran of InterestIJAR JOURNALNo ratings yet

- Optimized Production and Characterization of Highly Porous Activated Carbon From Algal-Derived HydrocharDocument16 pagesOptimized Production and Characterization of Highly Porous Activated Carbon From Algal-Derived HydrocharVũ Văn NguyênNo ratings yet

- Optimization of Post Combustion Carbon Capture Process-Solvent SelectionDocument11 pagesOptimization of Post Combustion Carbon Capture Process-Solvent SelectionYamini BNo ratings yet

- Study On Electricity Generation Through Biogas On Small ScaleDocument8 pagesStudy On Electricity Generation Through Biogas On Small ScaleEngineering ProjectNo ratings yet

- A D D Diallo Et Al.Document8 pagesA D D Diallo Et Al.Bilal KazmiNo ratings yet

- Equilibrium ModelingDocument9 pagesEquilibrium ModelingVineet SinghNo ratings yet

- Bioresource Technology: Contents Lists Available atDocument9 pagesBioresource Technology: Contents Lists Available atAtchaya அட்சயாNo ratings yet

- Articulo CientíficoDocument10 pagesArticulo CientíficoHeidy Jovana Huanca RamosNo ratings yet

- Upgrading Biogas by A Low-Temperature CO Removal Technique: Alexandria Engineering JournalDocument8 pagesUpgrading Biogas by A Low-Temperature CO Removal Technique: Alexandria Engineering Journalhazwan2283No ratings yet

- Absorber-Stripper System Design For Biogas PurificationDocument20 pagesAbsorber-Stripper System Design For Biogas Purificationkaye100% (1)

- Energies: Biogas Upgrading Approaches With Special Focus On Siloxane Removal-A ReviewDocument17 pagesEnergies: Biogas Upgrading Approaches With Special Focus On Siloxane Removal-A ReviewJia Yuan ChngNo ratings yet

- 2020 Ghazi-Properties of Geopolymer Mortar Subjected To High TemperatureDocument7 pages2020 Ghazi-Properties of Geopolymer Mortar Subjected To High TemperatureChi ĐặngNo ratings yet

- Design Hydrothermal Carbonization of Biomass Waste by Using A Stirred Reactor UndipDocument6 pagesDesign Hydrothermal Carbonization of Biomass Waste by Using A Stirred Reactor Undipraymond tambunanNo ratings yet

- View Project - Department of Economic Affairs - InfrastructureIndia - Gov.inDocument1 pageView Project - Department of Economic Affairs - InfrastructureIndia - Gov.inHarsh GutgutiaNo ratings yet

- Biogas PurificationDocument5 pagesBiogas PurificationHarsh GutgutiaNo ratings yet

- EOI for Tank Lorry EngagementDocument7 pagesEOI for Tank Lorry EngagementHarsh GutgutiaNo ratings yet

- Detailed Project Report FOR 120 KLPD Grain Based Distillery: Tandhan Biochemicals Pvt. LTDDocument55 pagesDetailed Project Report FOR 120 KLPD Grain Based Distillery: Tandhan Biochemicals Pvt. LTDHarsh GutgutiaNo ratings yet

- RegreenExcel Company Profile EthanolDocument20 pagesRegreenExcel Company Profile EthanolHarsh GutgutiaNo ratings yet

- RegreenExcel Company Profile EthanolDocument20 pagesRegreenExcel Company Profile EthanolHarsh GutgutiaNo ratings yet

- Detailed Project Report FOR 120 KLPD Grain Based Distillery: Tandhan Biochemicals Pvt. LTDDocument55 pagesDetailed Project Report FOR 120 KLPD Grain Based Distillery: Tandhan Biochemicals Pvt. LTDHarsh GutgutiaNo ratings yet

- Paper 4Document9 pagesPaper 4Kátia Sofia GomesNo ratings yet

- Pre 210414Document66 pagesPre 210414Israel López LagosNo ratings yet

- 20IPTC Call For Papers Brochure Extended DeadlineDocument8 pages20IPTC Call For Papers Brochure Extended DeadlineAnkit SharmaNo ratings yet

- The Global Warming Survival Guide - 51 Things We Can DoDocument17 pagesThe Global Warming Survival Guide - 51 Things We Can DoHoang VUNo ratings yet

- Oil & Gas Accounting 2Document91 pagesOil & Gas Accounting 2rajivNo ratings yet

- Bio GasDocument14 pagesBio Gasshivanigupta3003No ratings yet

- Gagasan Carriers SDNDocument1 pageGagasan Carriers SDNmoorthyNo ratings yet

- SInv Eng 20231016Document88 pagesSInv Eng 20231016shuhaaibNo ratings yet

- Spe 170789 MS PDFDocument17 pagesSpe 170789 MS PDFerikaberriomNo ratings yet

- GE Oil & Gas Centrifugal Compressor Antisurge TrainingDocument214 pagesGE Oil & Gas Centrifugal Compressor Antisurge TrainingBerhoof Dalch100% (1)

- Petrom Offshore Compression & Cogeneration Project: Proposal PresentationDocument18 pagesPetrom Offshore Compression & Cogeneration Project: Proposal Presentationuskaat2004No ratings yet

- 2016 July PDFDocument108 pages2016 July PDFmnasiroleslamiNo ratings yet

- The Case of Iran's Gas Turbine Industry PHD ThesisDocument296 pagesThe Case of Iran's Gas Turbine Industry PHD Thesismohmehr100% (1)

- Natural Gas PipelineDocument10 pagesNatural Gas Pipelineshaileshgadbail100% (1)

- 2425 Qatar Country SustDocument44 pages2425 Qatar Country SustfazlulfaisalNo ratings yet

- WELL SERVICE AND WORKOVERDocument52 pagesWELL SERVICE AND WORKOVERAndre YudhistiraNo ratings yet

- Farhan Masood ThesisDocument39 pagesFarhan Masood ThesisBelal AhmadNo ratings yet

- DFL CHEMICAL TRAINEES REPORT ON UREA PLANT PROCESSESDocument36 pagesDFL CHEMICAL TRAINEES REPORT ON UREA PLANT PROCESSESMuhammad Bello BabaNo ratings yet

- DistillationDocument25 pagesDistillationMohammadAslam100% (1)

- Ambre Submission To CPRSDocument2 pagesAmbre Submission To CPRSfreddy feltonNo ratings yet

- The Pipeline Begins in Escravos Southeast of Its TerminusDocument4 pagesThe Pipeline Begins in Escravos Southeast of Its TerminusGeorge AniborNo ratings yet

- Nateria Brochure PDFDocument6 pagesNateria Brochure PDFJavier Alejandro Muralles ReyesNo ratings yet

- SADC DBSA RGMP Phase 1 Consolidated ReportDocument289 pagesSADC DBSA RGMP Phase 1 Consolidated ReportWeddie MakomichiNo ratings yet

- DWA Oil Gas Glossary PDFDocument35 pagesDWA Oil Gas Glossary PDFPriya ElangoNo ratings yet

- Energy 21st CenturyDocument507 pagesEnergy 21st Centuryarabbig100% (2)

- Petroleum Reservoir Fluid Properties Whitson2Document6 pagesPetroleum Reservoir Fluid Properties Whitson2Ldtc ZerrotNo ratings yet

- Subchapter O: Oil and Gas 106.351 - 106.355, 106.359 Effective September 10, 2013 106.351. Salt Water Disposal (Petroleum)Document77 pagesSubchapter O: Oil and Gas 106.351 - 106.355, 106.359 Effective September 10, 2013 106.351. Salt Water Disposal (Petroleum)annakaisaNo ratings yet

- Zero Liquid Discharge (ZLD) System Case StudyDocument2 pagesZero Liquid Discharge (ZLD) System Case Studyhamid vahedil larijaniNo ratings yet

- Midterm ExamDocument25 pagesMidterm Examjo_aligoraNo ratings yet

- List of Oil Companies in MumbaiDocument13 pagesList of Oil Companies in Mumbaihashi.hashi67% (3)