Professional Documents

Culture Documents

2008 11105 Is Sugar An Explosion Hazard

Uploaded by

Yuda HerdiantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2008 11105 Is Sugar An Explosion Hazard

Uploaded by

Yuda HerdiantoCopyright:

Available Formats

Sponsored by

CCPS

http://www.aiche.org/CCPS/Publications/Beacon/index.aspx

Messages for Manufacturing Personnel Supporters

Is sugar an explosion hazard? May 2008

YES, if it is a fine powder or dust! Any material which can burn is

capable of causing a catastrophic dust explosion if it is suspended as a fine

dust or powder in air or other oxidizing atmosphere. On February 7, 2008

there was a severe explosion in a sugar refinery near Savannah, Georgia,

USA. The explosion injured more than 30 people, and the death toll had

reached 13 as of the end of March 2008. The explosion is still being

investigated, and the detailed causes are not yet known. However, the initial

investigation indicates that this was a dust explosion.

Many people are not aware of the explosion hazard of many dusts and

fine powders. Some examples of materials which may be a dust explosion

hazard if present as a fine powder include almost any organic material -

grain flour, sugar, plastic, corn starch, pharmaceuticals. Powdered metals

such as aluminum and magnesium also present a dust explosion hazard.

CCPS PSID

Members search

Dust Explosion

Do you know what conditions are necessary for a dust explosion?

The conditions needed for a dust explosion can be represented as a pentagon (see figure at left above):

• FUEL – The presence of a combustible dust. Particle size is important – smaller particles are more likely to be both

ignitable and dispersible.

• OXIDANT – usually oxygen in the air, which is generally enough to support an explosion.

• SUSPENSION – The dust needs to be dispersed into the air. The dust may normally be dispersed in air in the process

equipment. In a building, this could be done by a large leak or spill, a small initial dust explosion, or any other disturbance

which could shake dust layers off of equipment or lift dust off of the floor.

• IGNITION SOURCE – Energy is required to ignite the mixture. This may be something with as little energy as static

electricity or a stronger energy source such as an open flame or an electrical fault.

• CONFINEMENT – For example, the walls, ceilings, floors and roof of a building create confinement. Plant equipment

including process equipment, storage silos, dust collectors, and ducting also creates confinement..

Sometimes an initial explosion occurs and lifts larger amounts of dust that may have accumulated in the plant and

disperses this dust into the air. This creates the conditions for a second, much larger explosion, which can be catastrophic.

A small amount of dust – a layer as small as 1/32 inch (less than 1 mm) thick on exposed surfaces – can create an

explosive dust cloud once suspended. A dust layer can be considered to create a hazardous condition if it covers an area,

on all surfaces, greater than 5 % of the floor area of a room. How can you tell if there is too much dust? Two guidelines

which people have used are that there is too much dust accumulation (1) when you cannot tell the color of the equipment

or floor beneath the layer of dust, or (2) when you write your name in the dust and very slight ridges form at the edge of

the letters. Good housekeeping is a necessary safe work practice when dust hazards are concern. Other safe work

practices for dust include reducing static discharge potential through the use of grounding and bonding, proper electrical

area classification and equipment selection. If your plant handles potentially explosive dusts, make sure that you

understand the hazards, and all of the safe work practices and safety equipment needed for safe operations.

Know the hazards of the materials in your plant!

AIChE © 2008. All rights reserved. Reproduction for non-commercial, educational purposes is encouraged. However, reproduction

for the purpose of resale by anyone other than CCPS is strictly prohibited. Contact us at ccps_beacon@aiche.org or 212-591-7319

The Beacon is usually available in Afrikaans, Arabic, Chinese, Danish, Dutch, English, French, German, Gujarati, Hebrew, Hindi, Hungarian,

Indonesian, Italian, Japanese, Korean, Malay, Marathi, Persian, Polish, Portuguese, Russian, Spanish, Swedish, Tamil, Thai, Turkish, and Vietnamese.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- NTA Based JEE Main Practice Question Bank CHEMISTRYDocument352 pagesNTA Based JEE Main Practice Question Bank CHEMISTRYtwin masters100% (1)

- Emergency Evacuation Flow Chart Fire or ExplosionDocument1 pageEmergency Evacuation Flow Chart Fire or ExplosionYuda Herdianto100% (1)

- IAL As Chemistry SN 4Document116 pagesIAL As Chemistry SN 4Michael J George100% (2)

- Origin of The UniverseDocument44 pagesOrigin of The UniverseLuis PazNo ratings yet

- Applied Thermodynamics Course FileDocument252 pagesApplied Thermodynamics Course FileRakesh MahawarNo ratings yet

- Emergency Evacuation Flow Chart Minor InjuryDocument1 pageEmergency Evacuation Flow Chart Minor InjuryYuda HerdiantoNo ratings yet

- Ansys Linear Buckling Analysis Tutorial - by Drdalyo: L I E N FcritDocument2 pagesAnsys Linear Buckling Analysis Tutorial - by Drdalyo: L I E N FcritYuda HerdiantoNo ratings yet

- Emergency Evacuation Route and Ambulance Access Way Route - PT. Solusi Teknologi TerdepanDocument2 pagesEmergency Evacuation Route and Ambulance Access Way Route - PT. Solusi Teknologi TerdepanYuda HerdiantoNo ratings yet

- Emergency Organization Chart NumberDocument1 pageEmergency Organization Chart NumberYuda HerdiantoNo ratings yet

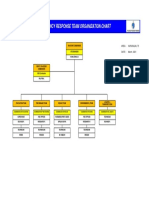

- Emergency Response Team Organization Chart: Kariangau 75 Date: Area: March, 2021Document1 pageEmergency Response Team Organization Chart: Kariangau 75 Date: Area: March, 2021Yuda HerdiantoNo ratings yet

- Planning The Wet Scrubber On Auxiliary Boiler Unit at Pt. Indonesia Power Ujp Jabar 2 Pelabuhan RatuDocument13 pagesPlanning The Wet Scrubber On Auxiliary Boiler Unit at Pt. Indonesia Power Ujp Jabar 2 Pelabuhan RatuYuda HerdiantoNo ratings yet

- 4-Medical Gases Systems. The Fourth Lecture.Document23 pages4-Medical Gases Systems. The Fourth Lecture.Fireproof Sistemas ElectromecánicosNo ratings yet

- Soal-Soal KD TroDocument24 pagesSoal-Soal KD TroTita Dian NofitaNo ratings yet

- 1 Fluid Statics: &RQWHQWVDocument33 pages1 Fluid Statics: &RQWHQWVHuy BuiNo ratings yet

- Gaseous Diffusion CoefficientsDocument117 pagesGaseous Diffusion CoefficientsXiaoqiang zhangNo ratings yet

- Thermodynamics II Course Project: November 21, 2019Document4 pagesThermodynamics II Course Project: November 21, 2019Ahmed AmarNo ratings yet

- Fuel Spec Confirmation TemplateDocument1 pageFuel Spec Confirmation TemplateGavin R MorganNo ratings yet

- OK Gen - Part - 19Document4 pagesOK Gen - Part - 19Jean Pango100% (1)

- 3249 SCH 101 Introduction To Physical ChemistryDocument91 pages3249 SCH 101 Introduction To Physical ChemistryNNMKJNo ratings yet

- Week 2 Lesson 2 1-Intro-OrgchemDocument17 pagesWeek 2 Lesson 2 1-Intro-OrgchemLuiz GuzmanNo ratings yet

- Basic Chemistry ReviewDocument5 pagesBasic Chemistry ReviewArman Neil J. BudogNo ratings yet

- Salt-Affected Soil Soil 206 - Soil Ecosystem Lab: ObjectivesDocument7 pagesSalt-Affected Soil Soil 206 - Soil Ecosystem Lab: ObjectivesmosoilNo ratings yet

- Klinkenberg e Ffect For Gas Permeability and Its Comparison To Water Permeability For Porous Sedimentary RocksDocument24 pagesKlinkenberg e Ffect For Gas Permeability and Its Comparison To Water Permeability For Porous Sedimentary RocksMuhammad Haiqal MokhtarNo ratings yet

- MD Mamunur Roshid Milon 01674898297: F/M 19 v12 q1Document12 pagesMD Mamunur Roshid Milon 01674898297: F/M 19 v12 q1Mahin IslamNo ratings yet

- ScriptDocument50 pagesScriptRon FamilaranNo ratings yet

- Lenchen's House PVsyst - VC0-ReportDocument7 pagesLenchen's House PVsyst - VC0-ReportBilly JhunNo ratings yet

- Penurunan PerkolasiDocument8 pagesPenurunan PerkolasiLutfi Abdullah HanifNo ratings yet

- q1 m6 Heat Temperature Activity Sheet Summative TestDocument5 pagesq1 m6 Heat Temperature Activity Sheet Summative TestALLYSA JANE SIANo ratings yet

- 20 MergedDocument97 pages20 Mergedjomarie apolinarioNo ratings yet

- Climate Change BibliographyDocument13 pagesClimate Change Bibliographytoitoine1991No ratings yet

- Gr9 Phy DensityDocument36 pagesGr9 Phy DensityKushagra SomaniNo ratings yet

- Energy ConservationDocument250 pagesEnergy ConservationSchreiber_DiesesNo ratings yet

- Everything You Need To Know About Eco-TourismDocument3 pagesEverything You Need To Know About Eco-TourismTIRTHA DEB NATHNo ratings yet

- Còpia de Energy - Calculations - Answer - SheetsDocument101 pagesCòpia de Energy - Calculations - Answer - SheetsManuel F. Merino MorenoNo ratings yet

- SAQ Ans 30Document2 pagesSAQ Ans 30harshanauocNo ratings yet

- Solid Waste Management: Anushi Jain MSC Ii Roll No.: 08 Paper IIDocument18 pagesSolid Waste Management: Anushi Jain MSC Ii Roll No.: 08 Paper IIradikaNo ratings yet

- Solar Tracking System: Abstract-The Solar Photovoltaic Panels Are Used To GenerateDocument4 pagesSolar Tracking System: Abstract-The Solar Photovoltaic Panels Are Used To GenerateAdrian Ebero NunezNo ratings yet