Professional Documents

Culture Documents

CAED101 - DE CASTRO - ACN1 - EOQ Activity

Uploaded by

Ira Grace De CastroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAED101 - DE CASTRO - ACN1 - EOQ Activity

Uploaded by

Ira Grace De CastroCopyright:

Available Formats

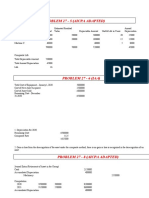

Ira Grace B. De Castro.

ACN1 | CAED101

ECONOMIC ORDER QUANTITY

Westside Auto purchases a component used in the manufacture of automobile generators directly from the

supplier. Westside’s generator production operation, which is operated at a constant rate, will require 1000

components per month throughout the year (12,000 units annually). Assume that the ordering costs are $25

per order, the unit cost is $2.50 per component, and annual holding costs are 20% of the value of the

inventory. Westside has 250 working days per year and a lead time of 5 days. Answer the following

inventory policy:

a. What is the EOQ for this component?

b. What is the reorder point?

c. What is the cycle time?

d. What are the total annual holding and ordering costs associated with your recommended EOQ?

a. Economic order quantity

2𝐷𝐶𝑜

EOQ =√

𝐶ℎ

2(12,000)($25)

=√

(0.20)($2.50)

600,000

=√

$0.50

= √1,200,000

= 1,095.4451 ∿ 1,095.45

b. Reorder point

r = dm

12,000

= (5)

250

= 240

c. Cycle time

250Q∗

T=

𝐷

250(1,095.45)

=

12,000

273,862.50

=

12,000

= 22.821875 ∿ 22.82 days

d. Total annual cost

1 𝐷

TC = 𝑄𝐶ℎ + 𝐶

2 𝑄 𝑜

1 12,000

= (1,095.45)(0.50) + (25)

2 1,095.45

= 273.8625 + 273.8600575

= 547.7225575 ∿ $547.72

You might also like

- AC13 Provisions, Contingencies and Other Liabilities Additional Guide ProblemsDocument2 pagesAC13 Provisions, Contingencies and Other Liabilities Additional Guide ProblemsDianaNo ratings yet

- 21 Problems - and - Answers - Reclassification - of - Financial - AssetDocument30 pages21 Problems - and - Answers - Reclassification - of - Financial - AssetSheila Grace BajaNo ratings yet

- Borrowing Cost Answer KeyDocument12 pagesBorrowing Cost Answer KeyHAZELMAE JEMINEZNo ratings yet

- Chapter 1 None CompressDocument9 pagesChapter 1 None CompressiadcNo ratings yet

- IA2 Worksheet-BONDS PAYABLE - 101010Document11 pagesIA2 Worksheet-BONDS PAYABLE - 101010aehy lznuscrfbjNo ratings yet

- Act. 3-9Document4 pagesAct. 3-9Fernando III PerezNo ratings yet

- MachineryDocument4 pagesMachineryDianna DayawonNo ratings yet

- CFAS - Chapter 7: Multiple ChoiceDocument1 pageCFAS - Chapter 7: Multiple Choiceagm25No ratings yet

- Lobrigas Unit3 Topic2 AssessmentDocument6 pagesLobrigas Unit3 Topic2 AssessmentClaudine LobrigasNo ratings yet

- Cost of Goods Manufactured Income Statement Norton IndustriesDocument2 pagesCost of Goods Manufactured Income Statement Norton IndustriesAmit PandeyNo ratings yet

- ACTG 431 QUIZ Week 2 Theory of Accounts Part 2 - FINANCIAL ASSET AT AMORTIZED COST QUIZDocument4 pagesACTG 431 QUIZ Week 2 Theory of Accounts Part 2 - FINANCIAL ASSET AT AMORTIZED COST QUIZMarilou Arcillas PanisalesNo ratings yet

- Absorption Costing Vs Variable CostingDocument20 pagesAbsorption Costing Vs Variable CostingMa. Alene MagdaraogNo ratings yet

- Nutty Company Problem 23 - 5Document2 pagesNutty Company Problem 23 - 5Ya NaNo ratings yet

- 2022 BS AIS 3B Law On Partnerships Chapter 3 AssignmentDocument11 pages2022 BS AIS 3B Law On Partnerships Chapter 3 AssignmentRose Jane AtabayNo ratings yet

- Quiz - Chapter 4 - Provisions, Cont. Liab. & Cont. Assets - 2021Document3 pagesQuiz - Chapter 4 - Provisions, Cont. Liab. & Cont. Assets - 2021Martin ManuelNo ratings yet

- Reclassification: of Financial AssetsDocument15 pagesReclassification: of Financial AssetsHazel Jane EsclamadaNo ratings yet

- Intermediate Accounting 1 - Chapter 15, Financial Assets at Fair ValueDocument8 pagesIntermediate Accounting 1 - Chapter 15, Financial Assets at Fair ValueAndrei FajardoNo ratings yet

- CHAPTER 3 - Notes To Financial StatementDocument32 pagesCHAPTER 3 - Notes To Financial StatementShane Aberie Villaroza AmidaNo ratings yet

- This Study Resource Was: InvestmentsDocument9 pagesThis Study Resource Was: InvestmentsMs VampireNo ratings yet

- Impairment of AssetsDocument21 pagesImpairment of AssetsDeryl GalveNo ratings yet

- Shaine Andrea P. Sabiña Project 1st HalfDocument15 pagesShaine Andrea P. Sabiña Project 1st HalfNicole Anne Santiago SibuloNo ratings yet

- Chapter 5Document20 pagesChapter 5Clyette Anne Flores Borja100% (1)

- Vallix QuestionnairesDocument14 pagesVallix QuestionnairesKathleen LucasNo ratings yet

- Receivable Financing Pledge Assignment ADocument34 pagesReceivable Financing Pledge Assignment AJoy UyNo ratings yet

- Chapter 18 - Investment in Associate (Other Accounting Issues)Document3 pagesChapter 18 - Investment in Associate (Other Accounting Issues)Liana LopezNo ratings yet

- Fair Value Model: Home My Courses ACC211 - 6387 - 2021-2022 - 2NDSEM-SEM - CAE 5th To 8th Examinations/Assessments Final ExamDocument2 pagesFair Value Model: Home My Courses ACC211 - 6387 - 2021-2022 - 2NDSEM-SEM - CAE 5th To 8th Examinations/Assessments Final Examkaeya alberichNo ratings yet

- Problem 2 10Document9 pagesProblem 2 10Carl Jaime Dela CruzNo ratings yet

- Problem 4-9Document2 pagesProblem 4-9maryaniNo ratings yet

- Problem 2 8Document6 pagesProblem 2 8Carl Jaime Dela CruzNo ratings yet

- Inventory Management PDFDocument21 pagesInventory Management PDFReverie SevillaNo ratings yet

- Flexible Company Debit Credit 2020Document1 pageFlexible Company Debit Credit 2020AnonnNo ratings yet

- Chapter 21 - Treasury Shares, Right Issue, Share SplitDocument28 pagesChapter 21 - Treasury Shares, Right Issue, Share Splitwala akong pake sayoNo ratings yet

- Bonds Payable: Intermediate Accounting 2Document38 pagesBonds Payable: Intermediate Accounting 2Rolando Verano TanNo ratings yet

- IA 1 Valix 2020 Ver. Problem 27-5 - Problem 27-7Document2 pagesIA 1 Valix 2020 Ver. Problem 27-5 - Problem 27-7Ariean Joy DequiñaNo ratings yet

- DEPRECIATION2Document9 pagesDEPRECIATION2Darlianne Klyne BayerNo ratings yet

- Acc 124 - Week 13-14 - Ulob - Investment in Equity Securities - Assignment - CainDocument2 pagesAcc 124 - Week 13-14 - Ulob - Investment in Equity Securities - Assignment - Cainslow dancerNo ratings yet

- Assign 1 Answer Valuation of Contributions of Partners Millan 2021Document4 pagesAssign 1 Answer Valuation of Contributions of Partners Millan 2021mhikeedelantarNo ratings yet

- Solman Chap10 Shareholders Equity - CompressDocument18 pagesSolman Chap10 Shareholders Equity - CompressDump DumpNo ratings yet

- Assignment Module-9 Coefficient of CorrelationDocument4 pagesAssignment Module-9 Coefficient of CorrelationFranchesca CuraNo ratings yet

- Year Sales Actual Warranty ExpendituresDocument5 pagesYear Sales Actual Warranty ExpendituresMinie KimNo ratings yet

- Accounts Receivable: QuizDocument4 pagesAccounts Receivable: QuizRisa Castillo MiguelNo ratings yet

- Test - Financial PlanningDocument3 pagesTest - Financial PlanningMasTer PanDaNo ratings yet

- 21 Financial Assets at Fair Value: Solution 21-1 Answer CDocument30 pages21 Financial Assets at Fair Value: Solution 21-1 Answer CLayNo ratings yet

- Chapter 13 - Gross Profit MethodDocument2 pagesChapter 13 - Gross Profit MethodBena CubillasNo ratings yet

- Chapter 7 - Compound Financial Instrument (FAR6)Document5 pagesChapter 7 - Compound Financial Instrument (FAR6)Honeylet SigesmundoNo ratings yet

- Chapter 5 Financial Management by CabreraDocument19 pagesChapter 5 Financial Management by CabreraLars FriasNo ratings yet

- Bonds PayableDocument10 pagesBonds Payablenot funny didn't laughNo ratings yet

- FAR 04-11.a Depletion of Mineral ResourcesDocument4 pagesFAR 04-11.a Depletion of Mineral ResourcesAi NatangcopNo ratings yet

- Intermediate Accounting 2 Chapter 3Document8 pagesIntermediate Accounting 2 Chapter 3Mau Dela CruzNo ratings yet

- Management Science Prelim - Ando RejieDocument3 pagesManagement Science Prelim - Ando RejieRejie AndoNo ratings yet

- Bonds PayableDocument39 pagesBonds PayableRuiz, CherryjaneNo ratings yet

- Seatwork Module 10Document3 pagesSeatwork Module 10Marjorie PalmaNo ratings yet

- Problem 23-16Document9 pagesProblem 23-16anneliban499No ratings yet

- Borrowing Cost DrillDocument2 pagesBorrowing Cost DrillJasmin Rabon0% (1)

- Land Building Machinery ProblemsDocument13 pagesLand Building Machinery ProblemsJomerNo ratings yet

- ValueDocument44 pagesValueRose Ann PaloayNo ratings yet

- ch21 ReclassificationDocument6 pagesch21 ReclassificationmercyvienhoNo ratings yet

- Inventory Problems SolutionsDocument3 pagesInventory Problems SolutionsSabbir Ahmed SounokNo ratings yet

- Average Waiting Time For An Order of Z39Document2 pagesAverage Waiting Time For An Order of Z39Elliot RichardNo ratings yet

- Introduction To Management Science Quantitative Approach 15Th Edition Anderson Solutions Manual Full Chapter PDFDocument41 pagesIntroduction To Management Science Quantitative Approach 15Th Edition Anderson Solutions Manual Full Chapter PDFcleopatrafreyane8c100% (11)

- Audit of BanksDocument10 pagesAudit of BanksIra Grace De Castro100% (2)

- Sugar Industry IVDocument10 pagesSugar Industry IVIra Grace De CastroNo ratings yet

- Crashing Activity Times - Excel SolverDocument2 pagesCrashing Activity Times - Excel SolverIra Grace De CastroNo ratings yet

- Important Points and Sample Questions On Audit of Specialized IndustriesDocument8 pagesImportant Points and Sample Questions On Audit of Specialized IndustriesIra Grace De CastroNo ratings yet

- Gantt Chart ActivityDocument2 pagesGantt Chart ActivityIra Grace De CastroNo ratings yet

- Hospital Industry IIIDocument6 pagesHospital Industry IIIIra Grace De Castro100% (1)

- Audit of Construction Industry: (Standard Industrial Classification)Document13 pagesAudit of Construction Industry: (Standard Industrial Classification)Ira Grace De CastroNo ratings yet

- Current Liabilities - PROBLEMSDocument11 pagesCurrent Liabilities - PROBLEMSIra Grace De Castro100% (2)

- Crashing Activity TimesDocument2 pagesCrashing Activity TimesIra Grace De CastroNo ratings yet

- Noncurrent Liabilities - PROBLEMS: B. A DiscountDocument12 pagesNoncurrent Liabilities - PROBLEMS: B. A DiscountIra Grace De Castro67% (3)

- Learning Curve ActivityDocument1 pageLearning Curve ActivityIra Grace De CastroNo ratings yet

- Inventory Model ActivityDocument1 pageInventory Model ActivityIra Grace De CastroNo ratings yet

- Simplex Method Additional ActivityDocument3 pagesSimplex Method Additional ActivityIra Grace De CastroNo ratings yet

- Uncertain Activity TimesDocument1 pageUncertain Activity TimesIra Grace De CastroNo ratings yet

- Caed101 de Castro Acn1 Assignment ProblemDocument2 pagesCaed101 de Castro Acn1 Assignment ProblemIra Grace De CastroNo ratings yet

- Project Scheduling - Uncertain Activity TimesDocument4 pagesProject Scheduling - Uncertain Activity TimesIra Grace De CastroNo ratings yet

- CAED101 - Model Building ActivityDocument2 pagesCAED101 - Model Building ActivityIra Grace De CastroNo ratings yet

- Transshipment ProblemDocument3 pagesTransshipment ProblemIra Grace De CastroNo ratings yet

- CAED101 - DE CASTRO - ACN1 - Assignment ProblemDocument2 pagesCAED101 - DE CASTRO - ACN1 - Assignment ProblemIra Grace De CastroNo ratings yet

- CAED101 - DE CASTRO - ACN1 - Network Model Transshipment Problem QuizDocument3 pagesCAED101 - DE CASTRO - ACN1 - Network Model Transshipment Problem QuizIra Grace De CastroNo ratings yet

- Exam Content Manual PreviewDocument6 pagesExam Content Manual PreviewThu Giang DuongNo ratings yet

- Dommety EXP22 Excel Ch04 ML1 InventoryDocument4 pagesDommety EXP22 Excel Ch04 ML1 Inventoryprempreethi19No ratings yet

- Chapter 7 Interm 1a Sol Man Millan (2019)Document20 pagesChapter 7 Interm 1a Sol Man Millan (2019)5555-899341No ratings yet

- Assignment 1 OM PDFDocument3 pagesAssignment 1 OM PDFSuman ChaudharyNo ratings yet

- The Inventory Control Account Balance of Magic Fashions at June 30Document2 pagesThe Inventory Control Account Balance of Magic Fashions at June 30Kesiah FortunaNo ratings yet

- Operation Management SyllabusDocument2 pagesOperation Management SyllabusPiyush Singh RajputNo ratings yet

- Course Material of IE 472Document98 pagesCourse Material of IE 472Joha Orellana IñiguezNo ratings yet

- Tutorial 7 Solutions - Material Requirements PlanningDocument9 pagesTutorial 7 Solutions - Material Requirements PlanningKhathutshelo KharivheNo ratings yet

- Toyota Production SystemDocument10 pagesToyota Production Systemjeshel caturanNo ratings yet

- Material Requirements PlanningDocument5 pagesMaterial Requirements PlanningNiño Rey LopezNo ratings yet

- InventoryDocument117 pagesInventoryHemn YasinNo ratings yet

- Notes Introduction To Logistics & Procurement 2023Document106 pagesNotes Introduction To Logistics & Procurement 2023Salmaan duraan CaliNo ratings yet

- Defining Supply ChainDocument7 pagesDefining Supply ChainGabriel SilvaNo ratings yet

- 6 Inventory Control TechniquesDocument8 pages6 Inventory Control TechniquesAngel TagudNo ratings yet

- Lorico - Quiz For Inventory Estimation - Acc124Document4 pagesLorico - Quiz For Inventory Estimation - Acc124maica G.No ratings yet

- Chapter 3 Channels of Distribution Management (A)Document25 pagesChapter 3 Channels of Distribution Management (A)muhdfirdausNo ratings yet

- Topic8. PPT. WCM - Inventory ManagementDocument21 pagesTopic8. PPT. WCM - Inventory ManagementHaidee Flavier Sabido100% (1)

- Rapid-Fire Fulfillment: Harvard Business Review November 2004Document9 pagesRapid-Fire Fulfillment: Harvard Business Review November 2004Andres Sanchez ArroyoNo ratings yet

- Purchase OrderDocument6 pagesPurchase OrderSK SchreaveNo ratings yet

- Chapter 5 Just in Time and Backflush AccountingDocument11 pagesChapter 5 Just in Time and Backflush AccountingSteffany RoqueNo ratings yet

- Gaurav Midha's ResumeDocument3 pagesGaurav Midha's Resumegaurika midhaNo ratings yet

- Marine-Logistics ListDocument13 pagesMarine-Logistics ListOindrilaNo ratings yet

- Department of Education: Schools Division of Zamboanga Del SurDocument2 pagesDepartment of Education: Schools Division of Zamboanga Del SurFharhan DaculaNo ratings yet

- Supply Chain Management Solved MCQS: Australian Telemarketing LeadsDocument6 pagesSupply Chain Management Solved MCQS: Australian Telemarketing Leadsjayant bansalNo ratings yet

- Astha School of Management 2 Semester Sub: Fundamentals of It & Erp (18mba207) Module - LLL (MCQS)Document12 pagesAstha School of Management 2 Semester Sub: Fundamentals of It & Erp (18mba207) Module - LLL (MCQS)MD Rehan100% (1)

- Business-to-Business Activities: Improving Efficiency and Reducing CostsDocument55 pagesBusiness-to-Business Activities: Improving Efficiency and Reducing Coststhanh nguyen100% (1)

- Resource Planning SystemDocument83 pagesResource Planning SystemShahmirBalochNo ratings yet

- Mike Rother, John Shook - Learning To See - Value Stream Mapping To Add Value and Eliminate MUDA-Lean Enterprise Institute (1999)Document132 pagesMike Rother, John Shook - Learning To See - Value Stream Mapping To Add Value and Eliminate MUDA-Lean Enterprise Institute (1999)Hellen HernándezNo ratings yet

- Aindump2go CSCP Study Guide 2021-Mar-31 by Edgar 296q VceDocument20 pagesAindump2go CSCP Study Guide 2021-Mar-31 by Edgar 296q VceamirMMNo ratings yet

- BPE Lec 10 JITDocument35 pagesBPE Lec 10 JITSaif UllahNo ratings yet