Professional Documents

Culture Documents

Misc 20190204

Misc 20190204

Uploaded by

Ashish Srivastava0 ratings0% found this document useful (0 votes)

102 views9 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

102 views9 pagesMisc 20190204

Misc 20190204

Uploaded by

Ashish SrivastavaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

Headquarter Office,

Churchgate, Mumbai-20

ufgerar Yer’

Western Railway

No. W 68/0 (Policy) (W3) Date : 04.02.2019

‘Sr.DEN(Cos) : BCT BRC RTM ADI RJT BVP

Dy.CE(Briline)Dadar Dy.CE(Br)BRC Dy.CE(Br)ADI CWM(EW)SBI

Sub : Dismantling / de-launching of Bridge super-structure

Ref: ()) Railway Board vide letter No. 2015/CE-IV/ROB/206 dt.15.02.2016

(ii) Railway Board's letter No. 2015/CE-IV/RUB/206 dated: 11.08.2016.

been unusual on one of the ROBs where a piece of concrete deck has dropped on the

Supporting steel plates while dismantling. Dismantling of bridge has safety implications

and therefore, it requires careful planning and execution.

There are various methods of dismantling of the bridge decks like sawing, using

Pneumatic breakers like Pavement breaker etc. The selection of method is to be

decided by field Engineers depending upon the site conditions. However, Cutting the

bridge deck with diamond cutter / wire cutters is widely used because of its efficiency,

‘safety and reliability as it causes no vibration and permits controlled dismantling making

the operation safer. The method involves cutting of bridge deck into manageable small

pieces which are being removed with over head cranes or lifting equipments. This in

turn requires a detailed dismantling scheme indicating the size of pieces in which the

slab is proposed to be cut, assessment of weight of each piece, ‘sequence of cutting of

the piece with due fegard to main and distribution reinforcement, assessment of

capacity of crane or lifting equipment and ear marking spaces for placing the dismantled

piece after cutting

Mobile cranes / Hydras are bei ing used for holding and disposing of the concrete

blocks during dismantling. These lifting equipment are also used for launching / de-

launching of steel ‘super-structure in case of FOBs, ROBs.

Railway Board vide letter under reference have issued the detailed instructions

for safe working cranes. These instructions are reproduced here under:

@ No machine shall be selected to do any lifting on a ‘Specific job until its size and

characteristics are considered against the weights, dimensions and lift radii of the

heaviest and largest loads.

bences)

2 es

(i) The contractor shall ensure that a valid Certificate of Fitness is available before

use of Road Cranes.

(ii) Contractors can utilize the services of any competent person as defined in

Factories Act, 1948 and approved by Chief inspector of Factories

(%) The laminated photo copies of fitness certificate issued by competent Person, the

operators’ photo, manufacturer's load chart and competency certificate shall

always be either kept in the operator cabin or pasted on the visible surface of the

lifting appliances,

(¥) All lifting appliances including all parts and gears thereof, whether fixed or

Further, Railway Board vide the letter under reference (i) above have circulated

instructions for Safe working of Road cranes for launching Girders. As per said

instructions:

1. Based on site conditions i.e maximum boom length and operating radius, safe

working load of crane shall be assessed which should be more than 1.5 times of

2. Before actually commencing the work near track, trial at site shall be done by

actually lifting the heaviest segment to be tackled with required boom length and

reduired operating radius. Once, the trial is successful, then only crane shall be

brought to site of actual work.

3. The stability of slope under imposed load of crane prop under worst loading

conditions and point nearest to edge of slope shall be checked. The location of

Prop, {ocations of working of crane and other relevant factor shall be clearly

indicated on plan.

4 At locations near crane propping, the strengthening of slope by driving the

(ails/Sal Ball Piling shall be done to prevent any chance of slope fallure. Also,

the proper compaction/strengthening of soil at prop location shall be done to

Prevent any settlement of prop.

5. Stone/quarry dust may be filed by side of precast units with hand compaction

before restoring train.

These instructions should be scrupulously followed at the site of launching / de-

launching of concrete / steel supérstructure. In addition to above, arrangements

brought out in Annexure ‘A’ should be ensured for safe operation of cranes.

Please acknowledge the receipt of this letter.

eer

Ofori 9

( Manjul Mathur )

Chief Bridge Engineer

Encl: As above

&)

3

Ci CAO (C)-CCG : for kind information. It is requested that the construction sites may

Please be sensitized about the issues brought out in this letter.

C/- Director - MRVC Mumbai : for information & Necessary action.

CI- Director ~ DFCCIL, New Delhi : for information & necessary action.

C/- Director - RVNL, Mumbai : for information & necessary action.

C/- Director ~ NHSRCL — New Delhi : for information & necessary action.

Luna

oHforfiq

Chief Bridge Engineer

C/-DRMs: BCT BRC RTM ADI RJT BVP - for information,

Coe

GOVERNMENT OF INDIA =,

MINISTRY OF RAILWAYS (129

(RAILWAY BOARD)

No.2015/CE-IV/RUB/206 New Delhi, dated 15.02.2016

Principal Chief Engincers,

All Zonal Railways

Chief Administrative Office(c),

All Zonal Railways

Sub: Special Conditions for working of Road Cranes

Ir has been observed that large number of ROBs/RUBs/Subway works are in

progress and launching of ROBs/RUBs/Subways are being done with the help

of Road Cranes. But it has been observed that sometimes Road Crane with

quitable capacity and having valid Certificate about safe condition of Rect

Cranes are not being used and it is leading to unsafe conditions,

In view of this, it is decided that the following condition should be incorporated

in all future tender conditions:

1 No machine shall be selected to do any lifting on a specific job until its

size and characteristics are considered against the weights, dimensions

and lift radii of the heaviest and largest loads.

2 The contractor shall ensure that a valid Certificate of Fitness is available

before use of Road Cranes

* Contractors can utilise the services of any competent person as defined

in Factories Act, 1948 and approved by Chief Inspector of Factories,

‘The laminated photocopies of fitness certificate issued by competent

Pea operators photo, manufacturer's load chart and competency

Certificate shall always be either kept in the operator cabin or pasted on

the visible surface of the lifting appliances.

5 All lifting appliances including all parts and gears thereof, whether fixed

or movable shall be thoroughly tested and examined by a competent

ene at least in every six months or after it has undergone any

alterations or repairs liable to affect its strength or stability.

In addition, it is also advised that for all the works being executed by the Road

Cranes, the above stipulations should be checked. These instructions

should be strictly observed.

Dae 16

(sc. Bath)

Executive Director CE/B&S-II

ws des ok)

No.2015/CE-IV/RUB/206

All Zonal Railways

of road cranes.

of road crane

issued by Railway Board

above, following items shal

modus operandi:

radius, safe working

be more

be done by actually

work.

(i) The stability of slope

GOVERNMENT OF INDIA 8

MINISTRY OF RAILWAY

RAILWAY BOARD

New Delhi, Dated 11.08.2016

‘The Principal Chief Engineers “/| WR

Sub: Safe working 6f Road cranés for launching of Girders/LHS.

Railway Board vide letter No 2015/CE-IV/RUB/206 dt 15 02 2016 has

advised to inchide special conditions in tender conditions for safe working

e

Recently, during launching of RCC box segments, an accident of toppling

‘occurred. Another accident ‘has taken place due to

» subsidence adjacent to precast RC Units in service.

Board (ME) has directed that strict compliance to instructions already

shall be ensured by Zonal Railways. Besides

also be ensured and properly incorporated in

@) Based on site conditions i.e. maximum boom length and operati

ting,

load of crane shall be assessed which should

f load to be handled.

(i) Before actually commencing the work near track, trial at site shall

lifting the heaviest segment to be tackled with

required boom length and required operating radius. Once, the trial

js successful, then only crane shall be brought to site of actual

under imposed load of crane prop under worst

joading conditions and point nearest to edge of slope shall be

hecked. The location of prop, locations of working of crane and

a ‘other relevant factor shail be clearly indicated on plan.

xX Ext ‘ions near crane propping, the. strengthening of slope by

OL & ing the rails/Sal Balli Piling shall be done to prevent any

we ‘ance of slope failure. Also, the proper compaction/strengthening

AX of soil at prop location shall be done to prevent any settlement of

prop ais

Xf () « Stone/quarry dust may be filled by side of precast units with hand

¥ compaction before restoring train.

Railway shall confirm receii

ipt of letter and action taken on the above.

TO

{A.K.Singhal)

Executive Director. CE/B&S

426

Annexure-A

Protocol for Safe Operation of Lifting equipment and lifting gears

1. Purpose:

The purpose of this document is to ensure safe working conditions during

‘Working with all kinds of Lifting equipment and Lifting gears.

2. Scope

It is applicable to Re-girdering sites, sites for Launching/ de-launching of

Superstructures at ROBs, FOBs, girder bridges, launching segments at LHSs

and all other places where Cranes and Hydras are used for erecting/

dismantling

3. Definition:

Crane — Any appliance equipped with mechanical means of raising and

lowering a load or for transporting the load while in suspended condition. These

can be crawler mounted, lorry mounted, tower types and wheeled telescopic.

The cranes shall also include Hydras.

Lifting Equipment — A derrick, winch, pulley blocks used for raising or lowering

load.

Lifting Gear — A chain sling, rope sling, ring or similar gear, and a link, hook,

plate clamp, D-shackle, swivel or eyebolt.

4. Working of Cranes:

() Cranes shall be installed under the supervision of a competent person

as defined under factories Act 1948 or as approved by Chief Inspector

of factories,

(i) No structural alteration or repair shall be made on any part of the lifting

appliances that affects the safety without the permission of the

Competent person.

(lil) Every Crane being operated outdoors should have a cabin for the

Protection of the operator against weather. All panes should be intact to

‘stop rainwater.

(iv) Crane shaill have load chart indicating safe working load at various radius

of operations (Load Chart). — Limiting switch, Boom light, swing horn,

flashing beacon. Safe Working Load (SWL) prominently displayed on the

‘crane body. This SWL should NEVER be exceeded

(v) No lifting equipment shall be loaded beyond the SWL.

(Wi) The lifting points on the load (girder or a dismantled piece) should be as

stipulated in the drawing.

(vil) Operators shall not leave Cranes/ lifting equipment unattended with

power on or with a load suspended.

(vill) Swing area of the crane shall be barricaded and no person should be

allowed in this area when the crane is in operation

(%) _ It should also be ensured that there is no object in the swing area of

crane

®)

(xi)

(xii)

(xii)

Annexure-A

When more than one crane is required to lift or lower one load ie.

Tandem Lifting arrangements shall be such that none of the cranes will

at any time be loaded beyond its SWL or be rendered unstable in the

lifting or lowering of the load and a competent person shall be specially

appointed to co-ordinate the operation of the cranes working together.

During lifting/ lowering operations, effective precautions shall be taken to

prevent any person from standing or passing under the load.

The crane must be operated on firm, level and fully compacted ground

and additional support by way of steel plates must also be provided

wherever required to ensure stability of cranes during its operation.

Before actually commencing the work near track, trial at site shall be

done by actually lifting the heaviest segment to be tackled with required

boom length and required operating radius. Once, the trial is successful,

then only crane shall be brought to site of actual work.

Cranes shall not be used: -

()__~ To lift material during rains, heavy winds and bad weather which likely

to endanger its stability.

(ii) To dolifting operations close proximity to live OHE or live electric power

lines.

(ii) To pull out fixed objects.

. Lifting gears:

Lifting gear used in connection with cranes and lifting equipment's:

®

wi

(i)

wy)

w™

A competent person shall inspect all lifting gear before they are put in

use. 4

Manufacturers shall issue a test certificate. Lifting capacity of gear

‘should be known beforehand.

Slings with evidence of cuts, excessive wear, distortion or kinks shall be

discarded.

‘Sharp bends of loads shall be padded by semi-circular metallic pipe

pieces or rubber pads etc.

‘When multiple slings are used, load shall be equally distributed.

Annexure-A

(vi) Where double or multiple slings are used, the-upper ends of the slings

shall be connected by means of a shackle or a ring and not be put

separately into a lifting hook

(vil) Eye splices should have sleeves and loops of wire ropes shall be

provided with thimbles,

(vill) Hooks shall be provided with a spring-loaded safety latches to prevent

the load from slipping.

+ The wire rope sling shall not be used and shall be disposed if they are:

Bird cages Kinks.

Noma! Normal dana Reduced deter Abomal

Surface wire are worn ‘Change of diameter of wire rope sling

by 18 or more

Check for wear

and deformation

Check for signs of

“opening up"

_ Check for cracks

and twisting

Check for wear

and cracks ——>

Annexure-A

6. Authorized Persons to Operate crane:

Only Authorized person with valid Driving License in respective category,

issued by Local Authority shall only be allowed to operate the Crane or Lifting

‘equipment.

All Operators of lifting equipment must have received adequate training from

3rd party, for purposes of safety, including training in Load Charts and the

Lifting methods which may be adopted when using the lifting equipment.

The Operator must be conversant with hand signal communications during the

operation of crane.

Gr)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Erosion Control Paper 2003Document12 pagesErosion Control Paper 2003Ashish SrivastavaNo ratings yet

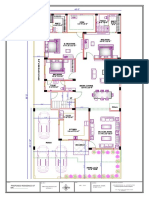

- Ground Floor 40X80 Option-2Document1 pageGround Floor 40X80 Option-2Ashish Srivastava100% (1)

- First Floor 40X80 Option-2Document1 pageFirst Floor 40X80 Option-2Ashish SrivastavaNo ratings yet

- Ground Floor 40X80 Option-1Document1 pageGround Floor 40X80 Option-1Ashish SrivastavaNo ratings yet

- First Floor 40X80 Option-1Document1 pageFirst Floor 40X80 Option-1Ashish SrivastavaNo ratings yet