Professional Documents

Culture Documents

Section 232300 - Refrigerant Piping

Uploaded by

Chase GietterOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 232300 - Refrigerant Piping

Uploaded by

Chase GietterCopyright:

Available Formats

SECTION

232300 - REFRIGERANT PIPING

PART 1 - GENERAL

1.1 SUMMARY

A. This Section includes refrigerant piping used for air-conditioning applications.

1.2 PERFORMANCE REQUIREMENTS

A. Line Test Pressure for Refrigerant R-134a:

1. Suction Lines for Air-Conditioning Applications: 115 psig.

2. Suction Lines for Heat-Pump Applications: 225 psig.

3. Hot-Gas and Liquid Lines: 225 psig.

B. Line Test Pressure for Refrigerant R-407C:

1. Suction Lines for Air-Conditioning Applications: 230 psig.

2. Suction Lines for Heat-Pump Applications: 380 psig.

3. Hot-Gas and Liquid Lines: 380 psig.

C. Line Test Pressure for Refrigerant R-410A:

1. Suction Lines for Air-Conditioning Applications: 300 psig.

2. Suction Lines for Heat-Pump Applications: 535 psig.

3. Hot-Gas and Liquid Lines: 535 psig.

1.3 ACTION SUBMITTALS

A. Product Data: For each type of valve and refrigerant piping specialty indicated. Include

pressure drop based on manufacturer's test data.

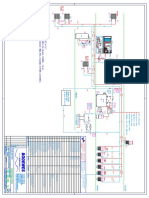

B. Shop Drawings: Show layout of refrigerant piping and specialties, including pipe, tube, and

fitting sizes, flow capacities, valve arrangements and locations, slopes of horizontal runs, oil

traps, double risers, wall and floor penetrations, and equipment connection details. Show

interface and spatial relationships between piping and equipment.

1. Refrigerant piping indicated on Drawings is schematic only. Size piping and design

actual piping layout, including oil traps, double risers, specialties, and pipe and tube sizes

to accommodate, as a minimum, equipment provided, elevation difference between

compressor and evaporator, and length of piping to ensure proper operation and

compliance with warranties of connected equipment.

1.4 INFORMATIONAL SUBMITTALS

A. Field quality-control test reports.

1.5 CLOSEOUT SUBMITTALS

A. Operation and maintenance data.

REFRIGERANT PIPING 232300 - 1

Transportation & Food Service Addition September 30, 2019

Fayetteville, AR 19102900 Construction Documents

1.6 QUALITY ASSURANCE

A. Comply with ASHRAE 15, "Safety Code for Refrigeration Systems."

B. Comply with ASME B31.5, "Refrigeration Piping and Heat Transfer Components."

1.7 PRODUCT STORAGE AND HANDLING

A. Store piping in a clean and protected area with end caps in place to ensure that piping interior

and exterior are clean when installed.

PART 2 - PRODUCTS

2.1 COPPER TUBE AND FITTINGS

A. Copper Tube: ASTM B 280, Type ACR.

B. Wrought-Copper Fittings: ASME B16.22.

C. Wrought-Copper Unions: ASME B16.22.

D. Solder Filler Metals: ASTM B 32. Use 95-5 tin antimony or alloy HB solder to join copper

socket fittings on copper pipe.

E. Brazing Filler Metals: AWS A5.8.

F. Flexible Connectors:

1. Body: Tin-bronze bellows with woven, flexible, tinned-bronze-wire-reinforced protective

jacket.

2. End Connections: Socket ends.

3. Offset Performance: Capable of minimum 3/4-inch misalignment in minimum 7-inch-long

assembly.

4. Pressure Rating: Factory test at minimum 500 psig.

5. Maximum Operating Temperature: 250 deg F.

PART 3 - EXECUTION

3.1 PIPING APPLICATIONS

A. Hot-Gas and Liquid Lines, and Suction Lines: Copper, Type ACR, drawn-temper tubing and

wrought-copper fittings with soldered joints.

3.2 PIPING INSTALLATION

A. Drawing plans, schematics, and diagrams indicate general location and arrangement of piping

systems; indicated locations and arrangements were used to size pipe and calculate friction

loss, expansion, pump sizing, and other design considerations. Install piping as indicated

unless deviations to layout are approved on Shop Drawings.

B. Install refrigerant piping according to ASHRAE 15.

C. Install piping in concealed locations unless otherwise indicated and except in equipment rooms

and service areas.

REFRIGERANT PIPING 232300 - 2

Transportation & Food Service Addition September 30, 2019

Fayetteville, AR 19102900 Construction Documents

D. Install piping indicated to be exposed and piping in equipment rooms and service areas at right

angles or parallel to building walls. Diagonal runs are prohibited unless specifically indicated

otherwise.

E. Install piping above accessible ceilings to allow sufficient space for ceiling panel removal.

F. Install piping adjacent to machines to allow service and maintenance.

G. Install piping free of sags and bends.

H. Install fittings for changes in direction and branch connections.

I. Select system components with pressure rating equal to or greater than system operating

pressure.

J. Install piping as short and direct as possible, with a minimum number of joints, elbows, and

fittings.

K. Arrange piping to allow inspection and service of refrigeration equipment. Install valves and

specialties in accessible locations to allow for service and inspection. Install access doors or

panels as specified in Section 083113 "Access Doors and Frames" if valves or equipment

requiring maintenance is concealed behind finished surfaces.

L. Install refrigerant piping in protective conduit where installed belowground.

M. Install refrigerant piping in rigid or flexible conduit in locations where exposed to mechanical

injury.

N. Slope refrigerant piping as follows:

1. Install horizontal hot-gas discharge piping with a uniform slope downward away from

compressor.

2. Install horizontal suction lines with a uniform slope downward to compressor.

3. Install traps and double risers to entrain oil in vertical runs.

4. Liquid lines may be installed level.

O. When brazing or soldering, remove solenoid-valve coils and sight glasses; also remove valve

stems, seats, and packing, and accessible internal parts of refrigerant specialties. Do not apply

heat near expansion-valve bulb.

P. Install piping with adequate clearance between pipe and adjacent walls and hangers or between

pipes for insulation installation.

Q. Identify refrigerant piping and valves according to Section 230553 "Identification for HVAC

Piping and Equipment."

R. Install sleeves for piping penetrations of walls, ceilings, and floors. Comply with requirements

for sleeves specified in Section 230517 "Sleeves and Sleeve Seals for HVAC Piping."

S. Install sleeve seals for piping penetrations of concrete walls and slabs. Comply with

requirements for sleeve seals specified in Section 230517 "Sleeves and Sleeve Seals for HVAC

Piping."

T. Install escutcheons for piping penetrations of walls, ceilings, and floors. Comply with

requirements for escutcheons specified in Section 230518 "Escutcheons for HVAC Piping."

REFRIGERANT PIPING 232300 - 3

Transportation & Food Service Addition September 30, 2019

Fayetteville, AR 19102900 Construction Documents

3.3 PIPE JOINT CONSTRUCTION

A. Soldered Joints: Construct joints according to ASTM B 828 or CDA's "Copper Tube Handbook."

B. Brazed Joints: Construct joints according to AWS's "Brazing Handbook," Chapter "Pipe and

Tube."

1. Use Type BcuP, copper-phosphorus alloy for joining copper socket fittings with copper

pipe.

2. Use Type BAg, cadmium-free silver alloy for joining copper with bronze or steel.

3.4 HANGERS AND SUPPORTS

A. Hanger, support, and anchor products are specified in Section 230529 "Hangers and Supports

for HVAC Piping and Equipment."

B. Install the following pipe attachments:

1. Adjustable steel clevis hangers for individual horizontal runs less than 20 feet long.

2. Roller hangers and spring hangers for individual horizontal runs 20 feet or longer.

3. Pipe Roller: MSS SP-58, Type 44 for multiple horizontal piping 20 feet or longer,

supported on a trapeze.

4. Spring hangers to support vertical runs.

5. Copper-clad hangers and supports for hangers and supports in direct contact with copper

pipe.

C. Install hangers for copper tubing with the following maximum spacing and minimum rod sizes:

1. NPS 1/2: Maximum span, 60 inches; minimum rod size, 1/4 inch.

2. NPS 5/8: Maximum span, 60 inches; minimum rod size, 1/4 inch.

3. NPS 1: Maximum span, 72 inches; minimum rod size, 1/4 inch.

4. NPS 1-1/4: Maximum span, 96 inches; minimum rod size, 3/8 inch.

5. NPS 1-1/2: Maximum span, 96 inches; minimum rod size, 3/8 inch.

6. NPS 2: Maximum span, 96 inches; minimum rod size, 3/8 inch.

7. NPS 2-1/2: Maximum span, 108 inches; minimum rod size, 3/8 inch.

8. NPS 3: Maximum span, 10 feet; minimum rod size, 3/8 inch.

9. NPS 4: Maximum span, 12 feet; minimum rod size, 1/2 inch.

D. Support multifloor vertical runs at least at each floor.

3.5 FIELD QUALITY CONTROL

A. Perform tests and inspections and prepare test reports.

B. Tests and Inspections:

1. Comply with ASME B31.5, Chapter VI.

REFRIGERANT PIPING 232300 - 4

Transportation & Food Service Addition September 30, 2019

Fayetteville, AR 19102900 Construction Documents

2. Test refrigerant piping and specialties. Isolate compressor, condenser, evaporator, and

safety devices from test pressure if they are not rated above the test pressure.

3. Test high- and low-pressure side piping of each system separately at not less than the

pressures indicated in Part 1 "Performance Requirements" Article.

a. Fill system with nitrogen to the required test pressure.

b. System shall maintain test pressure at the manifold gage throughout duration of

test.

c. Test joints and fittings with electronic leak detector or by brushing a small amount

of soap and glycerin solution over joints.

d. Remake leaking joints using new materials, and retest until satisfactory results are

achieved.

3.6 SYSTEM CHARGING

A. Charge system using the following procedures:

1. Install core in filter dryers after leak test but before evacuation.

2. Evacuate entire refrigerant system with a vacuum pump to 500 micrometers. If vacuum

holds for 12 hours, system is ready for charging.

3. Break vacuum with refrigerant gas, allowing pressure to build up to 2 psig.

4. Charge system with a new filter-dryer core in charging line.

3.7 ADJUSTING

A. Adjust thermostatic expansion valve to obtain proper evaporator superheat.

B. Adjust high- and low-pressure switch settings to avoid short cycling in response to fluctuating

suction pressure.

C. Adjust set-point temperature of air-conditioning or chilled-water controllers to the system design

temperature.

D. Perform the following adjustments before operating the refrigeration system, according to

manufacturer's written instructions:

1. Open shutoff valves in condenser water circuit.

2. Verify that compressor oil level is correct.

3. Open compressor suction and discharge valves.

4. Open refrigerant valves except bypass valves that are used for other purposes.

5. Check open compressor-motor alignment and verify lubrication for motors and bearings.

E. Replace core of replaceable filter dryer after system has been adjusted and after design flow

rates and pressures are established.

END OF SECTION 232300

REFRIGERANT PIPING 232300 - 5

Transportation & Food Service Addition September 30, 2019

Fayetteville, AR 19102900 Construction Documents

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Installation Manual - Chain Link FenceDocument2 pagesInstallation Manual - Chain Link FenceChase GietterNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 100 Basic Mechanical Engineering Interview Questions Answers PDF Basic Mechanical Engineering Interview Questions Answers PDFDocument9 pages100 Basic Mechanical Engineering Interview Questions Answers PDF Basic Mechanical Engineering Interview Questions Answers PDFRahulBharti100% (2)

- Oisd - RP - 174 Revision: S.N O. para No. Heading Existing para Proposed Revision Remarks 1Document68 pagesOisd - RP - 174 Revision: S.N O. para No. Heading Existing para Proposed Revision Remarks 1Ravi KantNo ratings yet

- Installation Instructions: 1. Mini USB ConnectionDocument12 pagesInstallation Instructions: 1. Mini USB ConnectionChase GietterNo ratings yet

- Section 017700 - Closeout ProceduresDocument5 pagesSection 017700 - Closeout ProceduresChase GietterNo ratings yet

- Fluidized Beds (Part 1)Document40 pagesFluidized Beds (Part 1)Dennis LingNo ratings yet

- Koio - Forged Steel Valve PDFDocument42 pagesKoio - Forged Steel Valve PDFThomasFrenchNo ratings yet

- CFD Manual FluentDocument82 pagesCFD Manual FluenttfemilianNo ratings yet

- Coriolis PDFDocument11 pagesCoriolis PDFdanielaNo ratings yet

- Technical Bulletin S-19-05 - Tremco PUMA Technology Systems FAQ - Tremco Construction Products GroupDocument2 pagesTechnical Bulletin S-19-05 - Tremco PUMA Technology Systems FAQ - Tremco Construction Products GroupChase GietterNo ratings yet

- Product Guide 2012 - Interior and Exterior Metal Framing - Studs UnlimitedDocument40 pagesProduct Guide 2012 - Interior and Exterior Metal Framing - Studs UnlimitedChase GietterNo ratings yet

- Reference Guide 2005 - Step by Step Carpet Care - Shaw Contract GroupDocument12 pagesReference Guide 2005 - Step by Step Carpet Care - Shaw Contract GroupChase GietterNo ratings yet

- Yale Cleaning and MaintenenceDocument1 pageYale Cleaning and MaintenenceChase GietterNo ratings yet

- SScleaning AVD3897Document1 pageSScleaning AVD3897Chase GietterNo ratings yet

- Step by Step Guide Instructions 2018 - Installing Floor Tile - DaltileDocument9 pagesStep by Step Guide Instructions 2018 - Installing Floor Tile - DaltileChase GietterNo ratings yet

- Chain Link Fence GuideDocument9 pagesChain Link Fence GuideChase GietterNo ratings yet

- Norton Closer MaintenanceDocument2 pagesNorton Closer MaintenanceChase GietterNo ratings yet

- Yale Closer MaintenanceDocument1 pageYale Closer MaintenanceChase GietterNo ratings yet

- How To Properly Clean and Maintain - Chain Link FenceDocument1 pageHow To Properly Clean and Maintain - Chain Link FenceChase GietterNo ratings yet

- Automatic Slide Door Systems - Owner's ManualDocument10 pagesAutomatic Slide Door Systems - Owner's ManualChase GietterNo ratings yet

- Short Form Application Guide 2018 - Cafco Blaze Shield II - IsolatekDocument2 pagesShort Form Application Guide 2018 - Cafco Blaze Shield II - IsolatekChase GietterNo ratings yet

- Section 237416-11 - Packaged Small Capacity Rooftop Air Conditioning UnitsDocument15 pagesSection 237416-11 - Packaged Small Capacity Rooftop Air Conditioning UnitsChase GietterNo ratings yet

- Section 221116 - Domestic Water Piping-PexDocument16 pagesSection 221116 - Domestic Water Piping-PexChase GietterNo ratings yet

- Operations & Maintenance - Ballpark Netting & Supports - AALCO ManufacturingDocument1 pageOperations & Maintenance - Ballpark Netting & Supports - AALCO ManufacturingChase GietterNo ratings yet

- Section 238126 - Mini Split System Air ConditionersDocument11 pagesSection 238126 - Mini Split System Air ConditionersChase GietterNo ratings yet

- Section 230516 - Expansion Fittings and Loops For Hvac PipingDocument5 pagesSection 230516 - Expansion Fittings and Loops For Hvac PipingChase GietterNo ratings yet

- Section 235400 - FurnacesDocument9 pagesSection 235400 - FurnacesChase GietterNo ratings yet

- Section 017900 - Demonstration and TrainingDocument5 pagesSection 017900 - Demonstration and TrainingChase GietterNo ratings yet

- Installation Instructions - Roof Hydrant Model SRH-MS - WoodfordDocument3 pagesInstallation Instructions - Roof Hydrant Model SRH-MS - WoodfordChase GietterNo ratings yet

- Section 230514 - Variable-Frequency Motor ControllersDocument11 pagesSection 230514 - Variable-Frequency Motor ControllersChase GietterNo ratings yet

- Instruction Manual 2018 - Electric Water Heaters Model 5-120 Gallons - AO Smith PDFDocument48 pagesInstruction Manual 2018 - Electric Water Heaters Model 5-120 Gallons - AO Smith PDFChase GietterNo ratings yet

- Guide - Copper Fittings For HVACR Applications - Mueller Industries PDFDocument7 pagesGuide - Copper Fittings For HVACR Applications - Mueller Industries PDFChase GietterNo ratings yet

- Installation Instructions - Fluid Hammer Arrestors - PPP Precision Plumbing ProductsDocument2 pagesInstallation Instructions - Fluid Hammer Arrestors - PPP Precision Plumbing ProductsChase GietterNo ratings yet

- iOS Instructions & Parts List 2014 - Smart Controller GBE Models From 2011 Water Softener - CulliganDocument38 pagesiOS Instructions & Parts List 2014 - Smart Controller GBE Models From 2011 Water Softener - CulliganChase GietterNo ratings yet

- List of Material-Assembly - Model Z1310 Wall Hydrant - ZurnDocument1 pageList of Material-Assembly - Model Z1310 Wall Hydrant - ZurnChase GietterNo ratings yet

- Installation - Thermostatic Mixing Valve EFX8 S19-2000 S19-2000EFX Series - Bradley PDFDocument26 pagesInstallation - Thermostatic Mixing Valve EFX8 S19-2000 S19-2000EFX Series - Bradley PDFChase GietterNo ratings yet

- BRAUN HydraulikaDocument95 pagesBRAUN HydraulikaPolNo ratings yet

- Cooling Tower Water Scale and Corrosion InhibitorDocument2 pagesCooling Tower Water Scale and Corrosion InhibitorArunkumar ChandaranNo ratings yet

- Rotamat Sludge Acceptance Plant Ro 3: The Quality Company - WorldwideDocument4 pagesRotamat Sludge Acceptance Plant Ro 3: The Quality Company - WorldwideUhwan SubhanNo ratings yet

- PCM in Vapour Refrigeration SystemDocument16 pagesPCM in Vapour Refrigeration SystemamarparimiNo ratings yet

- Basic Mechanical EngineeringDocument4 pagesBasic Mechanical Engineeringalex mcraeNo ratings yet

- 07-Absorption For HAP and VOCcontrolDocument118 pages07-Absorption For HAP and VOCcontrolTakeshi Tanohuye TanohuyeNo ratings yet

- Microchannel Fluid Coils - Technical ManualDocument26 pagesMicrochannel Fluid Coils - Technical Manualgreyhound726415No ratings yet

- 616-100-402a - 00 - Central Heating SchemeDocument1 page616-100-402a - 00 - Central Heating SchemeAnonymous yyjpEsydasNo ratings yet

- PDF Version!: Flowtite Pipe SystemsDocument48 pagesPDF Version!: Flowtite Pipe Systemsshrikant tilekarNo ratings yet

- Equilibrium Separation ColumnsDocument18 pagesEquilibrium Separation ColumnsWade ColemanNo ratings yet

- Flat Plate Boundary Layer CornellDocument39 pagesFlat Plate Boundary Layer CornellsidyantNo ratings yet

- Operate Main Andauxiliary Machineryand Associatedcontrol SystemsDocument18 pagesOperate Main Andauxiliary Machineryand Associatedcontrol Systemsanod shopNo ratings yet

- Factors Affecting Rate of ReactionDocument7 pagesFactors Affecting Rate of ReactionkailaNo ratings yet

- The Colloidal Activity of ClaysDocument5 pagesThe Colloidal Activity of ClaysHenrique ApolinarioNo ratings yet

- HS GB 0901 NG 16 Directional Control ValveDocument12 pagesHS GB 0901 NG 16 Directional Control Valvenikoleta_tmmNo ratings yet

- Aerodynamics EffectsDocument11 pagesAerodynamics EffectsVlad SamescuNo ratings yet

- Knowledge Sharing Water HammerDocument16 pagesKnowledge Sharing Water HammerNaveen NagisettiNo ratings yet

- Conduction Problems & Solutions Conduction Problems & SolutionsDocument30 pagesConduction Problems & Solutions Conduction Problems & SolutionsRoronoaNo ratings yet

- Thermoregulation PDFDocument1 pageThermoregulation PDFCarina JLNo ratings yet

- LMS Technologies Microbiology Test ReportDocument3 pagesLMS Technologies Microbiology Test ReportYewHouNo ratings yet

- Arkas PDFDocument24 pagesArkas PDFDaniel UrquizaNo ratings yet

- Phase Diagram For MulticomponentDocument23 pagesPhase Diagram For MulticomponentFaisal MumtazNo ratings yet

- Heat Tranfer Lecture NotesDocument30 pagesHeat Tranfer Lecture NotesNarayana Swamy G100% (1)

- Decanting System - Decanting - Water Discharge - Sequencing Batch Reactor1Document1 pageDecanting System - Decanting - Water Discharge - Sequencing Batch Reactor1Anonymous qRe192No ratings yet