Professional Documents

Culture Documents

Sep. Purif. Technol. 62 2 376-81

Uploaded by

BadzlinaKhairunizzahraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sep. Purif. Technol. 62 2 376-81

Uploaded by

BadzlinaKhairunizzahraCopyright:

Available Formats

[1] Ghaisani A D, Mahayum A, Kusumandari K and Saraswati T E 2019 Degradation of dyes in

textile industry wastewater using dielectric barrier discharge (DBD) plasma. In AIP Conf. Proc.

AIP Publishing LLC 2097 1 030097.

[2] He Z, Lin L, Song S, Xia M, Xu L, Ying H and Chen J 2008 Mineralization of C.I. reactive

blue 19 by ozonation combined with sonolysis: peformance optimization and degradation mechanism

Sep. Purif. Technol. 62 2 376-81.

(Li et al)

[4] Setyaningtyas, T. Dwiasi, D. (2012). Degradasi Zat Warna Azo Tartrazin pada Limbah Cair

Mie dengan Metode AOPs (Advanced Oxidation Processes). Fakultas MIPA Universitas Jenderal

Soedirman.

[3] Rico V J, Hueso J L, Cotrino J and González-Elipe A R 2010 Evaluation of different

dielectric barrier discharge plasma configurations as an alternative technology for green C1 chemistry

in the carbon dioxide reforming of methane and the direct decomposition of methanol J. Phys. Chem.

A 114 11 4009-16.

[6] Husodo F 2017 Model pola alir fasa cair dalam reaktor trickle bed dengan packing karbon

aktif Reaktor 9 2 73-8

[7] (Aziz et al)

[4] Brandhuber P and Korshin G V 2009 Methods for the detection of residual concentations of

hydrogen peroxide in advanced oxidation processes WateReuse Foundation.

[9] Santiko, Dipo Aji. (2012). Evaluasi Pembentukan Agen Pengoksidasi Menggunakan Proses

Oksidasi Lanjut Hydrodynamic Cavitation. Universitas Indonesia: Depok.

[5] Ershov B G and Morozov P A 2009 The kinetics of ozone decomposition in water, the

influence of pH and temperature Russ. J. Phys. Chem. A 83 8 1295-9.

[6] Beltran F J 2003 Ozone reaction kinetics for water and wastewater systems crc Press.

[7] Vanraes P, Ghodbane H, Davister D, Wardenier N, Nikiforov A, Verheust Y P, Van Hulle S

W, Hamdaoui O, Vandamme J, Van Durme J and Surmont P 2017 Removal of several pesticides in a

falling water film DBD reactor with activated carbon textile: energy efficiency Water res. 116 1-2.

[8] Duan L, Shang K, Lu N, Li J and Wu Y 2013 March Study on the factors influencing phenol

degradation in water by dielectric barrier discharge (DBD) In J. Phys.: Conf. Ser. 418 012129.

[14] Gunten et al

[9] Sawyer C N, McCarty P L and Parkin G F Chemistry for environmental engineering and

science.

[10] Nur M, Bonifaci N and Denat A 1998 Non-thermal electron mobility in high density gaseous

nitrogen and argon in divergent electric field TITLE AND SUBTITLE 4 12.

[11] Yao S, Wu Z, Han J, Tang X, Jiang B, Lu H, Yamamoto S and Kodama S 2015 Study of

ozone generation in an atmospheric dielectric barrier discharge reactor J Electrostat. 75 35-42.

[12] Liu B W, Chou M S, Kao C M and Huang B J 2004 Evaluation of selected operational

parameters for the decolorization of dye-finishing wastewater using UV/Ozone Ozone: Sci. Eng. 26 3

239-45.

[13] Chu W and Ma C W 2000 Quantitative prediction of direct and indirect dye ozonation

kinetics Water Research 34 12 3153-60.

[1] Sze S M 1969 Physics of Semiconductor Devices (New York: Wiley–Interscience)

[2] Dorman L I 1975 Variations of Galactic Cosmic Rays (Moscow: Moscow State University

Press) p 103

Table x.

Initial waste Final waste

pH Final degradation (%)

concentration (mg/L) concentration (mg/L)

4 98,4397753 48,03 0,75

Prosthesis merupakan alat kesehatan yang memiliki tujuan untuk mengembalikan fungsi dari bagian

tubuh yang hilang secara normal. Di indonesia, bahan socket prosthesis yang sering digunakan adalah

komposit berpenguat fiberglass yang memiliki beberapa permasalahan dalam pemanfaatannya.

Penggunaan serat rami dapat menjadi alternatif penguat pada komposit socket prosthesis karena

mengandung serat selulosa yang dapat dimanfaatkan sebagai bahan penyusun komposit. Penambahan

carbon nanotube (CNT) pada komposit diketahui melalui banyak penelitian dapat meningkatkan sifat

mekanik. Penelitian ini bertujuan memperoleh peningkatan sifat mekanis dari komposit serat rami-

CNT untuk pemanfaatan socket prosthesis. Serat yang digunakan adalah serat rami. Jumlah CNT pada

komposit divariasikan sebesar 0%, 0,5%, 1%, dan 3%. Bentuk serat yang digunakan adalah bentuk

chopped strand. Untuk meningkatkan kompabilitas, fungsionalisasi CNT digunakan dengan metode

mild acid oxidation yang dilanjutkan dengan perlakuan permukaan silane coupling agent untuk

meningkatkan ikatan antar komponen dalam material komposit. Perlakuan alkaline treatment

dilakukan pada serat untuk menghilangkan pengotor yang menutupi selulosa dari permukaan, yang

kemudian diperlakukan silane coupling agent untuk meningkatkan ikatan serat dengan matriks. Uji

yang dilakukan pada penelitian ini adalah uji FTIR, dan uji tekuk. Pengujian FTIR pada serat rami

setelah perlakuan menunjukan peningkatan gugus hidroksil dan hilangnya zat lignin, pektin, dan

hemiselulosa, serta menempelnya gugus silanol pada serat. Pengujian FTIR pada CNT setelah

perlakuan menunjukan terbentuknya gugus hidroksil dan karboksil, serta menempelnya gugus silanol

pada CNT. Hasil uji tekuk memperlihatkan terjadinya penurunan kekuatan tekuk komposit sebesar

48,96%, 35,44%, dan 6,31 % pada penambahan CNT 0,5%, 1%, dan 3%. Hasil komposit yang

didapatkan belum layak untuk diaplikasikan pada pemanfaatan socket prosthesis.

A prosthesis is a medical device that aims to restore the function of the body parts that are missing

normally. In Indonesia, the most commonly used prosthesis socket material is fiberglass-reinforced

composites that have several problems in their utilization. The use of natural fibers can be an

alternative amplifier on composite prosthesis composites because it contains cellulose fibers which

can be used as composites. The addition of carbon nanotubes (CNT) to composites is known through

many studies to improve mechanical properties. This study aims to obtain an increase in the

mechanical properties of the ramie-CNT fiber composites for socket prosthesis utilization. The fiber

used is ramie fiber. The amount of CNT in composites varied by 0%, 0.5%, 1% and 3%. The form of

fiber that will be used is the form of chopped strand. To increase compatibility, CNT functionalization

is used with mild acid oxidation method followed by the surface treatment of silane coupling agent to

increase bonding between components in composite materials. Alkaline treatment is used on the fiber

to remove impurities that cover the cellulose from the surface, which is then treated by a silane

coupling agent to increase the bonding of the fiber with the matrix. Tests that will be carried out in

this study are the FTIR test, and bending test. FTIR test on ramie fiber after treatment showed an

increase in hydroxyl groups and loss of lignin, pectin and hemicellulose, and sticking of silanol

groups to the fibers. FTIR test on CNT after treatment showed the information of hydroxyl and

carboxyl groups, and the sticking of silanol groups to CNT surfaces. The bending strength result

showed a decrease in the bending strength of the composite by 48.96%, 35.44% and 6.31% on the

addition of 0.5%, 1% and 3% of CNT. The composite results obtained are not yet feasible to be

applied to the use of socket prosthesis.

You might also like

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Accepted Manuscript: Chemical Engineering JournalDocument31 pagesAccepted Manuscript: Chemical Engineering JournalGhina Fatikah SalimNo ratings yet

- The Effect of Silane Addition On Chitosan-Fly Ash/CTAB As Electrolyte MembraneDocument9 pagesThe Effect of Silane Addition On Chitosan-Fly Ash/CTAB As Electrolyte MembraneAgoeng RiswantoNo ratings yet

- Tirumali2017Document38 pagesTirumali2017Riston SinagaNo ratings yet

- 10 1088@1009-0630@19@1@015503Document9 pages10 1088@1009-0630@19@1@015503ARIFFIN BIN ZULKIFLINo ratings yet

- of ProjectDocument24 pagesof ProjectamarparimiNo ratings yet

- Surface Modification of TiO2 Nanoparticles With 1,3,5-TriazineDocument11 pagesSurface Modification of TiO2 Nanoparticles With 1,3,5-TriazineKvsn RajuNo ratings yet

- 1 s2.0 S0304389410015517 MainDocument9 pages1 s2.0 S0304389410015517 Mainpetru apopeiNo ratings yet

- THESIS - Application of Magnetic Nanoparticles - Wastewater TreatmentDocument73 pagesTHESIS - Application of Magnetic Nanoparticles - Wastewater TreatmentIrvan Dahlan100% (2)

- Synthesis of Nata de Coco Fiber Composite With Conductive Filler As An Eco-Friendly Semiconductor MaterialDocument7 pagesSynthesis of Nata de Coco Fiber Composite With Conductive Filler As An Eco-Friendly Semiconductor MaterialDevit Hari AshariNo ratings yet

- 1 s2.0 S2213343720302657 MainDocument9 pages1 s2.0 S2213343720302657 MainThu Trang NguyenNo ratings yet

- Wang 2016Document6 pagesWang 2016tylerNo ratings yet

- Removal Performance of Ion From Groundwater by ElectrodialysisDocument7 pagesRemoval Performance of Ion From Groundwater by Electrodialysisishaq kazeemNo ratings yet

- Journal of Food Engineering: Francisco J. Rodríguez, María J. Galotto, Abel Guarda, Julio E. BrunaDocument7 pagesJournal of Food Engineering: Francisco J. Rodríguez, María J. Galotto, Abel Guarda, Julio E. BrunacriscristinaNo ratings yet

- Evaluation of Wastewater Treatment Efficiency Utilizing Coconut Fiber As Filter MediaDocument9 pagesEvaluation of Wastewater Treatment Efficiency Utilizing Coconut Fiber As Filter MediachaNo ratings yet

- Effect of MAPP As Coupling Agent On The Performance of Sisal - PP Composites - Mohanty2004Document17 pagesEffect of MAPP As Coupling Agent On The Performance of Sisal - PP Composites - Mohanty2004deathjester1No ratings yet

- 11 Full Textural and Morph FullDocument6 pages11 Full Textural and Morph FullNayla MunaNo ratings yet

- Minerals 08 00080Document15 pagesMinerals 08 00080BrunoBarrosNo ratings yet

- Surface-Modified Chitosan: An Adsorption Study of A "Tweezer-Like" Biopolymer With FluoresceinDocument17 pagesSurface-Modified Chitosan: An Adsorption Study of A "Tweezer-Like" Biopolymer With FluoresceinadiazcalidadNo ratings yet

- Removal of Oxide Nanoparticles in A Model Wastewater Treatment Plant: Influence of Agglomeration and Surfactants On Clearing EfficiencyDocument6 pagesRemoval of Oxide Nanoparticles in A Model Wastewater Treatment Plant: Influence of Agglomeration and Surfactants On Clearing Efficiencyramonik08No ratings yet

- Salman 1Document14 pagesSalman 1amirsNo ratings yet

- Textile Industrial Effluents: Using NanoparticlesDocument3 pagesTextile Industrial Effluents: Using NanoparticlesNehru CDFNo ratings yet

- A2.Adsorption Isotherm Models For Basic Dye Adsorption by Peat in Single and Binary Component System PDFDocument12 pagesA2.Adsorption Isotherm Models For Basic Dye Adsorption by Peat in Single and Binary Component System PDFCheela Venkata Ravi SankarNo ratings yet

- 1 s2.0 S2213343718307681 MainDocument7 pages1 s2.0 S2213343718307681 MainDr ChNo ratings yet

- Fabrication and Morphology Study of Electrospun Cellulose Acetate/polyethylenimine NanofiberDocument18 pagesFabrication and Morphology Study of Electrospun Cellulose Acetate/polyethylenimine Nanofiberomeraijaz599No ratings yet

- Photocatalysis PaperDocument14 pagesPhotocatalysis PaperGoutham RNo ratings yet

- Masturi JPCS 2018Document6 pagesMasturi JPCS 2018masturiNo ratings yet

- Rose RRLDocument2 pagesRose RRLguevarra1029035No ratings yet

- Visible Light Photocatalytic Degradation of Microplastic Residues With Zinc Oxide NanorodsDocument6 pagesVisible Light Photocatalytic Degradation of Microplastic Residues With Zinc Oxide NanorodsPedro QueroNo ratings yet

- Franc 2006Document6 pagesFranc 2006Xiongyu LuoNo ratings yet

- Synthesis and Characterization of Cellulose-Silica Composite Fiber in Ethanol/water Mixed SolventsDocument11 pagesSynthesis and Characterization of Cellulose-Silica Composite Fiber in Ethanol/water Mixed SolventsDenesh MohandNo ratings yet

- Treatment and Remediation of A Wastewater Lagoon Using Microelectrolysis and Modified DAT /IAT MethodsDocument8 pagesTreatment and Remediation of A Wastewater Lagoon Using Microelectrolysis and Modified DAT /IAT MethodsIna ElenaNo ratings yet

- Synergetic Photocatalytic-Activity Enhancement of Lanthanum Doped TiO2 On Halloysite Nanocomposites For Degradation of Organic DyeDocument8 pagesSynergetic Photocatalytic-Activity Enhancement of Lanthanum Doped TiO2 On Halloysite Nanocomposites For Degradation of Organic DyeBachi NanoNo ratings yet

- Cellulose Nanofibers ThesisDocument5 pagesCellulose Nanofibers ThesisVicki Cristol100% (2)

- Soares Et Al For Polymer CompositesDocument16 pagesSoares Et Al For Polymer CompositesElisangelaCordeiroNo ratings yet

- Free Vibration Characteristics of Banana Sisal Natural Fibers Reinforced Hybrid Polymer Composite BeamDocument5 pagesFree Vibration Characteristics of Banana Sisal Natural Fibers Reinforced Hybrid Polymer Composite BeamDr Engr Md Zillur RahmanNo ratings yet

- Interaction of Anionic Dyes With Polyaniline Implanted Cellulose 2018Document43 pagesInteraction of Anionic Dyes With Polyaniline Implanted Cellulose 2018Donny TNo ratings yet

- SA Series Manuscript and Supplement Document 2021-06-19 FinalDocument32 pagesSA Series Manuscript and Supplement Document 2021-06-19 FinalTrong TruongNo ratings yet

- Art:10.1007/s10570 013 0049 6Document10 pagesArt:10.1007/s10570 013 0049 6RKYNo ratings yet

- 2008 Huang&Logan AMBDocument7 pages2008 Huang&Logan AMBJayabrata DasNo ratings yet

- Visvesvaraya Technological University, Belagavi: Ph.D. Progress Report I For The Period July To December 2017Document6 pagesVisvesvaraya Technological University, Belagavi: Ph.D. Progress Report I For The Period July To December 2017Karthik Kalasipalya Vinod KumarNo ratings yet

- Comparison of Dye Degradation Potential of Biosynthesized Copper Oxide, Manganese Dioxide, and Silver Nanoparticles UsingDocument7 pagesComparison of Dye Degradation Potential of Biosynthesized Copper Oxide, Manganese Dioxide, and Silver Nanoparticles UsingRamNo ratings yet

- Characterization of Cdse/Polythiophene Nanocomposite by Tga/Dta, XRD, Uv-Vis Spectroscopy, Sem-Edxa and FtirDocument8 pagesCharacterization of Cdse/Polythiophene Nanocomposite by Tga/Dta, XRD, Uv-Vis Spectroscopy, Sem-Edxa and FtirShridhar MathadNo ratings yet

- Modification of Chitosan Membranes With Nanosilica Particles As Polymer Electrolyte MembranesDocument10 pagesModification of Chitosan Membranes With Nanosilica Particles As Polymer Electrolyte MembranesGiacomo AccomandoNo ratings yet

- UntitledDocument4 pagesUntitledaya louatiNo ratings yet

- Ma 2010Document11 pagesMa 2010Sy Nguyen VietNo ratings yet

- Multifunctional Sodium Lanthanide Silicates: From Blue Emitters and Infrared S-Band Amplifiers To X-Ray PhosphorsDocument6 pagesMultifunctional Sodium Lanthanide Silicates: From Blue Emitters and Infrared S-Band Amplifiers To X-Ray PhosphorsRupeshRaoNo ratings yet

- Articulo 5Document16 pagesArticulo 5nathaloaNo ratings yet

- Water Research: Zhongbo Zhou, Xiang He, Minghao Zhou, Fangang MengDocument9 pagesWater Research: Zhongbo Zhou, Xiang He, Minghao Zhou, Fangang Mengarun aryaNo ratings yet

- Zhao 2017Document45 pagesZhao 2017Nguyễn Phú SỹNo ratings yet

- FTIR Study For Natural FibresDocument25 pagesFTIR Study For Natural Fibresortizan8No ratings yet

- Huan2020 Article AcrylicAcidGrafted Multi WalleDocument15 pagesHuan2020 Article AcrylicAcidGrafted Multi WalleDivya MahalsekarNo ratings yet

- Treatment of Tunnel Construction Wastewater Using Chitosan CoagulantDocument9 pagesTreatment of Tunnel Construction Wastewater Using Chitosan CoagulantepebeNo ratings yet

- NANV03I03P0169Document6 pagesNANV03I03P0169nano_journalNo ratings yet

- English 6Document9 pagesEnglish 6Sitii NurjannahNo ratings yet

- 1 s2.0 S0304389408003488 MainDocument7 pages1 s2.0 S0304389408003488 MainiramtahiraNo ratings yet

- Synthesis and Characterization of Carbon Nanotubes/poly Vinyl Alcohol Nanocomposite Membranes For Dehydration of IsopropanolDocument11 pagesSynthesis and Characterization of Carbon Nanotubes/poly Vinyl Alcohol Nanocomposite Membranes For Dehydration of IsopropanolConicov IuliaNo ratings yet

- 1solar CharecterisationDocument9 pages1solar Charecterisationjk balooNo ratings yet

- DesalinizationDocument14 pagesDesalinizationmarcofriuli2No ratings yet

- Water Environment Research - 2018 - Deng - Textiles Wastewater TreatmentDocument15 pagesWater Environment Research - 2018 - Deng - Textiles Wastewater TreatmentShirley ramosNo ratings yet

- Chapter 7 Ama 8 - DodoDocument30 pagesChapter 7 Ama 8 - DodoBadzlinaKhairunizzahraNo ratings yet

- Kasus 1: 50 % Propana + 50% N-ButanaDocument2 pagesKasus 1: 50 % Propana + 50% N-ButanaBadzlinaKhairunizzahraNo ratings yet

- Scan Data PreliumDocument5 pagesScan Data PreliumBadzlinaKhairunizzahraNo ratings yet

- Design Constraints of Horizontal SeparatorDocument2 pagesDesign Constraints of Horizontal SeparatorBadzlinaKhairunizzahraNo ratings yet

- Slug Catcher DLLDocument28 pagesSlug Catcher DLLBadzlinaKhairunizzahraNo ratings yet

- Design Contraints BadzDocument2 pagesDesign Contraints BadzBadzlinaKhairunizzahraNo ratings yet

- UopDocument8 pagesUopBadzlinaKhairunizzahraNo ratings yet

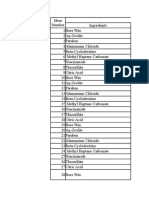

- Anti Stain Deodorant: Group 25Document13 pagesAnti Stain Deodorant: Group 25BadzlinaKhairunizzahraNo ratings yet

- Chemical Engineering Department, Faculty of Engineering, Universitas Indonesia, Depok, West Java, IndonesiaDocument6 pagesChemical Engineering Department, Faculty of Engineering, Universitas Indonesia, Depok, West Java, IndonesiaBadzlinaKhairunizzahraNo ratings yet

- Table X. Communication Cost Component Cost/month Cost/yearDocument15 pagesTable X. Communication Cost Component Cost/month Cost/yearBadzlinaKhairunizzahraNo ratings yet

- Chemical Engineering Department, Faculty of Engineering, Universitas Indonesia, Depok, West Java, IndonesiaDocument6 pagesChemical Engineering Department, Faculty of Engineering, Universitas Indonesia, Depok, West Java, IndonesiaBadzlinaKhairunizzahraNo ratings yet

- Metode DiferentsialDocument3 pagesMetode DiferentsialBadzlinaKhairunizzahraNo ratings yet

- Bab 3 - Ranya - RevisiDocument4 pagesBab 3 - Ranya - RevisiBadzlinaKhairunizzahraNo ratings yet

- Surface Facilities 2 PDFDocument54 pagesSurface Facilities 2 PDFBadzlinaKhairunizzahraNo ratings yet

- Cipro Flax inDocument4 pagesCipro Flax inBadzlinaKhairunizzahraNo ratings yet

- Concept Semuaaa IIIDocument53 pagesConcept Semuaaa IIIBadzlinaKhairunizzahraNo ratings yet

- Final Report - BadzDocument36 pagesFinal Report - BadzBadzlinaKhairunizzahraNo ratings yet

- POLYMATH Results: Multiple Linear RegressionDocument1 pagePOLYMATH Results: Multiple Linear RegressionBadzlinaKhairunizzahraNo ratings yet

- POLYMATH Results: Multiple Linear RegressionDocument1 pagePOLYMATH Results: Multiple Linear RegressionBadzlinaKhairunizzahraNo ratings yet

- Concept ScoringDocument4 pagesConcept ScoringBadzlinaKhairunizzahraNo ratings yet

- Asma Dan AlergiDocument7 pagesAsma Dan AlergiBadzlinaKhairunizzahraNo ratings yet

- Analisis Farmasi Dasar - 1 REVDocument126 pagesAnalisis Farmasi Dasar - 1 REVBadzlinaKhairunizzahra100% (1)

- Metode DiferentsialDocument3 pagesMetode DiferentsialBadzlinaKhairunizzahraNo ratings yet

- Concept Selection 25Document42 pagesConcept Selection 25BadzlinaKhairunizzahraNo ratings yet

- POLYMATH Results: Multiple Linear RegressionDocument1 pagePOLYMATH Results: Multiple Linear RegressionBadzlinaKhairunizzahraNo ratings yet

- UasssDocument9 pagesUasssBadzlinaKhairunizzahraNo ratings yet

- Latihan No 1Document37 pagesLatihan No 1BadzlinaKhairunizzahraNo ratings yet

- Wujud ZatDocument84 pagesWujud ZatBadzlinaKhairunizzahraNo ratings yet

- LuncheonDocument1 pageLuncheonBadzlinaKhairunizzahraNo ratings yet

- LuncheonDocument1 pageLuncheonBadzlinaKhairunizzahraNo ratings yet

- Photo EtchingDocument9 pagesPhoto EtchingMrIxolite100% (1)

- Coq 004DP44Document2 pagesCoq 004DP44m100% (2)

- RXN of Sulphuric Acid With SaltsDocument16 pagesRXN of Sulphuric Acid With SaltsSteve ClowesNo ratings yet

- 7.2 Factors A Ffecting Rate of Reactions: Activity 7.4 (Pg. 238)Document9 pages7.2 Factors A Ffecting Rate of Reactions: Activity 7.4 (Pg. 238)yusyus blablaNo ratings yet

- PEVA Full Project BookDocument50 pagesPEVA Full Project BookMahesh KumarNo ratings yet

- 9701 w15 Ms 31 PDFDocument5 pages9701 w15 Ms 31 PDFAl BeruniNo ratings yet

- Acid Leachability Copper Species PDFDocument10 pagesAcid Leachability Copper Species PDFJeyson Cornejo100% (1)

- Experiment 2 CHM 420Document6 pagesExperiment 2 CHM 420bellaamin100% (2)

- Biochem Lab ExperimentDocument15 pagesBiochem Lab ExperimentJeckha ReyNo ratings yet

- Qualitative Analysis of Lipids Through The Extraction of Total Lipids From Chicken Egg YolkDocument5 pagesQualitative Analysis of Lipids Through The Extraction of Total Lipids From Chicken Egg YolkJessa Mateum VallangcaNo ratings yet

- D BlockDocument17 pagesD Block145556No ratings yet

- Biomolecules & Polymers Exercise 1Document90 pagesBiomolecules & Polymers Exercise 1Aditya ShahNo ratings yet

- Ansi - Agma 2007-C00 - 06Document14 pagesAnsi - Agma 2007-C00 - 06gkhn100% (2)

- CHPT 11-13Document42 pagesCHPT 11-13Charles Borromeo LiNo ratings yet

- Acids and BasesDocument57 pagesAcids and Basesapi-263909505No ratings yet

- Capscaisin Synth - Synthesis of Some Capsaicin Analogues Using Fatty and BenzoicDocument3 pagesCapscaisin Synth - Synthesis of Some Capsaicin Analogues Using Fatty and BenzoicyunusNo ratings yet

- Midterm Exam in Cell BiologyDocument5 pagesMidterm Exam in Cell BiologyRetchel Cadayong NavalesNo ratings yet

- Novel Hydrotreating Technology For Production of Green Diesel - Haldor TopsoeDocument21 pagesNovel Hydrotreating Technology For Production of Green Diesel - Haldor Topsoebalarie100% (2)

- Hey 4-N/i'ethylenedio Yphenyl Sopropyl E.: 4-MethylenedioxyphenylisopropylamineDocument2 pagesHey 4-N/i'ethylenedio Yphenyl Sopropyl E.: 4-MethylenedioxyphenylisopropylamineAnonymous FigYuONxuuNo ratings yet

- Rate LawDocument3 pagesRate Lawnadia sykesNo ratings yet

- Seminar Sekolah Form 4 & Form 5 Chem 30.05.2023Document14 pagesSeminar Sekolah Form 4 & Form 5 Chem 30.05.2023Joehaimi ImanNo ratings yet

- Lewis Dot StructureDocument25 pagesLewis Dot StructureQuielle TangonanNo ratings yet

- Mud Design by Using KCL Polymer To Reduce Swelling Shale Control 2015 h2Document5 pagesMud Design by Using KCL Polymer To Reduce Swelling Shale Control 2015 h2Andi SusetioNo ratings yet

- The Role of Microbes in Plastic Degradation: August 2015Document31 pagesThe Role of Microbes in Plastic Degradation: August 2015JcNo ratings yet

- Thermodynamic Equilibrium For The Esterification of Acrylic Acid With Different Alcohols Catalyzed by Ion Exchange ResinDocument2 pagesThermodynamic Equilibrium For The Esterification of Acrylic Acid With Different Alcohols Catalyzed by Ion Exchange Resin1995CLNo ratings yet

- Sensors For Automotive and Aerospace Applications 2019 PDFDocument273 pagesSensors For Automotive and Aerospace Applications 2019 PDFAnurag Mishra100% (1)

- Chem 10 PDFDocument17 pagesChem 10 PDFDishank AgrawalNo ratings yet

- Chemical Bonding WK SHT 1Document2 pagesChemical Bonding WK SHT 1luis martinezNo ratings yet

- Chemistry of Life: By: Ruth Abigail C. ValdezDocument39 pagesChemistry of Life: By: Ruth Abigail C. ValdezPanJan BalNo ratings yet

- CFR 2011 Title21 Vol3 Sec175 105Document16 pagesCFR 2011 Title21 Vol3 Sec175 105ajoilhamNo ratings yet