Professional Documents

Culture Documents

Cswip3.1 Book

Cswip3.1 Book

Uploaded by

PBDC MEPFS0 ratings0% found this document useful (0 votes)

23 views84 pagesOriginal Title

Cswip3.1 Book - Copy

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views84 pagesCswip3.1 Book

Cswip3.1 Book

Uploaded by

PBDC MEPFSCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 84

WELDING INSPECTION

cwiss)

TwI

ir

“Cnbeee corso

4.0 VISUAL INSPECTION AND TYPICAL DUTIES OF

WELDING INSPECTORS.

4.4 GENERAL

Wilding inspectors are employed to assist with_te_aualty contel (QC)

acivtos tat are. neceseary to ensure that welded Hams wil Teel species

‘equremete snd be fr thes apa

For employers to have confidence in thei work Welding Inspectors need

hhave the aby 10 understanditerpet the varous QC procedures, ad ls) ha

‘Sound hroatedge of wong tectnagy.

sual inspecon is one ofthe Non-Destructive Examination discpines snd for

‘seme apeatons may be tre eny fm o NOE.

For more demanding service contens,vaualinepectonis usualy flowed by

‘one or more of he oer NDT fecnigues surtace ack Seecion and olunetne

Inspection of ut wee

Aeslicton SiandardsCodes wsualy spect (or refer to eter standards) the

scceptanescrtora for weld spect and may be very specic about the pret

Teatnques tobe used for sutae cack detection anf volumeti inspection, tay 0

ot usuly sive any guidance aul has requtemers for visual inspection,

Guidance and basic requirements fr visual inepecton are given by

'BS EN 870 Non-

Tneomec across ze Radice SSE a

aval speed Sverheatig can occ" nen ica ae

Rtorehng » Wal wal ihororiaT | Wels inte at postion arse muna | | Tonsiow a tavel speed Eu ces bal seen

‘eral potion (PB) wig tennis [Incotet etectiode angio Traut corel seco angi i wd

3.6.3 EXCESS PENETRATION

Description

Projection of the root penetration bead Beyond a specified limit can be lca or

Tiong polar used

(Gieceade | Erste cores polarty fe BOVE

polaty DEVE,

Comments

The tem “Tenorcoment” used to designate this feature ofthe weld is misleading

since the excess metal doesnot noimaty produce a sverger weld in 3 but at

‘rarary steel This mpertacian can bccme a problem, ae the srg ofthe Wed foe

an be shap, leading to an nereased evens concarraton athe foes the wa nd

{age eracting,

3.64 OVERLAP

Description

An perfection tthe 00 ofa weld caused by meal Sowing onto the trace of he

parent mt wahot eng

Causes Prevention

[Poor strode mangulaton NWIA) —| Retain wellcr

"Hh heatinptfow vavl speed | Redice Rest spd o Asa Oat wal |

causing surface flow of lt welds to Omm lg by ing muta weld

[nearest posting a wl ‘Change to fat poston

‘Wed heat ptt Reduce are voage andi walang cae

‘eae increase weldrg peed

Improve werkbecepreparaion

Trasrec was preparation

frcesive oot ga, thn odoe

preparation, ec of backing

sect elerose unauted to wang

pesto

Tek of welder sk

Uae covet ise fr postion

Ravan weer

Nae tthe maintenance of a pensation bead having unform dimensions requires

1 ea dal of atl partcary nppe but welding Ths can be made more dit

indies renrcoy secant the wo or aratfow peparaton. The use of pamanent

(or tomporary backing bare can be ured to asia nthe cmt of poeta,

tong Electode coating ype | Change slectase cong We amore |

resin in too igh ay Suttle fost teesng pe whic las

ot

Fora fet weld oveiap is often atsoiaed with undercut, a if the weld pod is too

‘uid the fop of te wel wil ow away To produce undercut t to top ai crea ot

the taco, he vane ofthe weld pout oo ge nave fae wo

hotizentaiverical poston (PB). weld metal wil eallapee dow to gy prosoing

Yom dec (adore the top ard vp the ae). Ti dtl cted

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

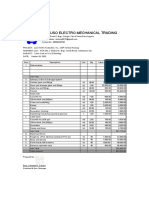

- Cost Proposal - Laon-HOA's FederationDocument2 pagesCost Proposal - Laon-HOA's FederationPBDC MEPFSNo ratings yet

- ClimatereviewDocument29 pagesClimatereviewPBDC MEPFSNo ratings yet

- TEst Guide FOr PLDocument3 pagesTEst Guide FOr PLPBDC MEPFSNo ratings yet

- Strength Classes For Concrete Pipes (Reinforced) U.S.A. ASTM C76 (Imperial)Document2 pagesStrength Classes For Concrete Pipes (Reinforced) U.S.A. ASTM C76 (Imperial)PBDC MEPFSNo ratings yet

- Sample Design Fire ProDocument22 pagesSample Design Fire ProPBDC MEPFSNo ratings yet

- Septic Tank 2 DesignDocument38 pagesSeptic Tank 2 DesignPBDC MEPFSNo ratings yet

- The Long Way of Fire Protection DesignDocument4 pagesThe Long Way of Fire Protection DesignPBDC MEPFS100% (1)

- Inspection GuidelinesDocument1,342 pagesInspection GuidelinesPBDC MEPFSNo ratings yet