Professional Documents

Culture Documents

Catalogue CVS HY LIFT 0318

Catalogue CVS HY LIFT 0318

Uploaded by

Nuñez Jesus0 ratings0% found this document useful (0 votes)

8 views12 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views12 pagesCatalogue CVS HY LIFT 0318

Catalogue CVS HY LIFT 0318

Uploaded by

Nuñez JesusCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

Wier evs FeRRar! introd ing HY-LIFT a

The redundancy of power hydraulic

directly mounted on the mast, all

1ew era has begun for container handling liftrucks.

heir replacemen

with electric powered winches

d to several other new and re-invented energy saving and power

hnologies, has made the unthinkable a reality. The validated and unconditional

slashing of the Total Cost of Ownership and of the Environmental Impact of these machine is now a fact,

thanks to this unique equipment destined to change both t of the users and the course

of the materials handling industry. HY-LIFT transforms otherwise wasted energy into major cash savings

and borderline container handling businesses into sustainable, profitable ones. It forever

eliminates maintenance cost icebergs and changes the focus from buying for less into making the

busines je. HY-LIFT is the GAME CHANGER of the container handling liftrucks sector

profitab|

KING ABILITY

Single Stack Spreader

8 Ton lover 5x 86

10 Ton lover 7x86

Double Stack Spreader

8 Ton 2over 5x86

10 Ton 2over 5x86

8 Ton 2over 7x86

10 Ton Dover 7x86

FERRARI

—40%

CONSUMABLES

- NO TRANSMISSION REPAIR OR OVERHAULING COSTS

- NO DIFFERENTIAL AND HALFSHAFTS BREAKDOWN AND REPAIR,

= NO HIGH PRESSURE HYDRAULICS MAINTENANCE COSTS

= NO HYDRAULIC OIL. LEAKS

"SLASHED LIFT MECHANISM MAINTENANCE COST

LOWER FUEL

CONSUMPTION

HY-LIFT features many innovative energy saving

design solutions and systems, but the hard-core

of the extraordinary fuel efficiency of this machine

isits ability to recover over 60% of the energy spent

tolift the spreader and a great deal of inertial

energy when breaking

TIRES

EXPENDITURE

HY-LIFTis built on radically new structural concept

that has transformed the mast into a “positive

(stabilizing) mass, as opposed to being a “negative”

(lestabilizing) mass as itis in any conventional

container handling liftruck. That makes the machine

a lot more stable and a lot mightier at the same

time. The lighter weight enables HY-LIFT to use

smaller size and sensibly cheaper tires than what

Isused on equivalent traditional trucks. That results

is much smaller tires consumption cost,

INVESTMENT IN

(

—

=)

- NO HYDRAULIC OIL. REPLACEMENT

NO TRANSMISSION OIL REPLACEMENT —,

NO TRANSMISSION OIL FILTER REPLACEMENT i

NO DIFFERENTIAL OIL REPLACEMENT. Lu

MINIMIZED ENGINE OIL AND FILTER COST gues)

EXTRAORDINARY

MAINTENANCE

@&

A N E W TECHNOLOGY

Lifting is achieved through electric motor driven winches

reeling steel ropes. No power hydraulics are involved.

HY-LIFT delivers maximum efficiency in energy use and

recovery, high lifting speeds, total safety granted by

three independent brake systems, along with

drastically reduced maintenance costs. Total reliability.

Drive is also electric motor operated. Motors are directly

mounted at the wheels and are the same of those operating

the winches. Inverters - one per each motor - provide responsive

control and exceptional and progressive acceleration, The electric

brake is supplemented by a wet disc brake system.

B RE A K S

The primary power source of HY-LIFT is a small electric generator actioned by a 90 kW

engine. This power pack delivers excellent durability due to regulated engine revolving

regime plus low fuel consumption, reduced noise and lower emissions. Then

inexpensive maintenance and drastically reduced engine overhauling and replacement cost.

HY-LIFT

+

A second source of power Is delivered to HY-LIFT by a rack of

supercapacitors. Charged by the generator or by recovered energy captured

when lowering and braking, the supercapacitor integrate the energy provided

by the generator boosting the performances of the machine to levels

equivalent to or superior to those of conventionally powered trucks, The

supercapacitors come with a manufacturer design life of one million cycles.

GREAT ENERGY RECOVERING AND RECYCLING

7, 7

&

The energy used to lift

and drive, is in large part

recycled by HY-LIFT as its

electric

energy out mast

lowering and machine

braking. The regenerated

energy is stored in

the supercapacitors

A sophisticated software

managed by the machines’ on

board computer optimizes

energy recycling, storage

and usage, leading to

massive fuel savings

The on-board computer

controls and shows the

generated, spent and

recovered energy flows;

provides detailed evidence of

consumed and saved fuel, as

well as of state and level of

supercapacitor charge

GREENER, CLEANER, QUIETER, SAFER

HY-LIFT is a gentle revolution in the container handling liftrucks world, because besides miniaturizing running

costs this machinery massively reduces the environmental impact of this equipment typology. Noxious

emissions are heavily reduced by HY-LIFT proportionally to the reduction of burnt fuel, With HY-LIFT.

exhausted oils and filters to dispose are decimated whilst its running is the quietest ever. Its diesel engine

half the size of those of any comparable conventional power truck and it is the most fuel efficient in its

class. The electric motors fitted by HY-LIFT are permanent magnet type, the most compact and silent

breed of brushless motors that exist. HY-LIFT is the greenest liftruck that ever handled a container and

besides making the business more profitable, it factually contributes to make the world a better place.

Chy-Liet

UNPRECEDENTED STABILITY

FERRARI

sted empty container handler,

er lateral stability electronic

cally reduces drive

stability reserve

behind

Ta

any

le machin ety that is further

by the electronic longitudinal stability

joment Indicator and limiter that is a

er but

THE FASTEST LIFTING SPEEDS EVER

HY-LIFT Is not only

about incredible

operational costs

reduction, cleaner

and safer operations.

HY-LIFT is also

the fastest truck on

earth when lifting

With lift and lowering

speeds that are up to

30% faster than those of

conventionally powered

trucks, HY-LIFT sets

new standards of

productivity and further

accelerates the return of

Investment of the user.

That is why HY-LIFT

changes the speed

gear of the Empty

container businesses.

That is why HY-LIFT is

the GAME CHANGER.

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Parker Hydraguide Steering Products PDFDocument32 pagesParker Hydraguide Steering Products PDFJorge CabreraNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Electric Control Valve For 4 Speed Trans. Models 28000, 32000, 33000, t40000Document15 pagesElectric Control Valve For 4 Speed Trans. Models 28000, 32000, 33000, t40000Nuñez JesusNo ratings yet

- Series Drive Axle d13500 5-72Document36 pagesSeries Drive Axle d13500 5-72Nuñez JesusNo ratings yet

- Eastar ManualDocument280 pagesEastar ManualNuñez JesusNo ratings yet

- Maintenance Manual of Chery A113 - Body Accessories & DimensionsDocument169 pagesMaintenance Manual of Chery A113 - Body Accessories & DimensionsNuñez JesusNo ratings yet

- Diagramas Electricos Chery OrinocoDocument115 pagesDiagramas Electricos Chery OrinocoNuñez JesusNo ratings yet

- Manual Usuario - Arauca - EspañolDocument147 pagesManual Usuario - Arauca - EspañolNuñez JesusNo ratings yet

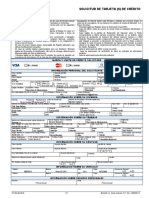

- Solicitud de Tarjeta de Credito MercantilDocument11 pagesSolicitud de Tarjeta de Credito MercantilNuñez JesusNo ratings yet

- Leeme - Despiece Chery OrinocoDocument1 pageLeeme - Despiece Chery OrinocoNuñez JesusNo ratings yet

- Instalar Despiece Chery OrinocoDocument8 pagesInstalar Despiece Chery OrinocoNuñez JesusNo ratings yet