Professional Documents

Culture Documents

Cristal-Flo High Rate Sand Filters: O W N E R ' S M A N U A L

Uploaded by

Enzo MoralesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cristal-Flo High Rate Sand Filters: O W N E R ' S M A N U A L

Uploaded by

Enzo MoralesCopyright:

Available Formats

CRISTAL-FLOTM

HIGH RATE SAND FILTERS

O W N E R’ S M A N U A L

Aquatools

.WATERFORD, WI.

53185

USA

S

A

W

K

W

C

A A

B S

T

E

E

RE

F C

IL CR

TE

IR ULAT

729 0294

INSTALLATION, OPERATION & PARTS

MODELS

T-150BP-1 T-170BP-1 T-200BP-1 T-240BP-1 T-300BP-2

T-240BP-2

This manual should be furnished to

the end user of this filter; its use will

reduce service calls and chance of

injury and will lengthen filter life.

Sta-Rite Pool/Spa Group

293 Wright Street, Delavan, WI 53115

North America: 800-752-0183, FAX 800-582-2217

International: 414-728-5551, FAX: 414-728-4461, TELEX: ITT 4970245

Union City, TN • Delavan, WI • Mississauga, Ont. • Murrieta, CA

©1998, Sta-Rite Industries, Inc. Printed in U.S.A. S242 (Rev. 10/29/98)

Downloaded from www.Manualslib.com manuals search engine

HIGH RATE SAND FILTERS

To avoid unneeded service calls, prevent possible injuries, and get the most

out of your filter, READ THIS MANUAL CAREFULLY!

The Sta-Rite Top Mounted Series High Rate Sand Filter:

• Is designed to filter water for swimming pools.

• Is an excellent performer; durable, reliable.

Table of Contents

Safety Instructions .......................................................................................2-3

Dimensions/Specifications..............................................................................4

General Information .......................................................................................5

Installation ..................................................................................................5-7

Filter Mount/Piping......................................................................................5

Filter Set-up.................................................................................................6

Loading Sand Media....................................................................................6

Valve Installation.........................................................................................6

Startup/Operation........................................................................................7

Maintenance ..................................................................................................8

Water Maintenance .....................................................................................8

Storage/Winterizing...................................................................................8-10

Mult-Port Valve Service ...............................................................................9

Drain Fitting Installation/Removal .............................................................10

Troubleshooting Guide .................................................................................11

Repair Parts List.......................................................................................12-13

Pressure Drop Curve ....................................................................................14

Warranty ......................................................................................................15

READ AND FOLLOW SAFETY

INSTRUCTIONS!

This is the safety-alert symbol. When you see this symbol on your valve

or in this manual, look for one of the following signal words and be alert to the

potential for personal injury.

warns about hazards that will cause serious personal injury,

death or major property damage if ignored.

warns about hazards that can cause serious personal injury,

death or major property damage if ignored.

warns about hazards that will or can cause minor personal in-

jury or property damage if ignored.

The label NOTICE indicates special instructions which are important but not

related to hazards.

Carefully read and follow all safety instructions in this manual and on filter.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

Downloaded from www.Manualslib.com manuals search engine

Incorrectly installed or tested equipment may fail, causing se-

vere injury or property damage. Read and follow instructions

in owner's manual when installing and operating equipment.

Have a trained pool professional perform all pressure tests.

1. Do not connect system to a high pressure or city water system.

2. Use equipment only in a swimming pool installation.

3. Trapped air in system can cause explosion. BE SURE all air is out of system

before operating or testing equipment.

Before pressure testing, make the following safety checks:

• Check all clamps, bolts, lids, and system accessories before testing.

• BE SURE all air is out of system before testing.

• Tighten Sta-Rite trap lids to 30 ft. lbs. (4.1 kg-cm) torque for testing.

• Water pressure for test must be less than 25 PSI (172 kPa).

• Water temperature for test must be less than 95˚ F. (35˚ C).

• Limit test to 24 hours. After test, visually check system to be sure it is ready

for operation. Remove trap lid and retighten hand tight only.

NOTICE: These parameters apply to Sta-Rite equipment only. For

non-Sta-Rite equipment, consult manufacturer.

BEFORE WORKING

ON FILTER:

Hazardous Pressure! 1. Stop pump.

Can cause severe 2. Open air release

injury or major valve.

property damage from

tank explosion. 3. Release all pressure

from system.

BEFORE WORKING

ON PUMP OR MOTOR

Filter pumps require Disconnect power to

hazardous voltage motor.

which can shock,

burn, or cause death.

Downloaded from www.Manualslib.com manuals search engine

Waste Outlet 1-1/2"

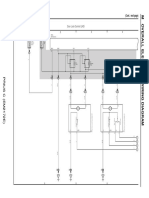

Union connection See Page 14 for Pressure Drop Curve.

Pump Inlet 1-1/2"

Return Outlet

2.88 (73)

RECOMMENDED SAND GRADES:

1-1/2" Slip

Use only: #20 Silica Sand, Size Range .40-.55mm., Uniformity Coefficient less

than 1.75.

NOTICE: Use of other sands will reduce filter performance, may damage

pump, and will void warranty.

C

Dia. B Recommended:

A 1. Wedron Silica/Best Sand Co., Sand Grade: Wedron .45-.55mm., Effective

D

Size .46mm, Uniformity Coefficient 1.22.

2. U.S. Silica - Silurian Filter Sand, Sand Grade.45-.55 mm., Effective Size

.48mm, Uniformity Coefficient 1.18.

TABLE I - FILTER OPERATIONAL DATA

1355 1094

E,F Max.

Filter Filter Flow Rate

Model Size in GPM (L/M)

Fig. 1: Dimensions, T-150BP-1,

T-170BP-1 T-200BP-1, T240BP-1 Dia. in Area in Ft2

Inches (mm) (M2)

T-150BP-1 15 (381) 1.26 (.117) 25.2 (95)

2" NPT Outlet

(Waste) T-170BP-1 17 (432) 1.57 (.146) 31.5 (123)

2" NPT Inlet T-200BP-1 20 (508) 2.18 (.203) 43.6 (165)

(Pump)

9.25 (235) T-240BP-1 24 (610) 3.10 (.288) 62.0 (234.7)

2" NPT T-240BP-2 24 (610) 3.10 (.288) 62.0 (234.7)

Outlet

(Return) T-300BP-2 30 (762) 4.90 (.455) 98 (371)

D

A Turnover in Hours Sand

Filter Volume

B Model 6 8 10 12 in lbs. (kg.)

C

gal. (L) gal. (L) gal. (L) gal. (L)

T-150BP-1 9,070(34 330) 12,100(45 799) 15,120(57 229) 18,144(68 675) 100 (45.4)

T-170BP-1 11,340(42 922) 15,120(57 229) 18,900(71 536) 22,680(85 844) 150 (68)

T-200BP-1 15,700(59 424) 20,930(79 220) 26,160(99 016) 31,390(118 811) 200 (90.7)

T-240BP-1 22,230(84 481) 29,760(112 642) 37,200(140 802) 44,640(168 962) 300 (136)

8.00(203) T-240BP-2 22,230(84 481) 29,760(112 642) 37,200(140 802) 44,640(168 962) 300 (136)

1356 1094 T-300BP-2 35,280(133 535) 47,040(178 046) 58,800(222 558) 70,560(267 070) 600 (272)

E,F

*NOTE: 1 cubic foot of sand weighs approx. 100 lbs. (45.4 kg). Do not use finer or

Fig. 2: Dimensions, T-300BP-2, coarser grade than recommended for best performance.

T240BP-2

TABLE II - DIMENSIONAL DATA In Inches (mm)

Base Base Piping

Width Length Port

Filter Model No. A B C D (E) (F) Size

T-150BP-1 27 (686) 33-13/16 (859) 15-3/4 (400) 24-11/16 (627) 13 (330) 16-1/4 (413) 1-1/2” SLIP

T-170BP-1 29-9/16 (751) 36-3/8 (924) 17-3/4 (451) 27-1/4 (692) 13 (330) 16-1/4 (413) 1-1/2” SLIP

T-200BP-1 31-5/8 (803) 38-1/2 (978) 20-3/4 (527) 29-3/8 (746) 13 (330) 16-1/4 (413) 1-1/2” SLIP

T-240BP-1 35-3/16 (897) 42 (1067) 24-3/4 (629) 32-7/8 (835) 16-7/8 (429) 21 (533) 1-1/2” SLIP

T-240BP-2 35-1/4 (895) 44-1/2 (1130) 24-3/4 (629) 32-7/8 (835) 16-7/8 (429) 21 (533) 2” (NPT)

T-300BP-2 42 (1067) 51-1/4 (1302) 31 (787) 39-5/8 (1008) 16-7/8 (429) 21 (533) 2” (NPT)

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION

• Clean a new pool as well as possible before filling pool and operating filter.

Excess dirt and large particles of foreign matter in the system can cause serious

damage to the filter and pump.

NEVER test this filter with compressed air.

Do not operate filter at water temperatures above 95°F (35°C).

NEVER operate this filter system at more than 50 pounds per square inch

(50 PSI/345 kPa) pressure!

INSTALLATION

Installation of filter should only be done by qualified, licensed personnel.

For assembly and filling instructions, see page 6.

Filter mount must:

• Provide weather and freezing protection.

• Provide space and lighting for easy access for routine maintenance. (See

Figures 1 and 2, Table II, Page 4, for space requirements.)

• Be on a reasonably level surface and provide adequate drainage.

• Be as close to pool as possible to reduce line loss from pipe friction.

Piping:

• Piping must conform to local/state plumbing and sanitary codes.

• Use pipe joint sealing compound or teflon tape on all male connections of

metal pipe and fittings (except unions). Use teflon tape or Plasto-Joint Stik1 on

all male connections of plastic pipe and fittings. DO NOT use pipe dope on

plastic pipe; it will cause the pipe to crack. Do not use sealant or tape on

unions – assemble them dry and hand tight.

• Do not damage union sealing surfaces and “O” Rings.

• Support pipe independently to prevent strains on filter or valve.

• Use 1-1/2 or 2” pipe to reduce pressure losses as much as possible.

NOTICE: Filter may be located away from pool, but for adequate flow larger

pipe may be needed. Check local codes when considering remote installation.

• Fittings restrict flow; for best efficiency use fewest possible fittings.

• Keep piping tight and free of leaks: pump suction line leaks may cause trapped

air in filter tank or loss of prime at pump; pump discharge line leaks may show

up as dampness or jets of water.

• When unions are provided, use as follows for leak free connections:

1. O-Ring and sealing surfaces must be clean.

2. Assemble hand tight only (no wrenches).

3. No pipe compound or teflon tape on unions.

Valves:

• A check valve installed between filter and heater will prevent hot water from

backing up into filter and deforming internal components.

• Use care before assembly not to damage union sealing surfaces or O Ring.

Wastewater:

• Be sure all provisions for waste water disposal meet applicable local, state or

national codes. 100 gallons (379 liters) or more of pool water will be dis-

charged during filter backwashing. Do not discharge where water will cause

flooding or damage.

1

Lake Chemical Co., Chicago, IL

Downloaded from www.Manualslib.com manuals search engine

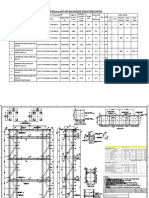

A. Insert first lateral into socket; Filter Setup

twist clockwise 1/4 turn

to lock lateral into hub. Assembly: See Figures 2 through 5 for filter assembly.

Lateral is correctly installed

when slots face down.

Loading Sand Media

B. Insert assembly 1.To keep sand out of collector assembly, place plastic sand shield over top

into top of

filter tank.

of collector tube before pouring sand into filter (See Figure 5).

731 0294 2.To support laterals and prevent lateral breakage during loading, fill tank

about half full of water before loading sand.

Fig. 2 3.Pour sand into filter tank. See Page 4, for correct type and quantity of sand

to use.

C. Hold assembly up NOTICE: Make sure gasket area on top of tank is free of sand before in-

near top of tank and stalling valve and clamp.

add remaining

laterals. 4.Before installing valve, double-check that correct quantity of sand has

been loaded (see Page 4).

732 0294

5.Remove plastic sand loading shield and keep for future use.

Valve Installation:

Fig. 3 See Figures 6, 7, and 8

1. Install O-Ring on valve flange; make sure O-Ring is clean, dry, and has

no nicks, tears, or scrapes.

2. Make sure tank and valve flanges are clean and free of sand; put valve

D. After all

laterals are

on top of tank. Vertical pipe of collector assembly inserts into base of

securely in valve.

sockets, 3.Install clamp; make sure knob is positioned for easy access for filter

position maintenance. Valve port labeled “PUMP” should point toward pump.

assembly on

centering 4.Tighten clamp knob until clamp ends (under bolt) are 1/4” (6mm) apart.

boss in Tap around outside of clamp with a mallet to help seat clamp.

bottom of

tank. Hazardous pressure. Clamp will not hold unless it is

seated properly! DO NOT START PUMP until clamp ends are 1/4”

(6mm) apart or less.

5.If clamp will not pull up to 1/4” (6mm) gap, wait 15-30 minutes and

retighten. Tap clamp gently with mallet to help seat clamp.

733 0294

Fig. 4 6.Connect pipe from pump discharge to valve port labeled “PUMP”; use

union half provided. Assemble union as follows for leakfree operation:

A. O-Ring and sealing surfaces must be clean.

Sand Shield B. Assemble hand tight only (no wrenches).

keeps collector

ND

SA hub assembly C. NO pipe compound or teflon tape on unions.

clean when

loading filter. 7.Complete all plumbing connections (see Page 5 for piping require-

::::

::::

ments).

Fill tank ::::

::::

::::

::::

::::::::

::::

::::::

::::

::::

::::

:::: A. Pipe from valve RETURN port to pool return.

::::::

:::::::::::::::::

::::

:::::

:::::::::::::::::::::::::: :::::::::::::::::::::

::::

:::::

about

:

:::::::::::::::::::::::::::::::::: ::::::::::::::: ::::: :::

::::::::

::::::::::::

:::::::::::::::::::::::::::::::::::::: ::::::::

:

:

:

half full

:::

B. Pipe from valve WASTE port to waste.

:

:

:

:

:

:

::

of water

::

before ::::

::::

:::: C. Suction piping from pool to trap inlet on pump.

::

::::

:: ::

:: ::::

adding

::

::

::::

::::::::::::::::::::::::::::::::::::::

::::::::::::::::

::

:: :: ::

sand. 8.System is ready for startup.

::

::::::::::

:::::::::::::: ::

::

::::::::::::::::

NOTICE: If there are leaks from beneath valve/clamp area, STOP

::::::::::

PUMP, release all pressure, remove clamp and valve and clean sealing

surfaces.

734 0294

Fig. 5

Downloaded from www.Manualslib.com manuals search engine

Startup/Operation (See Figure 9)

Hazardous pressure. To avoid explosion and possible se-

Aquatools

.WATERFORD, WI.

53185

USA

H

S

A

vere or fatal injury, filter system pressure must not exceed 50 PSI (345

CKW

WAS

BA

T

E

TE F IL

LA

CU TE R

RECIR

kPa) under any circumstances. NEVER test this filter system with com-

pressed air; never operate system with water temperature above 95° F

(35° C).

. Install O-Ring To prevent equipment damage and possible injury, turn

on valve flange. pump OFF before changing valve position.

Install valve on tank. NOTICE: Do not add chemicals directly into the pool skimmer. Adding

Tank flange must

be clean; insert undiluted chemicals may damage equipment and void warranty.

collector pipe

into bottom 1. Open system valves and make sure pump is filled with water. Make

of valve. sure pool water level is 2” (51mm) above bottom of skimmer open-

ing.

2. With pump OFF, set valve to ‘BACKWASH’ position.

Fig. 6

3. Start pump, circulating water backwards through filter to waste.

NOTICE: To prevent pump from running dry, be sure water level

ort labeled

never drops below bottom of skimmer inlet. Add water to pool if

necessary to keep skimmer flooded while backwashing and rinsing.

Aquatools

.WATERFORD, WI.

53185

PUMP" should

USA

E

H

S

oint toward

A

CKW

WAS

BA

4. Backwash until water runs clear (3-5 minutes).

T

E

ump. RECIR

CU

LA

TE

TER

F IL

5. Stop pump; set valve to ‘RINSE’ position.

6. Start pump; run pump for one minute.

Tap around 7. Stop pump; set valve to ‘FILTER’ position.

clamp while

1/4" Max. tightening to 8. Filter is now ready for service.

help seat

clamp. 9. Record clean starting filter pressure gauge reading as a reference.

Install clamp If unable to

and tighten close gap 10. When pool is first filled, backwash once a day until pool water is

736 0294

until clamp to 1/4" or less, sparkling clear. After that, backwash when pressure gauge shows 5 to

ends (under wait 15-30 7 PSI (34.5 to 48 kPa) higher than starting pressure.

bolt) are 1/4" minutes and

apart. retighten.

Fig. 7

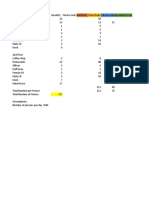

Valve Setting Purpose/Flow Valve Setting Purpose/Flow Valve Setting Purpose/Flow

FILTER FILTE

FILTER AS

TE

FILTER

BACKWASH ST

E

R

WASTE

TE

RI

WA

W

NS

RI

S

WA

NS

RI

Reverses flow for

E

Normal filtration and

NS

Lowers pool level or

E R

E

RECIRCULATE

ECIRC LATE

RECIRCULATE

WINTERIZE

cleaning; water

U

vacuuming; water goes

E

drains pool; water

ERIZ

IZE

ER

NT

T

WI

IN

through filter to pool. goes through filter

W

bypasses filter,

B

BA AC

ED

CK KW

ED S

WA S

O

BA AS

CLO SH

CL ED H

CK CLOS

WASH

to waste. goes to waste.

743 0294

FILTER

RI

N

RINSE AS

TE

FILTE

R

TE

W

SE

For initial startup cleaning

S

WA

CLOSED

RI

NS

E

RECIRCULATE

REC

WINTERIZE

and sand bed leveling Shuts off all flow to

IRCULATE

E

ERIZ

NT

after backwash; water goes

WI

filter and pool.

D

BA

B

CK AC

ED

SE

through filter to waste.

S WA KW

CLO SH

AS

CLO H

g

FILTER FILTER

FILTER FILTER

RI FILTER

TE

AS TE

TE N

W

RECIRCULATE W

AS

AS

TE

TE

WINTERIZE

RI

W

SE

RI

RI

NS

S

S

NS

RI

NS

WA

WA

NS

E

E

Circulates pool water;

RECIRCULA

WINTERIZE

RECIRCULATE

RECIRCULATE

RECIRCULATE

NTERIZE

Leaves all valve ports

RECIRCULATE

WINTERIZE

E

ERIZ

ERIZ

bypasses filter. partially open for

NT

NT

WI

WI

WI

TE

D

SE

ED

BA BA

O BA BA CK

CL S CK

winter storage.

CK ED

BAC D WA CL

O ED S WA S

WA

SE CK CLO SH CLO SH

KWASH CLO SH

WASH

737 029

738 029

Fig. 8 Fig. 9: Valve settings for startup. Stop

pump before changing valve position.

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE

General:

• Wash outside of filter with a mild detergent and water. Rinse off with hose.

NOTICE: DO NOT use solvents to clean filter; solvents may damage plastic

components in system.

• Inspect sand bed at least once a year to remove foreign material which has not

been backwashed out of system.

NOTICE: When the sand bed gets hard and crusty on top, remove all the old

sand and replace it with new sand.

Weekly Pool Equipment Inspection:

1. Check pressure during operation. When pressure is 5 to 7 PSI (34.5 to 48

kPa) higher than initial operating pressure, backwash filter (see instructions

under “Startup/Operation”, Page 7).

2. Except during hot weather with heavy swimmer loads, operating filter 6 to 12

hours per day should be sufficient. Carefully monitor water chemical balance

and follow recommendations of your local pool professional.

Water Maintenance

• Keep water level at least 2” (51mm) above bottom of skimmer opening.

Failure to do so can allow air to enter system, causing pump to lose prime

and air to enter filter.

• Maintain pH at 7.2 to 7.6 in pool.

To prevent damage to system components, keep water temperature below

FILTE

R

E

ST

WA

RI

NS

95° F. (35° C) at all times.

E R

ECIRC LATE

U

IZE

Vacuum Pool:

ER T

IN

W

AC

KW

AS

ED H

1. Fill vacuum hose by submerging in water from one end to the other.

CLOS

2. To vacuum, insert hose into skimmer suction manifold or into vacuum line

FILTER

in pool wall. See instructions provided by pool builder or pool manufac-

TE

RI

NS

S

turer. Start pump, making sure it is primed and pumping.

WA

E

RECIRCULATE

E

3. After vacuuming, clean pump trap to remove accumulated debris, then

ERIZ

NT

WI

ED

CLO

S

WA

SH

CK

BA

check filter pressure gage. If reading is 5 to 7 PSI (34.5 to 48 kPa) higher

than initial operating pressure, backwash filter.

Fig. 10: Valve settings to lower Lower or Drain Pool

pool water level. Stop pump 1. Turn pump ‘OFF’; set valve handle to ‘WASTE’.

before changing valve position. 2. Use vacuum cleaner hose and head.

3. Start pump; run until pool is lowered to desired level.

4. Turn pump ‘OFF’; set valve handle to ‘FILTER’.

5. Start pump.

FILTER

TE

AS

W

STORAGE/WINTERIZING

RI

NS

E

RECIRCULATE

NTERIZE

Pool chemicals may give off corrosive fumes. Store chemicals

WI

away from system in a well ventilated area.

BA

CK

D WA

SE

CLO SH

NOTICE: Allowing water to freeze will damage filter and void warranty. If an-

Fig. 11: Valve setting for winter tifreeze is needed, use propylene glycol; it’s plastic compatible and non-toxic.

storage. Stop pump before Follow manufacturers instructions. Do not use ethylene glycol based anti-

changing valve position. freeze – it’s toxic and it may damage plastic components.

1. Open all system valves. Set multiport valve at ‘WINTERIZE’ to allow air pas-

sage to all ports.

Downloaded from www.Manualslib.com manuals search engine

2. Remove drain plug from filter.

Aquatools

1A 3. Drain filter tank completely and replace drain cap (Figure 13, Page 10).

.WATERFORD, WI.

53185

4. Cover with plastic or tarpaulin to protect from weather, but do not seal from

USA

1

air circulation.

2 L

O

SE

D

WINTER

IZE

5. Protect from freezing.

C

W

A

ST

Startup for Winterized Equipment:

E

SH

A

W

K

C

A

B F

IL

TE

3

R

E

SE REC

IRCU NT

LIA

R

1. Remove any temporary weather protection placed around system for shut-

down.

2. See “Startup”, Page 7, for reactivation of the filter.

3. Inspect all electrical wiring to pump for damage or deterioration over the

shutdown period. Have a qualified serviceman repair/replace wiring as

4 needed. Inspect and tighten all watertight connections.

4. Open all valves in suction and return piping.

5. Remove any winterizing plugs in system.

6. Drain all winterizing chemicals (if used) from system; flush system.

5

7. Close all drain valves and replace all drain plugs in system (see Page 10).

8. Fill pool with water to proper level (see pool maufacturer’s instructions).

MULTI-PORT VALVE SERVICE

Hazardous pressure. Stop pump and release all pressure from sys-

6 tem before working on filter, valve, or clamp.

NOTICE: if Multi-Port valve is below pool water level, close suction and dis-

charge valves before disassembly to prevent draining pool.

Handle Replacement:

1. Stop pump.

744 0294

2. Place handle in ‘FILTER’ position.

Fig. 12A: Valve Disassembly

3. Remove pin (Key 1, Figures 12A and 12B) to disconnect handle. If it cannot

(1-1/2” Multiport Valve)

be removed by hand, use a hammer and center punch and lightly tap it out.

4. Remove handle; replace with a new one. Be sure new handle is in ‘FILTER’

1 position.

5. Replace pin.

1A

Lid and Plug replacement:

2

1. Remove Handle (see ‘Handle Replacement’ above).

3

2. Remove plug:

A. Remove all screws and nuts (Key Nos. 2 and 6, Figures 12A and 12B).

B. Remove lid (Key No. 3) by pulling straight up while holding plug shaft

4 (Key No. 5) down with thumb.

3. Inspect Internal Parts:

Inspect plug and gasket spring, O-Rings, and internal washers (Key No. 4).

Replace if necessary.

5

4. Reassemble Valve:

A. Replace plug gasket and shaft, mounting spring, washers, and O-Ring on

6 plug shaft. Lubricate O-Ring with Amojel.

B. Replace lid; match screw holes in lid and body.

C. Press down on lid to allow screws to engage nuts; tighten each nut se-

curely.

D. Replace top washer (Key No. 1A) and handle, making sure indexing pin

on plug shaft points in same direction as pointer on handle. Replace han-

1344 1094 dle pin.

E. Tighten all lid screws to 55 inch-lbs. (63.4 kg-cm) torque.

Fig. 12B: Valve Disassembly

(2” Multiport Valve)

Downloaded from www.Manualslib.com manuals search engine

Valve Removal

Hazardous pressure. Stop pump and release all pressure from sys-

tem before working on filter, valve, or clamp.

About 1" NOTICE: If multi-Port Valve is below pool water level, close suction and dis-

charge valves before disassembly to prevent draining pool.

Small 1. Disconnect piping from pump and pool.

O-Ring 2. Remove clamp.

Open end 3. Remove valve from filter top.

of lateral 4. To reinstall valve, follow instructions, Figures 6 and 7, Page 7. BE SURE to

follow clamp tightening instructions.

Seat small Drain Fitting Installation/Removal

O-Ring

NOTICE: If pool is above height of filter, first close valves in pump suction and

return lines to prevent draining pool. If there are no shutoff valves installed, dis-

connect suction and return lines and raise ends above pool water level.

Large

O-Ring 1. Installation: See Figure 13.

2. To Drain Filter:

End of lateral is A. Remove drain cap. Lateral tube should remain in place inside drain

flush with end of opening to prevent sand from draining out.

drain fitting 746 0294 B. Open union coupling on backwash port of Multi-Port valve. This will

allow air into filter and allow water to drain from filter tank.

C. Replace cap when tank is empty.

Figure 13: Drain Fitting Assembly. 3. Removing Sand From Filter:

This assembly allows water to drain

without losing the sand out of the fil- A. Remove both drain cap and slotted lateral tube (see Figure 13). Sand and

ter tank. water will drain from tank.

Make sure all surfaces are clean and B. To completely flush filter tank of sand, remove top clamp and multiport

free of sand. Don’t cross thread cap; valve and flush the inside of the tank with a hose.

don’t overtighten cap. C. Thoroughly clean sand from all parts and from tank drain opening be-

fore reassembling drain fitting.

10

Downloaded from www.Manualslib.com manuals search engine

TROUBLESHOOTING GUIDE

1. Short Cycle between backwashes:

NOTICE: Time between backwashes will vary with each installation and be-

tween different areas of the country. Ask installer about normal backwash in-

terval in your area. The following causes and remedies are for cycle times

shorter than normal for your area.

A. Flow rate too high or filter too small; consult dealer for system sizing rec-

ommendations.

B. Water is chemically out of balance; consult pool serviceman.

C. Excess dirt/dust in pool; vacuum pool directly to waste.

Hazardous pressure.

Can cause severe in- D. Body oil/lotion build-up in filter; consult dealer for chemical filter clean-

jury or major property ers and follow cleaner manufacturer’s instructions.

damage from tank

E. Filter inadequately backwashed. See instructions under

blow up.

“Startup/Operation”, Page 7.

Release all pressure

F. Algae in pool. Consult pool professional about proper chemical mainte-

and read instructions

before working on filter. nance.

G. Residual chlorine level too low. Consult pool professional about proper

chemical maintenance.

H. Inspect filter sand for solidification caused by dust, calcium, skin oils, of

suntan lotions.

2. Low Flow:

A. Pipe blocked downstream from filter; remove obstruction.

B. Piping too small; use larger pipe (consult dealer for sizing).

C. Plugged pump; plugged hair and lint trap or skimmer basket. Clean thor-

oughly.

3. Pool Water Not Clear:

A. Water is chemically out of balance; consult pool professional.

B. Filter is too small; consult dealer about equipment sizing.

C. Sand in pool means broken lateral. Drain both water and sand out of

tank. Remove valve; follow procedure under “Filter Setup”, Page 6, and

instructions with new lateral to replace broken part.

To avoid severe injury or major property damage, follow

instructions under 'Valve Installation', Figures 6 and 7, Page 7).

1. Follow valve removal procedure, Page 10.

2. Replace lateral according to instructions supplied with new lateral.

3. Reassemble filter according to instructions under “Filter Setup”, Page 6.

11

Downloaded from www.Manualslib.com manuals search engine

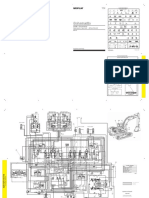

REPAIR PARTS – TANKS Aquatools

.WATERFORD, WI.

53185

USA

T-150BP-1, T-170BP-1,

E

S

A

W

K

W

C

A A

B S

T

E

E

RE

F C

IL CR

TE

IR ULAT

T-200BP-1, T-240BP-1, 1

T240BP-2, T-300BP-2

2

3

4

7

13

8

10

11

12

757 0294

Model

Key No.

No. Description Used T-150BP-1 T-170BP-1 T-200BP-1 T-240BP-1 T-240BP-2 T-300BP-2

1 Multiport Valve, Top Mount 1 WC112-148 WC112-148 WC112-148 WC112-148 14971-TM-22-L 14971-TM-22-L

2 O-Ring, Valve Flange 1 U9-369 U9-369 U9-369 U9-369 U9-369 U9-369

3 V-Clamp w/Knob 1 WC119-87A WC119-87A WC119-87A WC119-87A WC119-87A WC119-87A

4 Clamp Knob 1 WC36-22 WC36-22 WC36-22 WC36-22 WC36-22 WC36-22

5 Collector Hub Assembly 1 24200-0110 WC137-516P WC137-517P WC137-519P 24204-0029 24205-0010

6 Lateral 8 24600-0003 24600-0003 24600-0003 24700-0075 21180-0163 21180-0100

7 Filter Tank 1 24200-0100 24201-0100 24203-0100 24204-0100 24204-0100 24205-0100

8 O-Ring, Lateral 1 U9-370 U9-370 U9-370 U9-370 U9-370 U9-370

9 Drain Lateral 1 24201-0058 24201-0058 24201-0058 24201-0058 24201-0058 24201-0058

10 O-Ring, Drain Cap 1 U9-371 U9-371 U9-371 U9-371 U9-371 U9-371

11 Drain Cap 1 14965-0025 14965-0025 14965-0025 14965-0025 14965-0025 14965-0025

12 Pedestal 1 23910-0005B 23910-0005B 23910-0005B 23900-0105B 23900-0105B 23900-0205

13 Filter Tank Assembly 1 24200-0322E 24201-0322E 24203-0322E 24204-0322E 24204-0242 24205-0322E

• Union Coupling Package 1 C198-5 C198-5 C198-5 C198-5 – –

• Sand Loading Disc 1 24201-0043 24201-0043 24201-0043 24201-0043 24201-0063 24201-0063

• Model & Instruction Label 1 32155-4115A 32155-4115B 32155-4115C 32155-4115D 90000-1328 32155-4115E

• Clamp Warning Decal 1 32165-4030 32165-4030 32165-4030 32165-4030 32165-4030 32165-4030

• Information Decal 1 32155-4112 32155-4112 32155-4112 32155-4112 32155-4112 32155-4112

•Not Illustrated.

12

Downloaded from www.Manualslib.com manuals search engine

REPAIR PARTS – MULTI-PORT VALVES

WC112-148 #14971-TM-22-L

1

2 STA-RITE

STA-RITE IND., INC.

WATERFORD, WI.

53185

2

USA

3

11

4 D

WINTER

IZE

3

SE

LO

C

5 4

W

A

ST

E

SH

A

W

K

C

A F

B IL

TE

R

E

SE REC

IRCU NT

LIA

R

6 6

7 7

9A

8 10

9A

8

10

12

9B

11

12 12A

13

13

14

15

14

15 17

18

16

16

1343 1094

Key Part

No. Description Qty. WC112-148 14971-TM-22-L

1 Valve Handle Decal 1 14965-0021 ––

2 Handle 1 14962-0032 14971-SM10E1

3 Dowel Pin 1 35857-0021 14971-SM10E2

4 Washer 1 14965-0007 14971-SM10E3

5 Operating Instruction Decal 1 14965-0020 ––

6 Screw 37337-3056(7) 14971-SM10E4(10)

7 Valve Cover 1 14965-0011 14971-SM20E6

8 O-Ring 1 35505-1228 14971-SM10E10

9A Washer 2 14965-0007 14971-SM10E8

9B Washer 1 14965-0007 ––

10 Spring 1 14965-0006 14971-SM10E9

11 Pressure Guage 1 15060-0000T 15060-0000T

12 Plug & Gasket Assembly 1 14965-0028 14971-SM20E11

12A Gasket 1 –– 14971-SM20E12

13 Cover O-Ring 1 35505-1275 14971-SM20E7

14 Valve Body Assembly 1 14965-0013 14971-SM20E13

15 Nut 35407-0071(7) 14971-SM10E14(10)

16 Tank Flange O-Ring 1 U9-369 U9-369

17 Sight Glass Gasket 1 –– 14971-SM20E17

18 Sight Glass 1 –– 14971-SM10E16

13

Downloaded from www.Manualslib.com manuals search engine

14

T-240BP-1

12

T-300BP-2

10

T-150BP-1

T-170BP-1,

T-200BP-1

8

P.S.I. Loss

0 20 40 60 80 100 120

Capacity (GPM)

Figure 14 – Pressure Drop Curve

14

Downloaded from www.Manualslib.com manuals search engine

STA-RITE LIMITED WARRANTY

Pumps, filters, skimmers, underwater lights (except bulbs), the 2nd through 10th year after installation. The amount cov-

accessories and fittings manufactured by Sta-Rite are war- ered decreases by 10% each year. (ie., 2nd year 90% covered,

ranted to be free of defects in material and workmanship for 3rd year 80% covered, etc.).

one (1) year from date of installation.

The foregoing warranties relate to the original consumer pur-

Year from date chaser (“Purchaser”) only. Sta-Rite shall have the option to re-

Product specific warranties: pair or replace the defective product, at its sole discre-

of installation

tion. Purchasers must pay all labor and shipping charges nec-

HRPB, DEPB and System 3 – Tanks . . . . . . . . . . . .10 years essary to replace the product covered by this warranty.

Internal filter components and valves . . . . . . . . . 1 year Requests for warranty service must be made through the in-

stalling dealer. This warranty shall not apply to any product

Max-E-Therm – Pool/Spa Heaters . . . . . . . . . . . . . 2 years that has been subject to negligence, misapplication, im-

Heater Enclosure only (Upper RH & LH; proper installation or maintenance, or other circumstances

lower enclosure; and control board enclosure)… 10 years which are not in Sta-Rite’s direct control.

Automatic Pool Cleaners including Hose . . . . . . . 2 years This warranty sets forth Sta-Rite’s sole obligation and

Purchaser’s exclusive remedy for defective products.

Cristal-Flo filters – Tanks . . . . . . . . . . . .10 years pro-rated*

Valve and internal components. . . . . . . . . . . . . . . . 1 year STA-RITE SHALL NOT BE LIABLE FOR ANY CONSEQUEN-

TIAL, INCIDENTAL OR CONTINGENT DAMAGES WHATSO-

Posi-Flo II – Tanks . . . . . . . . . . . . . . . . . . . . . . . . . .10 years EVER.

Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 year THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN

Waterford Sand – Tanks . . . . . . . . . . . . .10 years pro-rated* LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WAR-

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 year RANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED

Valve and Internals . . . . . . . . . . . . . . . . . . . . . . . . . 1 year WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE

Waterford Cartridge – Filter Tank . . . . . . . . . . . . .10 years DURATION OF THE APPLICABLE EXPRESS WARRANTIES

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 year PROVIDED HEREIN.

System 3 Above Ground Systems – Tanks . . . . . . .10 years Some states do not allow the exclusion or limitation of inci-

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 year dental or consequential damages or limitations on how long

an implied warranty lasts, so the above limitations or exclu-

Platform and Internals . . . . . . . . . . . . . . . . . . . . . . 1 year sion may not apply to you. This warranty gives you specific

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 year legal rights and you may also have other rights which vary

When equipped with A.O. Smith from state to state.

2-compartment motors (Does not include Supersedes all previous publications.

pumps sold as part of a systems package) . . . . . . 2 years

Sta-Rite Industries, Inc.

* Full warranty coverage is in effect for one year after instal- 293 Wright Street

lation. The pro-rated warranty covers the tank only during Delavan, WI 53115

▲ Retain Warranty Certificate (upper portion) in a safe and convenient location for your records.

DETACH HERE: Fill out bottom portion completely and mail within 10 days of purchase/installation to:

▼ Sta-Rite, Attn: Warranty Dept., 293 Wright St., Delavan, WI 53115

Warranty Registration Card

Name Years pool has been in service ■ less than 1 ■ 1-3 ■ 3-5 ■ 5-10

Purchased from:

Address

Company name

City State Zip

Address

Purchase Date

City State Zip

Product Purchased

Please send me more information on these

■ New installation ■ Replacement

other products from Sta-Rite.

Type of Pool ■ Inground ■ Vinyl ■ Fiberglass ■ Gunite ■ Pumps ■ Filters ■ Automatic Pool Cleaners

■ Maintenance Equipment ■ Test Strips

Size of Pool

■ Heaters

S4877PS (2/20/98)

Downloaded from www.Manualslib.com manuals search engine

You might also like

- 40-Ipl32l-Pwg1xg China Psu PDFDocument3 pages40-Ipl32l-Pwg1xg China Psu PDFAlessandro Bonifacio BonifacioNo ratings yet

- Samsung Power Board Circuit BN44-00369A PDFDocument2 pagesSamsung Power Board Circuit BN44-00369A PDFmauriciobyteNo ratings yet

- Motoreductor CNHM8-6125-15 PDFDocument1 pageMotoreductor CNHM8-6125-15 PDFIH MedranoNo ratings yet

- Od-402 EsqDocument16 pagesOd-402 EsqEduardo AlvarezNo ratings yet

- ABL 8 BrochureDocument6 pagesABL 8 Brochurerubysultana100% (1)

- Shivpur BR 02 2x6x6 Double Cell r0-Br. 02 GadDocument1 pageShivpur BR 02 2x6x6 Double Cell r0-Br. 02 GadkumardityaNo ratings yet

- Sony - XM-2252Document20 pagesSony - XM-2252elmoyNo ratings yet

- NI WLS/ENET-9163: User Guide and SpecificationsDocument32 pagesNI WLS/ENET-9163: User Guide and SpecificationsJuan José CárdenasNo ratings yet

- Shivpur BR 03 1x6x6 Singel Cell r0-Br. 03 GadDocument1 pageShivpur BR 03 1x6x6 Singel Cell r0-Br. 03 GadkumardityaNo ratings yet

- 201 10-nm1 PDFDocument144 pages201 10-nm1 PDFErika MendozaNo ratings yet

- 1 Cover Page1508150590934Document1 page1 Cover Page1508150590934mohd sumerNo ratings yet

- Submittal Data Information: TC Series Pumps (60 HZ NEMA)Document2 pagesSubmittal Data Information: TC Series Pumps (60 HZ NEMA)Bagaskoro Dwi PrastioNo ratings yet

- Mazlan's Lecture MNE - Lifts and Elevators - 1stDocument15 pagesMazlan's Lecture MNE - Lifts and Elevators - 1stAzam RoslanNo ratings yet

- Troubleshooting Twin Engine AlternatorsDocument1 pageTroubleshooting Twin Engine AlternatorsGeorge Cunha LimaNo ratings yet

- Faculty of Engineering, Technology Applied Design and Fine ArtDocument48 pagesFaculty of Engineering, Technology Applied Design and Fine Artmuhammedssebatindira3No ratings yet

- NorthstarDocument2 pagesNorthstarfdpc1987No ratings yet

- Door Lock Control RHDDocument2 pagesDoor Lock Control RHDskNo ratings yet

- Steering System: SectionDocument5 pagesSteering System: Sectionguta wondemu mamoNo ratings yet

- Sbfi Rwy-15-33 Vac 20211104Document1 pageSbfi Rwy-15-33 Vac 20211104Fábio KastelamaryNo ratings yet

- Structures Project: Centre Line Grid LayoutDocument1 pageStructures Project: Centre Line Grid LayoutAlekhya DeviNo ratings yet

- Structures Project: Centre Line Grid LayoutDocument1 pageStructures Project: Centre Line Grid LayoutAlekhya DeviNo ratings yet

- Granco Flow Chart (50-100 Psi/Viscosities 32-1000 Ssu) Truck-Mounted PumpsDocument4 pagesGranco Flow Chart (50-100 Psi/Viscosities 32-1000 Ssu) Truck-Mounted PumpsJose PinillaNo ratings yet

- CD 2x100 BMSTDocument1 pageCD 2x100 BMSTAhmad SabraNo ratings yet

- Door Lock Control LHDDocument2 pagesDoor Lock Control LHDskNo ratings yet

- System Manuals (Volume 1 of 2) System Manuals (Volume 1 of 2)Document72 pagesSystem Manuals (Volume 1 of 2) System Manuals (Volume 1 of 2)Rodrigo Dos Santos SilvaNo ratings yet

- R08019043860EDocument28 pagesR08019043860EMatheus BorgesNo ratings yet

- Imd EleDocument1 pageImd EleabhishitewariNo ratings yet

- P2 Boiler ElectricDocument2 pagesP2 Boiler ElectricIlham HarisNo ratings yet

- (Vac) Rwy 15/33: en TR Ad A Ta NG U' en TR An CeDocument2 pages(Vac) Rwy 15/33: en TR Ad A Ta NG U' en TR An CeFábio KastelamaryNo ratings yet

- Ev SC - SW - Ew C910 2119 PDFDocument1 pageEv SC - SW - Ew C910 2119 PDFBbgGabrielNo ratings yet

- Metrolink ArrowDocument15 pagesMetrolink ArrowgodardsfanNo ratings yet

- Fujitec Step Chain Remove and ReplaceDocument4 pagesFujitec Step Chain Remove and Replacegeorge_zouridisNo ratings yet

- Plano Perimetrico, Lotizacion y Ubicacion Lote P-6Document1 pagePlano Perimetrico, Lotizacion y Ubicacion Lote P-6Ronald Mamani ChoquehuancaNo ratings yet

- Open Door: Residence of Sara MuzammilDocument1 pageOpen Door: Residence of Sara MuzammilMurtaza NooruddinNo ratings yet

- Office Blow Up Plan: W-5 WC FAUDocument1 pageOffice Blow Up Plan: W-5 WC FAUmichael jan de celisNo ratings yet

- Aisin Aw Tr-60snDocument1 pageAisin Aw Tr-60snJesus Alejandro Miranda PalaciosNo ratings yet

- Profile: ISO 17025, NABL Accredited Lab Cert. No.: T-0197 & T-0198Document12 pagesProfile: ISO 17025, NABL Accredited Lab Cert. No.: T-0197 & T-0198RB SinghNo ratings yet

- Exhaust Fan - VFD Controls (Hef) : Elektro-TekDocument1 pageExhaust Fan - VFD Controls (Hef) : Elektro-TekMoein MovahhedNo ratings yet

- ElevacionesDocument1 pageElevacionesRickyFrancoCoaguilaNo ratings yet

- New Bedford Marijuana MapDocument1 pageNew Bedford Marijuana MapAndy TomolonisNo ratings yet

- SHEMATIC DIAGRAM FOR INTERLOCK-ModelDocument1 pageSHEMATIC DIAGRAM FOR INTERLOCK-Modelbblk420No ratings yet

- Structure DetailsDocument9 pagesStructure Detailsisan.structural TjsvgalavanNo ratings yet

- Uow Telford CampusDocument1 pageUow Telford Campuswlv_uni_psoNo ratings yet

- Fda Double Inlet Centrifugal Fans: E C E N T R I F U G A L F A N SDocument4 pagesFda Double Inlet Centrifugal Fans: E C E N T R I F U G A L F A N SPrestoneKNo ratings yet

- 245 250 9807 DTD 20Dec2006-SW-dimensionsDocument2 pages245 250 9807 DTD 20Dec2006-SW-dimensionsjaime montielNo ratings yet

- 110V 60a FCBCDocument3 pages110V 60a FCBCKishore KumarNo ratings yet

- Ni-Daq MX For NI WLS/ENET-9163: Getting Started GuideDocument16 pagesNi-Daq MX For NI WLS/ENET-9163: Getting Started GuideJuan José CárdenasNo ratings yet

- Port Orange Proposed Panhandling OrdinanceDocument82 pagesPort Orange Proposed Panhandling OrdinanceCharles FrazierNo ratings yet

- Pulse Valve 06 BrochureDocument3 pagesPulse Valve 06 BrochurehendraNo ratings yet

- Pgas-kj-c004-Ecv-dg-105 - Metering Shelter PJB Muara Karang - As Built Drawing - FTHDocument10 pagesPgas-kj-c004-Ecv-dg-105 - Metering Shelter PJB Muara Karang - As Built Drawing - FTHIwan NugrohoNo ratings yet

- Escaape NissanDocument6 pagesEscaape NissanpruebaclavesNo ratings yet

- Double Door Feeder Pillar 250A MCCBDocument1 pageDouble Door Feeder Pillar 250A MCCBMiqdad AliNo ratings yet

- Maple Hill Rose Hill: Wilson ParkDocument2 pagesMaple Hill Rose Hill: Wilson ParkdanddminisNo ratings yet

- Kenwood Kca r71fm SMDocument18 pagesKenwood Kca r71fm SMrobotherNo ratings yet

- Anderson County Sheriff's Office: Heritage TraceDocument6 pagesAnderson County Sheriff's Office: Heritage Tracealpca8615No ratings yet

- Mimic C A B L E A L L E Y: Root EngineeringDocument1 pageMimic C A B L E A L L E Y: Root EngineeringRabindra SinghNo ratings yet

- Building Index Parking Lot Index Accessible Parking Legend ResidencesDocument1 pageBuilding Index Parking Lot Index Accessible Parking Legend ResidencesElliot ChiuNo ratings yet

- Delta Doc Center: DescriptionDocument4 pagesDelta Doc Center: DescriptionAnderson103No ratings yet

- Plano Perimetrico, Lotizacion y Ubicacion Lote P-5Document1 pagePlano Perimetrico, Lotizacion y Ubicacion Lote P-5Ronald Mamani ChoquehuancaNo ratings yet

- Electrical System: SectionDocument4 pagesElectrical System: SectionLadislav BreckaNo ratings yet

- Drainage Lect - 1 BAUDocument68 pagesDrainage Lect - 1 BAUAbed BaayounNo ratings yet

- 021 Standing Valves and Seating NipplesDocument1 page021 Standing Valves and Seating NipplesManuel Israel GuamoNo ratings yet

- For BoilerDocument71 pagesFor BoilerSonal PotdarNo ratings yet

- Check ValvesDocument12 pagesCheck ValvesddphilosophyNo ratings yet

- Measrement of FlowDocument12 pagesMeasrement of FlowSushil KumarNo ratings yet

- Oilfield Supply Parts Lot N8234Document13 pagesOilfield Supply Parts Lot N8234Dwiki RamadhaniNo ratings yet

- KTZ CatalogueDocument25 pagesKTZ CatalogueSaleem NasirNo ratings yet

- Swimming Pool General RequirementsDocument23 pagesSwimming Pool General RequirementsVee KeeNo ratings yet

- ASME B16.21 Ring and Full Face Dimensions 150 2500# B16.5 & 16.47 Series A&bDocument13 pagesASME B16.21 Ring and Full Face Dimensions 150 2500# B16.5 & 16.47 Series A&bMONo ratings yet

- Catálogo Accesorios PTFE DINDocument100 pagesCatálogo Accesorios PTFE DINdepinfor lusofabrilNo ratings yet

- Fluid Power ControlDocument25 pagesFluid Power Controlshantanuchoudhary007No ratings yet

- PVCU CompleteSectionDocument137 pagesPVCU CompleteSectionanac_mathNo ratings yet

- 003 Casing & Tubing Hanger PDFDocument4 pages003 Casing & Tubing Hanger PDFalaliali88No ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- Sanitary Services - 2022 PDFDocument35 pagesSanitary Services - 2022 PDFThet Naing OoNo ratings yet

- Coiled Tubing BHA ManualDocument12 pagesCoiled Tubing BHA ManualSamuel OnyewuenyiNo ratings yet

- AL Property Appraisal Manual Chapter 09 JDocument33 pagesAL Property Appraisal Manual Chapter 09 JfdlkasdfjNo ratings yet

- Plumbing Excel DesignDocument2 pagesPlumbing Excel DesignStephen TabiarNo ratings yet

- Senr1678senr1678 Sis PDFDocument2 pagesSenr1678senr1678 Sis PDFDennis OlayaNo ratings yet

- LX02 19-09-19Document106 pagesLX02 19-09-19jesus david villalobos rodriguezNo ratings yet

- Pipe Wall Thickness Calculations: Burnex Burner HeadDocument16 pagesPipe Wall Thickness Calculations: Burnex Burner Headpramodptvpm_65797156No ratings yet

- 28 X 44,5 (TYP.) : Mark Piece InformationDocument3 pages28 X 44,5 (TYP.) : Mark Piece InformationProorocu MikyNo ratings yet

- Rate List of Plumbing Work180208Document1 pageRate List of Plumbing Work180208Tejas kalaskarNo ratings yet

- Installation of Transmitter For Steam Pressure Below Tapping PDFDocument1 pageInstallation of Transmitter For Steam Pressure Below Tapping PDFPeter AntonyNo ratings yet

- 02 Ball - Valve KH143 ManualDocument14 pages02 Ball - Valve KH143 ManualMirela SimijdeanNo ratings yet

- Energy Losses in Hydraulic SystemsDocument17 pagesEnergy Losses in Hydraulic SystemsBassel DaradkehNo ratings yet

- Kxx9940 X-Ray Tube Tube X RöntgenröhreDocument3 pagesKxx9940 X-Ray Tube Tube X Röntgenröhre张明No ratings yet

- Standard - en 1555-5Document16 pagesStandard - en 1555-5ured cizminNo ratings yet

- BS en 200 2008 + Corr 1-2009-03Document54 pagesBS en 200 2008 + Corr 1-2009-03Abey VettoorNo ratings yet

- Agriculture Hydraulic Control Valves: Redefining ReliabilityDocument4 pagesAgriculture Hydraulic Control Valves: Redefining ReliabilityMiguel Angel Pimentel TamayoNo ratings yet

- To Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryFrom EverandTo Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryRating: 4.5 out of 5 stars4.5/5 (260)

- Blender 3D Basics Beginner's Guide Second EditionFrom EverandBlender 3D Basics Beginner's Guide Second EditionRating: 5 out of 5 stars5/5 (1)

- The Designer’s Guide to Figma: Master Prototyping, Collaboration, Handoff, and WorkflowFrom EverandThe Designer’s Guide to Figma: Master Prototyping, Collaboration, Handoff, and WorkflowNo ratings yet

- Skulls & Anatomy: Copyright Free Vintage Illustrations for Artists & DesignersFrom EverandSkulls & Anatomy: Copyright Free Vintage Illustrations for Artists & DesignersNo ratings yet

- Excel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceFrom EverandExcel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceNo ratings yet

- Learn Power BI: A beginner's guide to developing interactive business intelligence solutions using Microsoft Power BIFrom EverandLearn Power BI: A beginner's guide to developing interactive business intelligence solutions using Microsoft Power BIRating: 5 out of 5 stars5/5 (1)

- How to Create Cpn Numbers the Right way: A Step by Step Guide to Creating cpn Numbers LegallyFrom EverandHow to Create Cpn Numbers the Right way: A Step by Step Guide to Creating cpn Numbers LegallyRating: 4 out of 5 stars4/5 (27)

- Blender 3D for Jobseekers: Learn professional 3D creation skills using Blender 3D (English Edition)From EverandBlender 3D for Jobseekers: Learn professional 3D creation skills using Blender 3D (English Edition)No ratings yet

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Photoshop: A Step by Step Ultimate Beginners’ Guide to Mastering Adobe Photoshop in 1 WeekFrom EverandPhotoshop: A Step by Step Ultimate Beginners’ Guide to Mastering Adobe Photoshop in 1 WeekNo ratings yet

- Animation for Beginners: Getting Started with Animation FilmmakingFrom EverandAnimation for Beginners: Getting Started with Animation FilmmakingRating: 3 out of 5 stars3/5 (1)

- Portfolio and Investment Analysis with SAS: Financial Modeling Techniques for OptimizationFrom EverandPortfolio and Investment Analysis with SAS: Financial Modeling Techniques for OptimizationRating: 3 out of 5 stars3/5 (1)

- Windows 11 for Beginners: The Complete Step-by-Step User Guide to Learn and Take Full Use of Windows 11 (A Windows 11 Manual with Useful Tips & Tricks)From EverandWindows 11 for Beginners: The Complete Step-by-Step User Guide to Learn and Take Full Use of Windows 11 (A Windows 11 Manual with Useful Tips & Tricks)Rating: 5 out of 5 stars5/5 (1)

- A History of Video Games in 64 ObjectsFrom EverandA History of Video Games in 64 ObjectsRating: 4.5 out of 5 stars4.5/5 (26)

- Top Secrets Of Excel Dashboards: Save Your Time With MS ExcelFrom EverandTop Secrets Of Excel Dashboards: Save Your Time With MS ExcelRating: 5 out of 5 stars5/5 (1)