Professional Documents

Culture Documents

Align-Power-Feed-Instruction-Manual - PDF DON PABLO

Uploaded by

andres0 ratings0% found this document useful (0 votes)

68 views15 pageslIBRO DE ESPECIFICACIONES DE CONEXION LIMADORA MECANICA O TALADRO AUTOMATICO

Original Title

align-power-feed-instruction-manual.pdf DON PABLO

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentlIBRO DE ESPECIFICACIONES DE CONEXION LIMADORA MECANICA O TALADRO AUTOMATICO

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

68 views15 pagesAlign-Power-Feed-Instruction-Manual - PDF DON PABLO

Uploaded by

andreslIBRO DE ESPECIFICACIONES DE CONEXION LIMADORA MECANICA O TALADRO AUTOMATICO

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 15

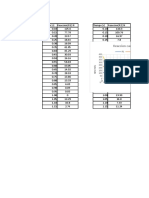

SPECIFICATION

Mode! RPM.

RPM.

Bevel

Drive | Max

Gear | Torque Voltage | Emperage

AL-500S(X.Y,Z) | 4~160

650 in-Ib

110V 60Hz

AL-4008(X,¥,Z)| 0~200

AL-3008(%,¥,Z)

4:1 | 550 in-lb | 110V 60Hz| 0.8~ 0.9Amp

4:1 | 440 in-Ib | 110V 60Hz| 0.5~ 0.6Amp

VOLTAGE AS 220V-440V HAVE TO ADOPT TRANSFORMER

WARNNING

Please make sure if power supply be

turned off before assembly, and avoid

from accident caused during proce-

dure of asssembly.

Please take apart the drill and remove

worked item before assembly.

Bb

Sg

d

Please adjust suitable length of cord

and watch out the wiring, never pres-

sure power cord by clog then ambroin

broken cause short or spark.

= 2¢

:

Please don’t disassemble for fixing or

refitment and free from accident or

break down caused by unhealth as-

sembly.

Please make sure input voltage for

power feed as A.C.110 V and avoid

wrong power then burn down circuit

board, except A.C.710 V, please adopt

the transformer.

Please don’t set the power feed in ex-

cessive wettish working zone and

don't wash down the power feed by

water or water shipped then cause

short or spark.

HOW TO INSTALL THE LONGITUDINAL FEED(X TYPE)

‘ADAPTOR: SEAL-BEVEL GEAR SHIM IHICKNESS:

BEARING FACE

LOCKING NUT

RAPID SPEED

SWITCH

When hold down the

yellow button, the

maximum speed,

POWER INDICATOR

If the indicator glows, the

power is on.

DIRECTION CONTROL

HANDLE

SPEED

CONTROL

KNOB

CIRCUIT BREAKER MAINIEOWERSWITCH)

When the current passing through "ON" position power is "ON".

the switch is over 3.16A within 10 "OFF" position power is

seconds, it will automatically break "OFF

the circuit.

To continue the operation, press

down the yellow-pusher and the

power indicator will glow.

HOW TO INSTALL CROSS FEED(Y TYPE)

HOW TO INSTALL T-WAY TRACK FOR CROSS-FEED

T-way bar and bracket for limit switeh

are designed for simple installation on

cross slide.

FIXED SUPPORT

T-WAY TRACK

STOP BLOCK

INSTALLATION INSTRUCTIONS

For ideal installation. You should not modify the cross travel lead screw.

ens Taste

FIT POWER FEED BODY

L NEEDLE REARING BUSHING

RIL AND FIT ROLL PL

svanD MOUNT THE EXTENSION SHAFT

[ BEVEL GEAR

Jcnoss peEp.200¥

HOW TO INSTALL T-WAY TRACK FOR KNEE-LIFT FEED

VIEW OF LIFT SIDE OF

KNEE AND COLUMN

HOW TO INSTALL KNEE LIFT FEED(Z TYPE)

Note: Remove hand crank, dial, dial socket, Bearing

flange and......Ete.

‘STAND Note: /nstaif extension shaft.

— Important:

(= s,

4.Shaft end must be against inner ring of bearing.

2.Ianer shait is 16 or 18 threaded unc.

Note: Tighten stand to flange then tighten knee feed

con the flange.

Important: For angular positioning.

Note: Install gear key not in.

Important: Use hand to push & turn bevel gear to

check backlash,

Tf necessary add a few shims to obtain proper

backlash.

sh.

2.Modify leading edge of gear to obtain proper back

Jash. Then repack gear with grease. Replace gear

then push and turn to check tor backlash.

Note: Remove the bevel gear arter STEP 4 is O.K.

then install key, replace gear, install dial, and

tighten dial nuf. Add a few shim if dial is

grinding the gear.

Important: Pack with grease before installing the

gear. Do not use silicon-lype grease.

Note: Install checkclutch against bevel gearthen

drive through one hole of Smm Dia. Then drive

spring pin.

Important: Be sure you have followed each step

carefully and correctly before installing

the saring pins.

Suggestions: /nstall hand crank rotate in clockwise

direction to check for proper shimming

and that there is no binding action.

Note: install spring handcrank (already installed),

then tighten washer and screw.

Important: For operational safety, please Ibricate

this part and instal! as per instruetions.

FIT FLANGE OF TABLE

FT POWER FEED Bony

STAD.

ASSY-LIMIT ASSEMBLY

CAUTION

1.lf will damage the gear of power feed if you suddenly change the direction of

power feed by pushing the direction control handle while the machine is under

high-speed operation. if you intend to change the direction, please push the

handle to the “off” position. Waiting until the machine is completely stopped, then

push the handle to your intended direction.

2.Please make sure the position of the stop screw for your milling machine is

keeping on "loose" status.

3.While the power feed is under operation, please don't change to use manual

control the direction suddenly.

4.POWER FEED can only move to one direction.

CHECK: if ASSY-LIMIT SWITCH is normal.

5. Touch ASSY-LIMIT SWITCH POWER FEED in-between the TABLE and

unable to stop it.

CHECK.If ASSY- LIMIT SWITCH is normal.

PARTS LIST

NO. PART NAME PART NO. | SPECIFICATION REMARK

1_| TOP_HOUSING PO1807 AL-500S

TOP HOUSING P1624 AL-~400S/300S

2_| BEVEL GEAR NUT AQ100-01

3 [ WASHER

4 | WASHER AQ100-028 | 0.4x. 4 34x ¢ 45mm

5 _| WASHER A0100-02C | 0.6x¢ 34x ¢ 45mm

6_| WASHER (COPPER). AQ100-02D | 0.1x¢ 34x ¢ 45mm

7_| WASHER A0100-04A | 0.2.4 16x 6 23. 58mm

8 _[ WASHER

9 | WASHER

10 [ WASHER (COPPER)

11 | WASHER

12 [ NEEDLE BEARING

14 | NEEDLE BEARING AQ10IC

15 | CIRCUIT BREAKER A102

16 | CAP OF CIRCUIT BREAKER AQ102-01

17 | BUSHING BEARING A0103 6x6 12x 11.5mm

18 | AL DRIVE GEAR SHAFT AQ106 AL-400S/3005

SP DRIVE GEAR SHAFT PO1022 AL-500S

19 | AL DRIVE GEAR AQLO6Y AL-400S/3005

SP DRIVE GEAR P01021. AL-500S

20 | SPACER AQ109

21 | LIGHT TRANSMITTER A0110

22 | HEX. SEAL BOOT P0181?

23 | NUT FOR RAPID SWITCH AQ111-01A

24 | RAPID SWITCH PLUNGER AQIII-02

25 | SPRING FOR RAPID SWITCH AQI11-03:

26 | RAPID SWITCH HOUSING AQ111-04

RAPTD SWITCH ASSY

ANL1115.

28 | SPRING FOR TOP HOUSING A0112

29 | ADAPTOR P01808-03

30 | SPRING FOR CLUTCH ‘A0301-05

31_| WASHER TRA 0301-06 _| 512

32 [ WASHER BEARING NTA A0301-07_[ 512

33 | BEARING CUP 0301-08.

34 | LIFTFORK 0301-09

36 | WASHER A0301-10_| 1x¢8X.¢ 16mm

36 | SHAFT MOUNT AQ301-124

37 | WIRE ALW-25-1_[ 24ANGX 59mm

36 | WIRE AUW+26 | 18ANGx 50mm

39 | WIRE ALWS 22ANG

ALW-6 22ANGx_L116mm

41 | WIRE ALW7 22ANGx L160mm

42 | WIRE ALWHB 22AWGx L100mm

43 | WIRE ALW-9 22ANGx L100mm

44 | BEARING Boo001 (| 62722

45 [ BEARING Bo0006 | 60822

46 | MICRO SWITCH HOLDER 0501

47 | MICRO SWITCH ASSEMBLY. C0501-6P AL-300S

MICRO SWITCH ASSEMBLY AL~5008/4005.

0502

49 | MICRO_SWITCH 00504 3P. AL-500S/400S.

50 | CAPACITOR C0506

52 | MICRO SWITCH ASSEMBLY C0508

54 | MICRO SWITCH C0508-02

5

55 | BOTTOM COVER AL-600S

56 | BOTTOM HOUSING P01806

[58 | CARBON BRUSH HOLDER | PO1004__ | 4.8x6.6x22.5 |

61.| CAP_OF ON-OFF SWITCH

62 | WASHER £0907-02

63 | SPRING WASHER E0910 627

64 | SET SCREW E0911 1/4"x 1/4"

66 | HANDLE KNOB P01812-03

67 | 180°_CONTROL HANDLE PO1810-1 X Axis

9° _CONTROL HANDLE P01616-1 Y/Z Axis

AL-B00S/400S.

300$ CIRCUIT BOARD ASSEMBLY OC2HS AL-300S

71 | STRAIN RELIEF £0917

72 | LIFTFORK SHAFT £0922

73 | AL ARMATURE ASSEMBLY E0925V-0 AL-4005/5005)

SP_ARMATURE ASSEMBLY AL-500S

74 | 400$/500S MOTOR FIELD. E0926V. AL-400S/3006)

3005 MOTOR FIELD E0926? AL-3008

75 | BEARING MOUNT £09274

76 | BUSHING £0928 8x9 14.8x 20

£0929-02

£0929-03

£0920-04

£0920-05

E092 | 10K AL-500S/4005

3008 POTENTIOMETER E0929P 5000 AL-300S

83 | POWER CORD £23017 0.75x 3Cx_2.7M

£0034-01_| $38

85 | WASHER E0934-02 | 1.5x¢38x¢54

86 | SPRING WASHER £0934-03 | 6205

87 | HUB OF ZYTEL GEAR E0934-04

88 | CRESCENT RING F01001 IR24

89 | E-RING F10040 E4

90 | E-RING F10060 | £5

91 | MICRO SWITCH F1104

92 | CONTROL CORD £24002 0.75% 4Cx_1.7M AL5008/4005

CONTROL CORD £23015 0.75x 2Cx 1.7M AL-300S

93.| TRAVEL STOP 0100-011

94 | NUT 0103

60106

60107

60108

wioo20 [M2

wioo30__ [M3

N22001__| 5/16"

£0906

Po1007

po1i6 | 16x 4 AL5O0S

poi? | 6/8"x 1/8" AL5OOS

BEVEL GEAR P01012 16x 4 AL300S/400S

BEVEL GEAR X/Y (STANDARD) P1013 5/8"x 1/8" AL3008/400S

REVEL GEAR 7 (STANDARD) pqini4 2%y A mm Al nN /4NNC|

104] LIMIT SWITCH COVER PO1015

105] LIMIT SWITCH HOLDER P01018

106] ACTUATOR P01019

107] LIFTFORK RING 01028:

30°

HOLD PLATE P1040

109[ AL DRIVE GEAR ASSEMBLY POISOL

|__| SP DRIVE GEAR ASSEMBLY P01902

110] LIFTFORK ASSEMBLY 01903.

111] MICRO SWITCH ASSEMBLY 01904.

400S/500S POTENTIOMETER ASSEMBLY

300S/200S POTENTIOMETER ASSEMBLY | P01908

ZYTEL GEAR ASSEMBLY P01909

114] LIMIT SWITCH ASSEMBLY P01910

|__| LIMIT SWITCH ASSEMBLY 01924

= CE LIMIT SWITCH ASSEMBLY 01925.

CE LIMIT SWITCH ASSEMBLY. 01926,

TRAVEL STOP SET P1916

117] LIFTFORK ASSEMBLY 01923.

2x_10 mm

3x_15 mn

118] SCREW 712010

119} SCREW 713015

120] SCREW 713020

3x_20 mm

3x_30_m

122] SCREW 714006.

12

4x 6 mm

4x 10 mn

SCREW T14010

124] SCREW T15010-1

M5x10

4x 70 mm

SCREW 714070

126] SET SCREW 720001

SET_SCREW 720003

3/16"x 3/8"

BGsxeals

5x_35_mn

SET SCREW 755035,

120] SET SCREW 760001

130] SET SCREW 774004

1/4"x1"

4x 4 mm

| u33025

2x 24.8 mm

#2.5x_16 mm

#3x 15 m

1 [ U32516

[ u33015

U35014

#5x 14 mm

PIN 42515 $2.5x 15 mim

136] PIN U43014. #3x 13.7 mm

3x 17.5 m

138

139

140

141

142

SPRING

WASHER

WASHER

WASHER

SPRING WASHER

04001

W10050

W10080

W10080-1

W20040

T1x¢5x¢12 mm

Tix¢8x¢18 mm

T0.6x@8x12 mm

¢4 im

143

144

ON-OFF_BRAND

LIMIT SWITCH FIXTURE

020283

P01919

145.

EXTENSION SHAFT.

EXTENSION SHAFT

P1922

P01929

16 t

20 t

146

T-WAY TRACK

T-WAY_TRACK

T-WAY TRACK

A0301-15A

0301-158

A0301-15E

60 CM

66_CM

30_CM

ALUM STAND

ALUM STAND

PFB-O1

PFB-02

2B t

6 t

TRON STAND

EXTENSION SHAFT

PFB-18

PFB-07

et

L_69 mm

EXTENSION SHAFT.

EXTENSION SHAFT

AQ| EXTENSION SHAFT RING

EXTENSION SHAFT RING

EXTENSION SHAFT RING

EXTENSION SHAFT RING

EXTENSION SHAFT RING

PFB-08

PFB-16

PFB-03,

PFB-09

PFB-10

PFB-13

L_80 om

L_60_m.

L 40 mm.

L 54.7 mm

L27 m.

33m.

L30 mm.

NUT.

O-RING

PFR-76A

00001

1/2-20x14. 3mm

P20

Part's kit_()

Part's kit_(¥)

P01911

P1912

Part's kit (2)

P1913

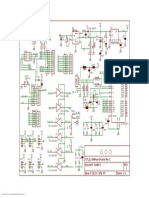

CIRCUIT DIAGRAM AL-300S

5 |. DIRECTION

ROI, Limit

CIRCUIT DIAGRAM AL-500S/AL-400S

BRAKE,

bol | SOF gee (485 c 150

ave coon PAST

pe lee Ha 470

i 820

rT 10K

papal

5404 Pan

7 4007

DIRBCTION unmsicaosw

SCHEMATIC DIAGRAM OF PARTS

= “e

© « ©) 449 iL 146

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- USBHostShield Rev2Document1 pageUSBHostShield Rev2andresNo ratings yet

- Anexo C ProgramacionDocument8 pagesAnexo C ProgramacionandresNo ratings yet

- Reaccion Carga de Volcamiento: 450 R1 R2 R3 R4Document2 pagesReaccion Carga de Volcamiento: 450 R1 R2 R3 R4andresNo ratings yet

- Anexo D Ficha TecnicaDocument1 pageAnexo D Ficha TecnicaandresNo ratings yet