Professional Documents

Culture Documents

Reference Only: Chip Ferrite Bead BLM21 N1 Reference Specification

Uploaded by

Phan Ngọc DuyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reference Only: Chip Ferrite Bead BLM21 N1 Reference Specification

Uploaded by

Phan Ngọc DuyCopyright:

Available Formats

Spec. No. JENF243A-0005AA-01 Reference Only P.

1/10

Chip Ferrite Bead BLM21□□□□□□N1□ Reference Specification

1. Scope

This reference specification applies to Chip Ferrite Bead BLM21_□N Series.

2. Part Numbering

(ex.) BL M 21 AG 121 S N 1 D

(1) (2) (3) (4) (5) (6) (7) (8) (9)

(1)Product ID (7)Category

(2)Type (8)Numbers of Circuit

(3)Dimension (L×W) (9)Packaging

(4)Characteristics D:Taping(φ180mm Reel, Paper Tape)

(5)Typical Impedance at 100MHz L:Taping(φ180mm Reel, Plastic Tape)

(6)Performance B:Bulk

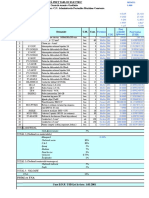

3. Rating

Impedance (Ω) DC Resistance

Rated Current

(at 100MHz,Under Standard (Ω) max.

Customer MURATA (mA)(*1)

Testing Condition) Initial Values Remark

Part Number Part Number Values After

at at

Typical Testing

85°C 125°C

BLM21PG220SN1D *1 *1

22±25% 22 0.009 0.018

BLM21PG220SN1B 6000 3300

BLM21PG300SN1D *1 *1

20 min. 30 0.014 0.028

BLM21PG300SN1B 4000 2300

BLM21PG600SN1D *1 *1

60±25% 60 0.02 0.04

BLM21PG600SN1B 3500 1900

BLM21PG121SN1D *1 *1

120±25% 120 0.03 0.06

BLM21PG121SN1B 3000 1550

BLM21PG221SN1D *1 *1

220±25% 220 0.045 0.09

BLM21PG221SN1B 2000 1250

BLM21PG331SN1D *1 *1

330±25% 330 0.07 0.14

BLM21PG331SN1B 1500 1000

BLM21SN300SN1D *1 *1

30±10Ω 30 0.004 0.005

BLM21SN300SN1B 8500 6000 For DC

BLM21SP700SN1D *1 *1 power line

70±25% 70 0.009 0.012

BLM21SP700SN1B 6000 4000

BLM21SP111SN1D *1 *1

110±25% 110 0.013 0.016

BLM21SP111SN1B 5000 3300

BLM21SP181SN1D *1 *1

180±25% 180 0.020 0.025

BLM21SP181SN1B 4000 2600

BLM21SP331SN1D *1 *1

330±25% 330 0.040 0.051

BLM21SP331SN1B 2800 1900

BLM21SP471SN1D *1 *1

470±25% 470 0.050 0.063

BLM21SP471SN1B 2500 1700

BLM21SP601SN1D *1 *1

600±25% 600 0.060 0.074

BLM21SP601SN1B 2300 1500

BLM21SP102SN1D *1 *1

1000±25% 1000 0.120 0.144

BLM21SP102SN1B 1600 1100

BLM21RK121SN1D

120±25% 120 200 0.15 0.25

BLM21RK121SN1B

BLM21RK221SN1D

220±25% 220 200 0.20 0.30

BLM21RK221SN1B

BLM21RK471SN1D For

470±25% 470 200 0.25 0.35 Digital

BLM21RK471SN1B Interface

BLM21RK601SN1D

600±25% 600 200 0.30 0.40

BLM21RK601SN1B

BLM21RK102SN1D

1000±25% 1000 200 0.50 0.60

BLM21RK102SN1B

MURATA MFG.CO., LTD.

Reference Only

Total page 3/16

Spec. No. JENF243A-0005AA-01 P.2/10

Impedance (Ω) DC Resistance

(at 100MHz,Under Standard (Ω) max.

Customer MURATA Rated Current

Testing Condition) Initial Values Remark

Part Number Part Number (mA)

Values After

Typical

Testing

BLM21BB050SN1D

5±25% 5 1000 0.02 0.04

BLM21BB050SN1B

BLM21BB600SN1D

60±25% 60 800 0.13 0.23

BLM21BB600SN1B

BLM21BB750SN1D

75±25% 75 700 0.16 0.26

BLM21BB750SN1B

BLM21BB121SN1D

120±25% 120 600 0.19 0.29

BLM21BB121SN1B

BLM21BD121SN1D

120±25% 120 350 0.25 0.35

BLM21BD121SN1B

BLM21BB151SZ1D

150±25% 150 600 0.21 0.31

BLM21BB151SZ1B

BLM21BD151SN1D

150±25% 150 350 0.25 0.35

BLM21BD151SN1B

BLM21BB201SN1D

200±25% 200 500 0.26 0.36

BLM21BB201SN1B

BLM21BB221SN1D

220±25% 220 500 0.26 0.36

BLM21BB221SN1B

BLM21BD221SN1D

220±25% 220 350 0.25 0.35

BLM21BD221SN1B

BLM21BB331SN1D

330±25% 330 400 0.33 0.43

BLM21BB331SN1B For

BLM21BD331SN1D high speed

330±25% 330 300 0.3 0.4

BLM21BD331SN1B signal line

BLM21BD421SN1D

420±25% 420 300 0.3 0.4

BLM21BD421SN1B

BLM21BB471SN1D

470±25% 470 400 0.40 0.50

BLM21BB471SN1B

BLM21BD471SN1D

470±25% 470 300 0.35 0.45

BLM21BD471SN1B

BLM21BD601SN1D

600±25% 600 300 0.35 0.45

BLM21BD601SN1B

BLM21BD751SN1D

750±25% 750 250 0.4 0.5

BLM21BD751SN1B

BLM21BD102SN1D

1000±25% 1000 250 0.4 0.5

BLM21BD102SN1B

BLM21BD152SN1D

1500±25% 1500 250 0.45 0.55

BLM21BD152SN1B

BLM21BD182SN1D

1800±25% 1800 250 0.5 0.6

BLM21BD182SN1B

BLM21BD222SN1L

1600 min. 2250 250 0.6 0.7

BLM21BD222SN1B

BLM21BD222TN1D

2200±25% 2200 200 0.6 0.7

BLM21BD222TN1B

BLM21BD272SN1L

2700±25% 2700 200 0.8 0.9

BLM21BD272SN1B

MURATA MFG.CO., LTD.

Reference Only

Total page 3/16

Spec. No. JENF243A-0005AA-01 P.3/10

Impedance (Ω) DC Resistance

(at 100MHz,Under Standard (Ω) max.

Customer MURATA Rated Current

Testing Condition) Initial Values Remark

Part Number Part Number (mA)

Values After

Typical

Testing

BLM21AG121SN1D

120±25% 120 1000 0.09 0.19

BLM21AG121SN1B

BLM21AG151SN1D

150±25% 150 1000 0.09 0.19

BLM21AG151SN1B

BLM21AG221SN1D

220±25% 220 900 0.12 0.22

BLM21AG221SN1B

BLM21AG331SN1D For

330±25% 330 800 0.15 0.25 general

BLM21AG331SN1B

use

BLM21AG471SN1D

470±25% 470 700 0.18 0.28

BLM21AG471SN1B

BLM21AG601SN1D

600±25% 600 700 0.2 0.3

BLM21AG601SN1B

BLM21AG102SN1D

1000±25% 1000 600 0.27 0.37

BLM21AG102SN1B

• Operating Temperature : -55°C to +125°C • Storage Temperature : -55°C to +125°C

R a te d C u rr e n t ( A )

85℃

x

(Note)As for Rated current marked with *1, Describe the Rated current as x[A]

in case of more than 1A.

Rated Current is derated as right figure

depending on the operating temperature. 1

125℃

0

85 125

Operating Temperature (°C)

4. Style and Dimensions

L W

■ Equivalent Circuit

( )

E

Resistance element becomes

dominant at high frequencies.

:Electrode

■ Unit Mass (Typical value)

0.010g

0.014g ( for 21BD222SN1□/21BD272SN1□)

L W T E

0.85±0.2

0.5±0.2

2.0±0.2 1.25±0.2 for 21BD222SN1□

21BD272SN1□ for 21BD272SN1□

1.25±0.2 0.3±0.2

(in mm)

5. Marking

No marking.

6.Standard Testing Conditions

< Unless otherwise specified > < In case of doubt >

Temperature : Ordinary Temp. (15 °C to 35 °C ) Temperature : 20°C±2 °C

Humidity : Ordinary Humidity (25%(RH) to 85%(RH)) Humidity : 60%(RH) to 70%(RH)

Atmospheric pressure : 86kPa to 106kPa

MURATA MFG.CO., LTD.

Spec. No. JENF243A-0005AA-01 Reference Only P.4/10

7. Specifications

7-1.Electrical Performance

No. Item Specification Test Method

7-1-1 Impedance Meet item 3. Measuring Frequency : 100MHz±1MHz

Measuring Equipment :

KEYSIGHT4291A or the equivalent

Test Fixture : KEYSIGHT16192A or the equivalent

7-1-2 DC Resistance Meet item 3. Measuring Equipment : Digital multi meter

* Except resistance of the Substrate and Wire

7-2. Mechanical Performance

No. Item Specification Test Method

7-2-1 Appearance and Meet item 4. Visual Inspection and measured with Slide Calipers.

Dimensions

7-2-2 Bonding Meet Table 1. It shall be soldered on the substrate.

Strength Applying Force(F) : 9.8N

Table 1 Applying Time : 5s±1s

Applied direction:Parallel to substrate

Appearance No damage

Side view

Impedance F

Change Within ±30% F

(at 100MHz) R0.5

DC

Meet item 3.

Resistance

Substrate

7-2-3 Bending It shall be soldered on the substrate.

Strength Substrate: Glass-epoxy 100mm×40mm×1.6mm

Deflection: 1.0mm

Speed of Applying Force : 0.5mm/s

Keeping Time : 30s Pressure jig

R340 F

Deflection

45mm 45mm

Product

7-2-4 Vibration It shall be soldered on the substrate.

Oscillation Frequency : 10Hz to 55Hz to 10Hz for 1 min

Total Amplitude : 1.5mm

Testing Time : A period of 2 hours in each of 3 mutually

perpendicular directions. (Total 6 h)

7-2-5 Resistance Meet Table 2. Pre-Heating : 150°C±10°C, 60s~90s

to Soldering Table 2 Solder : Sn-3.0Ag-0.5Cu

Heat Appearance No damage Solder Temperature : 270°C±5°C

Impedance Within ±30% Immersion Time : 10s±0.5s

Change (for BLM21SN Immersion and emersion rates : 25mm/s

(at 100MHz) Within ±50%) Then measured after exposure in the room condition

DC for 48h±4h.

Meet item 3.

Resistance

7-2-6 Drop Products shall be no failure It shall be dropped on concrete or steel board.

after tested. Method : free fall

Height : 75cm

Attitude from which the product is dropped : 3 direction

The number of times : 3 times for each direction(Total 9 times)

7-2-7 Solderability The electrodes shall be at Flux : Ethanol solution of rosin,25(wt)%

least 95% covered with new Pre-Heating : 150°C±10°C, 60s~90s

solder coating. Solder : Sn-3.0Ag-0.5Cu

Solder Temperature : 240°C±5°C

Immersion Time : 4s±1s

Immersion and emersion rates : 25mm/s

MURATA MFG.CO., LTD.

Spec. No. JENF243A-0005AA-01 Reference Only P.5/10

7-3. Environmental Performance

It shall be soldered on the substrate.

No. Item Specification Test Method

7-3-1 Temperature Meet Table 2. 1 cycle :1 step : -55 °C(+0 °C,-3 °C) / 30min±3min

Cycle 2 step : Ordinary temp. / 10min to 15min

3 step : +125 °C(+3 °C,-0 °C) / 30min±3min

4 step : Ordinary temp. / 10min to 15min

Total of 100 cycles

Then measured after exposure in the room condition for 48h±4h.

7-3-2 Humidity Temperature : 40°C±2°C

Humidity : 90%(RH) to 95%(RH)

Time : 1000h(+48h,-0h)

Then measured after exposure in the room condition for 48h±4h.

7-3-3 Heat Life Temperature : 125°C±3°C

(in case of Rated current is more than 1A,

do the test at : +85 °C±3°C)

Applying Current : Rated Current

Time : 1000h(+48h,-0h)

Then measured after exposure in the room condition for 48h±4h.

7-3-4 Cold Temperature : -55°C±2°C

Resistance Time : 1000h(+48h,-0h) Total page 6/16

Then measured after exposure in the room condition for 48h±4h.

8. Specification of Packaging

8-1. Appearance and Dimensions

Appearance and Dimensions

Part Number Type

a

1.75±0.1

2.0±0.05 Plastic Tape

BLM21 8mm- 4.0±0.1 4.0±0.1 +0.1 a

φ 1.5 -0

0.2±0.1 Paper Tape

except wide 1.1

21BD222SN1L Paper max.

21BD272SN1L tape

3.5±0.05

8.0±0.3

2.25±0.1

8mm-

1.45±0.1

BLM21BD222SN1L wide 1.3 a

Direction of feed

BLM21BD272SN1L Plastic ±0.1 There are holes in the cavity

tape of the Plastic tape φ 1.0 +0.3

-0

*Dimension of the Cavity is measured at the bottom side.

(in mm)

Paper tape Plastic tape

Taping Products shall be packaged in the cavity of the base Products shall be packaged in the each embossed

tape of 8mm-wide, 4mm-pitch continuously and cavity of 8mm-wide, 4mm-pitch plastic tape

sealed by top tape and bottom tape. continuously and sealed by cover tape.

Sprocket hole The sprocket holes are to the right as the tape is pulled toward the user.

Spliced point The base tape and top tape have no spliced point. The cover tape has no spliced point.

Cavity There shall not be burr in the cavity. -

Missing Missing components number within 0.025% of the number per reel or 1 pc., whichever is greater,

components and are not continuous. The specified quantity per reel is kept.

number

MURATA MFG.CO., LTD.

Spec. No. JENF243A-0005AA-01 Reference Only P.6/10

8-2. Tape Strength

(1)Pull Strength

Top tape

Paper tape 5N min.

Bottom tape

Plastic tape 5N min.

Plastic tape

Cover tape 10N min.

(2) Peeling off force of Top tape・Cover tape

Speed of Peeling off 300mm/min

Paper tape 0.1N to 0.6N

Peeling off force *

Plastic tape 0.2N to 0.7N

* Minimum value is typical.

• Case of Paper tape • Case of Plastic tape

Top tape

165 to 180 degree 165 to 180 degree

F F Cover tape

Bottom tape Base tape

Plastic tape

8-3. Taping Condition

(1) Standard quantity per reel

Type Quantity per 180mm reel

BLM21(except 21BD222SN1L/21BD272SN1L) 4000 pcs. / reel

BLM21BD222SN1L/BLM21BD272SN1L 3000 pcs. / reel

(2) There shall be leader-tape (cover tape/top tape and empty tape ) and trailer- tape(empty tape) as follows.

(3) On paper tape, the top tape and the base tape shall not be adhered at the tip of the empty leader tape for more

than 5 pitch.

(4) Marking for reel

The following items shall be marked on a label and the label is stuck on the reel.

(Customer part number, MURATA part number, Inspection number(∗1) , RoHS marking(∗2), Quantity, etc)

∗1) « Expression of Inspection No. » □□ OOOO ×××

(1) (2) (3)

(1) Factory Code

(2) Date First digit : Year / Last digit of year

Second digit : Month / Jan. to Sep. → 1 to 9, Oct. to Dec. → O, N, D

Third, Fourth digit : Day

(3) Serial No.

∗2) « Expression of RoHS marking » ROHS – Y (△)

(1) (2)

(1) RoHS regulation conformity parts.

(2) MURATA classification number

(5) Outside package

These reels shall be packed in the corrugated cardboard package and the following items shall be marked

on a label and the label is stuck on the box.

(Customer name, Purchasing order number, Customer part number, MURATA part number,

RoHS marking (∗2) ,Quantity, etc)

(6) Dimensions of reel and taping(leader-tape, trailer-tape)

MURATA MFG.CO., LTD.

Spec. No. JENF243A-0005AA-01 Reference Only P.7/10

8-4. Specification of Outer Case

Label

Outer Case Dimensions

Standard Reel Quantity in Outer Case

(mm)

H (Reel)

W D H

D 186 186 93 5

W

∗ Above Outer Case size is typical. It depends on a quantity of an

order.

9. ! Caution

9-1. Surge current

Excessive surge current (pulse current or rush current) than specified rated current applied to the product may

cause a critical failure, such as an open circuit, burnout caused by excessive temperature rise.

Please contact us in advance in case of applying the surge current.

9-2. Limitation of Applications

Please contact us before using our products for the applications listed below which require especially high

reliability for the prevention of defects which might directly cause damage to the third party's life, body or

property.

(1) Aircraft equipment (6) Disaster prevention / crime prevention equipment

(2) Aerospace equipment (7) Traffic signal equipment

(3) Undersea equipment (8) Transportation equipment (trains,ships,etc.)

(4) Power plant control equipment (9) Data-processing equipment

(5) Medical equipment (10) Applications of similar complexity and /or reliability requirements

to the applications listed in the above

10. Notice

This product is designed for solder mounting.

Please consult us in advance for applying other mounting method such as conductive adhesive.

10-1. Land pattern designing

• Standard land dimensions

< BLM21 series(except BLM21PG/BLM21S type) >

Chip Ferrite Bead

c

Soldering a b c

a Solder Resist Flow 1.1 3.5 0.95

b Pattern Reflow 1.2 2.4 1.25

(in mm)

< For BLM21PG/BLM21S type >

Chip Ferrite Bead

Rated Land pad thickness

Type Current and dimension d

(A) 18µm 35µm 70µm

c d 1.5 1.25 1.25 1.25

2 1.25 1.25 1.25

BLM21PG

3~4 2.4 1.25 1.25

6 6.4 3.3 1.65

a BLM21S 1~8.5 - 6.8 3.4

b

(in mm)

Solder Resist

Pattern Soldering a b c

Flow 1.1 3.5 0.95

Reflow 1.2 2.4 1.25

(in mm)

*The excessive heat by land pads may cause deterioration

at joint of products with substrate.

MURATA MFG.CO., LTD.

Spec. No. JENF243A-0005AA-01 Reference Only P.8/10

10-2. Soldering Conditions

Products can be applied to reflow and flow soldering.

(1) Flux, Solder

Flux Use rosin-based flux, but not highly acidic flux (with chlorine content exceeding 0.2(wt)%. )

Do not use water-soluble flux.

Solder Use Sn-3.0Ag-0.5Cu solder

Standard thickness of solder paste : 100 µm to 200 μm

(2) Soldering conditions

• Pre-heating should be in such a way that the temperature difference between solder and ferrite surface is limited

to 150℃ max. Also cooling into solvent after soldering should be in such a way that the temperature difference

is limited to 100℃ max.

Insufficient pre-heating may cause cracks on the ferrite, resulting in the deterioration of product quality.

• Standard soldering profile and the limit soldering profile is as follows.

The excessive limit soldering conditions may cause leaching of the electrode and / or resulting

in the deterioration of product quality.

(3) soldering profile

□Flow soldering profile

Temp.

(℃)

265℃±3℃

250℃

Limit Profile

150

Heating Time

Standard Profile

60s min. Time. (s)

Standard Profile Limit Profile

Pre-heating 150℃、60s min.

Heating 250℃、4~6s 265℃±3℃、5s max.

Cycle of flow 2 times 2 times

□Reflow soldering profile

Temp. 260℃

(℃)

245℃±3℃

230℃

220℃

Limit Profile

180

150

30s~60s Standard Profile

60s max.

90s±30s Time. (s)

Standard Profile Limit Profile

Pre-heating 150~180°C 、90s±30s

Heating above 220°C、30s~60s above 230°C、60s max.

Peak temperature 245±3°C 260°C,10s

Cycle of reflow 2 times 2 times

MURATA MFG.CO., LTD.

Spec. No. JENF243A-0005AA-01 Reference Only P.9/10

10-3. Reworking with soldering iron

• Pre-heating: 150°C, 1 min • Soldering iron output: 80W max.

• Tip temperature: 350°C max. • Tip diameter:φ3mm max.

• Soldering time : 3(+1,-0) seconds. • Times : 2times max.

Note :Do not directly touch the products with the tip of the soldering iron in order to prevent the crack

on the ferrite material due to the thermal shock.

10-4. Solder Volume

Solder shall be used not to be exceed as shown below.

Upper Limit

Recommendable

t 1/3T≦t≦T

(T:Chip thickness)

Total page

Accordingly increasing the solder volume, the mechanical stress to product is also increased.

Exceeding solder volume may cause the failure of mechanical or electrical performance.

10-5. Attention regarding P.C.B. bending

The following shall be considered when designing and laying out P.C.B.'s.

(1) P.C.B. shall be designed so that products are not subjected to the mechanical stress for board warpage.

<Products direction>

a

Products shall be located in the sideways

b direction (Length:a<b) to the mechanical

stress.

〈 Poor example 〉 〈 Good example 〉

(2) Components location on P.C.B. separation.

It is effective to implement the following measures, to reduce stress in separating the board.

It is best to implement all of the following three measures; however, implement as many measures

as possible to reduce stress.

Contents of Measures Stress Level

(1) Turn the mounting direction of the component parallel to the board separation surface. A > D *1

(2) Add slits in the board separation part. A > B

(3) Keep the mounting position of the component away from the board separation surface. A > C

C

Perforation

B

D

A

Slit

*1 A > D is valid when stress is added vertically to the perforation as with Hand Separation.

If a Cutting Disc is used, stress will be diagonal to the PCB, therefore A > D is invalid.

(3) Mounting Components Near Screw Holes

When a component is mounted near a screw hole, it may be affected by the board deflection that occurs

during the tightening of the screw. Mount the component in a position as far away from the screw holes

as possible.

Screw Hole Recommended

MURATA MFG.CO., LTD.

Spec. No. JENF243A-0005AA-01 Reference Only P.10/10

10-6. Mounting density

Add special attention to radiating heat of products when mounting the inductor near the products with heating.

The excessive heat by other products may cause deterioration at joint of this product with substrate.

10-7. Operating Environment

Do not use this product under the following environmental conditions, on deterioration of the Insulation

Resistance of the Ferrite material and/or corrosion of Inner Electrode may result from the use.

(1) in the corrodible atmosphere such as acidic gases, alkaline gases, chlorine, sulfur gases, organic gases and

etc (the sea breeze, Cl2, H2S, NH3, SO2, NO2,etc)

(2) in the atmosphere where liquid such as organic solvent, may splash on the products.

(3) in the atmosphere where the temperature / humidity changes rapidly and it is easy to dew.

10-8. Resin coating

The impedance value may change and/or it may affect on the product's performance due to high cure-stress of

resin to be used for coating / molding products. So please pay your careful attention when you select resin. In

prior to use, please make the reliability evaluation with the product mounted in your application set.

10-9. Cleaning

Excessive ultrasonic oscillation during cleaning can cause the PCBs to resonate, resulting in cracked chips or

broken solder joints. Before starting your production process, test your cleaning equipment / process to insure

it does not degrade this product.

10-10. Handling of a substrate

After mounting products on a substrate, do not apply any stress to the product caused by bending or twisting to

the substrate when cropping the substrate, inserting and removing a connector from the substrate or tightening

screw to the substrate.

Excessive mechanical stress may cause cracking in the product.

Bending Twisting

10-11 Storage Conditions

(1) Storage period

Use the products within 6 months after delivered.

Solderability should be checked if this period is exceeded.

(2) Storage conditions

• Products should be stored in the warehouse on the following conditions.

Temperature : -10°C to 40°C

Humidity : 15% to 85% relative humidity

No rapid change on temperature and humidity

• Don't keep products in corrosive gases such as sulfur, chlorine gas or acid, or it may cause oxidization

of electrode, resulting in poor solderability.

• Products should be stored on the palette for the prevention of the influence from humidity, dust and so on.

• Products should be stored in the warehouse without heat shock, vibration, direct sunlight and so on.

• Avoid storing the product by itself bare (i.e.exposed directly to air).

(3) Delivery

Care should be taken when transporting or handling product to avoid excessive vibration or mechanical shock.

11. ! Note

(1)Please make sure that your product has been evaluated in view of your specifications with our product being

mounted to your product.

(2)You are requested not to use our product deviating from the agreed specifications.

(3) The contents of this reference specification are subject to change without advance notice. Please approve

our product specifications or transact the approval sheet for product specifications before ordering.

MURATA MFG.CO., LTD.

You might also like

- SSPC Pa1Document12 pagesSSPC Pa1romeroberna100% (1)

- Study Notes Weather MeteorologyDocument35 pagesStudy Notes Weather MeteorologyNeeth100% (1)

- Setting Calculation 7SD522Document19 pagesSetting Calculation 7SD522Noptana TummasitNo ratings yet

- Problems of PET BlowingDocument14 pagesProblems of PET BlowingMohamedHassan100% (3)

- HVAC BasicsDocument25 pagesHVAC BasicsMohazfa100% (2)

- Buckling CalculatorDocument35 pagesBuckling CalculatorMunever Okić0% (1)

- ISTA Procedure 2B 11-12Document15 pagesISTA Procedure 2B 11-12Sloat tingNo ratings yet

- Enfa0003 1915778Document13 pagesEnfa0003 1915778Mateusz CzerwińskiNo ratings yet

- Reference Only: Chip Ferrite Bead BLM18 Z1D Murata Standard Reference Specification (AEC-Q200)Document11 pagesReference Only: Chip Ferrite Bead BLM18 Z1D Murata Standard Reference Specification (AEC-Q200)santhosha rkNo ratings yet

- 1N5221A To 1N5272DDocument3 pages1N5221A To 1N5272DlavinelllNo ratings yet

- 1N5937 Diodo ZenerDocument3 pages1N5937 Diodo Zenerluis daniel suarez narvaezNo ratings yet

- Diodo Zener In5236bDocument3 pagesDiodo Zener In5236bDidier DoradoNo ratings yet

- 1N52XXDocument5 pages1N52XXRegaNo ratings yet

- Silicon Planar Zener Diodes 1N5223B To 1N5273B 2.7V To 120V DO-35 Glass Axial PackageDocument6 pagesSilicon Planar Zener Diodes 1N5223B To 1N5273B 2.7V To 120V DO-35 Glass Axial PackageChelaru CosminNo ratings yet

- Kons (PPM) Abs: Kurva StandarDocument8 pagesKons (PPM) Abs: Kurva StandarTri LedianaNo ratings yet

- 1N43 1N7 1N43 1N7 Series Zener DiodesDocument2 pages1N43 1N7 1N43 1N7 Series Zener DiodesAllan Souza SantanaNo ratings yet

- MMZ1608B102CTD25 - TDK - 0603 - Ferrite BeadsDocument9 pagesMMZ1608B102CTD25 - TDK - 0603 - Ferrite BeadsAjay SadarNo ratings yet

- 500 MW DO-35 Hermetically Sealed Glass Zener Voltage RegulatorsDocument6 pages500 MW DO-35 Hermetically Sealed Glass Zener Voltage RegulatorsEduRoiNo ratings yet

- Street Lighting Voltage DropDocument12 pagesStreet Lighting Voltage Dropaliabdallah20232023No ratings yet

- 1N5221B THRU 1N5278B Silicon Zener Diodes 500mW, 2.4 THRU 170 VOLT 5% Tolerance DescriptionDocument6 pages1N5221B THRU 1N5278B Silicon Zener Diodes 500mW, 2.4 THRU 170 VOLT 5% Tolerance DescriptionKalin GeorgievNo ratings yet

- DatasheetDocument4 pagesDatasheetsajad hejaziNo ratings yet

- Zeners 1N5985B - 1N6025B: Absolute Maximum RatingsDocument3 pagesZeners 1N5985B - 1N6025B: Absolute Maximum RatingsZoltán ÁgostonNo ratings yet

- St1 LF Series 1W Isolated DC/DC ConverterDocument2 pagesSt1 LF Series 1W Isolated DC/DC ConverterStuxnetNo ratings yet

- Data Sheet: E Cores and AccessoriesDocument6 pagesData Sheet: E Cores and AccessoriesHarsh GajjarNo ratings yet

- INVESTIGACIONDocument4 pagesINVESTIGACIONJose Jairo Arregoces GranadilloNo ratings yet

- b3292x Ambient ConditionsDocument4 pagesb3292x Ambient ConditionsDimas ScrewNo ratings yet

- Inductor Automotive Decoupling mlz2012 enDocument12 pagesInductor Automotive Decoupling mlz2012 enFurkan Berk KayaNo ratings yet

- Transmission and Attaching PartDocument2 pagesTransmission and Attaching PartМаксимNo ratings yet

- BAS16Document4 pagesBAS16freddyNo ratings yet

- 2SK2696 01MRDocument1 page2SK2696 01MRcarlos eduardo peçanhaNo ratings yet

- MMBZ5225-V To MMBZ5267-V: Small Signal Zener DiodesDocument6 pagesMMBZ5225-V To MMBZ5267-V: Small Signal Zener DiodesgeraldoNo ratings yet

- Power Distribution Box, Rear Integrated Supply Module: Z11 F014 F011 F018 F08 F010 Z2a A361Document9 pagesPower Distribution Box, Rear Integrated Supply Module: Z11 F014 F011 F018 F08 F010 Z2a A361Ninh LỗNo ratings yet

- B3J Hinged Tactile Switch: Ordering InformationDocument3 pagesB3J Hinged Tactile Switch: Ordering InformationMuhamad PriyatnaNo ratings yet

- Bzg01 Series 2Document8 pagesBzg01 Series 2drain rainNo ratings yet

- Design of Beam (Transverse)Document58 pagesDesign of Beam (Transverse)Anissah ManialaNo ratings yet

- 1N4728A Through 1N4753A: Silicon Epitaxial Planar Zener Diodes For Stabilized Power SupplyDocument7 pages1N4728A Through 1N4753A: Silicon Epitaxial Planar Zener Diodes For Stabilized Power SupplyAdriana ContrerasNo ratings yet

- 2450LP15B050Document2 pages2450LP15B050Venkatesh ANo ratings yet

- BLM18KDocument4 pagesBLM18KRadu PaulNo ratings yet

- Bostitch 2 in 1 Brad Nailer / StaplerDocument5 pagesBostitch 2 in 1 Brad Nailer / StaplerJesus MartínezNo ratings yet

- Chip Emifil Inductor Type: Chip Ferrite Beads BLM21A Series (0805 Size)Document2 pagesChip Emifil Inductor Type: Chip Ferrite Beads BLM21A Series (0805 Size)Monica ShuNo ratings yet

- Kitchen Towel III - Specification SheetDocument2 pagesKitchen Towel III - Specification SheetKushagri JoshiNo ratings yet

- HT Combitest 2019 SpecificationDocument3 pagesHT Combitest 2019 SpecificationAlbertofullHdNo ratings yet

- Napkin II - Specification SheetDocument2 pagesNapkin II - Specification SheetKushagri JoshiNo ratings yet

- 1N47XXDocument4 pages1N47XXLuizNo ratings yet

- Murata LQH5BPN3R3N38KDocument9 pagesMurata LQH5BPN3R3N38Km2003021No ratings yet

- HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Document4 pagesHPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Er Umesh RohitNo ratings yet

- Description and Application: 80%ar - 20%CO / 100%CO EN ISO 17633-A T 19 9 L P C1/M21 1 AWS A5.22 E308LT1-1/4 EN 1.4316Document1 pageDescription and Application: 80%ar - 20%CO / 100%CO EN ISO 17633-A T 19 9 L P C1/M21 1 AWS A5.22 E308LT1-1/4 EN 1.4316amit singhNo ratings yet

- 0003401-01-01 DB 3g30aDocument2 pages0003401-01-01 DB 3g30amarcusNo ratings yet

- csl1103wbbw1 eDocument19 pagescsl1103wbbw1 eawswNo ratings yet

- BZX79B2V4 - BZX79B75: Taiwan SemiconductorDocument6 pagesBZX79B2V4 - BZX79B75: Taiwan SemiconductorAriel MercochaNo ratings yet

- M.I - (Lonclictot: 20 Stern Ave. Springfield, New Jersey 07081Document2 pagesM.I - (Lonclictot: 20 Stern Ave. Springfield, New Jersey 07081enriquevazquez27No ratings yet

- TP2L 3W PDFDocument3 pagesTP2L 3W PDFtoppowerNo ratings yet

- Exp - 2411 - 0542 - 2 - 2 48 PaDocument6 pagesExp - 2411 - 0542 - 2 - 2 48 PaHidayati ArsyfaNo ratings yet

- z1047 (TS)Document1 pagez1047 (TS)zero cloudNo ratings yet

- NIC Components NCC SeriesDocument3 pagesNIC Components NCC SeriesNICCompNo ratings yet

- Bn44-00050acb-Rb15 Inverter PDFDocument11 pagesBn44-00050acb-Rb15 Inverter PDFodilonsouzaNo ratings yet

- Zeners 1N5221B - 1N5279B: Absolute Maximum RatingsDocument4 pagesZeners 1N5221B - 1N5279B: Absolute Maximum Ratingsdballe7No ratings yet

- 6 Beads Commercial Signal mmz1608 en PDFDocument9 pages6 Beads Commercial Signal mmz1608 en PDFrakeeNo ratings yet

- Diodo BZXDocument3 pagesDiodo BZXAndrey SilvaNo ratings yet

- Stroke Tol. +1.8 - 1.6Document4 pagesStroke Tol. +1.8 - 1.6Todor NedyalkovNo ratings yet

- Furnizor U.M. Preţ Achiziţie (Plecare) Preţ Unitar (USD) : TOTAL Cu T.V.ADocument8 pagesFurnizor U.M. Preţ Achiziţie (Plecare) Preţ Unitar (USD) : TOTAL Cu T.V.AConstantin PopoviciNo ratings yet

- Diode Zener 1N5365BDocument4 pagesDiode Zener 1N5365BNader HechmiNo ratings yet

- Long-Stroke Tactile Switch B3MDocument2 pagesLong-Stroke Tactile Switch B3MMuhamad PriyatnaNo ratings yet

- Analog IC Test-Chip: Christian Vega R. Jacob Baker UNLV Electrical & Computer EngineeringDocument75 pagesAnalog IC Test-Chip: Christian Vega R. Jacob Baker UNLV Electrical & Computer EngineeringPhan Ngọc DuyNo ratings yet

- Digital Pad Operation: Christian Vega R. Jacob Baker UNLV Electrical & Computer EngineeringDocument19 pagesDigital Pad Operation: Christian Vega R. Jacob Baker UNLV Electrical & Computer EngineeringPhan Ngọc DuyNo ratings yet

- 3362 - 1/4 Square Trimpot Trimming Potentiometer: FeaturesDocument3 pages3362 - 1/4 Square Trimpot Trimming Potentiometer: FeaturesPhan Ngọc DuyNo ratings yet

- Practical Issues in High Speed PCB DesignDocument5 pagesPractical Issues in High Speed PCB DesignPhan Ngọc DuyNo ratings yet

- Part Number: XDMR14C-1: 14.2mm (0.56") SINGLE DIGIT NUMERIC DIS-PlayDocument3 pagesPart Number: XDMR14C-1: 14.2mm (0.56") SINGLE DIGIT NUMERIC DIS-PlayPhan Ngọc DuyNo ratings yet

- MF-MSMF Series - PTC Resettable Fuses: FeaturesDocument8 pagesMF-MSMF Series - PTC Resettable Fuses: FeaturesPhan Ngọc DuyNo ratings yet

- Chipguard MLC Series - Esd Protectors: Features ApplicationsDocument4 pagesChipguard MLC Series - Esd Protectors: Features ApplicationsPhan Ngọc DuyNo ratings yet

- Recommender PCB Layout: Header .100" Pitch, 2 Rows, StraightDocument1 pageRecommender PCB Layout: Header .100" Pitch, 2 Rows, StraightPhan Ngọc DuyNo ratings yet

- LP2985 150-Ma Low-Noise Low-Dropout Regulator With Shutdown: 1 Features 3 DescriptionDocument28 pagesLP2985 150-Ma Low-Noise Low-Dropout Regulator With Shutdown: 1 Features 3 DescriptionPhan Ngọc DuyNo ratings yet

- Kudremukh MgmtPlanDocument113 pagesKudremukh MgmtPlanherleprasNo ratings yet

- Design and Thermal Analysis of An Air Source Heat Pump PDFDocument17 pagesDesign and Thermal Analysis of An Air Source Heat Pump PDFJosé JorgeNo ratings yet

- Higrostat MFR012!04!2011 enDocument1 pageHigrostat MFR012!04!2011 enIRINA_CorrnelNo ratings yet

- Xenon Lamp Aging Test ChamberDocument6 pagesXenon Lamp Aging Test ChamberLisun GroupNo ratings yet

- The AWG5000 Is Engineered To Produce Large Quantities of Water in A Wide Range of Operating ConditionsDocument1 pageThe AWG5000 Is Engineered To Produce Large Quantities of Water in A Wide Range of Operating ConditionsFreddy MaxwellNo ratings yet

- IOT Based Automatic Plant Irrigation System Based On Weather Conditions Using Multiple Weather Sensors.Document4 pagesIOT Based Automatic Plant Irrigation System Based On Weather Conditions Using Multiple Weather Sensors.dileeppatraNo ratings yet

- Topic 3 - Air Handling SystemsDocument58 pagesTopic 3 - Air Handling SystemsAndy MakNo ratings yet

- bst161 FullDocument23 pagesbst161 FullchkznzjwfsNo ratings yet

- Climate and WeatherDocument10 pagesClimate and WeatherLKP GhNo ratings yet

- C1258 PDFDocument2 pagesC1258 PDFsenthilNo ratings yet

- Manual D530M DESHUMIFICADOR HAIERDocument35 pagesManual D530M DESHUMIFICADOR HAIERJose GutierrezNo ratings yet

- 20 Ijrerd-C153Document9 pages20 Ijrerd-C153Akmaruddin Bin JofriNo ratings yet

- Long Term Monitoring of Moisture in Concrete StructuresDocument27 pagesLong Term Monitoring of Moisture in Concrete StructuresAshutoshAparajNo ratings yet

- Auda0441 Dulux Acratex Acraprime Water Based: Product OverviewDocument5 pagesAuda0441 Dulux Acratex Acraprime Water Based: Product OverviewstephenbttanNo ratings yet

- Wd62purx 78b2my0Document61 pagesWd62purx 78b2my0Ibrahim AbbasNo ratings yet

- B.Tech 2nd Yr CHDocument22 pagesB.Tech 2nd Yr CHRobinNo ratings yet

- 3C Part 1 QuestionDocument113 pages3C Part 1 QuestionPritamjit RoutNo ratings yet

- Premium Grade Water Based High Velocity Duct Sealant: Low Brush Drag and SpreadabilityDocument2 pagesPremium Grade Water Based High Velocity Duct Sealant: Low Brush Drag and SpreadabilityMohsin RazaNo ratings yet

- Nihon Kohden 9010K Service Manual PDFDocument130 pagesNihon Kohden 9010K Service Manual PDFJumbo JamesNo ratings yet

- Green House Monitoring and Controlling Using Arduino: Submitted By-Abhishek Kumar JhaDocument32 pagesGreen House Monitoring and Controlling Using Arduino: Submitted By-Abhishek Kumar JhaVito cocNo ratings yet

- Abe 212 Laboratory 1Document8 pagesAbe 212 Laboratory 1Lopez Larry John P.No ratings yet

- 4-Calculating The Various Moisture LoadsDocument5 pages4-Calculating The Various Moisture LoadsamitbslpawarNo ratings yet

- (1B) Gaseous FuelsDocument41 pages(1B) Gaseous FuelsJadin Zam DoctoleroNo ratings yet

- Journal of Building EngineeringDocument16 pagesJournal of Building EngineeringVeronika PrymNo ratings yet

- Why Is The Supply Air Temperature 55°FDocument2 pagesWhy Is The Supply Air Temperature 55°FNagarjun ReddyNo ratings yet